Download Brother FAX1570MC Service manual

Transcript

FACSIMILE EQUIPMENT

SERVICE MANUAL

MODEL: FAX1170/1270/1570MC

FAX1010/1020/1030

MFC1770/1870MC/1970MC

© Copyright Brother 1997

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

PREFACE

This publication is a Service Manual covering the specifications, construction, theory of operation, and maintenance of the Brother facsimile equipment. It includes information required for

field troubleshooting and repair—disassembly, reassembly, and adjustment—so that service

personnel will be able to understand equipment function, to rapidly repair the equipment and

order any necessary spare parts.

To perform appropriate maintenance so that the facsimile equipment is always in best condition

for the customer, the service personnel must adequately understand and apply this manual.

This manual is made up of six chapters and appendices.

CHAPTER I.

GENERAL DESCRIPTION

CHAPTER II.

INSTALLATION

CHAPTER III.

THEORY OF OPERATION

CHAPTER IV.

DISASSEMBLY/REASSEMBLY AND LUBRICATION

CHAPTER V.

MAINTENANCE MODE

CHAPTER VI.

ERROR INDICATION AND TROUBLESHOOTING

APPENDICES

Circuit Diagrams

This manual describes the model and its versions to be destined for major countries. The specifications

and functions are subject to change depending upon each destination.

CHAPTER I.

GENERAL DESCRIPTION

CONTENTS

1.

EQUIPMENT OUTLINE .................................................................................

I-1

1.1 External Appearance and Weight ...........................................................

I-1

1.2 Components ............................................................................................ I-1

2.

SPECIFICATIONS .......................................................................................... I-2

1. EQUIPMENT OUTLINE

1.1

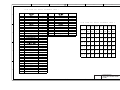

External Appearance and Weight

The figure below shows the equipment appearance and approximate dimensions.

(Unit: mm)

213 (H)

8.5" A4

A4 8.5"

Functio n

Tel/Inde

x Resolut

ion

Super

O. Scan

Mode

Help

IntelliFAX -1270

Hook

ABC

1

Hold

ause

02

09

#

Shift

21

10

22

Set

Sort

16

07

18

08

19

11

23

FACSIMILE

04

15

06

17

9

03

14

05

WXYZ

8

0

01

13

MNO

6

TUV

Speed Dial

*

3

JKL

5

PRS

7

PLAIN PAPER

DEF

2

GHI

4

Redial/P

Enlarge

/

Reduce

20

12

24

Copy

Stop

Start

Clear

385 (D)

* 317 mm for FAX1010 which has

no handset mount

385.5 (W)*

Weight: Machine proper

In package

1.2

FAX1010:

Approx. 5.0 kg (excluding a ribbon cartridge)

Other models: Approx. 5.2 kg (excluding a ribbon cartridge)

FAX1010:

Approx. 8.7 kg

Other models: Approx. 8.9 kg

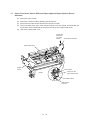

Components

The equipment consists of the following major components:

Recording paper cover ASSY

Control panel

ASSY

Handset

(Not provided on

the FAX1010)

Inner cover

Main cover

Handset mount

(Not provided on

the FAX1010)

Recording head

ASSY

Side cover

(Provided only on

the FAX1010)

Power supply PCB

Main frame

NCU PCB

Main PCB

Modular PCB

CIS unit

Bottom plate

Document

ejection tray

I–1

2. SPECIFICATIONS

Model

Color

Modem Speed

CCITT Group

Coding Method

Transmission Speed

Input/Output Width

ADF Capacity (pages)

Recording Paper Loadable

Paper Size

Ribbon Life (Letter-size print)

Handset

LCD Size

On-screen Programming

Gray Scale

Smoothing

One-touch Dial

Speed Dial

Telephone Index

FAX1170

Gray (1395)

9600 bps

G3

MH

15 sec.

8.5"/8.5"

20

200 sheets

Letter/Legal/A4

450 pages

Yes

16 x 1

Yes

64 by Dithered

Yes

12 x 2

26

Yes

FAX1270

White (1397)

9600 bps

G3

MH

15 sec.

8.5"/8.5"

20

200 sheets

Letter/Legal/A4

450 pages

Yes

16 x 1

Yes

64 by Dithered

Yes

12 x 2

36

Yes

FAX1570MC

White (1397)

14400 bps

G3

MH

9 sec.

8.5"/8.5"

20

200 sheets

Letter/Legal/A4

450 pages

Yes

16 x 1

Yes

64 by E/D

Yes

12 x 2

100

Yes

Multi-resolution Transmission

FAX/TEL Switch

Distinctive Ringing

Next Fax-reservation

Help

TAD Interface

Coverpage

Polling Type

Receive Password (password plus)

Delayed Transmission

Call Reservation

Call-back Message

Speaker Phone

Activity Report

Transmission Verification Report

Page Memory

Out-of-paper Reception

Quick Scan

Super Quick Scan

Broadcasting

ECM

Multi-transmission

Multi-copying w/Sorting

Enlargement/Reduction Ratio

TAD Type

OGM

ICM Recording Time

FAX Forwarding/Paging

FAX Retrieval

PCI (Missing link)

Message Center

Caller ID

Fax-/Voice-on-demand

Mail Box

Remote Control

Toll Saver

Memo/2-Way Recording

Auto Reduction

Confidential Mailbox

Optional Memory

Yes

Yes

Yes

Yes

Yes

Yes

Yes, Super

Sim/Del/Seq

Yes

3, timers

Yes

Yes

Monitor

Yes

Yes

512 KB (20 pages)

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes (50-150%)

No

No

No

No

No

Ready

No

Yes

No

No

Yes

No

No

Yes

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes, Super

Sim/Del/Seq

Yes

3, timers

Yes

Yes

Monitor

Yes

Yes

512 KB (20 pages)

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes (50-150%)

No

No

No

Yes

Yes

Ready

No

Yes

No

No

Yes

No

No

Yes

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes, Super

Sim/Del/Seq

Yes

3, timers

Yes

Yes

Yes, Full-duplex

Yes

Yes

1 MB (50 pages)

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes (50-150%)

DSP

Yes

Yes, 30 min.

Yes

Yes

Ready

Yes

Yes

Voice-on-demand

Yes

Yes

Yes

Yes

Yes

No

No

I–2

Model

Color

Modem Speed

CCITT Group

Coding Method

Transmission Speed

Input/Output Width

ADF Capacity (pages)

Recording Paper Loadable

Paper Size

Ribbon Life (A4-size print)

Handset

LCD Size

On-screen Programming

Gray Scale

Smoothing

One-touch Dial

Speed Dial

Telephone Index

FAX1010

White (1138)

9600 bps

G3

MH

15 sec.

A4/A4

20

200 sheets

Letter/Legal/A4

420 pages

No

16 x 1

Yes

64 by Dithered

Yes

12 x 2

36

Yes (Not Super)

FAX1020

White (1138)

9600 bps

G3

MH

15 sec.

A4/A4

20

200 sheets

Letter/Legal/A4

420 pages

Yes

16 x 1

Yes

64 by Dithered

Yes

12 x 2

36

Yes (Not Super)

FAX1030

White (1138)

14400 bps

G3

MH

10 sec.

A4/A4

20

200 sheets

Letter/Legal/A4

420 pages

Yes

16 x 1

Yes

64 by E/D

Yes

12 x 2

100

Yes (Not Super)

Multi-resolution Transmission

Yes

Yes

Yes

FAX/TEL Switch

Yes

Yes

Yes

Distinctive Ringing

Yes

Yes

Yes

Next Fax-reservation

Yes

Yes

Yes

Help

Yes, Simple

Yes, Simple

Yes, Simple

TAD Interface

Yes

Yes

Yes

Coverpage

Yes, Super

Yes, Super

Yes, Super

Polling Type

Std/Sec/Del/Seq

Std/Sec/Del/Seq

Std/Sec/Del/Seq

Receive Password (password plus)

Yes

Yes

Yes

Delayed Transmission

3, timers

3, timers

3, timers

Call Reservation

Yes

Yes

Yes

Call-back Message

Yes

Yes

Yes

Speaker Phone

Monitor

Monitor

Yes, Full-duplex

Activity Report

Yes

Yes

Yes

Transmission Verification Report

Yes

Yes

Yes

Page Memory

512 KB (20 pages)

512 KB (20 pages)

1 MB (50 pages)

Out-of-paper Reception

Yes (20 pages)

Yes (20 pages)

Yes (50 pages)

Quick Scan

Yes (18 pages)

Yes (18 pages)

Yes (18 pages)

Super Quick Scan

No

No

No

Broadcasting

Yes, 60 locations

Yes, 60 locations

Yes, 124 locations

ECM

Yes

Yes

Yes

Multi-transmission

Yes

Yes

Yes

Multi-copying w/Sorting

Yes

Yes

Yes

Enlargement/Reduction Ratio

Yes (50-150%)

Yes (50-150%)

Yes (50-150%)

TAD Type

No

No

DSP

OGM

No

No

Yes

ICM Recording Time

No

No

Yes, 30 min.

FAX Forwarding/Paging

Yes/No

Yes/No

Yes

FAX Retrieval

Yes

Yes

Yes

PCI (Missing link)

Ready

Ready

Ready

Message Center

No

No

Yes

Caller ID

UK, Sw., Holland (Ready for France) UK, Sw., Holland (Ready for France) UK, Sw., Holland (Ready for France)

Fax-/Voice-on-demand

No

No

Voice-on-demand

Mail Box

No

No

Yes, 5

Remote Control

Yes

Yes

Yes

Toll Saver

No

No

Yes

Memo/2-Way Recording

No

No

Yes

Auto Reduction

Yes

Yes

Yes

Confidential Mailbox

No

No

No

Optional Memory

No

No

No

I–3

Model

Color

Modem Speed

CCITT Group

Coding Method

Transmission Speed

Input/Output Width

ADF Capacity (pages)

Recording Paper Loadable

Paper Size

Ribbon Life (Letter-size print)

Handset

LCD Size

On-screen Programming

Gray Scale

Smoothing

One-touch Dial

Speed Dial

Telephone Index

MFC1770

White (1138)

9600 bps

G3

MH

15 sec.

8.5"/8.5"

20

200 sheets

Letter/Legal/A4

450 pages

Yes

16 x 1

Yes

64 by Dithered

Yes

12 x 2

36

Yes

MFC1870MC

White (1138)

14400 bps

G3

MH

9 sec.

8.5"/8.5"

20

200 sheets

Letter/Legal/A4

450 pages

Yes

16 x 1

Yes

64 by Dithered

Yes

12 x 2

36

Yes

MFC1970MC

White (1138)

14400 bps

G3

MH

9 sec.

8.5"/8.5"

20

200 sheets

Letter/Legal/A4

450 pages

Yes

16 x 1

Yes

64 by E/D

Yes

12 x 2

100

Yes

Multi-resolution Transmission

FAX/TEL Switch

Distinctive Ringing

Next Fax-reservation

Help

TAD Interface

Coverpage

Polling Type

Receive Password (password plus)

Delayed Transmission

Call Reservation

Call-back Message

Speaker Phone

Activity Report

Transmission Verification Report

Page Memory

Out-of-paper Reception

Quick Scan

Super Quick Scan

Broadcasting

ECM

Multi-transmission

Multi-copying w/Sorting

Enlargement/Reduction Ratio

TAD Type

OGM

ICM Recording Time

FAX Forwarding/Paging

FAX Retrieval

PCI (Missing link)

Message Center

Caller ID

Fax-/Voice-on-demand

Mail Box

Remote Control

Toll Saver

Memo/2-Way Recording

Auto Reduction

Confidential Mailbox

Optional Memory

Yes

Yes

Yes

Yes

Yes

Yes

Yes, Super

Sim/Del/Seq

Yes

3, timers

Yes

Yes

Monitor

Yes

Yes

512 KB (20 pages)

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes (50-150%)

No

No

No

Yes

Yes

Included (MFL3)

No

Yes

No

No

Yes

No

No

Yes

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes, Super

Sim/Del/Seq

Yes

3, timers

Yes

Yes

Yes, Full-duplex

Yes

Yes

512 KB (20 pages)

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes (50-150%)

DSP

Yes

Yes, 15 min.

Yes

Yes

Included (MFL3)

Yes

Yes

Voice-on-demand

Yes

Yes

Yes

Yes

Yes

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes, Super

Sim/Del/Seq

Yes

3, timers

Yes

Yes

Yes, Full-duplex

Yes

Yes

1 MB (50 pages)

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes (50-150%)

DSP

Yes

Yes, 30 min.

Yes

Yes

Included (MFL3)

Yes

Yes

Voice-on-demand

Yes

Yes

Yes

Yes

Yes

No

No

I–4

CHAPTER II.

INSTALLATION

CHAPTER III.

THEORY OF OPERATION

CONTENTS

1.

OVERVIEW ..................................................................................................... III-1

1.1 Functional Block Diagram ......................................................................

2.

III-1

MECHANISMS ................................................................................................ III-2

2.1 Transmitting Mechanism (Feeding and scanning documents) ...............

III-2

2.1.1 Automatic document feeder (ADF) ..................................................

III-2

2.1.2 Scanner ........................................................................................... III-3

2.2 Receiving Mechanism (Feeding paper and printing data) ......................

III-4

2.3 Power Transmission Mechanism ...........................................................

III-5

2.3.1 Structure of the gear train ...............................................................

III-5

2.3.2 Description of planetary gear system ..............................................

III-6

2.3.3 Power transmission for four operation modes .................................

III-7

[ 1 ] Scanning mode (Solenoid: OFF, Motor rotation : Reverse) ......................

III-8

[ 2 ] Paper feeding/ejection mode (Solenoid: ON, Motor rotation : Reverse) III-9

3.

[ 3 ] Recording mode (Solenoid: OFF, Motor rotation : Forward) ....................

III-10

[ 4 ] Copying mode (Solenoid: ON, Motor rotation : Forward) .........................

III-12

2.3.4 Power transmission route ...............................................................

III-14

2.4 Sensors and Actuators ...........................................................................

III-16

CONTROL ELECTRONICS ...........................................................................

III-19

3.1 Configuration ........................................................................................... III-19

3.2 Main PCB ................................................................................................ III-20

3.3 NCU PCB ................................................................................................ III-27

3.4 Control Panel PCB .................................................................................

III-29

3.5 Power Supply PCB ................................................................................

III-30

1. OVERVIEW

1.1

Functional Block Diagram

Control Panel

Recorder

LCD

Recording head

Ribbon sensor

Document

ejection tray

Modular PCB

(Cover sensor)

Scanner

Main PCB

CIS unit

(Document front

and rear sensors)

Ribbon cartridge

To PC

Main frame

NCU PCB

Line

Power supply

PCB

AC

Motor

Sensor PCB

(Paper-edge

sensor and paper

ejection sensor)

Handset

Hook switch

sensor

III – 1

2. MECHANISMS

The equipment is classified into the following mechanisms:

■ Transmitting Mechanism

Feeding and scanning documents

■ Receiving Mechanism

Feeding paper and printing data

■ Power Transmission Mechanism

Switching the power transmission route

■ Sensors and Actuators

2.1

Transmitting Mechanism (Feeding and scanning documents)

The transmitting mechanism consists of the document stacker, automatic document feeder

(ADF), document feeding related rollers, scanner, and document sensors. (For details about

the sensors, refer to Section 2.4.)

For the drive power source, refer to Section 2.3.

Document

Separation roller

Document

support

ADF parts

Pressure roller,

rear

Document

stacker

White pressure

roller

Pressure roller,

front

(Front)

Scanner

(CIS unit)

2.1.1

Document

ejection roller

Automatic document feeder (ADF)

If the operator sets documents on the stacker and starts the transmitting operation, the ADF

(consisting of the separation roller and ADF parts) feeds those documents into the equipment, starting from the bottom sheet to the top, page by page. Each document advances to

the scanner, and then it is fed with the white pressure roller and document ejection roller.

III – 2

2.1.2

Scanner

The scanner uses a contact image sensor (CIS) unit which consists of an LED array illuminating documents, a self-focus lens array collecting the reflected light, a CIS PCB carrying

out photoelectric conversion to output picture element data, and a cover glass on which a

document advances. When the document passes between the white pressure roller and the

cover glass, it is scanned.

III – 3

2.2

Receiving Mechanism (Feeding paper and printing data)

The receiving mechanism consists of the recording paper cover ASSY, paper feed roller

ASSY, platen, thermal recording head, paper ejection roller, and sensors. (For details about

the sensors, refer to Section 2.4.)

Paper

Paper feed roller ASSY

Chute ASSY

Recording

paper cover

ASSY

Paper ejection roller

Platen

(Front)

Thermal ink ribbon

Recording head

STEP 1: In the paper feeding mode

If the equipment receives data, the control electronics activates the solenoid and rotates the

motor counterclockwise to drive the paper feed roller (and paper ejection roller). This pulls in

a sheet of paper and feeds it until its leading edge reaches the point just before the printing

position.

STEP 2: In the recording (platen drive & ribbon take-up) mode

The control electronics deactivates the solenoid and rotates the motor clockwise to drive the

platen gear and the ribbon take-up gear as well as the paper ejection roller. This feeds the

paper up to the printing position where the thermal recording head prints, as well as feeding

the thermal ink ribbon.

STEP 3: In the paper ejecting mode

The same operation as for STEP 1 takes place so as to eject the paper.

III – 4

2.3

Power Transmission Mechanism

The equipment has a single drive motor whose power transmission route can be switched by

the planetary gear systems and the solenoid. This switching allows the equipment to function in four operation modes (scanning, paper feeding/ejecting, recording, and copying

modes). For the details about the planetary gear systems, refer to Subsection 2.3.2.

2.3.1

Structure of the gear train

At the left side of the equipment, the rotational torque of the motor on the main frame is

transmitted to the gears on the main frame and then to the gears on the platen frame. These

gears drive the document feeding/ejecting related rollers, paper feeding/ejecting related rollers, and the platen.

If the platen gear ("a" in the figure below) on the left end of the platen shaft rotates, the gear

33RB ("b") on the right end also rotates. This way, the rotational torque is transmitted to the

gears on the right side of the equipment.

At the right side of the equipment, the rotational torque is further transmitted via the friction

torque transmission ASSY to the ribbon drive gear ("e") which drives the ribbon take-up gear

in the ribbon cartridge.

Right side

d (Gear 18)

e (Gear 46 of Friction torque

transmission ASSY)

c (Gear 20/40)

Main frame

b (Gear 33RB)

Platen frame

e (Ribbon drive gear, Gear 24)

Left side

(Gears 18/41)

V

W (Clutch gear ASSY)

X (Paper ejection roller gear, Gear 40)

U

a (Platen gear, Gear 23)

Z (Gear 33/45)

T (Paper feed roller gear, Gear 55)

M (Gear 39)

Platen frame

C (Planet gear 20B of Arm B ASSY)

D (Gear 33)

F (Separation roller gear)

I (White pressure

roller gear)

S (Planet gear

34 of Arm P

ASSY)

(Front)

R (Sun gear

39/24)

O (Gear 39)

Main frame

Q (Gear 33)

P (Gear 18)

N (Sun gear

36/27)

Y (Planet gear 44 of

Arm C ASSY)

B (Sun gear 20/90)

Gear Train

III – 5

E (Gear

20/40)

G H

K (Document

ejection roller

J gear)

(Gears 14/20)

Clutch lever

A (Motor gear)

L (Planet gear 20A of Arm A ASSY)

: Gears on the main frame

: Gears on the platen frame

2.3.2

Description of planetary gear system

The equipment uses the following three planetary gear systems:

- Sun gear 20/90 ("B" in the figure given on the previous page) and its planet gears

- Sun gear 36/27 ("N") and its planet gear

- Sun gear 39/24 ("R") and its planet gear

This section describes the planetary gear system of the sun gear 20/90 ("B"). It consists of

the sun gear 20/90, two planet gears 20, arm A, and arm B, as shown below.

Planet gear 20B

Arm B

Sun gear 20/90

Arm A

Motor gear

Planet gear 20A

Planetary Gear System

If the motor rotates, the sun gear 20/90 rotates so that the rotational torque is transmitted to

the engagement between the sun gear and the planet gears 20. Since the arms and planet

gears are so designed that the moment of the arms is less than that of the planet gears, the

arms turn around the center shaft in the same direction as the sun gear 20/90.

If the planet gear(s) becomes engaged with any other gear so that the arm cannot turn furthermore, the rotational torque of the sun gear 20/90 is transmitted to that planet gear. Accordingly, the planet gear starts rotation in the opposite direction of the sun gear 20/90.

III – 6

2.3.3

Power transmission for four operation modes

Depending upon the solenoid ON/OFF state and the motor rotation direction, the planetary

gear train switches the power transmission route for the four operation modes.

Solenoid ON/OFF state

Motor rotation direction

Solenoid: OFF

Section y (to block the

stoppper of arm B)

Planet gear 20B

Stopper of

arm B

Clutch lever

Arm B

Cutout x (engaged

with the stopper of

arm A)

Solenoid

Sun gear

20/90

Spring

Planet gear

20A

Solenoid: ON

Section y (to block the

stoppper of arm B)

Clutch lever

Cutout x (engaged

with the stopper of

arm A)

Solenoid

Forward

Reverse

Spring

III – 7

Stopper

of arm A

Arm A

Motor

gear

[1]

Scanning mode (Solenoid: OFF, Motor rotation: Reverse)

In the scanning mode, the control electronics deactivates the solenoid. When the motor rotates in the reverse direction, the clutch lever turns counterclockwise with the spring so that

its cutout x becomes engaged with the stopper of arm A. Once arm A is locked, the planet

gear 20A ("L") will not be engaged with any other gear but simply idle.

The motor's rotational torque turns the sun gear 20/90 ("B") clockwise so that the planet gear

20B ("C") transmits the torque to the separation roller gear ("F"), white pressure roller gear

("I") and document ejection roller gear ("K") via the several gears.

C (Planet gear 20B)

Cutout x of clutch lever

Stopper of arm A

B (Sun gear 20/90)

Clutch lever

L (Planet gear 20A)

Solenoid

Arm A Locked by Cutout x of Clutch Lever

B (Sun gear 20/90)

C (Planet gear 20B)

F (Separation

roller gear)

I (White pressure

roller gear)

D

G

L

Solenoid

Active Gears

III – 8

E

Clutch lever

A (Motor gear)

H

J

(Front)

K (Document

ejection roller

gear)

[2]

Paper feeding/ejecting mode (Solenoid: ON, Motor rotation: Reverse)

In the paper feeding/ejecting mode, the control electronics activates the solenoid to release

the stopper of arm A. When the motor rotates in the reverse direction, the sun gear 20/90

("B") rotates clockwise so that the planet gear 20A ("L") transmits the torque via the gear 39

("M") and other gears to the paper feed roller gear ("T") and paper ejection roller gear ("X").

Since the stopper of arm B is blocked by the section y of the clutch lever, the planet gear

20B ("C") is merely idle without engaging with any other gear.

Stopper of arm B

C (Planet gear 20B)

Section y of clutch lever

Stopper of arm A

B (Sun gear 20/90)

Clutch lever

L (Planet gear 20A)

Solenoid

Arm B Blocked by Section y of Clutch Lever

X (Paper ejection roller gear)

T (Paper feed roller gear)

U

V

B (Sun gear 20/90)

W

C

Q

P

O

S (Planet

gear 34)

Y

N

M

(Front)

R (Sun gear 39/24)

L (Planet gear 20A)

Solenoid

Clutch lever

A (Motor gear)

Active Gears

III – 9

[3]

Recording mode (Solenoid: OFF, Motor rotation: Forward)

In the recording mode, the control electronics deactivates the solenoid. When the motor rotates in the forward direction, the clutch lever turns counterclockwise with the spring so that

its cutout x becomes engaged with the stopper of arm A. Once arm A is locked, the planet

gear 20A ("L") will not be engaged with any other gear but simply idle.

The motor's rotational torque turns the sun gear 20/90 ("B") counterclockwise so that the

planet gear 20B ("C") transmits the torque via the gear 39 ("M") and other gears to the platen

gear ("a") as well as the paper ejection roller gear ("X").

The platen advances recording paper and its paper movement rotates the paper feed roller.

Consequently, the paper feed roller shaft rotates faster than the paper feed roller gear ("T").

If the platen gear ("a" in the figure below) on the left end of the platen shaft rotates, the gear

33RB ("b") on the right end also rotates so as to drive the friction torque transmission ASSY

and ribbon drive gear ("e") that rotates the ribbon take-up gear ("f") in the ribbon cartridge, as

shown on the next page.

C (Planet gear 20B)

Cutout x of clutch lever

Stopper of arm A

B (Sun gear 20/90)

Clutch lever

L (Planet gear 20A)

Solenoid

Arm A Locked by Cutout x of Clutch Lever

X (Paper ejection roller gear)

a (Platen gear)

T (Paper feed roller gear)

U

V

C (Planet gear 20B)

B (Sun gear 20/90)

W

Z

Q

O

P

M

L

(Front)

S (Planet

gear 34) R (Sun gear 39/24)

Y (Planet gear 44)

Solenoid

Clutch lever

N (Sun gear 36/27)

A (Motor gear)

Active Gears on the Left Side

III – 10

Platen frame

f (Ribbon take-up gear

in the ribbon cartridge)

b (Gear 33RB)

(Front)

c

d

Ribbon

drive gear

(Gear 24)

Friction torque

transmission

ASSY (Gear 46)

Main frame

e

Active Gears on the Right Side

III – 11

[4]

Copying mode (Solenoid: ON, Motor rotation: Forward)

The control electronics activates the solenoid to release the stopper of arm A from the clutch

lever. When the motor rotates in the forward direction, the sun gear 20/90 ("B") rotates

counterclockwise so that the planet gear 20A ("L") transmits the torque to the document

scanner mechanism (e.g., the separation roller gear ("F"), white pressure roller gear ("I") and

document ejection roller gear ("K")) and the planet gear 20B ("C") transmits the torque to the

recording mechanism (e.g., the platen gear ("a"), paper feed roller gear ("T"), and paper

ejection roller gear ("X")).

If the platen gear ("a" in the figure below) on the left end of the platen shaft rotates, the gear

33RB ("b") on the right end also rotates so as to drive the friction torque transmission ASSY

and ribbon drive gear ("e") that rotates the ribbon take-up gear ("f") in the ribbon cartridge, as

shown on the next page.

Stopper of arm B

Stopper of arm A

C (Planet gear 20B)

Cutout x of clutch lever

B (Sun gear 20/90)

Clutch lever

L (Planet gear 20A)

Solenoid

Arm A Released from Coutout X of Clutch Lever

X (Paper ejection roller gear)

a (Platen gear)

T (Paper feed roller gear)

U

C (Planet gear 20B)

V

F (Separation roller gear)

W

a

Q

I (White pressure

roller gear)

Z

O

P

G

M

L

E

H

J

(Front)

S (Planet

gear 34) R (Sun gear 39/24)

Y (Planet gear 44)

N (Sun gear 36/27)

B (Sun gear

20/90)

Solenoid

Clutch lever

A (Motor gear)

L (Planet gear 20A)

Active Gears on the Left Side

III – 12

K (Document

ejection roller

gear)

Platen frame

f (Ribbon take-up gear

in the ribbon cartridge)

b (Gear 33RB)

(Front)

c

d

Friction torque

transmission

ASSY (Gear 46)

Ribbon

drive gear

(Gear 24)

e

Active Gears on the Right Side

III – 13

Main frame

2.3.4

Power transmission route

Rotation of the motor gear is transmitted as shown below.

U

V

X

T

W

S

a

R

Z

D

F

C

Q

O

P

I

G

B

N

Y

L

M

A

H

J

E

K

Gears on the Left Side

b

f

c

e

d

Gears on the Right Side

A:

B:

C:

D:

E:

F:

G:

H:

I:

J:

K:

L:

M:

N:

O:

P:

Motor gear

Sun gear 20/90

Planet gear 20B

Gear 33

Gear 20/40

Separation roller gear

Gear 14/20

Gear 14/20

White pressure roller gear

Gear 14/20

Document ejection roller gear

Planet gear 20A

Gear 39

Sun gear 36/27

Gear 39

Gear 18

Q:

R:

S:

T:

U:

V:

W:

X:

Y:

Z:

a:

b:

c:

d:

e:

f:

[1]

Scanning Mode (Solenoid: OFF, Motor rotation: reverse)

A➜B

(Motor)

C➜D➜E➜F➜G➜H

L (Idling)

[2]

Gear 33

Sun gear 39/24

Planet gear 34

Paper feed roller gear

Gear 18/41

Gear 18/41

Clutch gear

Paper ejection roller gear, Gear 40

Planet gear 44

Gear 33/45

Platen gear, Gear 23

Gear 33RB

Gear 20/40

Gear 18

Friction torque transmission ASSY (Gear 46)

and ribbon drive gear (Gear 24)

Ribbon take-up gear in the ribbon cartridge

(Separation

roller)

I (White pressure roller)

J➜K

(Document

ejection roller)

Paper Feeding/Ejecting Mode (Solenoid: ON, Motor rotation: reverse)

C (Idling)

A➜B

(Motor)

L➜M➜N

O➜P➜Q➜R➜S➜T➜U➜V➜W➜X

(Paper feed

roller)

Y (Idling)

III – 14

(Paper ejection

roller)

[3]

Recording Mode (Solenoid: OFF, Motor rotation: forward)

A➜B

(Motor)

C➜M➜N

L (Idling)

Y ➜ Z ➜ a (Platen) ➜ b ➜ c ➜ d ➜ e ➜ f (Ribbon take-up gear)

O➜P➜Q➜R➜S➜W

X (Paper ejection roller)

V➜U➜T

(Paper feed

roller, Idling)

[4]

Copying Mode (Solenoid: ON, Motor rotation: forward)

C➜M➜N

A➜B

(Motor)

Y ➜ Z ➜ a (Platen) ➜ b ➜ c ➜ d ➜ e ➜ f (Ribbon take-up gear)

O➜P➜Q➜R➜S➜W

L ➜ E ➜ F➜ G ➜ H

(Separation

roller)

I (White pressure roller)

J➜K

(Document

ejection roller)

III – 15

X (Paper ejection roller)

V➜U➜T

(Paper feed

roller)

2.4

Sensors and Actuators

This equipment has four photosensors and three mechanical switches (two for the FAX1010)

as described below.

Sensor name

Type

Located on

Document front sensor

Document rear sensor

Photosensor (PH1)

Photosensor (PH2)

Main PCB

Main PCB

Paper ejection sensor

Paper-edge sensor

Photosensor (PH1)

Photosensor (PH2)

Sensor PCB

Sensor PCB

Cover sensor

Mechanical switch (SW1)

Modular PCB

Ribbon sensor

Mechanical switch (SW1)

Recording head

Hook switch sensor*

Mechanical switch (SW1)

Hook switch PCB

•

Document front sensor which detects the presence of documents.

•

Document rear sensor which detects the leading and trailing edges of pages to tell the

control circuitry when the leading edge of a new page has reached the starting position

and when the scan for that page is over.

•

Paper ejection sensor which detects whether a paper jam has occurred.

•

Paper-edge sensor which detects the leading and trailing edges of paper and the presence of paper as well as detecting whether the paper front cover is closed.

These photosensors are of a reflection type consisting of a light-emitting diode and a lightsensitive transistor. Each of them has an actuator separately arranged (see the next page),

except that the paper-edge sensor has two actuators for sensing the paper and the paper

front cover. When an actuator is not activated, its white end lies in the path of light issued

from the light-emitting diode and reflects its light so that the reflected light enters the lightsensitive transistor. If a document or paper comes in so as to activate the actuator, the

actuator's white end goes out of the light path and no reflected light enters the light-sensitive

transistor. This way, the sensor detects the presence of documents or paper.

•

Cover sensor which detects whether the recording paper cover ASSY is closed.

•

Ribbon sensor which detects whether the ink ribbon is loaded.

•

Hook switch sensor* which detects whether the handset is placed on the handset mount.

The cover sensor has an actuator separately arranged (see page III-18). If the actuator is

activated, its lower end releases the cover sensor lever so that the sensor signals the detection.

Path of actuator's end

Approx. 0.7 mm

Glass

Lightemitting

diode

* Not provided on the FAX1010

III – 16

Lightsensitive

transistor

(Front)

Document rear sensor

Document rear sensor actuator

Document front sensor

Document front sensor actuator

Main PCB

Paper-edge sensor actuator

Paper-edge sensor

Paper ejection sensor

actuator

Paper ejection sensor

Front cover

sensing actuator

(Front)

Sensor PCB

Recording head

Ribbon sensor

Ribbon sensor actuator

Location of Sensors and Actuators (1)

III – 17

Cover sensor actuator

Cover sensor

Cover sensor lever

Modular PCB

Hook switch sensor actuator**

Hook switch sensor**

Hook switch PCB**

Handset mount*

Location of Sensors and Actuators (2)

* Not provided on the FAX1010

** Not provided on the FAX1010 or those versions equipped with a Binatone handset

III – 18

3. CONTROL ELECTRONICS

3.1

Configuration

The hardware configuration of the facsimile equipment is shown below.

Line

External

telephone

2-pin

Handset*

(Note)

12-pin: U.S.A. versions

18-pin: European versions

2-pin

4-pin

NCU PCB

(Note)

2

Modular*

PCB

PC I/F

Speaker

P2

8-pin

Main PCB

*1

14-pin

COG

5-pin

Control

panel PCB

2-pin

6-pin

Motor

7-pin

ASIC

14-pin

CIS unit

2-pin

Solenoid

FPC key

11-pin

5-pin

2-pin

*3

Sensor

PCB

*

Hook *4

switch

PCB

2-pin

2-pin

4-pin

Microphone

Ni-MH

battery

(Only on the FAX1570MC/1030/MFC1870MC/1970MC)

*5

Recording head

4-pin

Power supply PCB

*1 On the main PCB are these sensors:

• Document front sensor (PH1)

• Document rear sensor (PH2)

*2 On the modular PCB is the cover sensor.

*3 On the sensor PCB are these sensors:

• Paper ejection sensor (PH1)

• Paper-edge sensor (PH2)

*4 On the hook switch PCB* is the hook switch sensor (SW1).

*5 On the recording head is the ribbon sensor (SW1).

* Not provided on

the FAX1010

Configuration of Facsimile Equipment

III – 19

3.2

Main PCB

The main PCB, which is the nucleus controlling the entire operation of the equipment, consists of a FAX engine (ASIC), memories, MODEM, motor drive circuitry, sensor detection circuitry, and analog circuits for scanning, recording, and power transmission shifting.

ROM

Control panel

E2PROM

Recording head

DRAM

FAX

engine

NCU

CIS

(ASIC)

Motor

driver

Power

supply

Speaker

Motor

Sensors

Modular

PCB (for

PC I/F)

Ni-MH battery

Hook

switch

sensor*

Microphone

Sensors

E2PROM:

DRAM:

** Not provided on the

FAX1010 or those

versions equipped

with a Binatone

handset

Electrically Erasable Programmable Read-only Memory

Dynamic Random Access Memory

Block Diagram of Main PCB

On the following pages, the main PCB circuit diagrams are described on the basis of the

FAX1570MC/1030/MFC1870MC/1970MC.

III – 20

1

2

3

4

5

5

6

7

8

+ 5 V

Q6

L 3

0

RH5 V A 4 3

RS T L

R9 0

1 6 A , 4 7 B , 1 4 B , 5 7 E

# 9

T 7 D6 0

1 . 5 K

V CC

4 4

OUT

GND

A

F G

RV DD

C6 5

1 4 3

CC1 0 4

E X T L

1 4 1

R8 0

GND

+ 5 V

X T 1

C S A 1 6 MX

R8 2

2 5 D

RA S

0

2 5 D

CA S

1 0 0

R1 1 4 1 0 0

C6 1

C6 2

CC3 0 P

CC3 0 P

2 7 B

R MR D

2 7 B

R OMC

7 5

*

1 5 B

1

3

R9

1 5 B

S DOT

1 5 B

S DI N

2

GND

P CL K

4 7 0

2

1 2 B

R8 4

B 5 B - P H

WH I T E

C1 4

C1 5

C1 0 1 C1 0 1

P CL K

S DOUT

1 2 B

7 3

RS T L

GND

CC1 0 2 B

C6 7

4 2 F

DA S NO

DA RE C

R1 3 2

2 0 0

R5 9

1 0 k

R6 8

1 0 k

1 8

1 9

2 0

5 2 C

CL B S Y

5 2 D CL RX S

R1 3 3

1 0 k

L 5 V

C

C5 0

C3 8

C7 0

4 3 B

T A DH

0

0

CC1 0 4

4 4 D

T X S L

4 5 D

HA F H

2 1

2 2

2 3

2 4

2 5

2 0 5

+ 5 V

GND

M I O 0 ( P WM )

M I O 1 ( P WM )

M I O 2 ( P WM )

A D P D MD

A A P D MD

D P D MD T

MI O3

D P D MC K

MI O4

A P D MC K

MI O5

A P D MD T

MI O1 1

C5

MI O1 2

C4

MI O1 3

C3

MV D D

C2

C1

C3 9

C0

CC1 0 4

2 0 8

GND

2 0 4

MV S S

MON MD C K

A MU T E

MU T E

GND

1 6

R8 6

*

1 0 3

L I G T ( P WM )

ME X T L

MT X L

4 6 E

3 2 F

*

3 8 C

4 2 F

3 7 B

D

3 7 B

GND

E 5 V

+ 5 V

S P ON

RI B ON

F RNT

T L OF 2

F S E N

RS E N

1 7 B

CS E N

3 8 C

RE A R

8 0

7 6

7 7

7 8

1 4

A A MD

R6 7

1 2

2 0 0

7 9

3 0

3 1

3 2

S E N2

DA 0

S E N3

DA 1

S E N4

DA 2

S E N5

DA 3

S E N6

DA 4

S E N7

DA 5

S E N8

DA 6

DA 8

3 2 E

S T 1

3 2 E

S T 2

3 2 E

HDC

3 2 E

DI N

3 2 E

DOUT

9 2

9 1

9 3

9 4

9 0

S T 1

R6 6

3 0 0

D MK

R6 4

3 0 0

A MK

8

A MT

DA 9

7

3

C3

3 4 C

E 1 CS

3 4 C

S MC

3 6 C

RDA T

+ 2 6 V

2 3 C

MT I 1

2 3 C

MT I 0

3 2 A

RB

1 0 6

1 0 7

1 0 2

9 5

9 8

9 9

R9 6

3 7 D

7 5 K

S E ON

1 0 0

1 0 1

1 0 4

3 4 C, 3 2 A

T G

D0 1

DOUT

D0 2

E 1 CS

D0 5

S P S L ( S MC )

D0 6

RDA T

D0 7

CL 2

V DD

CL 1

V DD

CL B

V DD

RB

V DD

DI F

T G

V DD

V DD

V DD

5 2

R9 5

C7 9

3 3 B

CC1 0 4

3 3 D

E A T

4 2 B , 3 8 E

C ML H

4 2 E

RDP S

V I D

5 6

5 5

CP 3 I

5 4

5 3

E 0 V

RDA 6 1

V DD

CP 1 I

V DD

2

C4

1

C5

6

C0

5

N MI

8

C2

1 3

1 8 7

1 8 8

1 8 9

A MU T

4 6 E

V OL 3

4 6 D

RNGL

4 2 D

OT O

B S A K

( OD)

B S RQ

P WO N

WA I T

C ML

RF S H

DP S

M1

T E L

1 9 2

HOOK

1 9 3

CI

1 9 4

1

A 0

A 1

A 2

T L OF

1 9 5

3 9

4 0

A 3

S T D

A 4

RI NG

A 5

S P ON

1 8 4

A 6

E 2 CS

2 0 3

A 7

CT X D

A 8

MU T

7

2 0 7

L 2

A 9

4 8 A , 5 8 D

4

2 0 6

1 0 9

1 1 0

1 1 1

1 1 2

1 1 3

2 0 0

R1 1 8

2 0 0

RA 2

2 0 0

V S S

CP NN

V S S

V S S

5 0

5 1

E 5 V

5 8

R9 3

1 0 0 F

4 9

F

4 8

4 7

R9 4

C7 8

C7 7

C7 6

C7 3

7 5 F

CC1 0 4

CC1 0 4

CC1 0 4

CC1 0 4

5 9

3 2 F

8 9

L A T C

1 8 5

C L MP

3 3 C

P O1

P O2

1 8 6

C P WM

A 1 1

P 0 3

A 1 2

( OD)

A 1 3

DA 0

A 1 4

DA 1

R6 0

4

4 . 7 K

DA 2

DA 3

R6 1

DA 4

2 2 0

A 1 5

5 3 B

2 5 B

X T 2

2 6

CL S E L

2 7

E P CK

2 3 F

S OL

3 8 E

P WO N

2 8

D5 7 . 6 D6

DA 5

R M1

MA 1 6

R M2

MA 1 7

R M3

2 9

RA 1

2 0 0

MA 1 8

ODP I O0

DA 7

C4 2

DA 8

C4 1

CC5 P

CC5 P

R7 9

*

R7 8

*

ODP I O1

1 8 2

GND

DA 9

1 2 0

1 2 7

D0

1 2 8

D1

1 2 9

D2

1 3 0

D3

1 3 1

D4

1 3 3

D5

1 3 4

D6

1 3 5

D7

CK S

1 9 6

T X D

1 9 7

RX D

1 9 8

CT S

8 4

MM1

C- 0 0 1 R

C7 5

3 4 C

2 6 B , 2 6 E

1 8 3

1 0 8

S RA M

2 5 B

E P DO

2 3 E

MT V R

P I O1

ODP I O2

P I O2

ODP I O3

P I O3 ( S R A M) OD P I O4

4 1

C0 V

8 5

MM2

8 6

MM3

6 9

P I O5

F DCL K

P I O6

F DOUT

F DI N

R1 3 1

F CS 1

1 0 K

CC1 2 P

8 7

MM4

1 7 B

GND

P CI

+ 5 V

2 3 C

3

4 5

L 5 V

1 6 B

4 6

1 2 5

I ORQ

1 2 6

MR E Q

1 4 0

CK 1 6

R8 3

P B US

+ 5 V

1 0 K

8 8

P 7

6

5

RX D

1 4 4

R8 1

2 0 0

1 4 5

RD

1 4 6

WR

B

9

4

R1 0

CT S

4 . 7 K

1 2 D

RB US

1 6 8

2

CS E N

8

3 4 D

7

C1 7

1 6 9

*

1 7 0

GND

1 7 1

P 1 5

I MS A - 9 1 1 0 S - 0 8 L

1 7 2

GND

1 7 3

1 7 4

1 3 6

A 0

1 3 7

A 1

1 3 8

A 2

C

+ 5 V

1 3 9

A 3

1 4 8

A 4

R1 1

L 5

1 4 9

A 5

4 . 7 K

MMZ Y 6 0 1 B

1 5 0

A 6

1 5 1

1 5 C

HOOK

HOOK

1

A 7

1 5 2

A 9

1 5 4

A 1 0

1 5 5

A 1 1

2

C1 8

A 8

1 5 3

:

CC1 0 1

GND

P 1 4

B 2 B - P H

GND

1 5 7

WH I T E

1 5 8

A B US

1 5 9

2 6 B , 3 4 D

1 6 0

1 6 1

1 6 2

D

1 6 3

GND

CL RS T

1 7 8

CL CI

1 7 9

CL T X S

1 8 0

CL CK

1 8 1

V OL 2

+ 5 B

+ 5 V

CL B US

4 2

5 1 C

4 6 E

F CS 2

E I T 1

3 3

3 4

3 5

3 6

CT S E L

D1

R1 2 5

*

0

5 3 A , 5 3 B

A

3 7

RV DD

R1 2 7

1 0

1

CK S

T X D

L 5 V

+ 5 V

2 5 E , 3 6 D

CRX D

P I O4 ( OD)

1 2 1

L 5 V

C7 4

CC1 0 P

R M4

DA 6

1 1 6

1 1 8

7 4 V HCU0 4 F S

2

1

3 3 C

R1 1 7

1 1 5

1 1 7

# 1 2

3

1 0 0

CRX D

1 9 9

P L S

1 9 1

L 5 V

RNGO

S OL

8 2

T L OF

4 5 E

L N C R ( C OMP )

8 3

CI

4 2 F

C1

4

T E L L

HOOK

A

X T 3

C1 0 8

*

*

CC1 0 4

E

S HORT - 2

4 3

9 7

+ 5 V

L 4

1 1 4

GND

0

GND

1 3 2

C6

*

1 4 7

L 5 V

1 6 5

L 1

1 9 0

0

GND

2 0 1

CP 3 I

CP 4 I

7 5 F

RDA 6

V S S

A V DD

V S S

A V DD

V S S

RE F H

V S S

RE F L

V S S

A GND

V S S

A GND

V S S

V S S

1 5

1 4

3 8

# 1 2

C4 0

6 0

CC1 0 4

7 4 V HCU0 4 F S

8 1

5

9 6

1 0 5

C4 3

C5 1

C5 9

C6 0

c 6 3

C6 6

C6 9

C7 2

CC1 0 4

CC1 0 4

CC1 0 4

CC1 0 4

CC1 0 4

CC1 0 4

CC1 0 4

CC1 0 4

9

1 1

1 3

7

C0 V

F

1 1 9

1 4 2

L X

1 5 6

0

1 6 4

2 0 0

GND

E 0 V

E 0 V

1

WR

B A R M WE

5 7

P L S

4 3 A

1 7 C

4 2 F

DB US

E

R9 2

RD

B A R MR D

7 1

DA B US

D0 0

DI N

D0 4

1 0 K F

V OL 1

4 2 F

4 3 E

S T 2

HDC

D0 3

E 0 V

E 5 V

CK 8 M

B A K S E L

7 2

A DL C

4 6 E

D MT

1 1

9

S E ON( OD)

DA 7

GND

CK 1 6

A 1 0

DA S T

C6 8

4 2 F

GND

A D MD

T B US

4 2 F

B A R M WE

B A E NB

I NT

1 0 K

1 7

B A R MR D

2 5 C

MR E Q

CC1 0 4

T 7 D6 0

1 0 K

2 5 C

B A K CL K

B A V DD

6 5

GND

C7 1

T S T B

I ORQ

CC1 0 4

# 9

T S T A

CK 3 2

7 4

R8 7

MM4

CK 3 2 ON

1 0 0

1 4 A

R7 0

2 0 2

MB U S

R8 8

L I GT

MM3

S DI N

6 7

C1 3

+ 5 V

MM2

S DOUT

1 7 5

S DI N

+ 5 B

4 3 D

CT S

*

RS T L

C1 6

3 3 A

RX D

P CL K

1 7 6

6 8

GND

T X D

R OMC

I O WE

1 7 7

6 6

C1 0 1

CK S

R M WE

2 2 K

R8 5

1 4 A

1 2 B

+ 5 B

4

B

P 1 1

CRX D

R MR D

I ORD

MM1

4 7 0

3

1 4 A

RV DD

6 3

P B US

1 6 7

R7

RS T L

6 1

0

CA S

1 2 2

1 6 6

5

6 4

6 2

RA S 0

1 2 4

R8

RX T

R9 1

7 0

1 2 3

P A NE L

RE X T

X T L

1 M

R1 1 6

6

RT CCON

RS T

GND

GND

2

3

4

5

6

7

8

Main PCB Circuit Diagram 1/5

1 FAX engine (ASIC) which integrates a CPU, digital portion of MODEM and gate array

for managing the I/Os, memories, and drivers.

2 XT1, oscillator for the CPU.

3 XT3, oscillator for the calendar clock.

4 XT2, oscillator for the MODEM.

5 Reset IC which turns on at the powering-on sequence and at any of the reset operations.

6 Connector for the control panel

7 Recording head drive voltage detector

8 Inverters

9 Connector for the modular PCB

: Connector for the hook switch PCB

A Backup circuit for the calendar clock

III – 21

1

2

3

+ 2 6 V

A

# 3

+ 9 V

1

4

5

6

7

8

2

P S

K I A 7 8 0 5

8

4

1

I N

+ 5 V

OUT

GND

+ 5 V

A

+ 5 V

GND

C9 5

C3

C9 6

C9 7

C5

1 6 V 4 7

CC1 0 4

CC1 0 4

1 6 V 4 7

GND

C5 8

CC1 0 4

CC1 0 4

# 8

2

R1 2 0

1

8

GND

4

P 0 V

P 3

B 4 B - P H

+ 9 V

Q1 2

4

V CC

V S S

S CL

A 0

S DA

A 1

T E S T

A 2

6

1 5 D

E P CK

1 5 D

E P DO

3 2

1

R7 6

+ 5 V

RH5 RA 4 7

I N

7

R1 1 9

D. S

MOD E L = *

R7 7

S T D

MOD E L = *

D. S

MOD E L = 0

2 4 L C 1 6 ( 1 8 7 0 MC )

1 K

2 4 L C 3 2 ( 1 9 7 0 MC )

C4

1 6 V 4 7

DA B US

2

GND

GND

P 6

B 2 B - P H

B L A CK

1 6 D

A B US

MOT OR

# 1

3

5

MT D 2 0 0 3 F

4

2

2

7

6

C

8

5

1 3

1

3

5

P 2

6

B 6 B - P H

9

+ 5 V

1 0

1 2

1 9

2 4

R1 1 0

R1 3 0

0

2 0 K

OUT 1

I N1

OUT 2

I N2

OUT 3

I N3

OUT 4

I N4

2 6

MM3

1 7

MM2

1 6

MM4

MB U S

1 6 B

MT I 0

1 2 E

I 0

NC

2 5

MT I 1

1 2 E

NC

NC

NC

NC

NC

I 1

V R

C/ R

1 8

6

1 5 A

RA S

1 5 A

CA S

1 5 B

B A R M WE

R1 1 2

4

1 5 B

B A R MR D

+ 5 B

GND

C9 4

+ 5 B

V CC

R1 1 1

*

2 0

*

# 7

1

1 1

# 5

2 6

1 3

1 5

R2

R1

1 / 2 W

1 / 2 W

1

1

V CC

1 0

A 3

9

A 4

8

A 5

7

A 6

6

A 7

5

A 8

2 7

A 9

2 6

A 1 0

2 3

A 1 1

2 5

DA 3

4

DA 4

2 8

DA 5

2 9

DA 6

3

DA 7

2

DA 8

3 0

A 0

9

A 1

A 2

A 3

B

A 4

A 5

A 6

A 7

A 8

A 9

A 1 0

D0

A 1 1

D1

A 1 2

D2

A 1 3

D3

A 1 4

D4

A 1 5

D5

A 1 6

D6

A 1 7

D7

+ 5 B

1 3

D0

1 4

D1

1 5

D2

1 7

D3

1 8

D4

1 9

D5

2 0

D6

2 1

D7

GND

C6 4

CC1 0 4

( 1 9 7 0 MC )

# 6

( 1 8 7 0 MC )

H M5 1 4 8 0 0 J P

2 6

1 3

V S S

V CC

RS A

2 9

3 0

V CC

V S S

V CC

V S S

C1 0 7

C1

CC1 0 4

CC1 0 4

5 0 v

3 5 V / 2 2 0

- RA S

CC1 0 4

1 0 5

- RA S

2 3

6

- CA S

- CA S

NC

- WE

NC

7

3

2 1

- WE

2 2

2 8

8

4

2 3

- WE

C9 0

D

2 2

2 2

- OE

- OE

- OE

C

P 0 V

*

MT V R

1 5

1

V S S

1 4

4

C1 0 5

P 0 V

Q1 1

1 1

A 2

2 8

- CA S

GND

1 2

A 1

H M5 1 4 4 0 0

3

RS B

- P GM

A 0

CC1 0 4

( 1 9 7 0 MC )

H M5 1 4 4 0 0

2 3

GND

1 6

- OE

1 4

V S A

V S B

2 4

GND

C9 3

CC1 0 4

V MM

GND

- CE

+ 2 6 V

+ 5 V

- RA S

2 3

C1 0 6

CC3 3 2 B

D

R MR D

V P P

V CC

C

NC

V CC

2 1

MM1

NC

V MM

2 2

2 7

1 5 A

2 2

DA 9

1 4 D

C9 1

R OMC

3

# 4

CC1 0 4

1 5 A

3 1

R1 1 3

1

MOD E L = 0

+ 5 B

OUT

GND

B

S T D

2

5

*

DA 1

1 S S 3 7 8

B A T

3

P D2 7 C2 0 0 1 B - 1 5

+ 5 V

4 . 7 k

3

DA 0

9

DA 1

1 0

DA 2

1 1

DA 3

1 2

A 0

DA 4

1 4

DA 5

1 5

DA 6

1 6

DA 7

1 7

DA 8

1 8

DA 9

5

1

D0

DA 0

9

2

D1

DA 1

1 0

2 4

D2

DA 2

1 1

2 5

D3

DA 3

1 2

DQ1

A 1

DQ2

A 2

DQ3

A 3

DQ4

A 4

A 5

A 6

A 7

A 8

A 9

A 0

DA 4

1 4

DA 5

1 5

DA 6

1 6

DA 7

1 7

DA 8

1 8

DA 9

5

1

D4

DA 0

1 0

2

D5

DA 1

1 1

2 4

D6

DA 2

1 2

2 5

D7

DA 3

1 3

DQ1

A 1

DQ2

A 2

DQ3

A 3

DQ4

A 4

A 5

A 6

A 7

A 8

A 9

A 0

DA 4

1 6

DA 5

1 7

DA 6

1 8

DA 7

1 9

DA 8

2 0

DA 9

9

2

D0

3

D1

4

D2

5

D3

DQ1

A 1

DQ2

A 2

DQ3

A 3

DQ4

A 4

DQ5

A 5

DQ6

A 6

DQ7

A 7

DQ8

2 4

D4

2 5

D5

2 6

D6

2 7

D7

A 8

A 9

1 5 D

1 4 D

A

DA B US

E

1 4 E

E

DB A S

P 0 V

S OL

+ 2 6 V

:

1

7

Q2

D3

DT D1 1 3 Z K

1 S S 1 2 0

2

S OL

1 5 D

P 1 3

B 2 B - P H

F

B L UE

F

GND

1

2

3

4

5

6

7

8

Main PCB Circuit Diagram 2/5

1 Connector for the power supply PCB which supplies 25V and 8V.

2 3-terminal regulator which eliminates unstabilized components of the +8V source to

generate stabilized +5V source.

3 Connector for the Ni-MH battery which supplies approx. 5V.

(Provided on the FAX1570MC/1030/MFC1870MC/1970MC)

4 3-terminal regulator which generates +5B source from +8V to back up the DRAM

(that stores received data).

(Provided on the FAX1570MC/1030/MFC1870MC/1970MC)

5 Connector for the motor

6 Motor driver

7 Connector for the clutch solenoid (that switches the power transmission).

8 E2PROM (32-kilobit for the FAX1570MC/1030/MFC1970MC, 16-kilobit for other models.)

9 ROM (2-megabit. Note that the qualification machines for demonstration have a 4megabit ROM.)

: DRAMs (1-megabyte, two 4-megabit chips) provided on the FAX1570MC/1030/

MFC1970MC.

A DRAM (512-kilobyte) provided on the MFC1870MC. The FAX1170/1270/1010/1020/

MFC1770 has its equivalent DRAM on location #7.

III – 22

1

2

3

4

5

R5 V

CI S

1 -1

1 -2

1 -3

6

7

8

+ 5 V

A

A

1

+ 2 6 V

2

R5 V

R5 V

R9 7

4 7 0

R9 8

2 7 0

3

4

RB

1 2 E

T G

1 2 E

3 -2

R1 2 3

Q8

3 0 0

2 S C3 0 5 2

L I GT

R0 V

1 1 C

R5 V

GND

1 -7

0

1 W

6

R0 V

3 0

C1 0 0

C1 0 2

*

CC1 0 4

# 1 0

4 2

3 8

3 9

7

4 0

4 1

C8

P 9

1 6 V / 1 0

3 7

B 7 B - P H

V I D

K RC1 0 7 S

R1 0 2

1 0 K

R1 0 3

C7

C8 1

1 6 v

CC1 0 4

3 5

V DD

V DD

A T A P

A DRE F L

DGND

DGND

P ORT 0

DGND

P ORT 1

DGND

P ORT 3

A V DD

C1 0 1

S D/ P D7

P D5

P D3

R5 V

3 6

4 6

R0 V

A GND

P D2

A GND

P D1

T RI G

DA CK

I CL K

DRE Q

R1 0 0

P D0

2 . 2 K

Q7

1 2 E

2 S C3 0 5 2

1 2 E

C P WM

R9 9

T G

S MC

1 5 D

1 2 E

2 2 K

E 1 CS

1 5 D S RA M

I ORQ

C8 0

R1 0 1

CC1 0 4

1 -6

1 0 K

2

D

9

R1 0 7

+ 5 V

3 3 K F

CP 3 I

1 2 F

1 0

R1 0 8

1 0 0 K F

1 6 D

2 7

2 3

2 2

2 1

1 4 A

+ 5 V

2 8

MR E Q

WR

RB US

T M

2 9

RD

CK 1 6

1 6 B

R0 V

R0 V

3 1

3 0

RS T L

2 5

3 2

A 0

2 0

A 1

1 9

A 2

1 8

A 3

1 6

A 4

1 5

A 5

1 4

A 6

1 3

A 7

1 2

A 8

1 1

1 0

RS E N

4

3

3 -1

C1 1 2

*

+ 5 V

C1 0 3

CC1 0 2 B

B 5 B - P H

B

B L A CK

5 6

9

1 7

+ 5 V

2 6

C9 8

C9 9

4 9

CC1 0 4

CC1 0 4

6 4

4 -1

I OCS

MT P

4 7

GND

4 8

P H2

R1 2 6

S G- 1 0 5 F 3 0 8

1 0 0 K

RE A R

1 2 D

5 0

5 1

5 2

RDA T

1 2 E

5 3

GND

5 4

C

5 5

5 7

5 8

5 9

GND

+ 5 V

MC S

I OE

ME

S A MP

RD

RS

WR

S H

CL K I N

CL K 1

RE S E T

CL K 2

3 3

4 -2

6 2

6 3

6 1

P H1

R1 2 4

S G- 1 0 5 F 3 0 8

1 0 0 K

F RNT

1 2 D

6 0

A 0

A 1

D0

A 2

D1

A 3

D2

A 4

D3

A 5

D4

A 6

D5

A 7

D6

A 8

D7

8

D0

7

D1

6

D2

5

D3

4

D4

3

D5

2

D6

1

D7

A B US

GND

Q1 3

D

K RC1 0 7 S

1 2 E

DB US

S E ON

1 4 E

4

1 1

R1 0 9

C1 0 9

P 1

C1 0 4

CC1 0 2 B

GND

2 4

P ORT 2

P D4

CC1 0 4

R0 V

2

1 2 D

T E MP

P D6

4 3

R5 V

2 S K 1 3 9 9

C

RS T L

A I N

R0 V

R5 V

Q9

4 4

3 4

1 5 D

V DD

DGND

4 5

1 0

1 K

C L MP

R0 V

RS T H

1 2 E

1 -5

Q1 0

5

F S E N

1

L C8 2 1 0 2 W

R0 V

GND

1

R1 2 8

1 0 0 K

1 2 D

R1 2 1

R3

B

R1 2 9

1 0 0 K

2 0 0

C8 2

CC1 0 4

S E NS OR

+ 2 6 V

R1 2 2

1 -4

Q1

2 S D1 8 5 8

5

2 -1

2 -2

3

+ 5 V

GND

1 0 K F

CC1 0 2

GND

2 -3

2 -4

2 -3

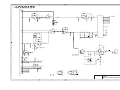

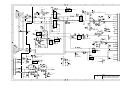

6

8

R1 0 6

1 0 0

R1 0 4

2 0 0

7

2

E

3

6

C8 9

C8 4

C8 8

C8 5

CC1 0 1

CC1 0 1

CC1 0 1

CC1 0 1

S T 2

1 2 D

DOUT

1 2 E

DI N

1 2 E

HDC

1 2 D

S T 1

1 2 D

3 3 F

HRL Y

4 2 E

C ML L

1

P WO N

1 5 D

C ML H

1 5 B

E

4

3

2

# 1 3

U MG5 N

GND

GND

1

2 -5

5

4

L A T C

1 5 C

HRL Y

3 6 E

RI B ON

P 5

C8 3

C8 7

C8 6

R1 0 5

*

*

*

1 0 K

1 2 D

B 1 1 B - P H

F

F

GND

1

2

3

4

5

6

7

8

Main PCB Circuit Diagram 3/5

1 Connector for the CIS

1-1:

1-2:

1-3:

1-4

1-5:

1-6:

1-7

Power for the CIS LED array

Clock output

Trigger signal output. One shot of this signal triggers a line of scan.

LED control signal output circuit which controls the intensity of the CIS LED array.

Input of video data (VID) to the FAX engine

Clamp circuitry that gives the bias level to the amplifier of the VID input circuit according to

the CLMP and CPWM signals issued by the CPU (that monitors the current video data

input) for compensating the DC component of video signals for the next scan line.

Working with the FAX engine, this circuitry carries out the standard scanning. (This

circuitry is provided on the FAX1170/1270/1010/1020/MFC1770/1870MC.)

SANYO LSI that carries out the high-quality scanning. (Provided on the FAX1570MC/1030/

MFC1970MC)

2 Connector for the thermal recording head

2-1:

2-2:

2-3:

2-4:

2-5:

Power 5V for the thermal recording head

Thermister signals which are normalized by the resistor network and fed to the FAX engine

Strobe signals

Data signals

Ribbon sensor signal

3 Connector for the sensor PCB

3-1: Paper-edge sensor signal

3-2: Paper ejection sensor signal

4 Document front and rear sensor circuitry that is active only while the SEON signal is on.

4-1:PH2, document rear sensor

4-2:PH1, document front sensor

III – 23

1

2

3

1

A

C2 0

CC6 8 1

R2 3

5 6 K

4

5

6

2 -1

T E L L

4

1 5 C

7

5

R2 6

7 5 K

C2 5

CC2 2 1

R6 5

CNT

R3 1

C2 7

1 0 K

1 3

CC1 0 4

1 5

0

2

CT S L

C

S L

5 3 B

R2 1

1 0 K

# 1 9

1 2

3

D P D MC K

T X OUT

D P D MD T

5

R3 3

4 0 5 3

+ 5 V

+

# 1 8

5 6 K

5 6 K

7

1

1 . 5 K

C4 9

+

+ 2 6 V

K I 3 2 4

R2 2

R3 0

# 1 8

4 . 7 K

I 3 2 4

A P D MC K

CC1 0 2 B

A P D MD T

A RE F

R2 0

1 / 1 0 W

R2 9

6

-

1

1 4

9

A

# 1 5

T C3 5 1 3 3 F

1 0

NCU

8

*

C3

1 K

A RE F

M0 V

M0 V

C4

D8

C5

C2 3

*

*

MU T E

C ML H

1 5 C

M0 V

T A DH

1 1

1 3

RL 2

1 2

1 4

2

0

C

C5 7

R7 1

CC1 0 4

2 7 K

9

A MK

1 0

A MT

1 1

V DD

2

-

C3

1 2

C4

1 3

C5

5

MU T

8

RS T L

1 5

1 4 A

1

B

RX I NA

3

4 0 5 3

5 3 B

1 4 D

CC1 0 4

1 K

# 1 7

1

2 -2

R6 3

1

4 0 5 3

T B US

C4 5

1 5

1

# 1 9

0

- P D

4 3 K

D MT

+ 5 V

CNT

1

C

7

R2 8

D MK

7

1 0

CNT

RL 1

6

B

1 2 C

6

+

C4 7

R7 4

# 1 8

R2 7

R6 2

1 0 0 K

K I 3 2 4

4 . 7 K

1 0 0 K

6

A RE F

CT S L

MOV

C4 4

CC1 0 4

CC2 2 1

1 6

2

D2

C4 6

HZ S 5 C

CC1 0 3 B

C9

RX I NB

V S S

V B I A S

V S S

4

1 4

C4 8

1 6 V 1 0

MOV

CC1 0 4

A RE F

C

5

T L S L

D4

*

R1 3

0

R1 8

0

D5

*

D7

M0 V

1 S S 1 2 0

7

5 1 B , 5 3 B

D6

1 S S 1 2 0

C2 1

CC6 8 1

C

+ 9 V

R2 4

R1 5

1 5 0 K

R2 5

9

1 . 5 K

2 0 0 K

-

T L RL

5 3 A

8

C2 2

1

CC1 0 3 B

1 0

C1 1 1

+

CC1 0 4

R1 6

R1 4

# 1 8

0

4 . 7 K

K I 3 2 4

A RE F

R1 9

R1 7

M0 V

CT RL

*

DA RE C

*

D

1 1 C

T X S L

1 2 C

HA F H

1 1

Q4

Q3

*

K RC1 0 7 S

A RE F

R7 2

1 . 5 K

R7 3

1 . 5 K

1

OT O

R1 2

5

4

3

4 0 5 3

M0 V

1 5 C

M0 V

+ 5 V

C1 1 0

CC1 0 4

1 1

E

GND

1 2

+ 2 6 V

+ 2 6 V

D9

1 S S 1 2 0

R5

1 K

3

P L S

8

1 3

1 5 C

C ML L

RDP S

1

+

8

2

4

R3 5

R1 1 5

C9 2

1 2 K

3 3 K

CC1 0 3 B

R8 9

R3 2

3 . 3 K

1 0 0 K

1 0

1

4 0 5 3

3 -2

: -1

: -2

: -3

1 0 V 1 0 0

5

# 1 9

0

4 0 5 3

1 . 5 K

HF RL

C2

7

-

3

4

5

# 1 7

1

R7 5

5 5 D

RNGO

1 5 B

V OL 1

1 5 E

V OL 2

D

S P

6

2

CC1 0 5 ( 2 1 2 5 CHI P )

C

9

8

1 5 C

C2 8

1

3

CC1 0 4

# 2

N J M3 8 6 M

RNGL

CNT

0

C

3 -1

1 5 C

1 0 0 K

1 4

# 1 7

GND

9

CNT

C

1 2

0

C1 9

1 2 C

9

CNT

1 3

2 -3

5 1 A , 5 3 B

R3 4

P 4

1 K

3 0 0

WH I T E

M0 V

Q5

GND

B 2 B - P H

R3 6

GND

D1 0

:

K RC1 0 7 S

1 S S 1 2 0

R1 3 4

1 K

1 5 C

E

C1 1 3

V OL 3

1 6 V 1 0

( 5 mm)

3 6 E

M0 V

1 5 C

1 2 D

S P ON

GND

+ 5 V

1 4

E A T

1 6

A DL C

1 5 B

1 5 B

1 7

DA S T

1 1 D

1 8

DA S ND

1 1 C

R6

R3 7

R4

2 2 K

2 2 K

1 K

+ 5 V

+ 5 V

2

T L OF

1 5

CI

+ 2 6 v

1 5 C

T L OF 2

4

1 2 D

1 6

1 5 C

F

1 6

# 1 9

C2 6

4 0 5 3

CC1 0 4

4

# 1 7

C5 6

# 1 8

4 0 5 3

CC1 0 4

K I 3 2 4

C2 4

6

CC1 0 3 B

7

8

6

7

8

F

5 0 V

C1 1

C1 2

P 1 0

CC1 0 4

3 5 V 1 0

1 1

I MS A - 9 1 1 0 S - 1 8 L

GND

1

2

GND

M0 V

M0 V

M0 V

3

4

M0 V

5

6

7

8

Main PCB Circuit Diagram 4/5

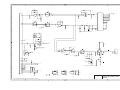

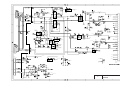

1 Connector for the NCU

2 Analog signal selectors

2-1: Selects either input signals from the handset or those from the MODEM.

2-2: Selects either RL1 or RL2 signals inputted from the communications network.

2-3: Selects either sound signals (e.g., alarm beeps, key clicks and ringer sounds)

generated by the FAX engine or signals selected by 2-2.

3 Voice switching analog selectors

3-1: Switches between the output line and input line for monitoring. When

switched to the output line, this selector allows FAX sending operation to be

monitored; when switched to the input line, it allows received voices to be

monitored.

3-2: Selects either voice signals inputted from the communications network or recorded voice signals inputted from the microphone or handset through the

MODEM.

4 Amplifier circuit for signals outputted from the MODEM.

5 Analog front end IC which processes the analog I/O signals from/to the MODEM.

6 Amplifier & shaper circuit for signals inputted from the communications network.

7 Telephone circuit for transmitting signals.

8 Speaker amplifier circuit which amplifies sounds issued from the above analog signal

selector 2-3 and feeds them to the speaker.

III – 24

9 Connector for the speaker

: Speaker volume control circuit

:-1: VOL1

OFF

ON

ON

:-2: VOL2

OFF

OFF

ON

:-3: VOL3

OFF

OFF

ON

Speaker volume

High

Medium

Low

III – 25

(ON: Closed OFF: Opened)

1

2

3

4

5

6

7

8

A

A

B

B

C

C

3

R5 5

7 5 K

C3 5

CC2 2 1

# 1 6

T C3 5 1 3 3 F

R5 6

R4 8

6

5 6 K

5 6 K

3

-

T X OUT

D P D MC K

7

4 4 D

D

HF RL

D P D MD T

5

C3 6

+

R4 7

4 . 7 K

B A 1 0 3 5 8 F

A P D MC K

CC1 0 2 B

# 1 4

A P D MD T

HRE F

C3

C3 7

2

6 8 1 B

+ 5 V

R5 7

1 0 0 K

R5 3

MI C

R4 3

RL 1

1 0 K

C3 1

R4 4

CC1 0 4

8 . 2 K

HRE F

M0 V

C4

C5

MU T E

- P D

*

5 1 B , 5 3 B

T B US

1 4 D

D

A MK

1 0

A A MD

1 1

C0

1 2

C1

1 3

C2

5

A MU T

8

RS T L

V DD

1 4 A

1

CC1 0 4

1

1 5

RX I NA

3

RL 2

+

R4 6

C3 2

R4 5

CC1 0 4

8 . 2 K

1 0 K

B 2 B - P H

C5 4

# 1 4

R5 8

R6 9

B A 1 0 3 5 8 F

4 . 7 K

1 0 0 K

C5 3

CC1 0 4

CC2 2 1

1 6

C3 3

R5 4

CC6 8 1 B

1 0 0 K

2

RE D

C1 0

MOV

1

A D MD

9

C5 2

2

7

P 1 2

D MK

7

+ 5 V

T L S L

6

E

6

RX I NB

V S S

V B I A S

V S S

C5 5

1 6 V 1 0

E

4

1 4

MOV

CC1 0 4

MOV

HRE F

HRE F

M0 V

+ 5 V

+ 5 V

1 6

F

8

# 1 1

C2 9

# 1 4

4 0 5 3

CC1 0 4

B A 1 0 3 5 8 F

6

7

8

C3 4

1

2

3

F

CC1 0 4

4

M0 V

M0 V

4

5

6

7

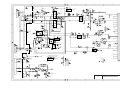

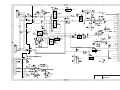

Main PCB Circuit Diagram 5/5

1 Connector for the microphone