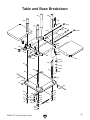

Download Grizzly G1021x Planer User Manual

Transcript