Download Miller MTT-2512WV Specifications

Transcript

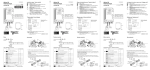

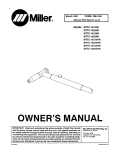

March 1988 FORM: OM-1562 Effective With Millerfi OWNERS MODEL MTT-251 2W MTT-2525W MTT-251 2WV MTT-2525WV MANUAL Read and understand the entire contents of both this IMPORTANT: manual and the power source manual used with this unit, with special emphasis on the safety material throughout both manuals, before in- stalling, operating, instructions safe are operation not maintaining this equipment. This unit and these only by persons trained and experienced in the welding equipment. Do not allow untrained persons to for of install, operate, or or Style No. JJ-20 use Miller Electric Mfg.Co. C~r~o~ ~o. Box 1079 Applelon, WI 54912 USA Tel. 414-734-9821 maintain this unit. Contact your distributor if you do fully understand these instructions. PRINTED IN U.S.A. ADDITION COPY PRICE 35 CENTS EFFECTIVE: FEBRUARY 16, 1988 This warranty supersedes all previous LIMITED WARRANTY hereof, Miller Electric - tions warrants to MILLER warranties and is exclusive with Subject to the terms Mfg. Co., Appleton, its Distributor/Dealer that all new and condiWisconsin and unused Equipment furnished by Miller is free from defect in workmanship and material as of the time and place of delivery by Miller. No warranty is made by Miller with respect to engines, trade accessories or other items manufactured by others. Such engines, trade accessories and other items are sold subject to the warranties of their respective manufacturers, if any All engines are warranted by their manufacturer for one year from date of original purchase, except Tecumseh engines which . Œ~ have ~ a two year warranty, as specified below, Millers warranty does not apply components having normal useful life of less than one (1) year, such as spot welder tips, relay and contactor points, MILLERMATIC parts that come in contact with the welding Except no other guarantees or warranties expressed or implied. In the case of Millers breach of warranty or any other duty with respect to the quality of any goods, the exclusive remedies therefore shall be, at Millers option (1) repair or (2) replacement or, where authorized in wTiting by Miller in appropriate cases, (3) the reasonable cost of repair or replacement at an authorized Miller service station or (4) payment of or credit for the purchase price (less reasonable depreciation based upon actual-use) upon ,~t and expense. MILLERs return of the goods as Customers option of repair or replacen~itt wit) be F.O.B., Factory,. at Appleton, Wisconsin, or F.O.B., at a MILLER authorized ~ice facility, therefore, no compensation for trarispo.latior. costs of any kind will be allowed. Upon receipt of notice of apparent defect or failure, Miller shall instruct the claimant on the warranty claim procedures to be followed. to wire ~ including not result nozzles and nozzle insulators where failure does from detect in workmanship or required to honor warranty claims on warEquipment in the event of failure resulting from a detect within the following periods from the date of delivery of Equipment to the original user: ranted k4 1. Arc welders, p~r sources, robots, and components 2. Load banks 3. ~ Original main power rectifiers (labor 1 year 4. All 4~ - ~ ~,j 7. Batteries 1 yser 1 year or days 1 year repair parts, exclusive of labor 60 days 6 months As matter of a general policy only, submitted by the original Miller may honor claims within the user WRITING, AS EXPRESSLY PROVIDED ARE MILLER PRODUCTS PURCHASE BY COMMERCIAL/INDUSTRIAL USERS AND FOR OPERATION BY PERSONS TRAINED AND ULTIMATE THE USE AND MAINTENANCE OF EXPERIENCED IN WELDING EQUIPMENT AND NOT FOR CONSUMERS OR CONSUMER USE. MILLERS WARRANTIES DO NOT EXTEND TO, AND NO RESELLER IS AUTHORIZED TO EXTEND MILLERS WARRANTiES TO, ANY CONSUMER. foregoing periods. - . , . ,.. BY MILLER IN INTENDED FOR .. of the date of such failure. !j~ fl CLUDED AND DISCLAIMED BY MILLER. EXCEPT 90 provided that Miller is notified in writing within thirty (30) days ~ AS 3 years 5. All other Millermatic Feeders Replacement . only) welding guns, feeder/guns and torches 6. WARRANTY, GUARANTY OR REPRESENTA TO PERFORMANCE, AND ANY REMEDY FOR BREACH OF CONTRACT WHICH, BUT FOR THIS PROVISION, MIGHT ARISE BY IMPLICATION, OPERATION OF LAW, CUSTOM OF TRADE OR COURSE OF DEALING, INCLUDING ANY IMPUED WARRANTY OF MERCHANTABIUTY OR OF FITNESS FOR PARTICULAR PURPOSE, WITH RESPECT TO ANY AND ALL EQUIPMENT FURNISHED BY MILLER IS EX TION material. Miller shall be ~f ~ ANY EXPRESS WARRANTY NOT PROVIDED HEREIN AND ANY IMPLIED ... . SECTION 1 - UNSAFE PROCEDURES OR PRAC- WARNING SAFETY RULES 1 3. - PROTECT EYES AND SKIN FROM ARC _________ serious personal injury or death. Read, understand, and follow ALL of these safety rules before installing, operating, or servicing this TICES can cause equipment. Be sure that all end users of this equipment, the RAYS; PROTECT EARS FROM NOISE Arc rays from the welding process produce intense heat and strong ultraviolet rays that can burn eyes and skin. Noise from some processes damage hearing. can operator and helpers, read and understand these safety ru/es. 1 a welding helmet fitted with a proper filter lens (see ANSI Z49.1 for detailed information). a. Wear b. Use 1. PREVENT ELECTRIC SHOCK - Touching live electrical parts can cause severe burns to the body or fatal shock. Severity of electrical shock is determined by the path and amount of current through the protective a. Do not touch live electrical parts. b. Do not work in wet c. Wear d. glare. protective clothing and foot protection. c. Wear d. Always or damp work 1 areas. dry insulating gloves and body protection. installing Disconnect all power before ing this equipment. when not in Turn off all f. Properly install and ground the welding power Manual and all source according to its Owners applicable codes. Do not that h. i. j. are equipment use worn or too small or Do not touch electrode and any or circuit at the same time. or a arc sparks other hot metal, equipment, can cause fires and burns. a. Wear correct eye, face, and body protection in the work area. b. Allow work and equipment to cool before handl ing. body. combustible material. c. Do not weld d. Watch for fire, and keep e. near a fire extinguisher near For additional information, refer to NFPA Stan dard 51 B, Fire Prevention in Use of Cutting and Welding Processes, grounded object available from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. or 1 PROTECTION safety goggles in by. only well-maintained equipment. Repair replace damaged parts at once. PROVIDE AND GASES or 4. PREVENT FIRES AND BURNS - The hot workpiece, hot cables Use 2. safety glasses use. damaged cables poorly spliced. Do not wrap cables around your wear area. servic or e. g. - barriers to protect or body. Therefore: spatter, and 1 screens others from flash and FROM 5. PROTECT COMPRESSED GAS CYLINDERS - FUMES Since gas cylinders are normally part of the welding carefully. pro cess, be sure to treat them Breathing welding fumes and gases be hazardous can to your health. a. Protect compressed gas cylinders from excessive heat, mechanical shocks, and a. Keep b. Use b. adequate ventilation in the work keep fumes and gases from and the general work your area breathing If ventilation breathing is zone or area. inadequate, use an approved Keep cylinders away from any welding or other electrical circuits. device. d. d. secure cylinders so that they cannot tip over by fastening them to a mounting bracket, wall, or other stationary support. Install and fall to c. c. arcs. your head out of the fumes. Read the Material Safety Data Sheets (MSDSs) instructions for any and the manufacturers Never allow a welding electrode to touch any cylinder. materials used. OM-1562 Page 1 1 6. PROVIDE SITUATIONS PROTECTION - FOR SPECIAL 1 -8. ADDITIONAL SAFETY INFORMATION For a. Do not weld or cut containers or materials which have held or been in contact with hazardous substances unless they are properly cleaned and inspected. information on safe practices for setting up operating electric welding and cutting equipment and on good working habits, ask your welding equip ment supplier. The following publications, which are available from the American Welding Society, 550 more and N.W. LeJuene Rd., Miami, FL 33126, b. Do not weld or cut painted or plated parts unless special ventilation is provided to remove highly toxic fumes or gases. are recommend ed to you: a. Safety in Welding and Cutting - AWS Z49.1 (ANSI) c. Since welding pacemaker affect pacemakers, keep all of the work area. Have doctor before coming near a can wearers out them consult a b. Recommended Safe Practices for Gas-Shielded AWS A6.1 Arc Welding - welding operation. c. PROVIDE MAINTENANCE 1 -7. Improperly work, but or death PROPER EQUIPMENT - maintained equipment can result in poor importantly it can cause physical injury most through fires Recommended Safe Practices for the Prepara tion for Welding and Cutting of Containers and Piping That Have Held Hazardous Substances AWS F4.1 d. NFPA Standard 51 B, Fire Cutting electrical shock. Therefore: or and Prevention in Use of Welding Processes, available from Fire Protection Association, Bat terymarch Park, Quincy, MA 02269. the- National a. Always have qualified personnel perform the in stallation, troubleshooting, and maintenance perform any electrical work unless fully qualified. work. Do not you are e. NFPA Standard 70, National Electrical Code, available from the National Fire Protection Association, Batterymarch Park, Quincy, MA b. Before performing power supply, form the electrical power a c. 02269. any maintenance work inside disconnect the power supply source. f. ANSI Standard Z87.1, Safe Practice for Oc cupation and Educational Eye and Face Protec tion, available from the American National Standards Institute, 1430 Broadway, New York, NY 10018. g. OSHA Standard 29 CFR, Part 1910, Subpart Q, Welding, Cutting, and Brazing, available from the Superintendent of Documents, U.S. Govern Maintain cables, grounding wire, connections, power cord, and power supply in safe working order. Do not operate any equipment in ques tionable condition. d. Do not abuse any equipment accessories. Keep equipment away from heat sources such as furnaces, wet conditions such as water puddles, oil or grease, corrosive atmospheres, and incle ment weather. or ment h. Printing Office, Washington, DC 20402. CSA Standard W117.2, Code Welding e. Keep all safety devices, guards, panels, and covers in position and in good repair. f. Use equipment for its intended modify it in any manner. OM-1 562 Page 2 purpose. Do not and Cutting, for Safety in available from the Cana dian Standards Association, 178 Rexdale Blvd., Rexdale, Ontario, Canada M9W 1 R3. i. See also the Standards Booklet Index in the welding power source Owners Manual. SECTION 2 - INTRODUCTION Ampere Rating at Tungsten 100% Duty Cycle Size Cable Torch Cooling DCEN; ACHF Capacity Length Body Method Model .020 thru 1/8 in. 250 Amperes With Argon MTT2525W 12.5 ft. (190.5 mm) (3.8 m) Handle Diameter: 25 ft. (7.6 ml MTT2525WV Figure 2 - 1. 1. DUTY CYCLE The duty cycle of a welding torch is the percentage of a ten minute period that a torch can be operated at a given load. This torch is rated at 100% duty cycle using argon shielding gas. This means that the torch can be operated at rated load con 2 - - ditions Water 0.75 in. (19.0 mm) (0.5 thru 3.2 mm) continuously. Weight Net S h I p 7.5 in. Length: MTT2512W MTT2512WV Coolant Flow Rate 2.5 Weight: 1 1.5 lbs. (0.7 kg) 2 lbs. (0.9 kg) 2.5 lbs. (1.1 kg) 3 lbs. (1.4 kg) qt/min (0.94 1/mm oz. (70.9 g) Specifications statements include I~Ii1 : II ~ and maintenance procedures carefully followed could result or in installation, operation, practices which if not serious personal injury loss of life. or THE RATED CAUTION statements include installation, operation, and maintenance procedures or practices which if not carefully followed could result in minor personal injury result in damage or ____________ ~ EXCEEDING AMPERAGE and duty cycle can damage to this equipment. to the torch. Do not exceed rated amperage and stated in Figure 2-1. S duty cycle signal word, IMPORTANT highlights instruc tions which need special emphasis to obtain the most efficient operation of this equipment. A third 2 -2. GENERAL INFORMATION AND SAFETY RECEIVING-HANDLING Before installing equipment, clean all packing material from around the unit, and carefully inspect for any damage that may have occurred during shipment. Any claims for loss or damage that may have occurred in transit must be filed by the purchaser with the carrier. A copy of the bill of lading will be furnished by the manufacturer on re 2 A. General Information 3. - - this presented in this manual and on various labels, tags, and plates on the unit pertains to equip ment design, installation, operation, maintenance, and troubleshooting which should be read, understood, and followed for the safe and effective use of this equip- quest if occasion to file claim arises. ment. When B. The Safety installation, operation, maintenance, and troubleshooting of arc welding equipment requires practices and procedures which ensure personal safety and the safety of others. Therefore, this equipment is to be installed, operated, and maintained only by qualified persons in accordance with this manual and all ap plicable codes such as, but not limited to, those listed at the end of Section 1 requesting information concerning this equip ment, it is essential that Model Description and Style - Safety Rules. 2 different levels of hazard. with the Gas cess. The - This torch is specifically for Arc Welding (GTAW) pro Tungsten alphanumeric model designation refers to the following: M T Safety instructions specifically pertaining to this unit ap pear throughout this manual highlighted by the signal words WARNING and CAUTION which identify on a 4. DESCRIPTION - use be supplied. The style label under the torch handle. equipment Numbers of the number is located T - 25 TIG/GTAW Torch Ampere Rating: 250 Amperes - 12 25 W V Miller - - - - - - 12.5 ft. (3.8 m) Cable 25 ft. (7.6 m) Cable Water-Cooled Gas Valve OM-1562 Page 3 SECTION 3 - INSTALLATION Medium 0-ring Backcap ~ Gas Valve (If Applicable) Heat Shield ~ 0-ring Hose left-hand threaded Consumables and Accessories from Welding Equipment Supplier Required Obtain coolant TA-120 502 fittings Power Cable/Coolant-Out Hose Figure 3 ELECTRIC SHOCK can - 1. Torch kill. Components CAUTION OVERHEATING Gas Tungsten Arc _________ Do not touch five electrical parts. Shut down welding power source and disconnect Welding (GTAW) torch can damage torch. If using recirculating coolant system, do not make pro connections from the coolant system to water valve; instead, make connections directly from the Lockout/tagging procedures consist of padlocking line disconnect switch in open position, removing fuses from fuse box, or shutting off and red-tagging circuit breaker or other disconnecting device. coolant system to torch hoses. If receptacle is available on power source, connect coolant supply/pump power cord to power source input power employing cedures 3 - before lockout/tagging installing 1. TORCH BODY torch. The torch body consumables and accessories in (Figure 3-1) dicated in 1. Install collet body into torch body making place. Install cup onto collet The coolant-in hose has hand 4. 5. 5/8-18 male, notched, left- To install coolant hose, connect coolant-in hose supply outlet (Figures 3-2 and 3-3). sure B. fitting body. Power Cable/Coolant-Out Hose The power cable/coolant-out hose has left-hand 3. a fitting (Figure 3-1). to coolant heat shield is in 2. Coolant-In Hose A. - shipped requiring Figure 3-1: cup, collet body, collet, power cable adapter, and tungsten electrode. Assemble torch body as follows: is receptacle. Remove backcap and install collet, slotted end first, through back of torch body into collet body. Loosely install backcap and 0-ring (supplied backcap) onto torch body. on properly prepared tungsten electrode (see Section 5-4) through front of collet body to posi tion electrode tip outside cup rim. Securely Install tighten backcap. a general rule, electrode extension equal electrode diameter; exact electrode exten 7/8-14 male, Install coolant-out/power hose fitting into power cable adapter. Connect a suitable length of coolant hose (not supplied) from power cable adapter to coolant supply return fitting. 3 -3. COOLANT REQUIREMENTS Where coolant freezing conditions may be encountered, mix according to the manufacturers recommenda tions for the ambient temperature encountered. CAUTION To readjust electrode, loosen backcap. a fitting (Figure 3-1). INCORRECT COOLANT LEVEL can _________ damage coolant system and torch. Maintain correct coolant level at all times. IMPORTANT As should sion may vary according to application. 3 -2. COOLANT HOSES (Figures 3-1, 3-2, and 3-3) OM-1562 Page 4 AND CONNECTIONS This torch is rated at a 1 qt./min (0.94 1/mm) coolant flow rate. Changes in flow rate may effect operating temperature of torch. Maintain proper flow rate at all times. Regulator! Flowmeter Recirculating Coolant Supply Work Clamp Gas TA-120 503 Figure 3 - 2. GTAW Torch Connection Diagram For Models With Gas Valve Regulator/Flowmeter Torch Work Ciamp TA120 Figure 3 3 -4. GAS VALVE (If A. HOSE - 3. GTAW Torch Connection CONNECTIONS AND GAS applicable) (Figures 3-1. 3-2, and 3-3) Diagram For Models Without Gas Valve The gas valve allows gas flow control at the torch. A one-half turn counterclockwise opens the gas valve, and a one-half turn clockwise closes the valve. Gas Hose And Connection The gas hose has The gas valve allows control of gas postflow time, or length of time gas flows after the arc is extinguish the a 5/8-18 male, right-hand fitting (Figure 3-1). If torch includes a gas valve, connect gas hose fitting to regulator/flowmeter outlet (Figure 3-2). An extra hose may be required to make connection. If torch is without gas valve, connect gas hose fitting to gas valve outlet. Connect gas hose (extra hose not sup plied) from gas valve inlet to regulator/flowmeter (Figure 3-3). ed. Insufficient gas postflow results in Torch Gas Valve oxidized IMPORTANT As a general rule, allow 10 seconds of gas postflow time per 100 amperes of weld current before closing valve. 3 - CABLE ADAPTER CONNECTION and 3-3) The power cable adapter 5/8-18 and 7/8-14 female, notched, left- 5. POWER (Figures 3-1, 3-2, Operation (If Applicable) an (black) electrode surface. If an oxidized electrode were used, the black surface would contaminate the weld and cause poor arc direction. has both B. 603 hand a - fitting (Figure 3-1). OM-1 562 PageS Install power cable adapter as follows (Figures 3-2 and 3-3): ELECTRIC SHOCK WARNING kill; MOVING can Lockout/tagging procedures consist of padlocking line disconnect switch in open position, removing fuses from fuse box, or shutting off and red-tagging circuit breaker or other disconnecting device. _________ PARTS can cause serious injury. 1. Install power cable/coolant-out hose fitting into power cable adapter (see Section 3-2). 2. Connect power cable minal. Do not touch five electrical parts. Shut down welding power source and disconnect input power cedures employing lockout/tagging installing torch. pro before SECTION 4 ELECTRIC SHOCK WARNING can all Keep covers and kill. in place operating. health. Ventilate to keep from breathing fumes and gases. If ventilation is inadequate, use approved breathing apparatus. HOT METAL, SPATTER, AND SLAG can cause fire and burns. Watch for fire. use fire ext/n quisher nearby, and know how to it. Allow work and equipment to regulator/flowmeter valve closed, open gas cylinder valve. With 5. Set power 6. Wear dry insulating clothing and gloves and welding helmet with proper filter lens according to ANSI Z49.1. 7. Energize welding 8. Set gas flow to desired level Wear correct eye, ear, and body protection. FUMES AND GASES can seriously harm your a ter while ARC RAYS, SPARKS, AND HOT SURFACES can burn eyes and skin; NOISE can damage hearing. Have output 4. parts. handle to weld SEQUENCE OF OPERATION - _________ Do not touch five electrical adapter source for desired power welding amperage. source. (requires open gas valve). Purge gas hose to c/ear hose of air, any other contaminants. Allow gas to flow 2 to 3 minutes on new torch; 5 to 6 seconds thereafter. Il~Ils]:Ifith~l~ moisture, or cool before handl ing. 9. MAGNETIC FIELDS FROM HIGH CURRENTS affect pacemaker operation. Begin welding. can 4 -2. SHUTTING DOWN Wearers should consult with their doctor before going near arc welding, gouging, or spot welding 1. Stop welding. operations. See Section 1 - Safety Rules for additional safety infor mation. 4 - As a genera/rule, allow 10 seconds of gas post/low time per 100 amperes of weld current before closing valve. 1. GAS TUNGSTEN ARC WELDING (GTAW) 1. Install and connect torch 2. Make sure according to 2. Turn off 3. Turn off the welding power source. Section 3. backcap and all gas connections are their shielding gas and coolant supplies at sources. securely tightened. CONCENTRATION HIGH SHIELDING GAS can harm health or kill. Shut off gas supply when not in use. ~ 3. Turn OM-1562 Page 6 on coolant supply. OF. SECTION 5 - MAINTENANCE INSPECTION AND UPKEEP Usage and shop conditions will determine frequency and type of maintenance required. Perform inspections once a 5 - 1. Disconnect torch from we/ding power source inspecting, maintaining, or servicing. Allow a cooling period before servicing. - before week. Once SHOCK ELECTRIC WARNING can HOT kill; week a inspect condition of torch body com ponents. _________ SURFACES can cause severe burns. Do not touch live electrical parts. Shut down on torch. welding power source before working from welding power source maintaining, or servicing. cooling period before servicing. Disconnect torch before inspecting, Allow 1. 2. a Inspect torch for broken areas, cracks and loose parts; tighten, repair and replace as required. Replace cup, heat shield, backcap, and 0-rings if crack ed. Maintain tight fit of torch components to ensure good weld quality. 5 -3. INSPECTING HOSES. CONNECTIONS AND CABLES ELECTRIC SHOCK can kill. Do not touch live electrical parts. Shut down welding power source and disconnect WARNING _________ Remove grease and dirt from components, and moisture from electrical parts and cables. 5 -2. TORCH BODY MAINTENANCE ELECTRIC WARNING SHOCK can (Figure 3-1) kill; HOT _________ SURFACES can cause severe burns. input power cedures employing lockout/tagging pro inspecting, maintaining, or ser before vicing. Lockout/tagging procedures consist of padlocking line disconnect switch in open position, removing fuses from fuse box, or shutting off and red-tagging circuit breaker or other disconnecting device. Do not touch live electrical parts. Shut down on torch. we/ding power source Table 5 Electrode Diameter Tungsten Pure (Green Band) working before - 1. Once Tungsten Size Amperage Range DC-Argon Negative/ Straight Polarity Electrode a inspect hoses week and connections. Chart - Polarity - Gas T ype DC-Argon Electrode Positive/ Polarity Reverse AC-Argon Using High Frequency .020 5-20 * .040 15-80 * 1/16 3/32 70-150 125-225 10-20 50-100 15-30 100-160 1/8 225-360 25-40 150-210 5-20 10-60 2% Thorium Alloyed Tungsten (Red Band) .020 15-40 * .040 25-85 * 1/16 50-160 10-20 3/32 1/8 135-235 15-30 250-400 25-40 15-35 20-80 50-150 130-250 225-360 Zirconium Alloyed Tungsten (Brown Band) 020 * * 15-35 040 * * 20-80 1/16 * * 3/32 1/8 * 50-150 130-250 * 225-360 *NOT RECOMMENDED figures are intended as a guide and are a composite Welding Society (AWS) and electrode manufacturers. The of recommendations from American OM-1562 Page 7 Coolant-In A. Inspect coolant-in hose for breaks and clogs. Keep tight to prevent coolant leaks. con nections clean and Tungsten electrode shaping should be done on a fine grit, hard abrasive wheel. Since tungsten is harder than most grinding wheels, causing the tungsten to be chip ped away rather than cut away, the grinding marks should run lengthwise with the electrode. Gas B. For additional Gas leaks may result in poor weld quality. Inspect hoses for breaks. Keep connections clean and tight. quest Arc Inspect cables for breaks in insulation, and ensure that all connections are clean and tight. Repair or replace cables if insulation breaks are present. Clean and tighten connections 5 - 4. at PREPARING Welding (GTAW) process. IDEAL Stable Arc.,. Straight each inspection. TUNGSTEN information, see your distributor or re factory on the Gas Tungsten handbook from TUNGSTEN PREPARATION: Power Cable/Coolant-Out C. a Ground Fiat (the Die, of this Fiat Governs ELECTRODES Amperage Capacity) 0 (Figure 5-1) TUNGSTEN PREPARATION: HOT FLYING METAL PARTICLES can injure personnel, start fires, and damage equip ment; TUNGSTEN CONTAMINATION can lower CAUTION WRONG _________ Arc Wander ~ weld quality. Point Shape tungsten electrode only with properly guarded grinder in a safe location wearing proper face, hand, and body protection. Do not use same wheel for any other job or the ____1:::::~~~::::::::::::: RadIal Ground Figure 5 tungsten will become contaminated. - 1. TA-120 630 Tungsten Preparation 9 1 1 17 & 18 22 Figure A OM-1562 Page 8 - Complete Torch Assembly TA-120 502 Item Miller No. Stock No. Figure Miller Model No. Description Quantity Complete Torch Assembly A 1 TUNGSTEN, electrode (consult your welding supply distributor) 2 3 CUP (see Figure B) COLLET BODY (see Figure B) TORCH BODY, W/ heat shield (consisting of) TORCH BODY, wlheat shield & valve (consisting of) VALVE KNOB, wlo-rings (consisting of) ..O-RING 2 4 4 5 6 7 116 223 116 222 116 279 116254 116221 7 300VK 100R 200HS 2GHS 8 9 116 225 200M 9 ti 16 226 9 t116 224 116227 200S 200L 10 200R 12 117585 118 516 116 205 116 206 13 13 116 232 116 233 14 118 512 15 16 116 236 2WN 116 269 116 231 3HF 212PC 18 116 230 116 267 225 PC 212AH 18 19 116 268 225AH 116 269 3HF 2AN 11 11 12 17 17 20 116 266 21 118 512 22 ti 16 228 212TF 225TF 212WH 225WH . 1 1 .HEATSHIELD,std 1 HEATSHIELD,gaslens COLLET (see Figure B) BACK CAP, long (consisting of) BACK CAP, short (consisting of) BACK CAP, medium (consisting of) 1 .0-RING HANDLE 1 1 1 1 1 HANDLE, models w/valve CABLE, Tn-Flex 12-1/2 ft (consisting of) 1 1 CABLE, Tn-Flex 25 ft (consisting of) .WATER HOSE, 12-1 /2ft (consisting of) WATER HOSE, 25 ft (consisting of) HOSE, black 1/8 ID (order by ft as required) . . . WATER NUT HOSE FITTING . . . . . . . 1 1 1 1 POWERCABLE,w/fittingsl2-1/2ft POWER CABLE, wlfittings 25 ft GAS HOSE, 12-1/2 ft (consisting of) GAS HOSE, 25 ft (consisting of) 1 1 1 HOSE FITTING . GAS NUT HOSE, black 1/8 LD (order by ft POWER CABLE ADAPTER . 1 1 . . . 2PCA 1 1 1 . . as required) 1 tOptional Parts BE SURE TO PROVIDE MODEL AND STYLE NUMBER WHEN ORDERING REPLACEMENT PARTS. OM-1562 Page 9 TO REF NC CROS COMPETIV MODEL NO. 13N20 13N21 13N2 13N23 13N24 N/A N/A N/A N/A N/A 13N25 13N26 13N27 13N28 13N29 45V41 45V42 45V43 45V4 45V45 13N14 13N15 13N16 13N17 13N18 13N19 796F70 796F71 796F72 796F73 13N08 13N09 13N10 13N1 13N12 13N13 53N58 53N59 53N60 53N61 NO. COMPETIV MIL ER MODEL 2C20 2C40 2C1 6 2C3 2 2C418 6C20 6C40 6C1 6 6C3 2 6C418 2CB20 2CB40 2CB1 6 2CB3 2 2CB418 2GL20 2GL40 2GL1 6 2GL3 2 2GL418 2C4 2C5 2C6 2C7 2C8 2C10 2C3L 2C4L 2C5L 2C6L 2A4 2A5 2A6 2A7 2A8 2A10 2AG4 2AG5 2AG6 2AG7 NO. MIL ER STOCK 1 6316 1 6317 1 6318 1 6319 1 6320 1 98 1 98 9 1 98 0 1 98 1 1 98 2 1 6321 1 632 1 632 1 6324 1 6325 1 98 7 1 98 1 98 9 1 9 0 907119 1 63 7 1 63 8 1 63 9 1 6340 1 6341 1 6342 1 6326 1 6327 1 6328 1 6329 1 6310 1 631 1 6312 1 631 1 6314 1 6315 1 98 3 894119 1 98 5 1 98 6 With Col et Series S t a n d r 1 62 1 C o l e t Heat Body 20 H5 Stand r Stock Stand r Col et S2CBeries Shield Body INDCATE USAGE 2C No. RSHADE ECOMND AREAS tI~ Rev rse Col et Series With Lens Body Series Heat Shield 6C Chart Col et 120 Lens No. Refrnce 2GHS Gas Stock Gas Col et 2GL Use Body 529 Use Cros Orif ce 1/4 5/16 Cup 3/8 7/16 3/16 1/2 5/8 1/4 5/16 3/8 5/16 1/4 3/8 7/16 1/2 5/8 L1~ 7/16 3/B Parts I 150-325 20-350 2C418 1 6320 6C418 1 98 2 2CB418 1 6325 3/32 (2.4) 10 -235 150-250 2C3 2 1 6319 6C3 2 1 98 1 2CB3 2 1 6324 torch( SELCTOR complet 1/16 (1.6) 50-150 70-150 2C16 16318 6C16 1980 2CB1 1632 PARTS required .040 (1.0) 10-80 15-80 2C40 1 6317 6C40 1 98 9 2CB40 1 632 ad pter .020 )~.5) 5-20 5-20 2C20 1 6316 6C20 1 98 2CB20 1 6321 cable (3.2) 4 16 :. j I ~. to CONSUMABLE power (m ) ACHF DCSP in end cup ModelN. StockN. ModelNo. Stock Mode) StockN. (Note: Diametr Range Tungsten Amperag Body CoIlet(Sandr) Co)let(Rvrs Col et ,fl r :~ .:~ No. No. No. gas body, col(et co(iet. ~ (2C4) (2C5) y (2C8) (2C10) No. (2C4L) No. :1wti: ju~c ~ 2GL418 1 9 01 2GL3 2 1 9 0 2GL1 6 1 98 9 2GL40 1 98 2GL20 1 98 7 (2A4) (2A5l (2A10) 310 311 116 116 315 116 ModelNo. StockN. j Cup Long 0 C e r a m i c 1 5 / 3 2 Standr 2C8andlOcups Cup Long Long 1 /8 Cup Ceramic 17/8 ~ Alumina . C GasLenColtBdy ~ J Consumable - B ~.. Figure .. L, ~ No, ::2::: (2AG6) (2AG7) Stock/Mde) 1637 1639(2C) 16340(2C7) 16341 16342 Stock/Mdel 1632)CL 16327 16328(C5L) 16329(CL) Stock/Mdel 1632(A) 163(2A7) 1634(2A8) Stock/Mdel ~:::: 338 116 and Lens Cup Gas ~ For Alumina 895 896 119 119 0