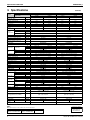

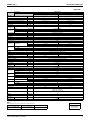

Download Daikin Quaternity H-Series Specifications

Transcript