Download Detecto EU544 Owner`s manual

Transcript

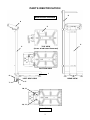

European Digital Scale Waist-High Models EU522/EU522HR and Floor Model EU544 Owner’s Manual 0049-M020-O1 Rev C 12/05 CARDINAL SCALE MFG. CO. PO BOX 151 v WEBB CITY, MO 64870 PH (417) 673-4631 v FAX (417) 673-5001 www.detectoscale.com 1 Printed in USA 2 EUROPEAN DECLARATION OF CONFORMITY Manufacturer: Detecto Scale Company Cardinal Scale Manufacturing Company PO Box 151 203 East Daugherty Webb City, Missouri 64870 USA Telephone No. + 417 673 4631 Fax No. + 417 673 5001 Product: Digital Waist-High Scale Model Numbers EU522 / EU522HR / EU544 Serial Number EXXXYY-ZZZ where XXX = day of year YY = last two digits of year ZZZ = sequential number The undersigned hereby declares, on behalf of Detecto Scale Company and Cardinal Scale Manufacturing Company of Webb City, Missouri, that the above-referenced product, to which this declaration relates, is in conformity with the provisions of: European Standard EN45501 and equivalent International Recommendation OIML R76, edition 1992 Test Certificate Number: GB-1136 Council Directive 73/23/EEC (19 February, 1973) Low Voltage Directive as amended by Council Directive 93/68/EEC (22 July, 1993) Council Directive 90/384/EEC (20 June, 1990) on the Harmonization Of the Laws of Member States relating to non-automatic weighing Systems as amended by: Council Directive 93/68/EEC (22 July, 1993) Certificate of EU Type Approval Number: UK 2655 European Standard EN55024 for radiated emissions Class A European Standard EN55024 for conducted disturbances Class A Test Report Number: 020424-537 The Technical Construction File required by this Directive is maintained at the corporate headquarters of Cardinal Scale Manufacturing Company, 203 East Daugherty, Webb City, Missouri. _____________________ Link Yeager Quality Assurance Administrator 3 Attachment to the Conformity document DECLARATION OF CONFORMITY with WELMEC 2 paragraph 12 Page 1 of 1 COMPATIBILITY OF MODULES Ref.: WELMEC 2 (2000) Non-Automatic Weighing Instrument, single-interval o Certificate of EU Type-Approval N : TAC: INDICATOR A/D (Module 1) Accuracy class according to EN 45501 and OIML R76: Maximum number of verification scale intervals (nmax): Fraction of maximum permissible error (mpe) Load cell excitation voltage: Minimum input-voltage per verification scale interval: Minimum load cell impedance: Coefficient of temperature of the span error: Coefficient of resistance for the wires in the J-box cable: Specific J-box cable-Length to the junction box for load cells Load cell interface: Additive tare, if available: Initial zero setting range Temperature range Type: 758CSV Classind ( I, II, III or IIII ) nind p1 Uexc [ Vdc ] [ µV ] ∆umin [ Ω] RLmin Es [ % / 25°C ] Sx [ % / Ω] (L/A)max [ m / mm² ] 4-wire (no sense) T+ [ % of Max ] IZSR [ % of Max ] [ °C ] Tmin / Tmax NWML GB-1136 Test report (TR), Test Certificate (TC) or OIML Certificate of Conformity: LOAD RECEPTOR (Module 2) Type: Construction: Fraction of mpe: Number of load cells: Reduction ratio of the load transmitting device: Dead load of load receptor Non uniform distribution of the load Correction factor: LOAD CELL III 5000 0.5 5 1.2 87 0.006 0.0152 175 -2 -10 0 / / 2 40 EU522 / EU522HR Platform p2 N R=FM / FL DL (NUD = 0 is acceptable) NUD Q = 1 + (DL + T+ + IZSR + + NUD) / 100 ANALOG (Module 3) Type: TSSP-200KGW COMPLETE WEIGHING INSTRUMENT Manufacturer: Detecto Accuracy class according to EN 45501 and OIML R76: Fractions: pi = p1² + p2² + p3²: Maximum capacity: Number of verification scale intervals: Verification scale interval Utilisation ratio of the load cell Input voltage (from the load cels): Cross-section of each wire in the J-box cable: J-box cable-Length Temperature range to be marked on the instrument Peripheral Equipment subject to legal control 0.5 1 1 8.7 4 1.147 [ % of Max ] [ % of Max ] ClassLC ( A, B, C or D ) nLC p3 C [ mV / V ] [ Ω] RLC vmin% [ % of Emax ] Emax [ kg ] [%] (Emin / Emax) * 100 [ °C ] Tmin / Tmax R60/2000-DK1-04.05 Accuracy class according to OIML R60: Maximum number of load cell intervals: Fraction of mpe: Rated output (sensitivity): Input resistance of single load cell: Minimum load cell verification interval: (vmin% = 100 / Y) Rated capacity: Minimum dead load, relative Temperature range Test report (TR) or Test Certificate (TC/OIML) as appropriate ClassWI pi n n n Emin vmin * √N / R UK2655 -10 C 3000 0.7 2 350 0.0125 230 0 / 40 Single-interval Type: EU522 / EU522HR ClassWI ( I, II, III or IIII ) pi Max [ kg ] n e [ kg ] α = (Max / Emax) * (R / N) ∆u = C * Uexc * α * 1000 / n [ µV/e ] A [ mm² ] L [m] Not required Tmin / Tmax [ °C ] Acceptance criteria for compatibility <= Classind & ClassLC (WELMEC 2: 1) <= 1 (R76: 3.5.4.1) (R76: 3.2) <= nmax for the class (WELMEC 2: 4) <= nind (R76: 4.12.2) <= nLC <= DL * R / N (WELMEC 2: 6d) <= e (R76: 4.12.3) or (if vmin is not given) (Emax / nLC) * (√N / R) ∆umin RLmin <= <= <= e ∆u RLC / N (WELMEC 2: 7) (WELMEC 2: 8) (WELMEC 2: 9) L/A Trange Q * Max * R / N <= <= <= (L / A)maxWI Tmax - Tmin Emax (WELMEC 2: 10) (R76: 3.9.2.2) (R76: 4.12.1) III 1.0 200 2000 0.1 0.87 4.35 0.5 3 Passed, provided no result below is < 0 ClassWI : PASSED 1 - pi = 0.0 nmax for the class - n = 8000 nind - n = 3000 1000 nLC - n = (DL * R / N) - Emin = 17.4 e - (vmin * √N / R) = 0.071 Alternative solutions: ↑ ↓ e - ((Emax / nLC) * (√N/ R)) = ∆u − ∆umin = 3.15 (RLC / N) - RLmin = 263 (L / A)maxWI - (L / A) = (Tmax - Tmin) - Trange = Emax - (Q * Max * R / N) = Signature and date: Conclusion . . . . . 607 20 0.6 PASSED This is an authentic document made from the program: "Compatibility of NAWI-modules version 3.0". Program made by DELTA Per Bengtsen, EU Notified Body No. 0199 Single-interval EU522_Comp_of_Modules_200kg1.xls Attachment to the Conformity document DECLARATION OF CONFORMITY with WELMEC 2 paragraph 12 Page 1 of 1 COMPATIBILITY OF MODULES Ref.: WELMEC 2 (2000) Non-Automatic Weighing Instrument, single-interval o Certificate of EU Type-Approval N : TAC: INDICATOR A/D (Module 1) Accuracy class according to EN 45501 and OIML R76: Maximum number of verification scale intervals (nmax): Fraction of maximum permissible error (mpe) Load cell excitation voltage: Minimum input-voltage per verification scale interval: Minimum load cell impedance: Coefficient of temperature of the span error: Coefficient of resistance for the wires in the J-box cable: Specific J-box cable-Length to the junction box for load cells Load cell interface: Additive tare, if available: Initial zero setting range Temperature range Type: 758CSV Classind ( I, II, III or IIII ) nind p1 Uexc [ Vdc ] [ µV ] ∆umin [ Ω] RLmin Es [ % / 25°C ] Sx [ % / Ω] (L/A)max [ m / mm² ] 4-wire (no sense) T+ [ % of Max ] IZSR [ % of Max ] [ °C ] Tmin / Tmax NWML GB-1136 Test report (TR), Test Certificate (TC) or OIML Certificate of Conformity: LOAD RECEPTOR (Module 2) Type: Construction: Fraction of mpe: Number of load cells: Reduction ratio of the load transmitting device: Dead load of load receptor Non uniform distribution of the load Correction factor: LOAD CELL III 5000 0.5 5 1.2 87 0.006 0.0152 175 -2 -10 0 / / 2 40 EU544 Platform p2 N R=FM / FL DL (NUD = 0 is acceptable) NUD Q = 1 + (DL + T+ + IZSR + + NUD) / 100 ANALOG (Module 3) Type: TSSP-200KGW COMPLETE WEIGHING INSTRUMENT Manufacturer: Detecto Accuracy class according to EN 45501 and OIML R76: Fractions: pi = p1² + p2² + p3²: Maximum capacity: Number of verification scale intervals: Verification scale interval Utilisation ratio of the load cell Input voltage (from the load cels): Cross-section of each wire in the J-box cable: J-box cable-Length Temperature range to be marked on the instrument Peripheral Equipment subject to legal control 0.5 1 1 8.7 4 1.147 [ % of Max ] [ % of Max ] ClassLC ( A, B, C or D ) nLC p3 C [ mV / V ] [ Ω] RLC vmin% [ % of Emax ] Emax [ kg ] [%] (Emin / Emax) * 100 [ °C ] Tmin / Tmax R60/2000-DK1-04.05 Accuracy class according to OIML R60: Maximum number of load cell intervals: Fraction of mpe: Rated output (sensitivity): Input resistance of single load cell: Minimum load cell verification interval: (vmin% = 100 / Y) Rated capacity: Minimum dead load, relative Temperature range Test report (TR) or Test Certificate (TC/OIML) as appropriate ClassWI pi n n n Emin vmin * √N / R UK2655 -10 C 3000 0.7 2 350 0.0125 230 0 / 40 Single-interval Type: EU544 ClassWI ( I, II, III or IIII ) pi Max [ kg ] n e [ kg ] α = (Max / Emax) * (R / N) ∆u = C * Uexc * α * 1000 / n [ µV/e ] A [ mm² ] L [m] Not required Tmin / Tmax [ °C ] Acceptance criteria for compatibility <= Classind & ClassLC (WELMEC 2: 1) <= 1 (R76: 3.5.4.1) (R76: 3.2) <= nmax for the class (WELMEC 2: 4) <= nind (R76: 4.12.2) <= nLC <= DL * R / N (WELMEC 2: 6d) <= e (R76: 4.12.3) or (if vmin is not given) (Emax / nLC) * (√N / R) ∆umin RLmin <= <= <= e ∆u RLC / N (WELMEC 2: 7) (WELMEC 2: 8) (WELMEC 2: 9) L/A Trange Q * Max * R / N <= <= <= (L / A)maxWI Tmax - Tmin Emax (WELMEC 2: 10) (R76: 3.9.2.2) (R76: 4.12.1) III 1.0 200 2000 0.1 0.87 4.35 0.5 3 Passed, provided no result below is < 0 ClassWI : PASSED 1 - pi = 0.0 nmax for the class - n = 8000 nind - n = 3000 1000 nLC - n = (DL * R / N) - Emin = 17.4 e - (vmin * √N / R) = 0.071 Alternative solutions: ↑ ↓ e - ((Emax / nLC) * (√N/ R)) = ∆u − ∆umin = 3.15 (RLC / N) - RLmin = 263 (L / A)maxWI - (L / A) = (Tmax - Tmin) - Trange = Emax - (Q * Max * R / N) = Signature and date: Conclusion . . . . . 607 20 0.6 PASSED This is an authentic document made from the program: "Compatibility of NAWI-modules version 3.0". Program made by DELTA Per Bengtsen, EU Notified Body No. 0199 Single-interval EU544_Comp_of_Modules_200kg.xls This page intentionally left blank. INTRODUCTION Thank you for your purchase of our Detecto European Digital Scale, Waist-High Models EU522 / EU522HR or Floor Model EU544. They were built with Detecto quality and reliability at our factory in Webb City, Missouri, USA. This manual will guide you through installation, and operation of your scale. Please read it thoroughly before attempting to operate this scale and keep it handy for future reference. All rights reserved. Reproduction or use, without expressed written permission, of editorial or pictorial content, in any manner, is prohibited. No patent liability is assumed with respect to the use of the information contained herein. While every precaution has been taken in the preparation of this manual, the Seller assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from use of the information contained herein. All instructions and diagrams have been checked for accuracy and ease of application; however, success and safety in working with tools depend to a great extent upon the individual accuracy, skill and caution. For this reason the Seller is not able to guarantee the result of any procedure contained herein. Nor can they assume responsibility for any damage to property or injury to persons occasioned from the procedures. Persons engaging the procedures do so entirely at their own risk. SPECIFICATIONS Capacity: ….…..……..…… 200 kg x .1 kg Platform Size: …….…..….. 280 mm x 335 mm Dimensions: ….…..………. EU522 = 280 mm W x 490 mm D x 888 mm H EU544 = 280 mm W x 515 mm D x 210 mm H Power Requirements: …… 230 VAC 50 Hz powering a 12 VDC 300 mA wall plug-in power supply OR Six (6) "C" size NICAD batteries, (not included) Operating Temp: ………… -10 to +40 oC Shipping Weight: …..…..… 7.7 kg PREPARATION Unpacking Instructions SCALE v Remove scale from carton by lifting up with equal force from column and platform base of scale. v When removing scale from its packing, inspect it for signs of damage, such as exterior dents and scratches. Keep carton and packing material for return shipment if it should become necessary. v Remove all plastic wrapping, foam fillers and cardboard material from scale. INDICATOR v Remove the indicator from shipping carton. v Inspect it for any evidence of damage (such as exterior dents or scratches) that may have taken place during shipment. v Keep carton and packing material for return shipment if it should become necessary. BATTERY INSTALLATION v If you wish to operate scale from batteries, you must first obtain and install batteries in the indicator before proceeding. v Refer to the 758C Series Operation Manual, 8555-M433-O1, for battery installation instructions. PLUG-IN POWER SUPPLY v The power supply for the scale includes a "round pin attachment plug" adapter. If another type of plug is required, it’s the responsibility of the customer to obtain correct power adapter. 1 ASSEMBLY Indicator Mounting To install the indicator on the column bracket, push the latch release (on the 758CSV) down flush with the back of the indicator and hold. Next, place the screw heads on the back of the indicator in the large end of the slotted holes in the bracket. Pull down to secure the indicator, and then release the latch release to lock the indicator to the bracket. To remove the indicator from the bracket, reverse this procedure. Load Cell Connection The load cell cable from the scale connects to the indicator via a 9-pin "D" connector on the rear panel of the indicator. Plug the cable from the scale to the load cell connector on the back of the indicator. Use the connector retaining screws to hold the load cell cable connector securely to the indicator. Power Supply To apply power to the indicator using the power supply, plug the power supply’s cable connector into the power jack on the back of the indicator and then connect the power supply module into the proper AC electrical outlet. The scale is now ready for operation. Bracket Mount Screws Latch Power Supply Latch Release 2 OPERATING INSTRUCTIONS Indicator Height Rod Spoon Indicator Platform Height Rod Column Platform Model EU544 Model EU522HR v Install six (6) "C" size batteries (if ordered with scale) in indicator or plug in power supply module. Plug small connector end of power supply cord into power jack located in bottom right corner at the back of indicator. v Set scale on any hard, level, flat surface or low-cut carpet. v With no weight on scale platform, press ON/OFF key to turn indicator on. After a few seconds display should indicate a zero weight with ZERO annunciator turned on. If display does not indicate zero, press ZERO key to zero weight display. v Step on scale and remain motionless for several seconds until scale displays your weight. v When weight is stable, (and stable (><) annunciator is on) press LOCK/RELEASE key to lock onto weight. Note that weight value will be flashing. v Press LOCK/RELEASE key to unlock display and prepare for next weighing operation or press ON / OFF key to turn display off. 758CSV Keypad 200 x 0.1kg 3 HEIGHT ROD INSTALLATION v Remove Height Rod from shipping container. Inspect for signs of damage. Contact our Customer Service Department if necessary. v Remove cardboard insert from height rod. v Place both height rod mount brackets over four (4) pre-installed screws in column and pull down, securing brackets. v Tighten screws as needed. Do not over tighten. Column Height Rod Bracket Pre-Installed Screws Height Rod HEIGHT ROD OPERATION v v Before patient steps onto scale platform, spoon should be rotated to horizontal position, and raised well above patient’s height. Patient may now step onto scale platform. Spoon should be held horizontal and above patient’s head. A B C E D v v Carefully lower spoon, while keeping it horizontal, until it rests gently on top of patient’s head. For shorter patients, push latch to right while simultaneously pushing down on spoon, until the spoon rests horizontally on top of patient’s head. Height Rod in “rest” position Read height of patient as follows: A = Latch B = Spoon C = Inner Height Rod D = Outer Height Rod E = Measurement “Read” Line If back of spoon points to outer height rod, then it points to correct height. If back of spoon points to inner height rod, then correct height is read at top of outer height rod (see "Read" arrow on outer height rod). v While holding spoon horizontally, raise spoon above patient’s head. Patient may now step off scale platform. Hold spoon horizontal until patient is clear of height rod. v Rotate spoon back to vertical position and adjust height rod back to rest position (i.e. spoon should be locked in place within inner height rod and inner rod should be at its lowest position). 4 ERROR AND STATUS DISPLAYS Display (1+ A7A $a% ".3 a." "%a Meaning Motion is present when attempting to perform one of the following operations: Power Up or Zero Weight Display. Attempting to display a negative number less than -9,999 or a positive number greater than 99,999. Scale weight exceeds scale capacity. Indicates improper stored calibration data, calibration is necessary. The analog to digital circuit has failed. Consult scale serviceman. The microprocessor has stopped receiving the signal from the analog circuit. To correct, remove load from the scale platform and power the indicator off and on. <:0 Indicates an attempt to zero a weight outside the scale zero range. (See Four Percent Zero Tracking Range Limit). 07a3< This indicates the batteries are low. Replace or remove and recharge the Ni-Cad batteries. Refer to the 758CSV Series Operation Manual, 8555-M433-O1, for additional information. CARE AND CLEANING v DO NOT subject scale platform to sudden shocks. v AVOID areas where scale might be exposed to moisture. v DO NOT submerge in water or spray water directly on scale platform or display indicator. v DO NOT use an abrasive cleaner, acetone or other volatile solvents for cleaning. v DO clean scale using a soft cloth dampened with a mild detergent. Display indicator may be removed and washed with a soft damp cloth and a mild detergent. 5 SECURITY SEAL INSTALLATION The indicator on the EU522 / EU522HR and EU544 has been designed for attachment of three separate lead-wire security seals. Two seals prohibit access to the calibration switch while a third seal prevents the scale cable from being disconnected from the indicator (see Figure A). Local metrology laws may or may not require these security seals. If your metrology laws require these security seals, follow the directions provided below to install each of the seals. Calibration Seal 1. Make certain the fillister screws (in the end cap and on the rear panel) are securely tighten before proceeding. 2. Thread the sealing wire through the hole in both fillister head screws as shown. 3. Pull the wire tight and install the lead seal. Refer to Figures B and C. 4. The screws can not be removed without damaging the seal. Load Cell Cable Connection 1. Make certain the load cell cable is securely tightened to the 9-pin “D” connector on the rear of the indicator before proceeding. 2. Thread the sealing wire through the hole in the connector and the fillister head screw securing the ground lug on the rear of the indicator as shown in Figure D. 3. Pull the wire tight and install the lead seal. Figure B Figure A Figure C Figure D 6 PARTS IDENTIFICATION Model EU522 / EU522HR 9 8 3 2 2 TOP VIEW (Cover & Indicator Removed) BOTTOM VIEW 1 6 LEFT SIDE VIEW REAR VIEW 5 7 4 10, 11 10, 11 Model EU544 7 PARTS IDENTIFICATION, Cont. Item Part Number Description 1 1 0049-D027-0A SUB ASSEMBLY: SCALE BASE 2 1 0049-D014-0A SUB ASSEMBLY: EU522HR COLUMN 3 1 593R986 4 1 6013-0045 NUT, HEX 1/4-20 5 2 6021-1426 SCREW, HEX HEAD 1/4-20 X 1.25 6 3 6024-0039 WASHER, LOCK HELICAL 1/4” REG. 7 1 6540-1138 GLIDE 1” BLACK 1/4-20 X 1.5 STUD 8 1 758CSV 9 1 0049-D020-1A 10 2 6013-0026 NUT 1/4-20 HEX ELASTIC STOP/JAM NUT SS 11 2 6021-1531 SCW BUTTON-HD. CAP-SCREW 1/4-20 X 1.25 SERIAL TAG INDICATOR HEIGHT ROD ASSEMBLY 8 9 10