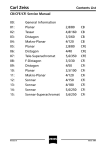

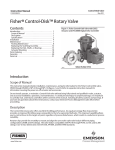

Download Miller System 9A Specifications

Transcript