Download Craftsman 315.114231 Operator`s manual

Transcript

Operator's Manual

5-1/2 in. 18 VOLT

CORDLESS TRIM SAW

Model No.

315.114231

Save this manual for

future reference

WARNING:

Read and follow

all Safety Rules and Operaling

Inslructions before using this

product.

Customer

• Assembly

• Operation

• Maintenance

• Parts List

Help Line: 1-800-932-3188

Sears Roebuck and Co., 3333 Beverly Rd. Hoffman Estates,

Visit the Craftsman web page: www.sears.com

983000-281

3-03

• Safety

• Features

IL 60179 USA

•

TableOf Contents and Warranty ......................................................................................................................................

2

•

Introductionand General Safety Rules ........................................................................................................................

3-4

•

SpecificSafety Rules and Symbols .............................................................................................................................

4-7

•

ProductSpecifications,Unpacking,andAccessodes ...................................................................................................... 8

•

Features .....................................................................................................................................................................

8-10

• Assembly...................................................................................................................................................................

11-13

•

Operation .................................................................................................................................................................

13-19

•

Maintenance...................................................................................................................................................................

•

ExplodedV'mwAndRepair Parts List.......................................................................................................................

•

Parts Ordedng / Servico.................................................................................................................................................

20

22-23

24

FULL ONE YEAR WARRANTY ON CRAFTSMAN CORDLESS TRIM SAW

If this CRAFTSMANCordless Trim Saw fails to give complete satisfactionwithin one year from the date of purchase,

RETURN IT TO THE NEAREST SEARS STORE OR SEARS SERVICE CENTER IN THE UNITED STATES, and Sears

will repair it, free of charge.

If this CRAFTSMANCordless Trim Saw is used for commercial or rental purposes,this warranty applies for onlyg0 days

from the date of purchase,

This warranty gives you specificlegal rights,and you may also have other fightswhich vary from state to state,

Sears, Roebuck and Co., DopL 817 WA, Hoffman Estates, IL 60179

_l,

A

Look for this symbol to point out important safety precautions.

Your safety is involved.

It means attentionlll

WARNING:

O

The operation of any powertool can result in foreign objects beingthrown intoyour eyes, whichcan result

in severe eye damage, Before beginningpower tooloperation, always wear safety gogglesor safety

glasses with side shieldsand a full face shieldwhen needed, We recommendWide Vision Safety Mask

for use over eyeglasses or standard safety glasses with side shields,available at Sears Retail Stores,

Always wear eye protectionwhich is marked to comply with ANSI Z87.1.

2

Yourtrim sew has manyfeatures for making yourcutting

operationsmore pleasant and enjoyable. Safety,

performance and dependabilityhave been given top

priorityin the design of this tdm sew makingit easy to

maintainand operate.

A

_k

WARNING: Read and follow all instructions.

Failure to followall instructionslisted below, may

resultin electricshock, fire and/or sadous personal

injury.

Personal Safety

Stay alert, watch what you are doing and use

common eanea when operating a power tool. Do

not use tool while tired or under the influence of

drags, alcohol, or medication. A moment of inattentionwhile operatingpower tools may resultin serious

personal injury.

•

Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts, Looseclothes,

jewelry,or long heir can be caught in moving parts,

Avoid accidental starting. Be sure switch is in the

locked or off position before inserting bsttery

pack. Carryingtools with your finger on the switchor

insertingthe battery peck intoa toolwith the switch on

invitesaccidents.

Work Area

Keep yourwork area clean and well lit. Cluttered

benches and dark areas inviteaccident.

•

Do not operate power tools in eaplosive strnospheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may Ignitethe dust or fumes.

•

•

Keep bystandam, children, and visitors away while

operating a power tool, Distractionscan cause you

to lose control.

Electrical Safety

•

•

•

•

A bette|y operated tool with Integral bettados or a

separate be#ely pack must be recharged only with

the specified charger for the betteiy. A charger that

may be suitablefor one type of battery may create a

riskof fire when used with another battery.

Use bsttary operated tool only with specifically

designated battery pock. Use of any other batteries

may create a dsk of tire. Use only with batterypack

listed.

Use bettely only with charger listed.

MODEL

BA'rrERY PACK

CHARGER

item No. _ t1045

(1323905)

•

Remove adjusting keys orwrenchea before turning the tool on. A wrenchera key that is left attached

to a rotatingpert of the tool may resultin personal

injury,

•

Do not overreach. Keep proper footing and balance at all times. Proper footingand balance enable

petter controlof the tool in unexpectedsituations.

•

Use safety equipment. Always wear aye protection.

Dust mask, nonskidsafety shoes,hard hat, or hearing

protectionmustbe used for appropriateconditions.

Tool Use and Care

Do not abuse the cord. Never use the cord to carry

the charger. Keap cord away from heat, oil, chaq)

edges, or moving parts. Replace damaged cords

immediately. Damaged cords may create a fire.

315.114231

Do not attemptto usa the tool until

you have read thoroughlyand understandcompletely

the operator's manual, Pay close attentionto the

safety rules, includingDangers, Warnings, and

Cautions. If you usa this tool properlyand onlyfor

what it is intended,you will enjoy years of safe,

reliable service,

•

SAVE THESE INSTRUCTIONS

•

WARNING:

Ram No. _!11041

(1425301)

3

•

Usa clamps or other practical way to secure and

support the workplace to a stable plstfonn. Holding

the work by hand or againstyour body is unstableand

may lead to loss of control.

•

Do not force tool. Use the con'act tool for your

application. The correcttool will do the job be_rarand

safer at the rate for which it is designed.

Do not use tool if switch does not turn it on or off.

A toolthat cannot be controlledwith the switch is

dangerous and must be repaired.

Disconnect batter/pack from tool or place the

switch in the looked or off position before making

any adjustments, changing accoseodes, or stodng

tool. Such preventivesafety measures reduce the dsk

of starting the tool accidentally.

Store idle tools out of the mech of children and

other untrained persons. Toolsare dangerous in the

handsof untrainedusam.

•

Check for miaslignmeot or binding of moving

pe4s, breakage of paris, and any other condition

that may affect the tool's operation, if damaged,

have the tool serviced before using. Many accidents

are caused by poorlymaintainedtools.

•

Use only ecneasodas that are recommended by

the manufaotumr for your model. Accessoriesthat

may be suitablefor one tool, may create a risk of injury

when used on another tool.

Service

Tool se_ice must be performed by qualified repair

personnel. Service or maintenance performedby

unqualifiedpersonnelmay result in a risk of injury.

When batter/pack is not in use, keep it away from

other metal objects like: paper clips, coins, keys,

nails, screws, or other small metal objects that can

make a connection from one terminal to another.

Shortingthe battery terminals together may cause

sparks,bums, or a fire.

When servicing a tool, use only identical replace.

merit pads. Follow instructions in the Maintenance

section of this manual. Usa of unauthorizedparts or

failure to follow MaintenanceInstructionsmay create a

_sk of shockor injury.

Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintainedtoolswith sharp

cuttingedges are less likelyto bind and are easier to

ccntrol.

•

Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact

hidden wiring. Contact with a "live" wire will make exposed metal parts of the tool "live" and shock the operator.

Additional

•

•

Rules For Safe Operation

•

Know your power tool. Reed operator's manual

carefully. Learn its applications and limitations, as

well as the specific potential hmrds misted to

this tool. Followingthis rulewill reduce the risk of

electricshock,fire, or seriousinjury.

•

Make sure your extension cord is in good condition. When using an extension cord, be sure to use

one heavy enough to carry the current your product will drew. Awire gage size (A.W.G.) of at least

16 is recommended for an extension cord 100 f_st

or less in length. A cord exceeding 100 feet is not

recommended. If in doubt, use the next heavier

gage. The smaller the gage number, the heavier

the cord. An undersizedcordwill cause a drop in line

voltage resultingin lossof power and overheating.

•

Important Rules For Battery Tools

•

Batter/tools do not have to be plugged into an

electrical outlet; therefore, they are always in

operating condition. Be aware of possible hazards

when not using your better/tool or when changing accessories.

4

Do not place batter/tools or their baHefies near

fire or heat. This will reduce the risk of explosionand

possibleinjury.

Batteriesvent hydrogengas and can explode in the

presenceof a sourceof ignition,such as a pilot light.

To reduce the risk of sedous personal injury,never

use any cordlessproductin the presence of open

flame. An exploded battery can propeldebds and

chemicals. If exposed, flush with water immediately.

Do not charge baiter/tool in a damp orwet location. Followingthis rule will reducethe risk of electric

shock,tim, or seriouspersonal injury.

•

Your belier/tool

should be charged in a location

where the temperature is more than 50°F hut less

then 100°F. Followingthis rule will reducethe risk of

electricshock,fire, or serious personalinjury.

•

Under extreme usage or temperature conditions,

batter/leakage may occur. If liquid comas in

contact with your skin, wash immediately with

soap and water, then neutralize with leman juice or

vinegar. If liquid gets into your eyes, flush them

with clean water for at Isesl 10 minutes, then seek

immediate medical attention. Following this rule will

reducethe risk of serious personalinjury.

Additional Specific Safety Rules

•

DANGERI Keep hands away from cutting am and

blade. Keep your second hand on auxilianj handle

or motor housing. If both handsam holdingthe saw,

they cannot be cut by the blade,

•

Never use damaged or incorrect blade washers or

bolts. The blade washers and boltwere specially

designedfor your saw,for optimum performanceand

safety of operation.

•

Causes and Operator Prevention of Kickback:

•

Kasp your body positioned to either side of the

saw blade, but not in line with the sew blade.

KICKBACK could cause the saw to jump backwards.

Kickback is a sudden reactionto a pinched, bound,or

misalignedsaw blade, causing an unccntmlledsaw to

lift up and out of the workpiecetowardthe operator.

•

Do not reach underneath the work. The guard

cannot pmtactyou from the blade below the work.

•

Chack the lower guard for proper closing before

each use. Do not operate saw if lower guard does

not move freely and close instantly, Never clamp

or tie the lower guard into the open position. If

saw is accidentallydropped,lower guard may be bent.

Raise the lower guard with the retractinghandle and

make sure it movesfreely and does not touchthe

blade or any other part, in all angles and depthsof cut.

Check the operation and condition of the lower

guard spdng, If the guard and the spdng are not

operating properly, they must be serviced before

use. Lowerguard may operate sluggishlydue to

damaged parts,gummy deposits,or a buildupof

debds.

When the blade is pinchedor hound tightlyby the kerr

closingdown, the blade stallsand the motorreaction

drivesthe unit rapidlybeck towardthe operator.

•

•

Lower guard should be retracted manually only for

special cute such as =Pocket Cuts" and "Compound Cuts". Raise lower guard by Retracting

Handle. As soon as blade enters the mstadal,

lower guard must be released. For all other sawing,

the lower guard shouldoperate automatically.

•

Always obeerve that the lower guard is covedng

the blade before placing saw down on bench or

floor. An unprotected,coastingblade will cause the

saw to walk backwards, cuttingwhatever is in its path,

Be aware of the time it takes for the bladeto stop after

switchis released.

If the blade becomes twistedor misalignedin the cut,

the teeth at the back edge of the blade can dig intothe

top surface of the wood causing the blade to climbout

of the ken'and jump back toward the operator.

Kickback is a resultof tool misuse and/or incorract

operating proceduresor conditionsand can be

avoided by taking properprecautionsas given below:

•

•

•

When restarting a sew in the workplace, canter the

saw blade in the kerr and check that teeth are not

engaged into the mstedal. If saw blade is binding,it

may walk up or KICKBACKfrom the workpiecaas the

saw is restarted.

•

Support large panels to minimize the dsk of blade

pinching and KICKBACK. Large panels tend to sag

under theirown weight. Supportsmustbe placed

under the penal on bothsides, near the lineof cutand

near the edge of the panel.

•

Do not use dull or damaged blade. Unsharpenedor

impmpedy set bladesproducenarrow ken'causing

excessivefriction, blade binding,and KICKBACK.

•

Blade depth and bevel adjusting locking levera

must be tight and secure before making cut. If

blade adjustmentsh_ftswhilecutting,it will cause

bindingand KICKBACK.

•

Use extra caution when making a "Pocket Cut"

into existing walls or other blind areas. The protruding blade may cut objectsthat can cause KICKBACK.

NEVER hold piece being cut in your hands or

across your leg. It is important to supportthe work

properlyto minimizebody exposure,blade binding,or

lossof control.

•

Hold tool by insulating gripping sudecse when

performing an operation where the cutting tool

may contact hidden widng. Contactwith a "live"wire

will also make exposed metal parts of the tool"live"

and shockthe operator.

•

When dpping always use a rip fence for a straight

edge guide. This improvesthe accuracyof cutand

reducesthe chance of blade binding.

•

Always use blades with cowect size end shape

(diamond vs. round) arbor holes. Bladesthat do not

matchthe mountinghardware of the saw will run

eccentdcally,causing loss of control.

5

Maintain a finm grip on the sew and position your

body and arm in a way that allows you to resist

KICKBACK forces. KICKBACK forces can be controlled by the operator,if proper precautionsare taken.

When blade is binding, orwhen intemupting a cut

for any reason, release the trigger and hold the

saw motionless in the mutadal until the blade

comas to a complete stop. Never attempt to

remove the saw from the work or pull the sew

backward while the blade is in motion or KICKBACK may occur. Investigateand take corrective

actions to eliminatethe cause of blade binding.

•

Neverusea batterythat

has been dropbed or received a sharp blow, A damaged bakery is subjectto

explosion,Pmpedy dispose of a dropped battery

immediately. Failure to head this warning can result in

serious personal injury.

•

Do not operate charger if It has received a sharp

blow, been dropped, or othanNise damaged in any

way; take It to a qualified serviceman. Following this

rule will reducethe risk of electdc shock,fire, or

serious personal injury.

•

Before using battery charger, read ell instructions

and cautionary markings in this manual, on battery

charger, and product using battery charger. Following this rule will reducethe dskof electricshock,fire,

or sedouspersonal injury.

•

Do not dissessmbls charger, take it to a qualified

serviceman when ssrvica or repair is required.

Incorrect ressssmbly may result in a risk of electric shock or fire. Followingthis rulewill reducethe

dsk of electricshock,firs, or seriouspersonal injury,

•

To reduce dsk of injury, charge only nickelcadmium type rechargeeble bottedss. Other types

of batteries may burst causing personal injury end

damage. Followingthis rulewill reduce the dsk of

electric shook, tim, or sedous personal injury.

Do not expose charger to rein or snow. Following

this rule will reduce the dsk of electdc shock,fire, or

serious personalinjury.

•

To reduce the risk of electric shock, unplug

charger from outlet before attempting any mainte.anco or cleaning. Turning off controls will not

reduce this risk, Followingthis rulewill reducethe

dsk of electric shock'firs,or sedous personalinjury.

Do not use charger outdoors. Followingthis rulewill

reduce the risk of electric shock,fire, or sadous

personal injury.

Usa of an attachment not recommended oraold by

the battery charger manufacturer may result in •

risk of fire, electric shock, or injury to penmns.

Followingthis rule will reduce the risk of electric shock'

fire, or sedous personalinjury,

•

•

•

•

•

•

•

•

To reduce the dek of damage to charger body and

cord, pull by charger plug rathor than cord when

disconnecting charger. Following this rule will reduce

the risk of sedous personal injury.

Make sure cord is located so that it will not be

stepped on, tdpped over, or othanvise subjected to

damage or stress. Followingthis rule will reducethe

dsk of seriouspersonalinjury.

An extension cord should not be used unless

absolutely necsssmy. Use of improper extension

cord could resultin a dsk of fire end electric shock.If

extensioncord must be used, make sure:

a. That pins on plug of extension cordam the same

number,size and shape as those of plug on

charger.

50"

100"

Cord Size (AWG)

16

16

16

A

WARNING" . Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm,

Some examples of these chemicals are:

• arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a wall

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopicparticles.

Note: AWG = AmadcanWire Gage

•

Save thsse instructions. Refer to tbem frequently

and use them to instnJnt others who may use this

tool. if you loan someone this tool, loan them

these instructions also. Followingthis rule will

reduce the risk of electric shock'fire, or serious

personal injury,

• crystalline silica from bdcks and cement

and other masonry products, and

c. That wire size is large enough forAC ampere rating

of charger as specifiedbelow:

25"

•

• lead from lead-besed paints,

b. That extensioncord is pmpedywired and in good

electrical condition; and

Cord Length (Feet)

Dieconnect charger from power supply when not

in use. Followingthis rule will reduce the risk of

electricshock,tim, or serious personal injury,

RISK OF ELECTRIC SHOCK. DO NOT TOUCH

UNIHSULATED PORTION OF OUTPUT CONNECTOR OR UNINSULATED BA'I-rERY TERMINAL.

Donot operatechargerwith adarnaged cord or

plug. If damaged, have replaced immediately by a

qualified sstvicaman, Followingthis rulewillrsduce the

dsk of electricshock,fire,or serious personalinjury.

SAVE THESE INSTRUCTIONS

6

Important: Some of the followingsymbolsmay be used on yourtool, Please study them and leam their moaning.

Proper interpretationof these symbolswill allow you to operate the tool better and safer.

SYMBOL

NAME

DEBIGNATIONIEXPLANATION

V

Volts

Voltage

A

Amperes

Current

Hz

Hertz

Frequency (cyclesper second)

W

Watt

Power

min

Minutes

Time

ARematingCurrent

Type of current

no

No Load Speed

Rotational speed, at no load

[]

Class II Construction

Double-insulatedconstruction

.../min

Per Minute

Revolutions,strokes, surface speed, orbitsetc., per minute

Safety Alert

Preoauttonsthat involveyour safety

O

Eye Protection

and

a full face

shield

when operating

this product.

Alwayswear

,safety

gogglesor

safety glasseswith

,sideshields

_)

Wet ConditionsAlert

Do not expose to rain or use in damp locations.

,_

The purposeof safety symbols is to attract your attentionto possibledangers, The safety symbols, and the

explanationswith them, deserve your careful attention and understanding.The safety warningsdo not by

themselves eliminate any danger. The instructionsor warningsthey give am not substitutesfor proper accident

prevention measures.

SYMBOL

A

A

A,

MEANING

DANGER: Indicates an immlnontlyhazardous situation, which, if not avoided, will rasult in death or

sedcos injury.

WARNING: Indicates a potentiallyhazardous situation,which, if not avoided, could resultin death or

serious injury.

CAUTION: Indicates a potentiallyhazardous situation,which, if not avoided, may result in minor or

moderate injury.It may also be usedto alert against unsafe practicesthat may cause propertydamage.

Impodant: Advisesyou of importantinformationor instructionsvital to the operationor maintenanceof

the equipment.

Note: Advisesyou of additionalinformationconcerningthe operationor maintenanceof the equipment.

7

TRIMSAW

BladeDiameter

BladeArbor

315.114231

5-1/2in.

318in,

CuttingDepth at 900

1-9/16 in.

CuttingDepth at 450

1-118in,

No lead Speed

4,500/min,

Motor

18 Volt DC

CHARGER

Input

ITEM NO. 1 11041

(1425301)

120 V, 60 Hz, AC only

ChargingVoltage

7.2 - 24 Volt

Charge Rate

BA'I-FIERYPACK

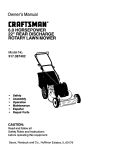

Your trim saw has been shippedcompletelyassembled

exceptfor the blade. Inspect it carefullyto make sure no

breakage or damage has occurredduringshipping,If any

parts are damaged or missing,contact your nearestSears

Retail Store to obtain replacementparts beforeattempting

to operate saw. A blade, bladewrench (5 mm hex key), dp

guide (edge guide) and this operators manual are also

included,

1 Hour

ITEM NO. 9 11045

(1323905)

WARNING: If any partsare missing,do not operate

yoursaw until_e missingpatts are replaced,Failureto

do so could resultin passible seriouspersonalinjury.

The following recommendedaccessoriesare currentlyavailable at Bears Retail Stores,

• 5-1/2 in, Thin Kerr Blade

WARNING:

The use of attachmentsor aceassodes not listedmightbe hazardous.

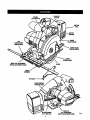

KNOW YOUR TRIM SAW

See Figure 1.

SWITC H

Your saw is equippedwith a lock-offbuttonwhich reduces

the possibilityof accidentalstarting. The lock-offbuttonis

located on the handle above the switchtdgger.You must

depressthe lock-offbuttonin order to pull the switch

trigger.The lock resetseach timethe trigger is released.

Note: You can depressthe iock-off buttonfrom either the

left or dght side.

Beforeattempting to use your tdm saw,familiarize yourself

with all operatingfeatures and safety requirements.

Features includeeasily operated bevel cut and depthof

cut adjustmentmechanisms;positive0° bevel stop;

spindlelock; and blade wrench storage.

APPLICATIONS

(Use only for the purposes lieted below)

,l_k WARNING: Do not allowfamiliarity with your saw

to make you careless. Remember that a careless

fraction of a second is sufficientto inflictsevere

injury.

•

8

Cuttingall types of wood products(lumber,plywood,

paneling).

LOCK-OFF

BUTrON

SPINDLE

LOCKBUTFON

BA'n'ERY

PACK

TRIGGER

RIP

GUIDE8CREW

(WINGSCREW)

BLADEGUARD

, LOWERBLADE

GUARDHANDLE

LOWER

BLADEGUARD

BEVELCUTADJUSTMENT

(BEVELADJUSTMENT

KNOB)

BLADE

BASE

ASSEMBLY

FlIPGUIDE

BLADEWRENCH

STORAGEAREA

BLADEWRENCH

(5 mmHE)(KEY)

9

DEPTHOF

CUTADJUSTMENT

(DEPTHADJUSTMENT

KNOB)

Fig. 1

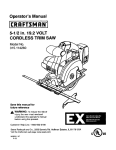

LEDFUNCTIONS

OFCHARGER

LEDWILLBEONTO INDICATESTATUSOFCHARGERANDBATTERYPACK:

•

Red LED on = Fast chargingmode,

•

Green LED on = Fully charged and in tricklecharge mode,

•

Green LED on = When battery pack is insertedintocharger, indicates hot hatter/pack or that batterypack is out of or

below normaltemparatum range,

•

Yellow and Green LEDs on = Deeply dischargedor defective batter/pack.

•

No LED on = Defective charger or battery pack.

BATrERYPACK

SHOWNIN CHARGER

CHARGER

REDLEDONINDICATES

GREENLED ON AFTER FAST CHARGING

CYCLE, INDICATESFUlly CHARGEDBATrERY

PACKANDIN TRICKLECHARGEMODE

YEllOW ANDGREENLED6ONINDICATES

DEEPLY

DISCHARGER

ORDEFECTIVE

BA'I'rERYPACK,

Fig. 2

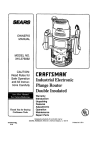

C HARG ER

See Figure 3.

Your charger has a "key hole" hanging feature for

convenient, space saving storage, Screws shouldbe

installed so that canter distancesare 4-1/2 inchesapart,

4-1/2In,

Fig, 3

10

LED FUNCTIONS OF CHARGER

LED WILL BE ON TO INDICATE STATUS OF

CHARGER AND BATTERY PACK:

WARNING: Do not allow familiaritywith your trim

sew to make you careless. Remember that a

careless fraction of a second is sufficientto inflict

severe injury.

BATTERY

PACK

The battery peck for your tool has bean shippedin a low

charge condition to preventpossibleproblems.Therefore,

you shouldcharge it until light on front of charger changes

from red to green,

Note: Batterieswill nut reach fullcharge the firsttime they

are charged, Allow several cycles (cuttingfollowed by

recharging)for them to become fully charged,

CHARGING BATTERY PACK

See Figure2.

•

Charge battery peck onlywith the charger provided.

•

Make sure power supply is normal household

voltage, 120 vo#s, 60 Hz, AC only.

Connect chargerto power supply.

•

•

•

Place battery pack in charger aligningraised ribon

battery peck with groove in charger. See Ffgure2.

Press down on battery packto be sure contacts on

battery peck engage probedywith contacts in charger,

•

Normally, the red LED on charger will come on, This

indicatescharger is in fast charging mode,

•

Red LED shouldremainon for approximately1 hour

than the green LED will come on, Green LED on

indicates battery peck is fully charged and charger is in

tdckie charge mode, Note: Green LED will remainon

until battery peck is removedfrom charger or charger

is disconnectedfrom power supply,

•

If bothyellow and green LED coma on, this indicatesa

deeply dischargedor defective battery pack.

•

The battery peck will become slightlywarm to the

touchwhile charging.This is normal and does not

indicate a problem.

•

•

Green LED on = Fully charged and in tricklecharge

mode,

•

Green LED on = When battery pack is insertedinto

charger, indicateshut battery pack or that batterypack

isout of or below normal temperaturerange.

•

Yellow and Green LEDs on = Deeply dischargedor

defective battery peck.

•

No LED on = Defective charger or battery peck.

_,

CAUTION: To preventdamage to battery pack,

remove battery peck from charger immediatelyif no

LED comes on. Ratum battery peck and charger to

your nearest Seers Service Canter for checking or

replacing,Also, ifyou are removingbattery peck from

charger and no LEDs am on, return both battery pack

and charger to your nearest Sears Service Center,

Do nut Insert another battery peck Into charger.A

damaged charger may damage a better/peck.

FOR RECHARGING

When usingyour tdm sew continuously, the batteries in

your battery peck will become hot.You should let • hot

battery pack cool down for approximately30 minutes

before attemptingto recharge,When the battery peck

becomes discharged and is hot,this will cause the green

LED to coma on insteadof the red LED. After 30 minutes,

reinsert battery peck in charger. If green LED continuesto

remain on, ratum battery peck to your nearest Sears

Repair Center for checking or replacing.

Note: This situationonly occurswhen continuous use of

your saw causes the bettedas to become hot. It does not

occur under normal circumstances.Refer to "CHARGING

BAI'TERY PACK" for normal recharging of bettafias. If

the charger does not charge your battery peck under

normal circumstances,return both the battery peck and

charger to your nearest Sears Repair Center for electrical

check.

If red LED does nut come on after 30 minutes,this

indicatesa defective battery peck and shouldbe

replaced.

After normal usage, a minimumof 1 hour of charging

time is requiredto fully recharge battery peck.

Red LED on = Fast chargingmode.

IMPORTANT INFORMATION

HOT BATTERY PACK

Allow battery pack to remain in charger for 15 to 30

minutes.When battery pack rsaches normalvoltage

range, red LED shouldcoma on.

•

•

IMPORTANT INFORMATION

COOL BATTERY PACK

FOR RECHARGING

If battery pack is below normal temperature range, the

green LED on charger will come on. Allow battery peck to

reach normal temperature, than the red LED will come on,

Note: Refer to "CHARGING BATTERY PACK" for

normal rechargingof batteries. If the charger does not

charge your battery peck under normal circumstances,

return both the battery pack and charger to your nearest

Sears Repair Center for electrical check.

Do not place charger and battery pack in an area of

extreme heat or cold, It willwork best at normal room

temperature,

Note: Charger and battery pack shouldbe placed in a

locationwhere the temperature is more than 50°F but

less than 100=F,

When battedes become fully charged, unplugcharger

from power supplyand remove the battery pack.

11

SRNDLE

LOCKBUTTON

WARNING:Alwaysremove

batterypackfrom your

sew when you are assemblingparts, making

adjustments,assemblingor removingblades,

cleaning, or when not in use. Removing battery pack

will prevent accidental startingthat could cause

serious personalinjury.

LOWERBLADE

GUARDHANDLE

Note: Your sew is assembled with the battery pack

attached,

TO REMOVE BATTERY

See Figure 4.

BLADE

PACK

•

Locate latches on side of battery pack and depress to

release battery pack from your sew. See Ffgure 4.

•

Remove battery pack from your sew.

DEPRE88LATCHr-._TO

RELEASE

BATI'ERY

PACK

INNER

BLADEWASHER

OUTER

BLADEWASHER

TO

REMOVE

BLADESCREW Fig. 5

TO

INSTALL

LATCHES

•

Remove blade wrench (5 mm hex key) from storage

area. See Figure 1.

•

Depress spindlelock button and remove blade screw

and outer blade washer, See Figure 5.

Note: Turnblade screwdcckwise to remove,

•

Wipe a drop of oil onto inner bladewasher and outer

blade washer where they contact blade.

WARNING: If inner blade washer has been removed, replace it before placingblade on spindle.

Failureto do so could cause an accidentsince blade

will not tighten pmpedy,

BATrF._RY

PACK

Fig, 4

TO ASSEMBLE

OR REMOVE BLADE

•

TO ASSEMBLE BLADE:

Note: The sew teeth paint upward at the frontof sew

as shownin figure 5.

See Figure 5.

WARNING: A5-1/2 in. blade is the maximum blade

capacity of your sew. Never use a blade that is too

thick to allow outer blade washer to engage with the

fiats on the spindle. Larger blades will come in

contact with the blade guard, while thicker blades will

prevent blade screwfrom securingblade on spindle,

Either of these situationscould resultin a serious

accident.

•

A

•

Fit sew blade insidelower blade guard and onto

spindle,

• Replace outer bladewasher.

•

Depress spindlelock button,than replace blade screw,

"nghtanblade screw securely,

Note: Turn blade screw countemlockwiseto tighten.

•

Ratum blade wrench to storage area.

REMEMBER: Never use a blade that is too thick to

allow the outer blade washer to engage with the fiats

on the spindle.

Remove battery pack from saw,

WARNING: Failure to remove battery pack from

sew could result in accidental startingcausing

passible serious personal injury.

Locate latcheson side of batterypack and depressto

release battery pack from yoursew. See F/gum 4.

12

TOREMOVE

BLADE

See Figure 6.

•

Remove batter/pack from saw,

WARN ING: Failure to remove battery back from

sew could result in accidental startingcausing

possiblesedous personal injury.

m Remove blade wrenchfrom storagearea. See/:?gum 1.

•

LATCHES

Position sew as shown in figure 5, depress spindlelock

button, and remove blade screw.

Note; Turn blade screw clockwiseto remove.

BATrERYPACK

M Remove outer bladewasher.See F/gum 5.

Fig. 7

BLADE GUARD SYSTEM

Note: Bledo can be removed at this point.

The lower blade guard attached to your tdm sew is

there for your protection and safety. It should never be

altered for any mason. If it becomes damaged or

begins to mtum slow or sluggish, do not operate your

sew until the damage has been repaired or replaced.

Always leave guard in operating position whon using

DEPRESSSPINDLE

LOCKBUTFON

SaW.

_k

LOOSEN

SCREW

DANGER: When sewing through workpiese,lower

blade guard does not cover blade on the underside of

workpiece,Since blade is e_pesed on undersideof

workpiece,keep handsand fingers away from cutting

area. Any part of your body coming in contact with

moving blade will resultin serious injury,

See Figure 8.

LOWERBLADEGUARD

IS IN UP POSITION

WHEN MAKINGA CUT

BLADE

WRENCH

TO

TIGHTEN

Fig. 6

TO INSTALL BATTERY PACK

See Figure 7.

Note: Battery pack is shipped in a low charge condition,

Therefore, it must be charged pdor to use. Refer to page

10, =CHARGING BATTERY PACK" for charging

instructions,

•

•

Place battery back in your sew. Align raised db on

battery back with groove inside sew, then slide battery

pack in saw as shown in figure 7,

BLADEEXPOSED

ON

UNDERSIDE

OFWORKPIECE

Make sure the latches on each side of your battery

back snap into place and battery pack is secured in

saw before beginningoperation,

Fig. 8

Never use sew when guard is not obamtingcorrectly.

Guard shouldbe checked for correct operation before

each use. If you drop your sew, checkthe lower blade

guard and bumperfor damage at all depth settingsbefore

reuse. Note: The guard is operatingcorrectly when it

moves freely and readilyratums to the closed position. If

for any reason your lower blade guard does notclose

freely, take itto the nearest Sears Parts and Repair Center

for service before using,

CAUTION: When placing battery back in your sew,

be sure raised fib on battery back aligns with groove

inside saw end latches snap into place properly,

Improper assembly can cause damage to sew and

battery peck.

13

KICKBACK

See Figure 9.

nm

TO LESSEN THE CHANCE OF KICKBACK:

•

mum),

Always keep the correctblade depthsetting- the

correct blade depth settingfor all cuts should not

exceed 1/4 in. below the materialto be cut.

See Figure 11.One blade tooth belowthe matedal to

be cut w_rks bestfor most efficientcuttingaction.

K]CKBACK

lmalnk

BLADESETTOODEEP

Fig, 9

Tho best guard against kickback is to avoid dangomus

practices.

Kickbackoccurswhen the blade stalls rapidlyand the saw

is ddven back towardsyou. Blade stallingiscaused by any

actionwhich pinchesthe blade in the wood.

_k

DANGER: Release switchimmediately if blade

bindsor sew stalls. Kickback couldcause you to lose

control of your saw. Loss of controlcan lead to

sadous injury,

KICKBACK

IS CAUSED

CORRECT'

BLADEDEPTHSETrlNG•

BLADEEXPOSED

ONEBLADETOOTH

BELOWTHE MATERIAL

TOBECUT

BY:

Fig. 11

•

Inspectthe workpiece for knotsor nails before

beginninga cut. Never sew intoa knot or nail.

•

Make straight cuts,Always use a straightedge guide

when dp cutting.This helps preventtwistingthe blade

in the cut.

•

Incorrect blade depth setting,See Figure 9.

•

•

Sawing into knotsor nails in workpiece.

Twistingbladewhile makinga cut.

•

Making a cut with a dull, gummed up. or improperlyset

blade.

•

Always use clean, sharpand properlyset blades.

Never make cutswith dull blades,

•

Incorrectlysupportingworkplace. See Figure 10.

•

To avoid pinchingthe blade, supportthe workpieco

properly before beginninga cut. The right and wrong

ways to supportlarge pieces of work am shown in

figures 10 and 12.

Fig, 10

•

Forcinga cut,

• Cuttingwarped orwet lumber,

•

RIGHT

Tool misuse or incon'ectoperatingprocedures.

14

Fig. 12

• When making a cut use steady, even pressure,

Never force cuts.

STARTING A CUT

•

Know the right way to use your saw.

See Figure 14.

Do not cut waq_edor wet lumber,

• Always hold your saw firmlywith both hands and keep

your body in a balanced positionso as to resist the

forces of kickback should it occur,

When using your saw, always stay alelt and oxeroiso

control. Do not remove your saw from workplace

white the blade is moving,

DEPTH OF CUTADJUSTMENT

Always keep correct blade depth setting. The correct

blade depth setting for all cuts shouldnot exceed 1/4 inch

below the materialto be cut. More blade depthwill

increasethe chance of kickback and cause the cut to be

rough, One blade tooth below the matedal to be cut works

best for mostefficient cutting action.

TO ADJUST BLADE DEPTH

•

Remove battery pack from saw.

WARNING: Failure to remove battery packfrom

saw could result in accidental starting causing

possibleserious personal injury.

•

Fig, 14

Never use your saw as shown in figure 15.

Loosen depth adjustment knob. See Figure 13,

TORAISE

SAW

BASE

ASSEMBLY

TO

J

TO

LOOSEN

•

TIGHTEN

DEPTH

ADJUSTMENT

KNOB

Fig, 13

Hold base flat againstthe workpiece and raise or lower

saw untilthe required depth is reached.

WRONG

Fig. 15

Never place your hand on the workplace behind your

sewwhile making a cut.

• "13ghten

depth adjustment knob securely.

_k

15

WARNING: To make sawing easier and safer,

always maintain propercontrol of your saw, Loss of

controlof your saw could cause an accident resulting

in possibleserious injury.

TOHELPMAINTAINCONTROL:

Hold your sew firmly with both hands.

See Figure 17.

• Always supportyour workpiece near the cut.

•

Supportyour workpiece so the cutwill be on your left.

•

Clamp yourworkplece so itwill not move dudngthe cut.

Place your workpiece with its good side down,

Note: The good side is the side on whichappearance is

important,

Before beginninga cut, draw a guidelinealong the desired

line of cut. Then place front edge of base on that port of

yourworkpiece that is solidily supported, See F{gure 14.

Never place your saw on that part of the workpiece

that will fall off when the cut is made. See Ffgure 16.

RIGHT

Fig, 17

Depressthe lock-offbutton and squeeze the switchtdgger

to startyour saw, Always letthe blade reach full speed,

then guide your saw intothe workpiece.

_i,

WARNING: The blade coming in contactwith the

workpiece before it reaches full speed couldcause

your saw to "kickback" towardsyou resultingin

cedous Injury.

When makinga cut use steady, even pressure,Forcing

causes roughcuts, could shortenthe llfe of your sew and

could cause "kickback."

WRONG

REMEMBER:

When sewing throughwork, the lower blade guarddoes

not cover the blade, exposingit on the underside of work,

Keep your hands and fingers away from cuttingarea. Any

pert of your bodycoming in contact with the moving blade

will result in serious injury,

Fig, 16

After you completeyour cut release the trigger and allow

the blade to come to a complete stop. Do not remove

your saw from workpieee while the blade is moving.

_k

16

CAUTION: When liftingyour sew from the

workpiece,the blade is exposed on the undersideof

your sew until the lower blade guard closes, Make

sure lower blade guard is closed before setting your

saw downon work surface,

TO CROSS CUT OR RIP CUT

A width of cut scale has been providedon the base of

your saw. When making straightcross cutsor rip cuts, the

scale can be used to measure up to four inchesto the

right side of the blade. It can he used to measure up to

one inch to the left side of the blade.

When making a cross cut or rip cut, align your line of cut

with the outer blade guide notchon the saw base as

shown in figure 18.

TOPVIEWOFSAW

GUIDEUNE

RIP GUIDE (EDGE GUIDE)

BLADE

GUIDENOTCH

Use the rip guide providedwith your saw when making

wide rip cuts.A five inchscale has been providedon the

rip guide. When using the width of cut scale on the base

in combinationwith the rip guide, cuts can be made up to

6 in. to the left of the rip guide or 8-7/8 in. to the right of

the dp guide.

The rip guide helps preventthe bladefrom twistingin a

cut. The bladetwisting in a cut can cause kickback.

TO ASSEMBLE

•

RIP GUIDE

Remove battery pack from saw.

WARNING: Failure to remove battery pack from

saw could result in accidental startingcausing

possiblesedous personalinjury.

AUGNOUTERBLADEGUIDENOTCHONSAWBASEWITHUNE

OFCUTASSHOWNWHENMAKINGCRO6SCUTSOR RIPCUTS

Fig. 18

Since blade thicknessesvary, always make a trial cut in

scrap materialalong a guidelineto determine how much,

if any, the guideline must be offsetto producean accurate

cut.

Note: The distancefrom the line of cut to the guidelineis

the amount you shouldoffsetthe guideline.

RiP

GUIDESCREW

(WINGSCREW)

WIDTH OF CUT SCALE

See Figure 19.

I_IPGUIDE

(EDGEGUIDE)

BASE

ASSEMBLY

PLACERiP

GUIDETHRUHOLES

•

Fig. 20

Place rip guide through holes in saw base as shown in

figure 20.

• Adjust ripguide to the width needed.

• "nghtenrip guide screw (wing screw) securely,

CUTSCALE

When usinga rip guide, position the face of the dp guide

firmlyagainst the edge of workpiece, This makes for a

true cut withoutpinchingthe blade. The guidingedge of

workplece must be straightfor your cut to he straight. Use

caution to preventthe blade from bindingin the cut.

BLADE

Fig. 19

17

ALTERNATIVE

RIP METHOD

Alignyour line of cut with the inner blade guide notchon

the sew base when making45 ° bevel cuts.

See Figure 21.

Since blade thicknesses vanj and different angles

require different sottings, always make atdal cut in

scrap materiel along a guideline to determine how

much you should offset the guideline on the board to

be cut,

Using C-clamps, firmlyclamp a straightedge to the

workbaica and guide the sew along the straightedge to

achieve a straight dp cut. Do not bindthe blade in the cut.

ALTERNATIVE

METHODFORRIPCUTrlNG

WORI_ECE

When makinga bevel cut hold your sew firmly with both

handsas shown in figure 23,

STRAIGHT

EDGE

NOTE:C-CLAMP

BOTHENDSOFSTRAIGHT

EDGEBEFOREMAIONGCUT

Fig. 21

LOWER

BLADEGUARDFig. 23

Rest the front edge of the base on the workpieca, Depress

the lock-off button and squeeze the switchtrigger to start

your saw, Always let the blade reach full speed, then

guide your saw into the workpieco.

TO BEVEL CUT

The angle of cut of your sew may be adjusted to any

desired settingbetween zero and 50 °. Note: When

making cuts at 50 °, blade shouldbe set at full depth of

cut.

A

When making 45° bevel cuts, there is a notch in the sew

base to help you line up the blade with the line of cut. See

F/gum 22.

BEVEL

ADJUSTMENT

KNOB

WARNING: The blade coming in contact with the

workplace before it reaches full speed could cause

saw to "kickback" toward you resultingin serious

injury.

After you complete your cut release the triggerand allow

the blade to come to a complete stop, After the blade has

stopped, lift your sew from the workpiece.

TO ADJUST

•

BeVel

SCALE

BEVEL SETTING

Remove battery

pack from saw,

WARNING: Failure to remove battery pack from

saw could resultin accidental starting causing

possible serious personal injury.

W

•

BLADE

GUIDE NOTCH

Loosen bevel adjustment knob, See Figure 22.

• Raise motorhousingend ofsew untilyou reachdesired

angle settingon bevel scale.See FIgure22.

• Tighten bevel adjustment knobsecurely.

WARNING: Attemptingbevel cut withoutknob

securelytightened can resultin serious injury.

AUGNINNERBLADEGUIDENOTCHON SAWBASEWITH

UNE OFCUTAS SHOWNWHENMAIQNG45° BEVELCUTS

Fig. 22

18

POSITIVEO° BEVELSTOP

• Turn screw and adjust base until squarewith sew

blade.

See Figure 24.

• "13ghtan

hex nut and bevel adjustmentknobsecurely.

BEVEL

ADJUSTMENT

KNOB

_h

WARN ING: Attemptingto make cutswithout bevel

adjustment knob securelytightenedcan result in

serious injury.

TO POCKET CUT

See Figure 25.

A

HE)(NUT

BLADE

PosrI'IVE0°

BEVELSTOP

WARNING: ,aJways

adjustbevel settingto zero

before maldnga pocketcut. Attemptinga pocketcut at

any other settingcan resultin lossof controlofyour

caw possiblycausingseriousinjury.

Adjust the bevel settingto zero, cat bladeto correct blade

depth setting, and swingthe lower blade guard up using

the lower blade guard handle.

Always lisa the lower blade guard with the handle to

avoid serious injurj,

CARPENTER'S

80UARE

While holding lower blade guard by the handle, firmly rest

the front of the base flat againstthe workplace with the

rear of the handle raised so the blade does not touchthe

workpieca. See Figure 25.

LOWERBLADE

GUARDHANDLE

Fig. 24

Your caw has a positive0° bevel stop, that has been

factory adjusted to assure O° angle of your saw blade

when making 90° cuts, However, micalignmantcan occur

dudng shipping.

TO CHECK

•

_.

•

•

Remove battery back from caw.

WARNING: Failure to ramove battery back from

caw could result in accidental starting causing

possible serious personal injury,

Place your caw in an upside down positionon

workbench, See Figure 24.

POCKETCUT

Using a carpenter's square, check squareness of caw

blade to the base of your sew.

Depress the lock-offbuttonand squeeze the switchtdgger

to start your caw. Always let the blade reach full speed

then slowly lower blade into the wod_piace until base

is flat against workpieoe.

TO ADJUST

•

Remove battery pack from caw,

Alter you complete your cutraiease the tdggerand allowthe

bladeto come to a completestop,After the bladehas

stopped, remove it from the workpieoe,Comers may then be

clearedoutwith a hand saw or sabre saw.

,_k WARNING: Failure to remove battery pack from

caw could result In accidental starting causing

possible sadous personal injury.

•

•

LOWERBLADEGUARD

FIg. 25

Loosen bevel adjustment knob.

Loosen hax nut secudng adjustment screw.

WARNIN G: Never tie the lower blade guard in a

raised position, Leaving the blade exposedcould

lead to sedous injury.

19

A

WARNING:Whenservicing,

useonlyidentical

Craftsman

replacement

parts,Useofanyotherpart

maycreatea hazardorcauseproduct

damage,

Avoidusingsolvents

whencleaning

plasticparts.Most

plastics

aresusceptible

todamage

fromvadoustypesof

commercial

solvents

andmay be damaged by their use.

Do not abuse power tools. Abusive practicescan damage

toolas well as workpiece.

Use clean clothsto remove dirt, dust, oil, grease, etc.

_

_

Only the parts shownon parts list,page 23, are intended

to be repairedor replaced by the customer, All other parts

shouldbe replaced at a Sears Service Center.

WARNING: Do not at any time let brake fluids,

gasoline, patrcleum.-pased products,penetratingoils,

etc. come in contact with plastic parts. They contain

chemicalsthat can damage, weaken or destroy

plastic.

BATTERIES

To preservenatural resources,please

recycle or disposeof batteriesproperly.

Your saw's bakery pack is equipped with nickel-cadmium

recbargeable batteries. Length of service from each

charging will depend on the type of work you are doing.

This productcontains nickel-cadmium

batten/. Local, state, or federal laws may

prohibitdisposalof nickel-cadmium

batteries in ordinarytrash.

Consult your local waste authorityfor information

regardingavailable recyclingand/or disposaloptions.

The battedes in this tool have been designed to provide

maximum trouble free life. However, like all batteries, they

will eventually wear out. Do not disassemble battery pack

and attempt to replace the batteries. Handlingof these

battedes, especially when weadng dngs and jewelry,

could result in a serious bum.

BATFERY PACK REMOVAL AND PREPARATION

FOR RECYCLING

To obtain the longest possiblebattery life, we suggestthe

following:

•

WARNING: Do not attempt to modifythis tool or

craata accessoriesnot recommendedfor use with

this tool.Any such alterationor modificationis

misuse and could result in a hazardous condition

leadingto possiblesedous personalinjury,

_i

Store and charge your batteries in a cool area.

Temperatures above or below normal room

temperature will shorten battery life.

•

Never store battedes in a dischargedcondition.

Recharge them immediatelyafter they are discharged.

• All batteriesgradually lose their charge. The higherthe

temperature the quickerthey lose their charge. If you

store your toolfor long padods of time without using it,

recharge the battedes every month or two. This

practicewill prolongbattery life.

20

WARNING: Upon removal, cover the battery pack's

terminals with heavy duty adhesive tape. Do not

attempt to destroyor disassemble battery pack or

remove any of its components. Nickel-cadmium

battades mustbe recycledor disposedof properly.

Also, never touch bothterminalswith metal objects

and/or body parts as shortcircuitmay result. Keep

away from children.Failure to comply with these

warningscould resultin fire and/or sedous injury.

21

CRAFTSMAN

18 VOLT CORDLESS

TRIM SAW-

MODEL

NUMBER

315.114231

26

12

14

28

19

104_

6

T -j9

,

_

16

20

23

21 22

I

24

5

2

25

i

22

CRAFTSMAN

18 VOLT CORDLESS

TRIM SAW-

MODEL

NUMBER

315.11423t

1

The model numberwill be found on a plato attachedto the motorhousing,Always mention the model number in all correspondenceregardingyour

CORDLESS TRIM SAW or when orderingrepair parts.

SEE BACK

PAGE

FOR PARTS

ORDERING

I

INSTRUCTIONS

PARTS LIST

Key

NO.

Part

Number

1

975546-000

Cardage Bolt(MS x 102 ram) ..................... 1

16

6619302

Bumper Screw............................................ 1

2

3025516

Base Assembly.......................................... 1

17

6867201

3

975544-00O

LockNut ..................................................... 2

18

5599401

Torsio_ Spdng............................................ 1

Lower Blade Guard .................................... 1

4

5224502

Knob ........................................................... 2

19

6807001

Ball Bearing (NTN #6000ZZ) ..................... 1

5

975552-000

Spdng ......................................................... 1

20

6850303

Bearing Retainer ........................................ 1

6

975551-000

Wing Screw ................................................ 1

21

6620104

BearingRetainer Screw ............................. 4

7

975549-,000

Base Screw................................................ 1

22

6112004

Inner BladeWasher ................................... 1

8

975559000

Hex Nut ...................................................... 1

23

* 982296-001

Saw Blade .................................................. 1

Dsecrlptlon

Key

No.

Quan.

Part

Number

nelmrlptlon

Quse.

9

9755,58-000

Screw ......................................................... 1

24

975533-00O

Outer Blade Washer .................................. 1

10

975550-000

Carriage Bort(M6 x 13 ram) ....................... 1

25

975532-000

Blade Screw ............................................... 1

11

983726-001

Data Plate .................................................. 1

26

** Item No. _ 11041

Charger (1425301) ..................................... 1

12

975557-000

Warning Label............................................ 1

27

"_'Item No. 9 11045

Battery Pack (1323905) ............................. 1

13

64556O8

Upper BladeGuard .................................... 1

28

975554-000

Rip Guido ................................................... 1

14

6620803

Upper BladeGuard Screw ......................... 4

29

975553-000

Blade Wrench (5 mm Hex Key) ................. 1

15

5217802

Bumper ....................................................... 1

30

3073011

Carrying Case - NOtShown ...................... 1

983000-281

Operator's Manual

* Available At Your Nearest Sears Catalog Order Or Retail Store

** Can Be Purchased Thru RSO6 (Retail Special Order System)

23

Your Home

For repair-in your home-of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold itl

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800.4-MY-HOME

®

(1_oo..4_9-4_s3)

Call any0me, day or night (U.S.A.

www,sears,com

and Canada)

www, sears,ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location of your nearest

Sears Parts & Repair Center.

1-800-488-1222

Call anytime, day or night (U.S.A. only)

www, sears,com

To purchase a protecUonagreement (U.S.A.)

or maintenance agreement (Canada) on a product serviced by Sears:

1-800-827-6655

(U.S.A.)

Para pedir sarvicio de reparacibn

a domicilio, y para ordenar piazas:

1-888-SU-HOGAR

sM

1-800-361-6665

(Canada)

Au Canada pour service en fran_;ais:

(1-888-784-6427)

1-800-LE-FOYER _c

(1-800-533-6937)

www.sears.ca

8E U 8

® RegisteredTradem_'k I TMTrademark/ au SendeeMKk ofSears. RoebuckandCo.

® Marea Reglotrade/ "rMMarca de F_bdcaI aMMaro=de Sen.'ldo de Sears, RodauGkandCo.

MCMarque de cornrneme/ M®Marque d6pos6ede Sear_ RoebuckandCo.

® Sea's, Roebuckand Co.