Download Monogram ZISW420D Specifications

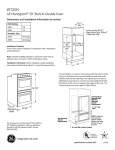

Transcript