Download Strebel SC-B Wall-Hung Condensing Boiler

Transcript

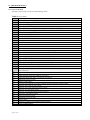

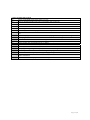

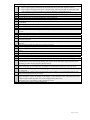

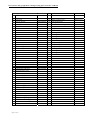

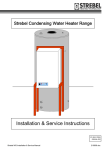

Strebel SC-B Wall-Hung Condensing Boiler INSTALLATION OPERATING & MAINTENANCE INSTRUCTIONS Version 3.1-Jul/06 Strebel is not liable for any damage caused by incorrectly following these instructions. 1. SAFETY GUIDELINES 4 2. TYPICAL SYSTEM LAYOUT 5 2.1. Single Boiler layout & quick Reference 5 2.2. Cascade Boiler layout & quick reference 6 3. TECHNICAL DATA S-CB BOILERS 7 4. INTRODUCTION 8 4.1. Operation of the S-CB Boiler 8 4.2. Controls 8 4.3. Frost Protection 8 4.4. Cascade Control 8 5. ACCESSORIES 9 6. INSTALLATION OF THE S-CB 9 6.1. Unpacking 9 6.2. Select the position of the boiler 6.2.1 11 6.3. Mounting the boiler 12 6.4. Air Supply & flue gas discharge types 12 6.5. The air inlet and gas outlet system 12 6.5.1 SC-B Flue resistance table and example calculation 1 13 6.5.2 Single & cascade table air inlet resistance 14 6.5.3 Single & cascade table flue resistance 15 6.6. Example flue resistance calculation 2 16 6.7. Example flue resistance calculation 3 16 6.8. Condense water drain 17 6.9. Central heating material 17 6.10. 7. Important provisions 10 6.9.1 Central Heating circuit 17 6.9.2 The expansion vessel 17 6.9.3 S-CB Internal Pump 18 Low loss header & cascade layout 18 INSTALLATION INSTRUCTION FOR THE ELECTRICIAN 19 7.1. Connecting to the mains power supply 19 7.2. Connector strip 19 7.3. Polarity sensitivity 23 7.4. Fuses – Main & boiler internal 23 7.5. Sample Cascade Electrical Layout 23 7.6. Electrical Circuit Diagram 24 Page 2 of 51 Page No 8. PUTTING INTO OPERATION 25 8.1. Control panel, control knobs & L.E.D. 25 8.2. Sensors 26 8.3. Run and Fault Codes and Display meanings 27 8.4. Display buttons 28 8.4.1 Service Button 28 8.5. Filling and venting the boiler and system for light up 28 8.6. Starting the boiler and Commissioning 29 8.7. 8.8. 8.6.1 General 29 8.6.2 Commissioning 29 Adjusting and setting the output 29 8.7.1 Setting the maximum output 29 8.7.2 Setting the minimum output 31 Gas conversion 31 9. LONG TERM SHUTDOWN 32 10. LOCK OUT / USER COMPLAINT 33 11. TROUBLESHOOTING 34 11.1. Cause of the fault 34 11.2. Troubleshooting table 36 12. 13 14 INSPECTION AND MAINTENANCE 38 12.1. General 38 12.2. Inspection 38 12.3. Maintenance 39 LPG Settings SCB 60 to 120 40 SCB 150 to 180 41 EXPLODED VIEWS AND SPARES 42 14.1Burner, fan, gas pipe, heat exchanger, casing S-CB60 – S-CB120 14.1.1Spare Parts S-CB60 – S-CB120 14.2.Burner fan, gas pipe, heat exchanger, casing S-CB150 – S-CB180 14.2.1 Spares Parts S-CB150 – S-CB180 14.3 Pipelines & pumps S-CB60 – S-CB120 14.3.1 Spare Parts S-CB60 – S-CB120 43 44 45 46 47 48 14.4 Pipelines & pumps S-CB150 – S-CB180 49 14.4.1Spare Parts S-CB150 – S-CB180 50 Page 3 of 51 1. SAFETY GUIDELINES Read all these instructions before commencing installation. This appliance is free from any asbestos material. It is the law that all gas appliances and fittings are installed by a competent person (such as a CORGI registered installer) and in accordance with the Gas Safety (installation and Use Regulations), the relevant British standards for installation, codes of practice or rules in force and in accordance with the Manufactures’ instructions. The installation shall also be carried out in accordance with the following regulations, codes and standards: The Building Regulations issued by the Department of the Environment. The Building Standards (Scotland) (Consolidation) Regulations issued by the Scottish Development Department. The Local Building Regulations and Local water by-laws, the gas services area and the Local Authority recommendations. Wiring to the appliance must be in accordance with the IEE (BS 7671) Wiring Regulations the Health and Safety Document No 635 “The Electricity at Work Regulations 1989” and any local regulations that apply. Relevant British standards insofar as the relevant areas that are not covered by these instructions. BS 5440: Parts 1 and 2 (Flues and Ventilation). CP 342: Part 2, 1994. Code of practice for centralised hot water supply – buildings other than individual dwellings. British Gas Publications: IM/2 purging procedures, IM/5 soundness testing, IM/11, IM/16 Installation of gas pipe work and boosters. HSE guidance note PM 5, automatically controlled steam and hot water boilers. CIBSE, IHVE, Guide ports A, B and C. IGE/UP/1, IGE/UP/2 and IGE/UP/7. Failure to comply with these regulations could lead to prosecution and deem the warranty invalid. This appliance must be installed in accordance with the rules in force and used only in a sufficiently ventilated space when not in a room sealed application or compartment ventilation as current regulations. Page 4 of 51 2. TYPICAL SYSTEM LAYOUTS 2.1 Single Boiler Layout Page 5 of 51 2.2 Typical Cascade Layout Equipment shown may not be supplied. Please see tender for the actual equipment supplied Page 6 of 51 3. TECNICAL DETAILS General Product Identification Number Dimensions (h x w x d) Classification Gas Appliance Type Boiler Type S-CB Water content etc. Weight (empty) Gas connection Co-axial flue connections Separate Flue Exhaust / Air Inlet Possible with Adaptor (extra cost) Power consumption Protection class CE 0063 BP3254 835 x 458 x 485 890 x 458 x 670 II2H3P B23; C13X,C23X,C33X,C43X, C53X, C63X,C83X 60 80 100 120 150 180 3,9 5 6,5 8,3 10,4 12,9 46 73 78 83 92 101 Mm Ltr Kg ” mm mm R ¾” 80/125 80-80 W 355 IP40 kW kW m³/hr % % % kW kW 18-74 20-82 7,9 98 109,5 110 73 20-80 107 <15 23-92 25-102 9,8 98 109,5 110 90 25-100 107 <15 27-111 30-123 11,8 98 109,5 110 109 30-120 107 <15 34-138 38-154 14,7 98 109,5 110 136 36-150 107 <15 43-166 48-184 17,6 98 109,5 110 163 45-180 107 <15 <20 <20 <20 <20 <20 1,5 1,5 Central heating Nominal input (Nett) 80/60ºC Nominal input (Gross) 50/30ºC Gas flow max. (G20) Efficiency at 80/60ºC Efficiency 50/30ºC Efficiency 40/30ºC RAL 61 Nominal output at 80/60ºC Nominal output at 50/30ºC Norm efficiency 75/60ºC RAL-UZ61 NO x emission, RAL 61 mg/kWh 14-56 15-61 5,9 97 109 109,5 55 15-60 107 <15 CO emission, RAL 61 mg/kWh <20 Data CO2- flue gas Dew point combustion gas Temp. Flue gas @ ambient temp 20ºC Flue resistance capability* PH value condensate Available pressure at 25ºC Max. flow temp. Min./Max. Boiler Pressure Sound level at Maximum Output Average Sound level R ¾” R ¾” R ¾” R 1” R 1” 80/125 100/150 100/150 100/150 100/150 80-80 100-100 100-100 130-130 130-130 100-100 130-130 355 355 375 460 460 IP40 IP40 IP40 IP40 IP40 % °C °C Pa mwk °C bar dBA dBA 2,5 3 46.0 32.0 47.0 33.0 9 53 85 250* up to 600* 4 to 5,5 1,5 1,5 90 0.5 – 6 48.0 33.0 49.0 50.0 34.0 35.0 Table 1: Data 50.0 35.0 Boiler control includes: Cascade control for up to 8 boilers ( requires flow temperature sensor at extra cost ) see item G page 8 Remote run & fault indication 0-10 VDC control connection ( requires flow temperature sensor at extra cost ) Control for external calorifier primary pump ( pump not included ) via relay at extra cost ( see page 22) Weather compensation control (with outside detector at extra cost) Control for an external pump via relay at extra cost,( see page 22 )external pump not included. Electronic Ignition. Boiler output modulated between 25% and 100%, Page 7 of 51 4. INTRODUCTION Warning: For trouble free operation of the boiler, and to be assured of the full guarantee, the following items are required: A. An automatic air and dirt separator must be installed in the installation and a strainer in the return also devices as shown on pages 5 or 6. B. Minimum static water pressure should be more than 0.5 bar. C. The system is flushed, water tested and additive utilised if required. D. Boiler auto air vent cap must be open and all system air vents open. E. Low and high water cut out pressure switches ( usually in the fill unit) connected in the Boiler volt free control circuit in series with other controls on terminals 13 - 14 or by 0 volt when using external 0 to 10 volt control by others. F. Control of Boiler on/off must never be by interruption of the mains supply. G. When using a common flue the inbuilt cascade control must be used. These instructions are written for the installer of Strebel products and contain all necessary information on the installation and adjustment of S-CB boilers. We suggest that you read the instructions before installation to ensure that all work is done correctly. We suggest that you keep these instructions near the boiler. 4.1 Operation of the S-CB Boiler The heating boilers from the Strebel S-CB series are central heating boilers with maximum high efficiency. Such performance is reached by, among other things, using a special heat exchanger made of stainless steel. The heat exchanger allows flue gases to cool down below condensation point, condensing the flue gases and releasing extra heat. This has an immediate positive impact on the efficiency, exceeding 100%net calorific. • S-CB flue gases have a low temperature (below 85°C), the boiler needs to have a high efficiency approved stainless steel or plastic flue system .Aluminium flue systems are not allowed to be connected to these boilers. Adequate drain points must be added to the flue system with a u trap. 4.2 Controls The Strebel S-CB Boiler adjusts to the demand for heat by using flame modulation and external controls. That is on the basis of 1) 0 to 10 volt control. 2) Strebel optimiser control 3) Built in weather compensation with an outside detector. 4) RC or E-BUS .For RC or E-Bus system, see separate booklet. The boiler control is equipped with: Control for a DHW Cylinder with a diverter valve or a pump (pump via a relay both not supplied) Connection for a Heating pump via a relay (pump and relay not supplied) Connection for a room thermostat, on/off control, optimiser or 0 to 10 volt control (see 4.4.1). 4.3 Frost protection Frost protection does not protect the system or system pumps. It protects the boiler. Frost protect the system by fitting devices to link out any time controls. In a frost condition (at 7° Boiler temperature) the Boiler internal pump starts. When the boiler water temperature falls down to 3°C, the burner is also ignited. This operation will cease as soon as the boiler temperature has reached 10°C. 4.4 Cascade control Using the integrated cascade control, a maximum of 8 boilers can be controlled in a cascade configuration. The Cascade has in-built full logic step control. The Boiler will require a Flow temperature sensor and 2 wires to each boiler in a daisy chain. When using a common flue the cascade control must be used 4.4.1 0-10 VDC connection available The boiler is equipped to take a 0-10 VDC signal from a controller by others (set at time of commissioning) with which up to 8 boilers can be controlled in cascade, utilising the built in cascade manager. (0 Volt is no heat demand.) The Boiler will require a Flow temperature sensor at extra cost. Page 8 of 51 5. ACCESSORIES Dependent on the choice of control and hydraulics etc, accessories are available from Strebel at extra cost. See Page 50 for details 6. INSTALLATION OF THE STREBEL S-CB 6.1 Unpacking The Strebel S CB includes the following documents and accessories: • 1 Installation and cascade instructions for the installer. • User instruction (incorporated). • 1 suspension bracket. • Fuses and 3 nuts for mounting the burner plate (attached to the front of the gas valve). • 1 siphon with tightening nut and gasket. • Reducing couplings (where required) for flue gas discharge and air supply. THE BOILER IS SET FOR NATURAL GAS G20.On delivery, immediately check that the Strebel S-CB is complete and without any defects. Report any damage immediately to the supplier or Strebel Ltd. . . 2 6 1 4 5 1. After removing the carton, the easiest way to take the boiler off the pallet is as follows: 2. Lift the pallet including the boiler (at the side of the flue outlet) to a vertical position. 3. The boiler has a polystyrene block, which now supports the Boiler on the floor. 4. Push the Boiler a little forward, until the pallet is not touching the floor anymore. 5. The boiler stands now on the flow- and return pipes and the polystyrene block. 6. Take away the pallet (See also 6.3). The boiler can now be lifted (unclip and remove the Boiler door before lifting) easily for mounting, by putting a hand at the lower side of the boiler. Page 9 of 51 6.2 Select the position for the Boiler Select a position in the building with adequate access to the front, side and the bottom of the boiler for future maintenance and servicing. The boiler must have at least 20 mm space at each side. Boiler Type S-CB 60, 80, 100, 120 Co-axial flue is standard supply on 60kw to 100kw Boilers. Parallel flueing requires an adaptor at extra cost. Parallel flueing is standard on the SCB 120 .Co-axial adaptor available at extra cost Co-Axial connection at the rear. Separate exhaust and air inlet connections are: Flue exhaust at the rear and air inlet at the front Parallel Flue D D1 S-CB S-CB 60 80 100 120 80 100 100 130 S-CB S-CB 60 / 80 100 120 Page 10 of 51 80 100 100 130 Concentric Flue D D 80/125 mm 100/150 mm 100/150 mm Boiler Type S-CB 150 and S-CB 180 150kw and 180kw Boilers are supplied with parallel flue connections an adaptor is available for co axial flue-ing at extra cost Air inlet D1 Flue D 890 Parallel Flue S-CB S-CB D D1 150 130 130 180 130 130 Co- Axial Flue D 100 /150 130 /150 6.2.1The installation area must have the following provisions: • Items listed in 4 page 8 also see drawings 2.1 page 5 and 2.2 page 6. • Electrical point with earth connection; • Connection to the drains for condensation water or suitable condense removal device • A sound wall or suitable mounting. The wall or frame used for mounting the boiler must be able to hold the weight of the boiler. • Both the air supply (if room sealed) and the flues are to be connected to the outside wall and/or the roof. (see safety guidelines page 4) • Install horizontal Flue parts under 1% fall in the direction of the boiler (one centimetre for every linear metre) complete with extra drain points with a 60mm water trap. • The installation area must be dry and frost-free and conform to relevant regulations. • Installers are advised to choose a part of their building where slight noise emission will not cause disturbance. • A minimum of 15 mbar gas pressure (and or current regulations) all plant running. Page 11 of 51 6.3 Mounting the Boiler Prepare the Boiler for mounting as in 6.1.Determine the positions for the flow and return pipes using the suspension bracket or a suspension frame, if any. When marking the holes, ensure that the suspension bracket or frame is level. Drill the holes for the flow and return pipes if required then hook the heating boiler onto the bracket or place it upon the frame. 6.4 Air supply & flue types When using multiple SCB Boilers on a common flue the inbuilt cascade control must be used. SCB Boilers 60kw to 100kw use a co-axial flue. Twin pipe flue-ing utilises an adaptor at extra cost .Boilers 120. 150 and 180 kw use parallel i.e. one air inlet tube and one exhaust tube a co-axial adaptor is available at extra cost. . All Boilers can be used in a room sealed application or, if the boiler room or fitting space complies with the relevant ventilation requirements Boilers can be non room sealed I.E. exhaust only, Providing ventilation as per current regulations is in place. See pages 10 and 11 for flue connections. Install the horizontal flue parts under 1% fall in the direction of the boiler (one centimetre for every linear metre). Adequate drain points should be installed throughout long horizontal exhaust runs and at the base of any vertical flue exhaust run. 60 mm (minimum ) “u” traps should be utilized. 6.5 The air inlet and flue gas outlet system. The Boiler is ( normally )room sealed, the casing is airtight with air entering through the air supply connection only. Always ensure the casing is placed over the boiler when the boiler is in operation! The available pressure for the inlet and flue system is 250 kW Pa, unless data from the table is being used. 180 A180 180 160 A150 150 N.B.! Install the horizontal flue parts under 1% fall in the direction of the boiler (one centimetre for every linear metre). Failing to do so may result in water condensation building up in the flue gas tube. In turn, this may cause failure. 140 The impact of the flue to the output 120 A120 120 100 A100 100 80 A80 80 60 A60 60 40 0 100 200 300 400 500 600 The table on the left shows the relationship between the Boiler output and the resistance of the air inlet and flue. Up to a resistance of around 250 Pa the output will be approximately the same as the Boiler data plate In the event of a greater resistance ( up to maximum 600 Pa ) this will change the Boiler output . The resistance and the change of output only affect the maximum output and not the minimum. Tip! Remember that possible output changes may influence hot water production and transmission/absorption calculations. Pa Resistance up to 250 Pa 300 Pa 350 Pa 400 Pa 450 Pa 500 Pa 550 Pa 600 Pa Page 12 of 51 Decrease of input 0% -3% -4% -6% -7% -8% -9% -10 % 6.5.1 Strebel S-CB Flue/Air inlet Resistance table The output of the boiler is affected by the resistance of the air inlet and flue system. At a resistance up to 250 Pa, the output will be as indicated on the name plate of the boiler. See page 12 for higher flue resistance. Table 1; Resistance table (mm) Co axial ( Twin) Flue gas discharge (Twin )Air supply Termina ls Co-axial Item Boiler S-CB roof terminal outside wall terminal roof terminal outside wall terminal straight tube/mt straight tube/mt straight tube/mt straight tube/mt 45° bend 45° bend 45° bend 45° bend 90° bend 90° bend 90° bend 90° bend straight tube/mt straight tube/mt straight tube/mt straight tube/mt 45° bend 45° bend 45° bend 45° bend 90° bend 90° bend 90° bend 90° bend straight tube/mt straight tube/mt 45° Concentric bend 45° Concentric bend 90° Concentric bend 90° Concentric bend 125/80 125/80 150/100 150/100 80 100 130 150 80 100 130 150 80 100 130 150 80 100 130 150 80 100 130 150 80 100 130 150 125/80 150/100 125/80 150/100 125/80 150/100 60 25 15 12 10 4 1 0,35 X 2 0,6 0,2 X 4 1 0,35 X 5 2 0,45 X 2,5 1 0,2 X 5 2 0,45 X 8.5 2.5 4.2 1.2 8.5 2.5 Resistance inlet and outlet system [Pa] 80 100 120 150 45 X X X 30 X X X 30 35 40 X 25 28 32 X 5,5 8 10 15 3 3,5 4 6 0,75 0,8 1 1,2 X 0,3 0,4 0,6 3 4 5 7.5 1,5 1,7 2 2,2 0,4 0,4 0,5 0,6 X 0,15 0,2 0,3 5.5 8 10 15 3 3,5 4 6 0,7 0,8 1 1,2 X 0,3 0,4 0,6 8 12 15 20 3,5 4 6 9 0,8 1,2 1,5 2 X 0,5 0,5 1 4 6,5 8 14 1,7 2 3,2 4.5 0,4 0,6 0,8 1 X 0,2 0,4 0,8 8 12 15 20 3,5 4 6 9 0,8 1,2 1,5 2 X 0,5 0,7 1,1 11.5 X X X 4.5 5 8.0 15 5.5 X X X 2.2 2.5 4 8 11.5 16 21 X 4.5 5 8 15 *Parallel Roof & wall terminal air inlet/exhaust resistance equals 1 meter straight length of same size Strebel S-CB Example calculation - Boiler type: S-CB 60 S-CB 60 using a co-axial flue system 125/80, with through the roof terminal. For the stated output the boiler has 250 Pa fan pressure Roof terminal = 25 Pa Resistance 25 Pa subtracted from 250 Pa leaves 225 Pa Each metre length of 125/80 flue has a resistance of 8.5 Pa. 225 divided by 8.5 =26.4 Therefore the above example allows a straight flue run of 26.4 metres. Reduce this flue run by 1 metre for each 90 degree bend or ½ metre for each 45 degree bend. See also sample parallel flue calculation on page 16 Install horizontal Flue parts under 1% fall in the direction of the boiler (one centimetre for every linear metre). Page 13 of 51 180 X X X X 24 9 2 1,0 12 4.5 1 0,6 24 9 2 1,2 X 12 3 1.5 X 6 1.5 1.8 X X 3 1.5 X 20 X 10 X 20 6.5.2 Single & Cascade resistance tables of air inlet and flue. The output of the boiler is affected by the resistance of the air inlet and flue system (as a result of controlled gas/air ratios in the Boiler). At a resistance up to 250 Pa, the output will be as indicated on the Boiler data plate. Higher resistance of up to 600 Pa max can be overcome with reduced Boiler output (see page 12). An under pressure, in the flue gas outlet, is not required, a positive pressure is created by the fan of the Boiler which is specially designed for this purpose. As a result of this, the diameter of the common air inlet and flue gas outlet is minimised; while the built in non return air valve prevents recirculation between the Boilers when 2 or more are used on a common flue. Table Resistance of the air inlet system The stated Air inlet diameter is that used between the boilers and the roof or wall terminal. Transmission kW 60 90 120 150 180 210 240 270 300 330 360 390 420 450 480 510 540 570 600 630 660 690 720 750 780 810 840 870 900 930 960 990 1020 80 mm Pa/m 4 7 10 15 24 100 mm Pa/m 1 2 4 6 9 12 15 18 21 25 130 mm Pa/m 0.35 0.6 1 1,5 2 2,5 3 4 5 7 8 9 10,5 12 13 14 15 16 18 20 22 23 25 27 28 30 150 mm Pa/m 180 mm Pa/m 200 mm Pa/m 250 mm Pa/m 0,4 0,6 1 1,4 1,8 2,2 2,6 3 3,4 3,8 5,3 5,8 6,3 6,5 7 8 9 10 11 12 13 14 15 16 17 18 20 21 22 23 25 0,5 0,6 0,7 0,8 0,9 1,1 1,3 1,5 1,7 2 2,3 2,6 2,9 3,3 3,6 3,9 4,2 4,6 5 5,4 5,8 6,2 6,6 7,0 7,5 8 8,5 9,0 9,5 0,8 0,9 1 1,2 1,3 1,4 1,5 1,8 2,1 2,3 2,4 2,5 2,6 3 3,5 4 4,2 4,3 4,3 4,5 4,7 4,9 5,2 5,5 0,65 0,7 0,75 0,8 0,85 0,90 0,95 1 1,1 1,2 1,3 1,4 1,6 1,8 2 Resistance of the different parts of the inlet system: Standard Flue pipe can be used for the air inlet. *Bend 90° : equal to 1 meter straight tube of the same diameter. *Bend 45° : equal to 0,5 meter straight tube of the same diameter. *Cascade T-piece on top of the boiler equal to 1 meter straight tube. *Parallel Roof & wall terminal air inlet resistance is equal to 1 meter straight length of same size. * See sample calculation page 16. Install horizontal Flue parts under 1% fall in the direction of the boiler (one centimetre for every linear metre). Page 14 of 51 6.5.3 Single & Cascade Table Resistance of the Flue in Pa/m SIZE Output kW 80mm Pa/m 100mm Pa/m 60 90 120 150 180 210 240 270 300 330 360 390 420 450 480 510 540 570 600 630 660 690 720 750 780 810 840 870 900 930 960 990 1020 5 8 15 26 2 4 6 9 12 15 20 25 130mm Pa/m 1 1,5 2 3 4 5,5 7 8,5 10 11 12 13 15 17 19 21 23 27 28 30 150mm Pa/m 180mm Pa/m 200mm Pa/m 250mm Pa/m 0,6 1 1,5 2 2,5 3 3,5 4 4,5 6 7 8 9 10 11,5 13 14,5 16 17,5 19 20,5 22 23 24 25 26 27 28 29 30 31 0,5 0,6 0,8 1 1,2 1,5 1,7 2 2,3 2,5 3 3,5 4 4,5 5 6 6,3 6,5 7 7,5 8,2 8,4 8,7 9 9,5 10,1 10,6 12 13 14 0,8 0,9 1,1 1,3 1,5 1,7 1,9 2,1 2,3 2,5 2,8 3 3,3 3,7 4,0 4,3 4,6 4,9 5,2 5,6 6 6,4 6,8 7,3 8,0 8,8 X X X X 0,8 0,9 1,0 1,2 1,4 1,5 1,6 1,7 1,8 1,9 2,1 2,2 2,3 2,4 2,5 2,6 Resistance of the different parts of the inlet system: Bends 90° : equal to 1 meter straight flue of the same diameter Bends 45° : : equal to 0,5 meter straight flue of the same diameter. T-piece on top of the boiler is equal to 1 meter straight flue . Co axial flueing, roof and wall terminal see page 13 Parallel Roof & wall terminal flue resistance is equal to 1 meter straight length of same size • See sample calculation page 16 Install horizontal Flue parts under 1% fall to the boiler (one centimetre for every linear metre). Page 15 of 51 6.6 Example of a Flue Resistance Calculation Boilers: Horizontal air inlet: Vertical air inlet to the roof: T-pieces over the boilers Number of bends 90°: Roof terminal: 4 x 150 kW + 1 x 180 kW; Total 780 kW 5 meter 8 meter 4 2 1 Air inlet: Choosing a diameter of: 180 mm Horizontal duct , 5 meter Vertical duct, 8 meter Bends 90°:x 2 T-pieces: x.4 Roof terminal 5 8 2 4 x 5.8 x 5.8 x 5.8 x 5.8 5.8 Total Resistance 29.0 Pa 46.4 Pa 11.6 Pa 23.2 Pa 5.8 Pa 116 Pa Flue gas exhaust Choosing a diameter of: 180 mm Horizontal flue , 5 meter Vertical flue, 8 meter Bends 90°: x 2 T-pieces: x.4 Roof terminal 5 x 8.4 8 x 8.4 2 x 8.4 4 x 8.4 8.4 Total Resistance 42.0 Pa 67.2 Pa 16.8 Pa 33.6 Pa 8.4 Pa 168.0 Pa Total resistance of the system : 116 Pa+168Pa = 284 Pa Total resistance is 284 Pa; higher than 250 Pa,(at which the Boiler output stays the same as stated on the data plate) therefore according to the table on page 12, the output will be lowered by about 3%. This means, that the total output will be 780 kW – 3% = 756 kW 6.7 Chosing a diameter of 150 mm for the whole 780 kW system, Air inlet system: (uses flue material) Choosing a diameter of: 150 mm Horizontal duct, 5 meter Vertical duct, 8 meter Bends 90°: x. 2 T-pieces: x. 4 Roof terminal 5 x 15 8 x 15 2 x 15 4 x 15 15 Total Resistance 75 Pa 120 Pa 30 Pa 60 Pa 15 Pa 300 Pa Flue Choosing a diameter of: 150 mm Horizontal Flue, 5 meter Vertical Flue, 8 meter Bends 90°: x. 2 T-pieces: x. 4 Roof terminal Resistance 5 x 23 115 Pa 8 x 23 204 Pa 2 x 23 46 Pa 4 x 23 102 Pa 23 23 Pa Total 490 Pa Total resistance: 300+490 = 790 Pa. It is clear, that the resistance is higher than the 250 Pa, even higher than the maximum 600 Pa; the diameter of 150 mm is too small. Page 16 of 51 6.8 Condense water drain The condense water drain is next to the centre at the bottom of the boiler and has a ¾ inch hose discharge. Connect this flexible hose to the drains via a tundish or oversize waste pipe. Also consider a waste trap. N.B.! Use only plastic parts with the condense water drain. Metal lines are not allowed. Tip! Blockage of this drain may cause damage to the boiler. The drain connection is correct when the condense water can be seen flowing away, e.g. using a funnel. Any damage that may occur due to a blockage is not covered by the warranty. 6.9 Central Heating If plastic material for the flow and return from the radiators or under floor heating is being used and not oxygen diffusion proof to DIN standard 4726/4729 a separation between the central heating water of the boiler and the system will be required, e.g. using a plate heat exchanger. This will prevent contamination of the boiler heat exchanger with magnetite. If the plastic material is not to the DIN standard failure to provide such separation will void the warranty of any boiler parts relating to water. 6.9.1 Central Heating circuit The S-CB has no pressure relief safety valve. This should be fitted in the flow of the system in close proximity to the boiler (Boiler side of any valves). See pages 5 & 6. The S-CB has no internal bypass. Low loss headers must be used to allow flow, even when all system valves are closed. Tip! To prevent contamination of the S-CB heat exchanger, it is recommended to thoroughly flush the system with clean running water prior to first use. 6.9.2 The expansion vessel Please remember that the capacity of an expansion vessel is chosen or installed to match the capacity of the central heating system and the static pressure. Fit the expansion vessel in the return of the central heating system (see page 5 & 6 2.1 and 2.2) Expansion vessels and fill units available at extra cost from Strebel. Page 17 of 51 6.9.3 Internal Pump The pump has a speed regulator adjusted to the highest setting: Do not change this setting! The S -CB has a built-in pump control with a standard 3-minute over run. The pump will work at top speed when heat is required. When heat is no longer required, the pump will continue to run for another 3 minutes. The pump and connected three-way valve for the calorifier or external pump (if fitted) are also activated for one minute every 24 hours. The 24 hour cycle starts as soon as the power supply to the boiler is activated. 6.10 Low loss header. Low Loss Headers must be used with the S-CB Boiler Typical Cascade Layout. Hidden Detail AAV Air & Dirt seperator Low loss header D4 H2 STRAINER Low Loss Header FILL UNIT D1 Diameter of common flow & return headers H3 H1 LSV DOC EXP VESSEL For Low Loss Header size, Flow and Return size see table. Low Loss Header & Common Flow/Return OUTPUT H1 H2 H3 D4 D1 KW mm mm mm inch inch . 60 80 100 120 150 180 240 300 360 420 480 540 600 330 340 345 360 400 445 445 560 680 780 780 780 780 370 380 390 405 450 505 505 620 780 850 850 850 850 465 480 510 565 610 665 665 725 865 980 980 980 980 3 3 4 4 4 5 5 6 8 10 10 10 10 1 1/2 1 1/2 2 2 2 2 2 1/2 2 1/2 2 1/2 4 4 4 4 Boiler Connections Group I Type S-CB 60 80 100 120 1 1/2” 1 1/2” 1 1/2” 1 1/2” 3 /4” 3 /4” 3 /4” 3 /4” Boiler Connections Group II Type S-CB 150 180 Note to Design Engineer: See Quotation for equipment supplied. Page 18 of 51 Flow/Return Gas connection Flow/Return Gas connection 2“ 2“ 1” 1” 7. INSTALLATION INSTRUCTIONS FOR THE ELECTRICIAN 7.1 Connecting to the mains power supply The console has an ON / OFF button to switch the Boiler on or off. The electrical connections to the S-CB are made via discreet plugs and sockets which are located within the boiler casing, on top of the control panel. Connections must only be made using appropriate diameter multi strand flexible cables. Cable entry must only be via the rubber glanded cable points located at the bottom rear of the appliance: the low voltage cables are at the left side (top in the drawing below) and the 230 VAC cables are at the right hand side of the boiler (bottom in the drawing below). If the boiler is to be room sealed, then care must be taken to ensure the cable entries are reasonably air-tight. 7.2 Boiler Plug & Connector Strip The stated items may be attached using the available plugs/sockets (use relays for pumps) Interruption of the mains supply for on/off control must not be used 1 2 Outside sensor 18 19 C33536 LO 3 4 5 Flow Sensor 20 HD 6 7 NOT USED 21 L1 22 N 8 9 L2 Use for 3 way valve on DHW. Use 2223 for D H W Primary Pump 24 L1 11 25 26 N L2 NOT USED 27 L1 13 14 Boiler On/off ( low voltage) SEE DATA for RC or E-BUS 28 29 N L2 Heating Pump 27 - 28 See below C = Common HD = Heat Demand/Run LO = Lock Out 12 + 0 to 10 v DC in NOT USED DHW Sensor or Thermostat 23 10 15 16 Cascade Bus Connection 34 35 36 L N E Mains connection 230 AC Interruption of the mains supply for on/off control must not be used Connector strip Strebel S-CB Heating curve When an outside temperature sensor has been connected, the boiler will respond to the program of weather compensation (but not when 0 to 10 volt control is used) Through the parameter menu the heating curve (see page 20) can be set: to do this, use the parameter menu with the interface cable together with a laptop and the necessary software. When the outside temperature sensor is connected, the cable terminals “13” and “14” should be bridged; or an On/Off control should be used. For RC and E-BUS see separate data. With the temperature button on the display (CH) this heating curve can be shifted with + and - 5°C. The default for the heating curve of the main circuit is set to K-factor “3,5” See graph page 20 Page 19 of 51 Diagram Outside temperature versus Flow temperature and the K-factor Flow Temperature Flow temperature °C K-Factor K=3 K=3,5 K=2,5 K=2 90 K=1,5 80 70 K=1 60 50 K=0,5 40 30 20 30 25 20 15 10 Outside Temperature + Outside Outsidetemperature temperature°C °C + 5 0 10 -5 -10 -15 Outside Temperature - Plug Connection Description 1-2 Outside Temperature Sensor When an outside temperature sensor is connected, the boiler will be weather compensated. When no Roomstat or control is connected, the terminals “13 and “14” should be bridged. A remote room thermostat with or without time switch can be connected. The RC or E –Bus (for RC and E-Bus see separate data), with or without built in room compensation can be used,see other instructions. When the outside temperature sensor is not connected, the boiler is controlled by the roomstat or On/Off control (when connected to plug no. 13 and 14 ) 3–4 Flow temperature sensor Page 20 of 51 In cascade the flow temperature sensor for the central heating circuit is connected to these terminals and placed directly on the flow to the installation (after any low loss header). This flow sensor can work in conjunction with or without an outside temperature sensor and is required for 0 to 10 v control by others. 5–6 Not used 7–8 Hot Water Temperature Sensor 9–10 Not usedtemperat ure control with clock for secondary circuit 11-12 0 – 10 VDC The boiler can be controlled by external control, through a 0 to 10 V signal, by which 0 Volt is no heat demand and 10 V is maximum output. The DC supply “+” has to be connected to terminal 11, while the “-“ has to be connected to terminal 12. A Flow Temperature sensor is also required available at extra cost from Strebel 13-14 Room temperature control (with or without timer) for the heating circuit These terminals have the following possibilities: 15-16 Cascade connection NOTE : When a Calorifier is connected, a hot water sensor or an on/off thermostat can be connected. If a sensor is connected, the domestic hot water is set at 60 in the Boiler and also the water temperature will be shown on the display when active on DHW. 1. When no on /off control is connected, the boiler temperature is controlled by the maximum flow temperature, (set by the CH Control Knob on the Panel). In this case a link has to be used between 13 and 14 .When an outside temperature sensor is connected, the boiler is controlled through the heating curve, which can be shifted with the CH Control knob on the Panel. 2. When an On/Off Control (with or without a timer) is connected, this control switches the boiler Off, when the desired temperature reaches the temperature set on such control. (with or without outside temperature compensation). When two or more boilers are connected to the boiler control (every boiler control has a built in cascade manager) each boiler of the cascade has to be connected to the next boiler, using a two wire bus (cascade connection) terminals. A Flow Temperature sensor is also required available at extra cost from Strebel. The cascade control must be used on multiple Boiler systems sharing the same flue. Page 21 of 51 18-19- Remote Fault Through the use of an external power (e.g. BMS, 230 VAC or 24 v), one Volt Free 20 Lock-out and contact closes in a Lock Out condition and the other on Heat Demand. remote signal A BMS, lamp or a buzzer can be connected for Heat demand. HEAT DEMAND N LOCK OUT SUPPLY 21-22-23 Diverter Valve primary hot water circuit or primary pump relay Diverter Valve (3 Port ) for charging a Calorifier DHW primary pump relay is connected to 22 & 23 When a zone 2 circuit (low temp) is installed, the pump for this circuit has to be connected to the terminals “N” and “L2” and the PE to the main PE terminal at the right side of the panel. 24-25- not used 26 secondary circuit Mixing Valve for zone 2 (low temp) where the L2 is the Closing hydraulic connection: (closing when the temperature is rising.) 27-28- HTG Pump 29 Heating pump relay 27– 28 30-31 No connection No connection 32-33 No connection No connection 34-35- Permanent 36 Supply Page 22 of 51 The permanent supply is connected to these terminals. This supply must not be interrupted for control purposes. 7.3 Phase sensitivity The S-CB boilers are not phase (polarity) sensitive. 7.4 Fuses Main supply fuse should be 5 Amp, slow blow (Not Strebel supply). On the PCB. Board, there are 3 auto fuses and 1 mains fuse. Fuse nr. Use Value F1 Ignition Automatic re-set F2 Electronics Automatic re-set F3 Electronics Automatic re-set 230 VAC Mains 3.15 Amp Maximum electrical load for the boiler. a. For the boiler types S CB60 to S CB120: The total load connected for external diverter valves and or pumps should not exceed a maximum of 345 Watt (1.45A). Any external pump should be connected to the boiler via a relay. When the total of the connected pumps and valves exceeds 345 Watt, these items must be controlled through relays. b. Boiler types S CB150 + S CB180: The total load connected for external diverter valves and or pumps should not exceed a maximum of 255 Watt (1.1A). Any external pump should be connected to the boiler via a relay. When the total of the connected pumps and valves exceeds 255 Watt, these items must be controlled through relays. 7.5 Sample Cascade Electrical Layout All items are not used on every installation. P2 North Wall FS 0 to 10 v see notes below See Drawings in the installation operating and maintenance instructions pages 6 and 20 for full cascade hydraulic layout detail Notes: a. b. c. d. When using 0 – 10 Volt, no room thermostat can be connected When using 0 – 10 Volt, no bridge is needed for the 13 and 14 connection When using 0 – 10 Volt, no outside sensor can be connected When using 0 – 10 Volt, a flow sensor is required on the Heating Flow. P1 = Inbuilt Boiler pump P2 = Heating pump FS = Flow sensor OS = Outside sensor RT = Room thermostat See “ a “ NOTE: See Quotation for equipment supplied. Page 23 of 51 7.6 Electrical circuit diagram 60-80-100- 120 KW SINGLE GAS VALVE 150-180 KW DUAL GAS VALVE PCB with plug numbers Ferrite Article no 7427113 Fig 2; Electrical circuit diagram Page 24 of 51 8. PUTTING INTO OPERATION 8.1 Control panel Available control elements for the user (also see 8.4 and 8.41 on page 28) Control Console 1. Pressure Gauge – 0 to 6 bar .Filling pressure minimum: 0.5 bar. 2. Control knob with indication: “CH”- Setting maximum Flow temperature a. With this knob, the max flow temperature of the Central Heating can be adjusted even when using 0 to 10 volt control. b. The set temperature will always be displayed unless an outside sensor is fitted. c. When an outside temperature sensor is connected, the set heating curve temperature will be displayed: this set heating temperature can be shifted within limits: +10 and – 10°C. 3. The Display – Shows the set flow temperature or,when 0 to 10 volt control is used the temperature dictated by the voltage, example 10 volts equals maximum temperature see 2a above. Where an outside temperature sensor is fitted, the compensated temperature is shown. Exception: lock out and other faults. When there is a Lock out situation the cause of this Lock out, is shown in a code on the display. The code is flashing on and off. 4. Green LED named: Flame. - When the burner is working and firing properly (there is ionisation), the LED is green; in case there is no Heat Demand, the LED is off. 5. Press button named RESET: When the display is flashing, there is a lock out situation: by pressing this button, the boiler will start again: before pressing this button, note the code in the display in order to record the reason for the lock out see page 27. 6. Service: Behind the small plastic cap, a plug is available for connection of a cable with interface, for connection to a computer. This will allow extensive changes to the parameters in the boiler control when in service mode. 7. Below the plug, there is a small hole, through which one can push a sharp point (e.g. ball pen), this will enable the fan speed to be set by turning the CH-knob when in service mode.(for setting the gas valve see 8.4.1 page 28) When completed, push this small button once again, to return to the automatic program. 8. Double pole On/Off switch O – no mains to the control I– Control is switched on, and all the components in the boiler. Page 25 of 51 8.2 Sensors The boiler uses the following temperature sensors (S3 to S7 when fitted) S1 = The flow sensor (on the front left of the heat exchanger). S2 = The return sensor (on the rear left of the heat exchanger). S3 = Cascade flow temperature sensor. S4= NOT USED S5= DHW temperature (if fitted). S6 = The outside temperature sensor (if fitted). S7= NOT USED. The sensors used in the Strebel S-CB are of the NTC type (negative temperature coefficient) and have the values shown below: Temperature [°C] 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 Resistance Sensor 1, 2, 3, 4,5,7 [Ohm] 32550 25340 19870 15700 12490 10000 8059 6535 5330 4372 3605 2989 2490 2084 1753 1481 1256 1070 915 786 Temperature [°C] -30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 Resistance Sensor 6 [Ohm] 171800 129800 98930 76020 58880 45950 36130 28600 22800 18300 14770 12000 9804 8054 6652 5522 Table 2: Sensor table S-CB If the CH water temperature rises very sharply, the boiler will be blocked by combined action of the supply and return sensors until the water temperature has fallen again. Page 26 of 51 8.3 Run and fault Information and Display Meanings Display Two kinds of information may be displayed: a. Display codes Steady and not Flashing on and off. When a code is displayed, it means that there is a heat demand (except the code 0), but the boiler is not working, example, because the temperature is higher than the set temperature. After cooling down, in most cases the appliance will automatically start to function again. Codes not flashing on and off (A2 to O are not faults) Status Code on display Action Flow temperature achieved Flow temperature achieved DHW Calling Boiler off on Temperature Anti constant recycle ( hunting on & off ) Speed of the fan is too high Speed of the fan is too low No call for Heat ( external control contacts are open & not calling for heat ) A2 A3 A4 A5 A6 A7 O High limit thermostat is in a short term (10 Sec) limit condition C3 The condition may clear on cooling down (else F2 condition) Not used C5 Wait for cooling down Wait until temperature decreases Check cylinder control Wait for cooling down Wait until the speed is OK Switch the external control to call for heat b. Codes flashing on and off A code which is flashing on and off will show that the boiler is in a lock out position, and will not restart automatically. The RESET button needs to be pressed, until the flashing lock out code disappears. Without any adjustments or repairs to the appliance, it is likely that the same lock out will happen again: so please look at pages 33 to 39 of this booklet, on how to prevent this particular lock out. Faults with codes flashing indication. Status Short circuit on ionisation probe Code on display F0 High limit thermostat condition Fan speed not correct No flame after 5 attempts Flame lift off during heat demand Flow temperature too high DHW temperature too high Return temperature too high Boiler not operational Not used New Parameter programmed correctly Parameter incorrectly programmed Burner control out of order F2 F4 F5 F6 E0 E1 E2 F1 E5 PP PE nc Action. Read page 37 & information below Check Probe etc Press Reset Button Press Reset Button Press Reset Button Press Reset Button Press Reset Button Press Reset Button Press Reset Button Press Reset Button Program Fault Press Reset Button Press Reset Button Program again Switch the mains off, wait 5 seconds then on Page 27 of 51 8.4 Display console buttons There are a couple of uses of the buttons and knobs on the display console, namely to adjust settings or to get information: -- means the “OFF” “0” on the display means: “No heat Demand” On Heat Demand, the required boiler temperature is shown on the Display or domestic water temperature during DHW demand (DHW if fitted ) 8.4.1 Service Button SERVICE press button. In order to set the gas-valve for the maximum output as well as for the minimum output, the appliance has to be put into the SERVICE mode: press a ball pen (or similar) into the small hole beneath the plastic cap at the right side of the control fascia (see 8.1 page 25). By turning the CH knob, the speed of the fan can be set between the maximum and minimum speed. The display will show the speed of the fan e.g. 25 means 2500 r/min. After 10 min. the boiler switches back to the automatic program: If the setting of the gas-valve is not complete, press the switch again. The temperature of all the connected sensors can be shown (without the help of a laptop) on the display. Press the RESET button, the first temperature is now shown (blinking) together with the code of the sensor (blinking). To see the temperature of the next sensor, press again the RESET button. FL rE dH o temperature temperature temperature temperature Flow temperature Return temperature Hot water temperature Outside temperature 8.5 Filling and venting the Boiler and the system in preparation for light up. Fill the central heating boiler and the heating system using the appropriate filling method. The correct fill pressure is >0.5 bar max 6 bar Pay attention to the following aspects in order to prevent corrosion of the CH system: • • • • Fill water: if desired use X100 (only) additive to the water for the central heating. The pH value should be higher than 5 (if not, we suggest you contact Strebel).Test the water. Use additive as required Thoroughly flush out the central heating system removing all traces of flux and debris. Ensure that any plastic pipes that are being used are oxygen diffusion-proof in accordance with DIN 4726/4729. If not, separate the boiler circuit and the plastic pipes using a plate heat exchanger Check the circuit for leaks to prevent oxygen from entering the system. The boiler has an automatic air vent, at the top of the boiler, this must be opened when the boiler is put into operation. Check that the A/V screw cap is open by at least one twist. Check all system air vents are open. Shortly after putting the boiler into operation, check the filling pressure and add more water to maintain the required pressure, if necessary .Cure any leaks on the heating and dhw system Page 28 of 51 8.6 Commissioning 8.6.1 General Measure the gas pressure in the gas pipe at the pressure nipple (3) of the gas safety valve. The gas pressure needed for the boiler to work properly under full output is a minimum of 15 mbar (or current regulations, if greater) all plant running. 3 2 1 2 1 2 3 S-CB 60/80 S-CB 100 / 120 S-CB 150/180 Figure 4; Gas valve(s) Strebel S-CB NOTE: THE SCREW 2 ON THE GAS VALVE BLOCK SCB 60/80/150/180 IS THE SMALL SCREW AS SHOWN 8.6.2 Boiler Commissioning Light Up • • • • • • Once the system has been filled, vented, (see 8.5 page 28) tested and everything is in order according to this manual, connect the central heating boiler to the mains and turn the boiler on.. Make any external control device. IE room stat, control panel etc When the boiler is turned on, the display will show the requested water temperature (see 8.4 , 8.4.1 ) The burner control will repeatedly give an electronic spark until a flame appears. If no flame appears after several attempts, check 1), the gas supply. 2), the gas valve has been set correctly. The Boiler has a built in hot water control, the boiler will first heat up the calorifier (when connected). Once the calorifier is hot (if fitted), adjust the room thermostat (or make an external control) to a higher value to start the burner for CH. 8.7 Adjusting and setting the output or when checking or replacing a new gas control valve Set the valve via measuring the CO2 percentage (LPG is set by CO see page 40 & 41) and gas consumption rate (The flue may effect the Boiler output see pages 13, 14 and 15) Use this method to set both the minimum and the maximum output: first set the maximum output and then set the minimum output. 8.7.1 Setting the maximum output Press with a ball pen (or similar) the SERVICE button (8.4.1) in the small hole beneath the plastic cap at the right side of the control fascia and then turn the CH knob to give the maximum fan-speed (See table 4. page 30) Measurement of the emissions and CO2 percentage is via the measuring point in the flue gas pipe, (after unscrewing the plastic cap). If necessary, turn the adjusting screw 2 (see Figure 4 above) for setting; either anticlockwise to increase the CO2 percentage or clockwise to reduce the CO2 percentage (see fig 4 page 30). For setting the minimum output CO2 percentage see page 31 8.7.2 ( LPG is set by CO see page 40 &41). Boiler Minimum fan revolutions (RPM) For setting CH Maximum fan revolutions (RPM) for setting CH S-CB 60 S-CB 80 S-CB 100 S-CB120 S-CB 150 S-CB 180 1800 1800 1800 1800 1800 1800 6500 6500 6500 6500 5500 5500 Table 3 Revolutions S-CB Page 29 of 51 IF the setting takes more than 30 minutes the Boiler will return to auto mode. If so, press the SERVICE button again. Also for returning to the normal menu press SERVICE. Set the Boiler via measuring the CO2 percentage (as shown in the table 4a below), and gas consumption rate. Comment: Measurement of the emissions and CO2 percentage is via the measuring point in the flue gas pipe, (after unscrewing the plastic cap). For gas valve adjustments see illustration on Page 29 Fig. 4 5. Gas consumption. Boiler S-CB-60 S-CB-80 S-CB-100 Natural gas (G20) 0.098 m³ per minute 0.130 m³ per minute LPG See 40&41 See 40&41 See40&41 See 40&41 0.164 m³ per minute S-CB-120 S-CB-150 S-CB-180 0.196 m³ per minute 0.245 m³ per minute 0.293 m³ per minute See 40&41 See 40&41 Table 4, Maximum settings Injector (Gross)(MJ/m3) Cal. value Net (MJ/m3) CO2 max. Output (%) CO2 min. Output (%) * measured without casing Type of gas Natural gas G 20 LPG none none 50.7 76.64 34 88.00 8.8(+/-0.3)* See LPG 8.5(+/-0.3)* See LPG Table 4a Co2 settings Page 30 of 51 8.7.2 Setting the minimum output Set the minimum load once the maximum load has been set. In service mode turn the CH knob until the minimum RPM setting has been reached (20 on the display). In order to set or adjust the minimum load, twist the screw [1] for the minimum setting. Turn the screw clockwise to increase or anti-clockwise to decrease the CO2 percentage, (see table 4 a page 30). The gas valve on the S-CB150 and S-CB180, you only are allowed to set the gas valve on the right hand side. DO NOT ADJUST THE LEFT HAND SIDE GAS VALVE For Gas Valve Adjustment see illustration on page 29 Figure 4 8.8 Gas conversion Converting from Nat. gas to LPG: Boilers with a single gas valve: SCB 60 up to 120 kW: See page 40 Boilers with a two gas valves: SCB 150 up to 180 kW: See page 41 NOTE: Set LPG by CO emission Setting LPG CO² % is not important, because it is influenced by the quality of the LPG, which differs quite a lot; mostly the measured CO² % is roughly between 9.5% and 10%. High Fire CO: is set to less than 100 ppm CO. Low Fire CO is set to less than 10 ppm . Page 31 of 51 9. LONG TERM SHUTDOWN It is recommended to leave the boiler turned on all year round to prevent frost damage in winter and moving parts seizing due to corrosion during other times of the year. To switch the boiler off break the frost protected control circuit (by others) or turn the room thermostat down (minimum power consumption is now assured); the pump for the central heating and the fan will stop after a short delay. If the boiler has to be put out of operation, the following action must be taken: • Close the gas cock. • Remove the electrical plug from the wall socket, or switch off the mains-power. • In the event of possible frost damage: drain both the boiler and the system. When draining the boiler, drain the system first. Then open the two drain cocks of the boiler. • • • Put the O/I switch to position “O” and the On / OFF switch in position “OFF”. Isolate at local isolation. Open the filling and drain valve of the central heating system and the boiler drain valve on the right- and left-hand side of the boiler. Page 32 of 51 10. LOCK OUT As the burner control goes into Lock Out, the display will show a code (see also 8.3 page 27) which corresponds with the cause of the error; the table below shows the errors. Only by pressing the “Reset-button” the boiler can be reactivated. Meaning Code on Display F0 F2 F4 F5 F6 E0 E1 E2 E4 E5 Possible cause of the Lock Out See fault numbers Page 34 to 37 18; 35; 61 4;5;21;23;24;29;30;42;46 7;8;9;13;19;39;40;41 10;11;16;18;22;25;35; 10;12;16;22;25;26;32;44 4;5;23;29;46 3;4;21;24;25;38;43;55; 4;5;23;29;46 3;4;21;24;25;38;43;55; 1;2;3;4;21;24;30;43;46;51;55;63; New Parameters programmed correct Parameters incorrectly programmeerd Burner Control has malfunction No communication (in cascade mode) PP PE nc nc, Burner defect H1 Press Re Set Button Revise programme Switch power off then on Check cables to all boilers and Bus address numbers Press reset button Short Circuit in Ionisation Circuit Limit Temperature Wrong Fan speed No Flame after 5 Ignition attempts Flame lost (4 times) during running Flow sensor shorted or interrupted Return Sensor short/interrupted There are several faults or complaints that the display is unable to convey. Some of these faults or complaints are: Complaint a. b. c. d. e. f. g. h. i. j. k. l. The building is not warming up but the boiler is working Noisy ignition Burner of the boiler is continuously on, but the CH water is not warming up Room thermostat demanding heat, but boiler is not firing Burner of the boiler is continuously on; building is getting too hot Boiler is very noisy during CH operation Tops of radiators are insufficiently hot ON DHW, the water is cold Temperature of the DHW is far too hot ON DHW, the water remains below 60°C ON DHW, the boiler is very noisy Fault after replacement of the burner control Cause of the fault (see page 34 to 37) 45;53;54 16;35 45 1;42;52 2 29;46;66 55 24;56 51;57 51;58 23;59 60 Table 5; Other faults Page 33 of 51 11. TROUBLESHOOTING 11.1 Cause of the fault The faults listed on page 33 may have the following causes. Table 6: Causes of faults 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. Page 34 of 51 Room thermostat incorrectly connected. Room thermostat not turning off, short-circuit in cable. Sensor causing short-circuit in cable or internally. Pump not running; got seized Water pressure in the CH system too low. on external pressure gauge Water pressure in the CH system too high. on external pressure gauge Fan not connected (unplugged). Fan has been damaged or dirty Fan is defective Gas valve not open. Gas pressure is too low. Gas pipe diameter is too small. Fuse F3 defect Fuse F4 defect. Fuse F5 defect. Gas valve setting for lowest RPM incorrect. Gas valve is not or incorrectly connected to the power supply. Ignition cable incorrectly connected Transformer defect. Connecting plug to gas valve connected incorrectly, or moist inside Power plug of the pump connected incorrectly. Siphon blocked. Opening and closing manual de-aerator, after bleeding. Three-way valve has been damaged. Too much resistance in the flue system, or flue system is restricted or blocked. Flue system having a leak to the inlet system; re-circulation of flue gas, only in case of concentric flue connection. Heat exchanger blocked (insufficient circulation). High-limit thermostat defect (insufficient circulation). Maximum load is too high. Burner control defect. Ignition electrode defect (porcelain cracked), incorrect distance to burner control Moist or wet on the gas valve cables. Moist or wet on the PCB of the burner control. Moist or wet in the pump wiring. Moist or wet in the fan and/or the fan connection. Fan plug connected incorrectly. Plug connected incorrectly. Damaged connecting cable. Sensor defect. Flue gas circulation from behind the heat exchanger. Flow or DHW leakage Causes of faults table (cont’d) 46. Setting of the RPM switch of the pump is too low. 47. Sensors changed around (return sensor -S2 and hot water sensor S5). 48. Fuse F1.Automatic re set 49. Fuse F2 Automatic re set 50. Line voltage 230 VAC. 51. Parameter(s) in the installer program entered incorrectly. 52. Open control, room thermostat, or common thermostat connected to an incorrect connector strip port. 53. Pulse width program in the installer menu incorrectly programmed; or steps are too long. 54. Clock program of the clock thermostat should start earlier in the morning. 55. Flow and return on the boiler have been changed around. 56. Cable or plug to the three-way valve connected incorrectly. 57. Priority sensor (S3) not placed correctly, or defect. 60. Cable harness connectors incorrectly mounted on the PCB. 61. Gas safety valve defect. 62. After programming using the computer, confirms the new settings. 63. Incorrect parameters or values outside the range of the program have been entered. 64. The burner control is frequently checking the supply voltage. 65. Mechanical defect in the Reset key when “H” is blinking; when the H is not blinking, the burner control is defective. 66. Gas valve is not correctly adjusted at maximum input. Page 35 of 51 11.2 Troubleshooting table Numbers are corresponding with Table 7 Table 7: Troubleshooting table 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. Page 36 of 51 Check cable or replace the cable, check that the cable is connected to the correct connector strip. Replace room thermostat or cable: has the correct thermostat been used? Replace sensor or find cable fault. Try and loosen the pump spindle, or replace the pump drive. Add water and detect leak, also check the expansion vessel for leaks. Too much water added; drain, check the pressure in the expansion vessel for correct air cushion pressure(only check with 0 water pressure) replace the expansion vessel if defective Place the plug: with the cables on the fan side. Clean the fan blades. Replace the fan Open gas valve. Check line and gas meter, make a resistance calculation, as required. Change gas lines. Check fuse F4- check all 230 V connections: pump, PCB. See paragraph 6.4 Check the cabling using the wiring diagram, check the connection to the gas valve, be aware of moister Check cable for short-circuit, overheating, nearby or jammed between steel plate; check spark plug cap for cracks, replace cap. Replace the burner control. Moister trapped, check the cable sockets which should fit tightly around the plug pins, check the position of the cable socket, possibly adjust before the plug slides in. Check that the plug(s) are fitting tightly. Open the drain line (left-hand side of the boiler) by unscrewing the cap. Keep a jug on hand to catch the amount of water drained. Poke through the line using a pen, moving left upward and right upward. Take the burner unit from the boiler as required and pour some water in the heat exchanger to rinse out the siphon. Bleed the unit, not only the boiler itself but the entire system – in the event of such overall deaeration it is recommended to remove the 230 V off the boiler from the wall switch as the CH pump should not be activated during the process. Check the cut-off valve of the three-way valve. Take the pump motor out by unscrewing the four fastening screws. Check the valve on the inside of the housing. The driving motor can be removed by taking out the fastening screw at the front of the housing (right bottom) and subsequently pressing the “snap in” lug on the side of the housing, just above the motor, while pressing the motor down at the same time. Check the air inlet and flue lines for blockage. Check the inlet and flue system. See 26. REPLACE THE BOILER Replace the high-limit thermostat by unscrewing from the brass nut: no draining is needed (do not remove the brass nut). Go over the settings as outlined in paragraph 6.6.1. Troubleshooting table (cont’d) 34. Remove the burner control from the boiler by: a. Removing the ignition cable from the electrode and remove the cable from the console b. Removing the wiring from the spiral – 1X2-pole plug, 1X8-pole plug and the 230V-plug (right side of the front). Unscrew the facia (4x) remove the burner control and replace it. 35. Replace, when bending: take care as bending near the burner plate may give a risk of cracking. 36. Dry, using a hairdryer as necessary, and check if working. Replace as necessary. 37. See 36. 38. See 36. Remove the connection and blow dry, using a hairdryer. 39. See 36. Remove the connection and blow dry, using a hairdryer. 40. The plug/ wire connection must point to the outside of the fan and one side should fit into the groove on the PCB. 41. Check plugs and fit into one another correctly. 42. Check cables for possible damage or being trapped, and replace as required. 43. Check connections, or replace sensor. 44. Check the seal of the heat exchanger on the flue gas casing, and replace as required, fit a new rotary lip seal. 45. Check flow and DHW-Pipes. 46. Turn the pump switch to position 3. 47. Check if the sensors are interchanged. 48. Possibly replace the fuse (must be a reason for the defect); there is no spare fuse present, see diagram on page 26. 49. Possibly replace fuse (must be a reason for the defect); there is no spare fuse present, see diagram on page 26. 50. Check the mains lead, the wall box for voltage; main fuse 51. Check the programmed parameters 52. Check the type of room thermostat and the indication on the sticker of the connector strips on the boiler. 53. Change the pulse width program; see parameter manual. 54. Change the “wake-up” times of the clock thermostat. 55. Flow is on the left-hand side of the boiler; return on the right-hand side. 56. Check three-way valve including cables on the valve as well as on the connection strip. 57. Check the sensor on the calorifier. 60. It may occur that the 18-pin PCB plug moved up one pin too far; this may cause a fault in the communication between the wiring and the pins: check both the left and the right-hand side of the PCB plug to make sure the plugs are placed correctly. 61. A defect to the gas block usually has one of two causes: the electric coils are defective, or an internal defect on the gas valve. In either case it would be recommended to replace the entire gas valve. 63. Use the correct software (please check) for programming. Also, do not exceed the value limits. Try to reprogram. 64. Check the supply voltage using a universal meter; if the voltage is correct (should be between 190 and 250 Volt) replace the burner control. 65. In order to restore the Reset key, take the display from the plastic spacers and try the proper working again. If negative, replace the display. If the display works outside the boiler, check that the key has sufficient space under the plastic cover (not being blocked); make room. If the letter “H” is not blinking, replace the burner control. 66. Re-adjust the gas valve as per the instructions. Page 37 of 51 12 INSPECTION AND MAINTENANCE 12.1 General The boiler requires inspection at least once every 12 months. As a rule of thumb, inspection/maintenance is to be carried out when the boiler generates a number of similar error codes. 12.2 Inspection (Items J K L Major Service) An inspection should cover at least the following matters. a. Ask the user about any problems with the CH boiler and/or any comments. b. Check the system (water) pressure. c. Remove the casing of the boiler and check all lines and connections for traces of water and water leakage. d. Inspect the top of the casing and/or the top of the boiler for water leakage or traces of water from the air supply pipe or the de-aerator. e. Open the condense siphon and remove any dirt. f. If a laptop computer is available, connect this computer and check the service page for error messages, starts and failed / successful starting attempts. g. Fire the boiler on maximum output, and measure the output and the CO2 percentage.(CO on LPG) h. Fire the boiler on minimum output, and measure the output and the CO2 percentage.(CO on LPG) i. Note the noise of the CH pump and the fan. j. Dismantle the burner unit: remove the 6 x M6 nuts and the ignition cable, and move the burner unit forward. Remove the plug of the fan cable to the fan when the burner has been pulled half-way from the combustion chamber Check the inside of the heat exchanger. k. Dismantle the air gas mixing box on the suction side of the fan and check the fan blades. l. Check the distance from the electrode to the burner; there should be 4 to 5 mm gap. Figure 3; Distance from electrode to burner S-CB Page 38 of 51 12.3 Maintenance Depending on the outcome of the inspection, (preventative) maintenance should be considered. Reasons may be: ref. a. Comments and notes from the customer should be taken seriously and an effort should be made to find the cause of any deficiencies and problems. ref. b. The pressure of the system should be set between 1 and 6 bar: find possible leaks in the system and have these fixed. ref. c. Any leakage must be repaired. ref. d. Flue: Find the cause of any water leakage from the air supply (possible cause from the roof surface). Check the concentric flue and trace any leaks in the flue gas discharge and rectify. ref. e. Rinse if the condensed water from the siphon is badly contaminated. Several options are available. 1. If the burner has already been removed: using a filling hose, pour water into the heat exchanger (it will eventually reach the siphon). 2. Adjust the drain line up (if possible) allowing the water to flow to the drain of the boiler. ref. f. Act upon the findings from the service screen using the service program or a laptop computer (if used). and change any parts that may be the cause of these faults, ref. g. See under h. ref. h. Adjust the gas setting at the gas safety valve, as necessary, under minimum output. ref. i. If the CH pump has become noisy (certainly when the pump has been working for more than five years) it is recommended to replace the pump motor as a precaution. ref. j. Never clean the burner itself it is not required If dirt has built up on the inside of the heat exchanger and/or scale has formed on the inside of the stainless steel pipes, it should be removed using a hard brush and citric acid do not use a steel brush! Always vacuum any dirt away. ref. k. If deposits have built up on the fan blades, carefully clean the blades one by one until the blades are clean again. Work consistently in cleaning the blades, or else the fan may run irregularly and get out of balance. ref. l. Carefully bend the electrode until the gap is correct 4 to 5 mm or replace (see page 44) 13 INSTRUCTING THE USER Show the user how to operate the entire system. Above all, the user should be made familiar with all safety precautions. The user should be told that service and maintenance of the central heating boiler is required every 12 months or more. Regular service is essential for the safe operation of the boiler. Hand the user the documents supplied with the S-CB boiler. Page 39 of 51 Boilers with a single gas valve: SCB 60 up to 120 kW: - Converting from Nat. gas to LPG: 1. 2. 3. Turn the small "throttle"(see page 29) screw 2 clockwise about nr. 4 half turns. press the service switch (with a pen). The appliance should start: when there is no ignition, open the throttle 2 (anti - clockwise) with about another half turn. 4. Turn the red control knob on the control panel to the maximum -the speed of the fan will go to maximum: the colour of the flame should be blue: if yellow, give a little less gas (throttle clockwise, or when the flame disappears, anti- clockwise). 5. When the flame has the right colour: place the analyser in the measuring hole of the tube not before, otherwise you could get too much CO in the analyser . 6. Set the throttle screw 2to obtain a reading of about 100 ppm CO Note CO² % is not important it will be around 9,5 %. 7. Turn the red control knob on the control panel to the left to about 9 O’Clock. 8. Set the screw 2 to obtain about 50 ppm CO. 9. Turn the red control knob on the control panel to the minimum. 10. Set the screw 1 so the analyser shows a CO value lower than 10ppm. 11. Turn the red control knob on the control panel to the maximum, to check the max. CO value, reset (if required) the CO to less than 100 ppm with help of the Throttle screw. When fitting a new gas valve: 1. Open the throttle (see page 29) screw 2 (anti - clockwise) completely; then turn screw 8 half turns clock wise. 2. Press the service switch (with a pen). • The appliance should start, if there is no ignition, open the throttle (anti - clockwise) about a half turn. 3. Turn the red control knob on the control panel to the maximum -the speed of the fan will go to maximum: the colour of the flame should be blue: if yellow give a little less gas (throttle clockwise, or when the flame disappears, anti- clockwise). 4. When the flame has the right colour: place the analyser in the measuring hole of the tube - not before, otherwise you could get too much CO in the analyser. 5. Set the throttle screw 2 to obtain a reading of: about 100 ppm CO (CO² % is not important it will be around 9,5 %). 6. Turn the red control knob on the control panel to the left about to 9 O’ Clock . 7. Set the screw 2 to obtain about 50 ppm CO. 8. Turn the red control knob on the control panel to the minimum. 9. Set the screw 1 to obtain a CO value lower than 10 ppm. 10. Turn the red control knob on the control panel to the maximum, to check the max. CO value , reset (if required) the CO to less than 100 ppm with help of the Throttle screw. Page 40 of 51 Boilers with a double gas valve: SCB 150 and 180 kW - Converting from Nat. gas to LPG: 1. Disconnect electrically the left hand gas valve, by separating the white plug and contra plug of the left hand gas valve. 2. Turn the small "throttle" (see page 29) screw 2 (on the right hand gas valve) clockwise about 4 half turns. 3. Press the service switch (with a ball pen). 4. The appliance should start, if there is no ignition, open the throttle 2 (anti - clockwise) about a half turn. 5. Turn the red control knob on the control panel to the maximum -the speed of the fan will go to maximum: the colour of the flame should be blue, if yellow, give a little less gas (throttle clockwise, or when the flame disappears, anti- clockwise). 6. When the flame has the right colour: place the analyser in the measuring hole of the tube - not before, otherwise you could get too much CO in the analyser. 7. Set the screw 2 to obtain a reading of about 100 ppm CO. CO² % is not important it will be around 9,5 %. 8. Turn the red control knob on the control panel to the left to about 9 O’clock . 9. Set the screw 2 to obtain about 50 ppm CO. 10. Turn the red wheel to the minimum. 11. Set the screw 1 to give a CO value less than 10 ppm. 12. Turn the red control knob on the control panel to maximum, reset (if required ) the CO at less than 100 ppm with help of the Throttle screw. Setting after replacing the right hand gas valve: 1. 2. Open the throttle screw (anti - clockwise) completely; then turn the screw 8 half turns clock wise. Press the service switch (with a pen) . Commission the valves as per the commissioning instructions above starting at no 3 Conclusion Set the Boiler on CO emission Setting LPG CO² % is not important, because it is influenced by the quality of the LPG, which differs quite a lot; mostly the measured CO² % is about between 9,5 and 10%) High Fire CO: less than 100 ppm Low Fire CO less than 10 ppm. Page 41 of 51 14 EXPLODED VIEW DIAGRAMS Page 42 of 51 14.1 Burner /fan/gas pipe/heat exchanger/casing S-CB 60 / S-CB 80 / S-CB 100 / S-CB 120 Figure 4; S-CB60 / S-CB80 / S-CB100 / S-CB120 Page 43 of 51 14.1 1 Burner /fan/gas pipe/heat exchanger/casing Spare S-CB 60 - S-CB 120 Spare parts S-CB60/120 Duo-Z GB Article-name 1 4 4 4 5 5 5 5a 6 7 7 8 9 10 10 10 11 12 13 14 15 15 16 16 16 17 18 19 20 20 20 21 22 23 23 24 25 25 26 27 27a 28 29 30 Front panel Seal ring 80 mm Seal ring 100 mm Seal ring 130 mm Air inlet connection excentr 80 Air inlet connection excentr 100 Air inlet connection excentr 130 Gasket air inlet connection 162/135 Automatic air vent Seal ring 80 mm Seal ring 100 mm NTC sensor Insulation burner chamber Heat exchanger 6+3 Heat exchanger 8+4 Heat exchanger 10+6 NTC sensor Insulation burner door Burner door Nuts M6 Electrode Gasket electrode Burner 6+3 Burner 8+4 Burner 10+6 Gasket burner inlet pipe ø5x14 mm Torx screw M5x12 DIN7985 screw Gasket inlet pipe & fan A60 Gasket inlet pipe & fan A80 / A100 Gasket inlet pipe & fan A120 Fan O-ring 70x3 mm Air gas mixing plate A60 / A80 Air gas mixing plate A100 / A120 Pipe coupling ¾"x ¾" Gasvalve A60 / A80 Gasvalve A100 / A120 O-ring 33,4x2 NBR Siphon 90 mm grey Siphon cleaning tube grey Flexible tube 600 mm grey On/off switch black Display-unit DU-910 incl. cable Page 44 of 51 Order code E07.004.023 E07.004.024 E07.004.025 E01.008.002 E01.008.003 E01.008.004 E04.015.008 E07.004.023 E07.004.024 E04.016.287 E07.010.098 E04.016.287 E07.010.093 E03.010.013 E06.010.012 E04.009.014 E07.001.024 E04.012.025 E04.012.026 E04.012.027 E07.001.029 E04.016.132 E07.002.007 E04.016.014 E04.016.281 E07.002.018 E04.016.278 . 31 32 33 34 35 35 35a 36 36 37 37 38a 40 40 40 41 41 41 Article name Burner control F-910 Tube gland siphon Tube gland ø38 mm PG-9 swivel + cable gland 8mm Adapter concentr. 80/125 Adapter concentr. 80-100/150 Gasket flue gas outlet 194/150 Seal ring 80 mm Seal ring 100 mm Seal ring 125 mm Seal ring 150 mm Gasket flue gas outlet 194/150 Adapter flue gas outlet 80/80 Adapter flue gas outlet 80/100 Adapter flue gas outlet 100/130 Seal ring 80 mm Seal ring 100 mm Seal ring 130 mm Order code E04.016.277 E04.010.033 E05.000.064 E01.008.010 E01.008.012 E07.004.023 E07.004.024 E07.004.026 E07.004.027 E01.008.014 E01.008.008 E01.008.009 E07.004.023 E07.004.024 E07.004.027 14.2 Burner/fan/gas pipe/heat exchanger/casing S-CB 150 – S-CB 180 Figure 5; S-CB150 / S-CB 180 Page 45 of 51 14.2.1 Burner/fan/gas pipe/heat exchanger/casing Spare S-CB 150 – S-CB 180 Spare parts S-CB150-180 Duo-Z GB . Article name 50 51 52 52a 53 54 55 56 56 57 58 59 60 61 62 62 63 63 64 65 66 67 68 68 69 70 71 72 72 73 74 74a 75 76 77 78 79 80 80a 81 Front panel Seal ring 130 Air inlet connection 130 Gasket air inlet connection 162/135 Automatic air vent NTC sensor Insulation burner chamber Heat exchanger 12+6 Heat exchanger 15+8 Nut M8 DIN934 RVS NTC sensor Insulation burner door Burner door Nut M6 Electrode Gasket Electrode Burner 12+6 Burner 15+8 Gasket burner & air/gas inlet pipe ø5x14 mm Torx screw Air-gas inlet pipe 12+6 15+8 M8x8 DIN912 screw Gasket air-gas inlet pipe & fan A150 Gasket air-gas inlet pipe & fan A180 Fan O-ring 111x3 NBR Air-gas mixing box Gasvalve right Gasvalve left O-ring 33,4x2 NBR Siphon 90 mm grey Siphon cleaning tube grey Flexible tube 600 mm grey Display-unit DU-910 incl. cable Burner control F-910 Tube gland siphon Tube gland ø38 mm Adapter flue gas outlet 100/130 Gasket flue gas outlet 194/150 Seal ring 130 mm Page 46 of 51 Order code E07.004.025 E01.008.004 E04.015.008 E04.016.287 E07.010.098 E04.016.287 E07.010.093 E03.010.013 E06.010.012 E04.009.014 E07.001.024 E04.012.028 E04.012.029 E07.001.029 E03.010.016 E04.016.290 E07.002.029 E04.016.014 E04.016.281 E07.002.018 E04.016.278 E04.016.277 E04.010.033 E01.008.009 E07.004.025 14.3.1 Pipes + pump Spare S-CB 60 – S-CB 120 . 90 91 91a 91b 92 Spare parts S-CB60/120 Duo-Z GB page 3 Article name Check valve ¼"x¼" Pump complete Pump motor Pumphouse 130 mm Drain 3/8" Page 48 of 51 Order code E04.015.005 E04.016.298 E04.016.310 E04.015.064 E04.008.002 14.4 Pipes + pump S-CB 150 / 180 Figure 6; S-CB 150 / S-CB 180 Page 49 of 51 14.4.1 Pipes + pump Spare S-CB 150 – S-CB 180 . 100 100a 100b 101 102 103 Spare parts S-Cb150/ 180 Duo-Z GB Article name Order Code Pump complete Pump motor Pumphouse Drain 3/8" Pressure gauge 6 bar Flange with thread 50-2" DIN2566 E04.016.288 E04.016.311 E04.015.065 E04.008.002 E04.015.062 E04.010.120 Accessories 1 2 3 4 5 7 8 9 Item Outside air temperature sensor : 12kOhm@25°C External Flow temperature sensor after low velocity header : 10kOhm@25°C, to be wired to the boiler 3 & 4 Calorifier temperature sensor: 10kOhm@25°C; to be connected to the boiler 7 & 8 Conversion set from concentric to parallel flue and air terminal for SCB 60 & 80 Conversion set from concentric to parallel flue-air terminal for SCB80 &,100 &120* Conversion set from concentric to parallel flue- air terminal for SCB120 &150 &180 Diverter valve Mounting frame with flow- , return- and gas tube – see CASCADE Manual Page 50 of 51 Part no. E04.016.306 E04.016.304 E04.016.303 E61.001.158 E61.001.159 E61.001.161 E04.000.041 Declaration of Conformity Under the EC DIRECTIVE on machinery (89/392/EEC, 91/386/EEC, 93/68/EEC) and the EC DIRECTIVE ON ELECTROMAGNETIC COMPATIBILITY (89/336/EEC, 91/263/EEC, 92/31/EEC, 93/68/EEC) have been constructed in conformity with the applicable provisions of the EC DIRECTIVE on machinery and the EC DIRECTIVE on EMC. Strebel Ltd Page 51 of 51