Download Carrier 48PD05 Product data

Transcript

48PD05---06

Displacement Ventilation or Single Zone Variable Airflow

Rooftop Units Single Package, Electric Cool, Gas Heating

with PURONr (R---410A) Refrigerant and COMFORTLink™ Controls

Product Data

Copyright 2010 Carrier Corp. D 7310 W. Morris St. D Indianapolis, IN 46231

Printed in U.S.A.

Edition Date: 06/10

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

Catalog No:48PD---01PD

Replaces: NEW

TABLE OF CONTENTS

GAS HEATING CAPACITIES AND EFFICIENCIES . . . . . . . 6

S Evaporator fan motor system with high performance belt drives

and variable speed motors from 20% to 100%

S Internally protected, shaft down totally enclosed condenser

motors

S 2 inch filter standard, field convertible to 4 inch capability

S 24 volt control system with resettable circuit breakers

S Induced draft combustion (gas units)

S Redundant gas valves with up to two stages of heating

S ENERGY STAR qualified

PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maintenance Features Include:

FIOP AND ACCESSORY TABLE . . . . . . . . . . . . . . . . . . . . . . 9

S Single slab, single pass evaporator and condenser coils with dual

side access panels

S Hinged access doors with, quick turn latches and door retainers

S Slide out indoor fan assembly for added service convenience

S Dedicated, fully insulated compressor compartment

S Rust--proof, slide out evaporator condensate pan

S Permanently lubricated evaporator, condenser and inducer

motors

FEATURES AND BENEFITS . . . . . . . . . . . . . . . . . . . . . . . . . . 2

UNIT SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DISPLACEMENT VENTILATION SUMMARY . . . . . . . . . . 3

SINGLE--ZONE VAV SUMMARY . . . . . . . . . . . . . . . . . . . . . . 3

MODEL NUMBER NOMENCLATURE . . . . . . . . . . . . . . . . . 4

AHRI CAPACITY RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ACCESSORY WEIGHT ADDERS . . . . . . . . . . . . . . . . . . . . . 10

BASE UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ROOF CURB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SELECTION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MAXIMUM COOLING CAPACITY . . . . . . . . . . . . . . . . . . . 14

FAN PERFORMANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . 16

ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . 23

APPLICATION DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

GUIDE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

FEATURES AND BENEFITS

The Centurion 48PD rooftop units use Puronr (R--410A)

refrigerant and ComfortLinkt DDC controls. These units are

intended to be used in a either a displacement ventilation or a

single--zone variable air volume application. In addition, the

standard features and benefits of a Centurion rooftop unit, the PD

units include a factory installed variable capacity compressor and

variable frequency drive indoor fan motor.

Performance Features Include:

S

S

S

S

S

S

S

S

S

S

S

S

S

Puron (R--410A) HFC refrigerant

SEER up to 15.2, EER up to 12.8

AHRI certified outdoor sound levels as low as 72 db

Fully hermetic, digital scroll compressors with capacity

modulation provide any capacity between 15 and 100%.

ComfortLink Direct Digital Controls (DDC)

Phase loss and compressor reverse rotation protection

TXV refrigerant metering system on each circuit

High Pressure, Low Pressure/Loss of charge, and Freeze

protection.

Solid core liquid line filter drier on each circuit.

Ambient cooling operation from 0_F up to 125_F

Foil faced insulation throughout entire unit

Pre--painted exterior panels and primer--coated interior panels

tested to 500 hours ASTM B117 (scribed specimen)salt spray

protection

Rust--proof, internally sloped condensate pan conforms to

ASHRAE 62 standards

Installation Features Include:

S

S

S

S

S

S

S

Thru the bottom and side weather tight electrical access plate

Thru the bottom and side gas connection capabilities

Single point electrical and gas connections

Return and supply duct fits between 24” on center joist

Field convertible from vertical to horizontal airflow

Single piece outdoor air hoods

Full perimeter base rail with built--in rigging adapters and fork

truck slots

Factory Installed Options Include:

S

S

S

S

S

S

S

S

S

S

S

S

S

S

S

2

Supply and/or return air smoke detectors

Powered or non--powered 115 volt convenience outlet

Non--fused disconnect switch or circuit breaker

Dry bulb or enthalpy economizer with/without return air CO2

sensor

Two--position motorized outdoor damper

Barometric relief damper

Power Exhaust

Condenser coil guard

Copper/Copper coils

Pre--coated condenser coil

E--coated coils

Fan status and filter status switches

High static indoor fan and drive systems

Stainless steel gas heat exchanger (gas units)

Low NOx models that meet California Air Quality Management

requirements (gas units)

UNIT SUMMARY

There are two key elements that separate a Centurion PD unit from

other Centurion units; the use of a variable speed fan and a

modulating compressor. The modulating compressor allows the fan

speed to slow down without the refrigerant coil freezing during

low load, and also allows for variable supply air temperatures. In

general, a space temperature input is used to control the airflow and

a supply air temperature input is used to control the compressor

load. All other components of this machine are similar to concepts

used on other Carrier package units. An economizer is used to take

advantage of any free cooling opportunities in addition to

providing the required outside air. Additionally, all units will come

standard with factory installed ComfortLinkt controls which

makes demand controlled ventilation easy to install and implement.

If this unit is to be integrated with an open protocol type building

automaton system a translator card or LEI card can be installed and

the unit can be viewed on an up front system. If humidity is a

concern, a humidistat can be installed in the zone, and the indoor

fan will slow down to ensure proper moisture removal from the

supply air.

Although this unit was designed for the requirements of a

displacement ventilation system, it can also be used in a

single--zone variable air volume application. However, the use of a

supply air pressure input to control the Centurion PD unit is not

supported nor recommended; the unit is not designed to provide a

constant supply air pressure.

Centurion PD units are ideal on buildings that are looking for

either maintenance friendly units or trying to achieve LEED

certification. The units have a high SEER value, but more

importantly, the modulating compressor and fan system allow a

significant reduction in overall energy consumption beyond what

is quantified by the SEER value. This can contribute significantly

to the LEED intent of achieving overall lower building energy

consumption. Initial studies have shown that a Centurion PD unit

can use up to 35% fewer kilowatts than a typical constant volume

unit over the cooling season.

DISPLACEMENT VENTILATION

SUMMARY

Displacement Ventilation (DV) systems are very closely related to

the design of underfloor air systems. Although the air delivery

method is slightly different, the design philosophy is the same.

Displacement ventilation discharges air horizontally near the floor

at very low velocities and near laminar flow conditions. The goal is

to use only the buoyancy effects to create air motion within the

space and maintain the stratification layer above the controlled

zone that is not mixed. The air is introduced at the floor level at

approximately 65_F and the air moves upward through the space

taking both heat and any contaminants that might be in the air up

out of the occupied space to the ceiling. Unlike displacement

ventilation a mixing ventilation system requires more cooling

capacity since air must be cooled significantly before it is

introduced into the classroom or office. Displacement ventilation

does not require the same cooling capacity; it uses warmer air

delivered at 63_ to 68_ to achieve that same space set point.

The DV system use is a feasible alternative to the current practice

of mixing air distribution systems. It is energy efficient, quiet and

distributes air more efficiently than other ventilation systems. It

improves the indoor air quality (IAQ) by providing supply air

directly to building occupants and saves energy by conditioning

only the lower occupied portion of a space. Displacement

Ventilation is a means of providing cool supply air directly to the

occupants in a room such as a classroom or auditorium. In the case

of a school classroom, cooling is localized where the occupants are

located. The air is heated or cooled so that it enters the room at

~65_F, considerably warmer than with a conventional air

conditioning system.

The fresh air, supplied near the floor at a very low velocity, falls

towards the floor due to gravity and spreads across the room until it

comes in contact with heat sources, such as people and computers.

As this cool air picks up heat from the school’s occupants and

equipment it slowly rises. This creates a vertical airflow pattern

near each occupant: often called a thermal plume. Contaminants

such as germs are caught in the thermal plume and removed from

each occupant toward the ceiling, where they exit the classroom or

auditorium.

Displacement Ventilation applications are desirable due to the

potential for energy savings that result from only having to size

unit capacities for approximately 1/3 the zone volume used for

conventional constant volume packaged rooftop unit applications.

In practices, displacement ventilation applications have recorded

30--35% less kilo--watt/hr usage when compared to a similarly

efficient constant volume unit.

See the California Energy

Commission Displacement Ventilation Design Guide for further

details on displacement ventilation.

Refer to Carrier Application Data for the 45XC (Catalog No. 04-51450001--01) for the design of Underfloor Air Distribution

Systems for additional details on Displacement Ventilation

Application and Design.

SINGLE--ZONE VAV SUMMARY

A Single--Zone Variable Air Volume (VAV) concept utilizes a

variable capacity compressor system and a variable speed fan

system to modulate the cooling, dehumidification and airflow as

required meeting the space needs. Unlike traditional VAV

applications, there are no mixing boxes or bypass ducts because the

application is a single zone. The space temperature can be set and

maintained very accurately using a space temperature sensor (not a

thermostat). Space humidity control is a built in feature with the

addition of a humidistat. Supply air temperatures and airflows will

vary based on the demand from the space.

Design parameters of the system should be based around the

maximum cooling and heating design parameters, just like on a

constant volume system. The unit will modulate the cooling,

dehumidification and airflow to meet not only the design cooling

demand, but the part--load cooling and dehumidification demand

as well. Good applications for Single--Zone VAV include any

situation where a constant volume unit would be used, but one or

more of the following criteria are desired:

More consistent space conditioning

With the combination of the modulating compressor and variable

speed indoor fan, the unit will be able to maintain a much more

consistent space temperature and/or humidity level than a

traditional CV unit which must cycle the compressor on/off.

Significant energy savings

With the combination of the modulating compressor and variable

speed indoor fan, the unit will use less power over the cooling

season. Job site application measurement data indicates that the

PD units can use up to 40% less kW/h than the same size &

efficiency constant volume unit.

Reduced indoor fan noise

With the variable speed indoor fan, indoor airflow noise & fan

start--up noise will be significantly reduced.

Increased ventilation air

With the combination of the modulating compressor and variable

speed indoor fan, the unit can achieve higher volumes of outside

air and still achieve typical supply air conditions.

3

MODEL NUMBER NOMENCLATURE

48PD

D

C

06

A

A

A

6

---

---

BB

Product Series

48PD --- Single Packaged Rooftop Unit with PURONR

Gas Heat,Variable capacity

compressor and variable speed indoor fan

FIOP Codes

Not Used

Gas Heat Options**

D --- Low Heat with Standard Heat Exchanger

E --- Medium Heat with Standard Heat Exchanger

F --- High Heat with Standard Heat Exchanger

L --- Low Heat Stainless Steel Heat Exchanger

M --- Medium Heat Stainless Steel Heat Exchanger

N --- High Heat with Stainless Steel Heat Exchanger

Factory Design Revision

Voltage--- Phase--- Hz

5 --- 208/230--- 3--- 60

6 --- 460--- 3--- 60

Base Unit Controls

C --- ComfortLinkt

Coil Options

--- --- Standard AL/CU Coils

A --- Pre--- Coated AL/CU condenser

B --- E--- coated AL/CU condenser

C --- E--- coated AL/CU condenser and evaporator

D --- CU/CU condenser

E --- CU/CU condenser and evaporator

F --- E--- coated CU/CU condenser

G --- E--- coated CU/CU condenser and CU/CU evaporator

H --- E--- coated CU/CU condenser and evaporator

Nominal Capacity --- Tons

05 --- 4 Tons

06 --- 5 Tons

Control Options

----None

A

--CO2 Sensor

B

--Return air smoke detector

C

--CO2 Sensor, Return air smoke detector

D

--Fan and filter switches

E

--CO2 Sensor, fan and filter switches

F

--CO2 Sensor, Return air smoke detector, fan and filter switches

G

--Return air smoke detector, fan and filter switches

H

--Return and supply air smoke detectors

J

--CO2 Sensor, Return and supply air smoke detectors

K

--CO2 Sensor, fan and filter switches, Return and supply air smoke detectors

L

--Fan and filter switches, Return and supply air smoke detectors

Indoor Fan Options*

A

--- Low Range Motor/Drive with Vertical Supply and Return

Air Configuration

D

--- High Range Motor/Drive with Vertical Supply and Return

Air Configuration

J

--- Low Range Motor/Drive with Vertical Supply and Return

Air Configuration and Phase Loss

M --- High Range Motor/Drive with Vertical Supply and Return

Air Configuration and Phase Loss

* Units are field convertible to horizontal supply and/or return air configuration. Horizontal conversion may require

different accessory devices.

** Gas heat options L, M, and N are compliant with the California Low NOx requirements.

Quality Assurance

This product has been designed and manufactured

to meet Energy Star® criteria for energy efficiency.

However, proper refrigerant charge and proper air

flow are critical to achieve rated capacity and

efficiency. Installation of this product should follow

all manufacturer’s refrigerant charging and air flow

instructions. Failure to confirm proper charge and

air flow may reduce energy efficiency and

shorten equipment life.

Certified to ISO 9001:2000

Well exceeds

ASHRAE 90.1 and

Energy Star Standards

4

AHRI CAPACITY RATINGS

UNIT 48PD

NOMINAL

CAPACITY (Tons)*

COOLING CAPACITY

(MBtuh)

SEER

EER

RATED

CFM

05

06

4

5

47,500

58,500

15.2

14.65

12.55

12.25

1,600

1,750

SOUND

RATING

(dB)

72

78

NOTES:

1. Tested in accordance with AHRI Standards 210/240.

2. Ratings are net values, reflecting the effects of circulating fan heat.

3. Ratings are based on:

Cooling Standard: 80 F db, 67 F wb indoor entering---air temperature and

95 F db air entering outdoor unit.

4. All 48PD units are in compliance with ENERGY STARR and ASHRAE

90.1 2004 Energy Standard for minimum SEER and EER requirements.

5. Units are rated in accordance with AHRI sound standards 270 or 370.

* Nominal cooling tons shown is the maximum design capacity value.

LEGEND

AHRI

--- Air Conditioning, Heating and Refrigeration Institute

Test Standard

dB

--- Decibel

EER

--- Energy Efficiency Ratio

SEER

--- Seasonal Energy Efficiency Ratio

Use of the AHRI Certified

TM Mark indicates a

manufacturer’s

participation in the

program For verification

of certification for individual

products, go to

www.ahridirectory.org.

Outdoor Sound Power (Total Unit)

UNIT

48PD

05

06

AHRI

RATING

(dB)

72

78

OCTAVE BAND LEVELS dB

A --- WEIGHTED

(dB)

63

125

250

500

1000

2000

4000

8000

82.6

83.8

80.1

82.4

81.1

83.4

78.8

81.6

77.2

79.1

77.4

78.8

76.4

76.9

72.4

72.9

70

70.2

LEGEND

AHRI

--- Air Conditioning, Heating and Refrigeration Institute Test Standard

dB --- Decibel

NOTE:

---Indoor sound power is available via Carrier’s Electronic Catalog Program for specific operating parameters.

---Because Centurion PD units utilize a variable speed indoor fan system, the resulting indoor sound values are 6 ---8 dB below a similar unit with constant volume

airflow.

5

GAS HEATING CAPACITIES AND EFFICIENCIES

Vertical and Horizontal Supply Units with Natural Gas (Three Phase)

48PD

Standard

Stainless Steel

HEATING INPUT

Stage 2 (Btuh)

—

D05

E05

F05

D06

E06

F06

L05*

—

M05

N05*

L06*

M06*

N06*

51,000

56,000

75,000

113,000

75,000

113,000

151,000

HEATING

INPUT Stage 1

(Btuh)

35,700

39,200

52,500

79,100

52,500

79,100

105,700

OUTPUT CAPACITY

Stage 2 (Btuh)

41,300

45,400

60,800

91,500

60,800

91,500

122,300

TEMPERATURE

RISE

Min --- Max (F)

25 --- 70

25 --- 70

20 --- 60

30 --- 75

20 --- 60

30 --- 75

45 --- 75

MINIMUM

HEATING CFM**

500

600

940

1,130

940

1,130

1,510

THERMAL

EFFICIENCY

(%)

81.0

81.0

Vertical and Horizontal Supply Units With Propane Gas (Three Phase)

Standard

D05

E05

F05

D06

E06

F06

48PD

Stainless

Steel**

L05

M05

N05

L06

M06

N06

HEATING

INPUT Stage 2

(Btuh)

55,000

74,000

111,000

74,000

111,000

148,000

HEATING

INPUT Stage 1

(Btuh)

38,500

51,800

77,700

51,800

77,700

103,600

OUTPUT

CAPACITY Stage 2

(Btuh)

44,600

60,000

90,000

60,000

90,000

120,000

NG Altitude Compensation* — 48PD

ELEVATION

(ft)

0--- 1,999

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

11,000

12,000

13,000

14,000

NATURAL GAS

ORIFICE SIZE{

45

47

47

47

48

48

48

49

49

50

51

51

52

52

LP

ORIFICE SIZE{

52

52

53

53

53

53

53

54

54

54

54

55

55

56

MINIMUM

HEATING

CFM**

600

940

1,130

940

1,130

1,510

TEMPERATURE

RISE Min --- Max (F)

25

20

30

20

30

45

-------------

70

60

75

60

75

75

THERMAL

EFFICIENCY

(%)

81.0

81.0

Orifice Quantity — 48PD

UNIT

Low Heat (D/L)

Medium Heat (E/M)

High Heat (F/N)

05

3

4

6

06

4

6

8

* As the height above sea level increases, there is less oxygen per cubic foot of

air. Therefore, heat input rate should be reduced at higher altitudes. Includes a 4%

input reduction per each 1000 ft.

** Gas heat options L, M and N are compliant with the California Low NOx requirements

{ Orifices available through your local Carrier dealer.

6

PHYSICAL DATA

BASE UNIT 48PD

NOMINAL CAPACITY (Tons)

OPERATING WEIGHT (lb)*

Base Unit

Economizer

Vertical

Horizontal

Roof Curb

14-in.

24-in.

REFRIGERANT SYSTEM

Refrigerant

Metering Device

# Circuits/ # Compressors

Charge (lb)

High Pressure Switch Cutout (psig)

High Pressure Switch Auto Reset (psig)

COMPRESSOR

Oil Type

Oil (oz)

CONDENSER COIL

Circuit

Rows...Fins/in.

Face Area (sq ft)

CONDENSER FAN

Quantity…Diameter (in.)

Nominal Cfm (Total, all fans)

Motor Nominal Hp/Watts

Nominal Rpm

EVAPORATOR COIL

Standard Coil Tube/Fins

Rows…Fins/in.

Face Area (sq ft)

Condensate drain conn size (in.)

EVAPORATOR FAN (See motor and drive tables)

05

06

4

5

901

921

40

50

40

50

122

184

122

184

Puron® (R---410A) Refrigerant

Balanced---Port TXV with Bypass

1/1

1/1

14.5

16.0

660 ± 10

660 ± 10

505 ± 20

505 ± 20

Copeland Digital Scroll

Copeland 3MA

42

42

Round Tube Plate Fin

Outer/Inner

Outer/Inner

2…17

2…17

12.6

12.6

Propeller

1…24

1…24

3500

3500

0.125/227

0.25/351

825

1100

Round Tube Plate Fin

Cu/Al

Cu/Al

2…15

3…15

9.3

9.3

3/4 NPT

3/4 NPT

Fan Quantity/Type

Belt Size (in.)

Blower Pulley Type

Fan Type

Fan Bearing Type

Maximum Fan RPM

Blower Shaft Diameter (in.)

Motor Max HP

Motor Frame Size

FILTERS

Unit Filter Type

Unit Filter Qty/Size (in.)

Economizer OA Inlet Screen Qty/Size (in.)

* Aluminum evaporator coil/aluminum condenser coil with low heat

7

1/Belt

12 x 9

Fixed

Centrifugal

Ball ---Concentric Lock

2000

0.75

2.4

56Hz

1/Belt

12 x 9

Fixed

Centrifugal

Ball ---Concentric Lock

2000

0.75

2.4

56Hz

Fiberglass fill, non ---pleated

4/16 x 20 x 2

1/25.8 x 16.4

Fiberglass fill, non ---pleated

4/16 x 20 x 2

1/25.8 x 16.4

BASE UNIT 48PD

GAS HEAT SECTION

# of Gas Valves

Gas Supply Line Pressure Range (in.wg)

Gas Supply Line Pressure Range (PSIG)

Manifold Pressure (in.wg)

Natural Gas Vertical/Horizontal

Liquid Propane Vertical/Horizontal

Thermostat Heat Anticipator Setting (amps)

Field Gas Connection Size (in.)

Natural Gas

Low Heat

# of burners (total)

Rollout switch opens/closes (deg F)

Temperature Rise Min --- Max (deg F)

Burner Orifice Diameter (in./drill size)**

Medium Heat

# of burners (total)

Rollout switch opens/closes (deg F)

Temperature Rise Min --- Max (deg F)

Burner Orifice Diameter (in./drill size)**

High Heat

# of burners (total)

Rollout switch opens/closes (deg F)

Temperature Rise Min --- Max (deg F)

Burner Orifice Diameter (in./drill size)**

Propane

Low Heat

# of burners (total)

Rollout switch opens/closes (deg F)

Temperature Rise Min --- Max (deg F)

Burner Orifice Diameter (in./drill size)**

Medium Heat

# of burners (total)

Rollout switch opens/closes (deg F)

Temperature Rise Min --- Max (deg F)

Burner Orifice Diameter (in./drill size)**

High Heat

# of burners (total)

Rollout switch opens/closes (deg F)

Temperature Rise Min --- Max (deg F)

Burner Orifice Diameter (in./drill size)**

05

** For applications less than 2000 ft elevation.

{ PD unit does not support the use of conventional Y1/W1 thermostat

8

06

1

1

5.0 ---13.0

0.180 ---0.469

3.50/3.50

3.50/3.50

NA{

1/2

5.0 ---13.0

0.180 ---0.469

195

3.50/3.50

3.50/3.50

NA{

1/2

3

195/115

25 --- 70

0.0820/45

4

195/115

25 --- 60

0.0820/45

4

195/115

25 --- 60

0.0820/45

6

225/175

30 --- 75

0.0820/45

6

225/175

30 --- 75

0.0820/45

8

195/115

45 --- 75

0.0820/45

3

195/115

25 --- 70

0.0650/52

4

195/115

20 --- 60

0.0650/52

4

195/115

20 --- 60

0.0650/52

6

225/175

30 --- 75

0.0650/52

6

225/175

30 --- 75

0.0650/52

8

195/115

45 --- 75

0.0650/52

FIOP AND ACCESSORY TABLE

CATEGORY

ITEM

Hinged Access Panels

Cabinet

OPTION*

X

X

X

X

Thru--- the--- Bottom Connections Gas

Copper Fins --- condenser coil

X

Copper Fins --- evaporator and condenser coil

X

E--- Coat outdoor coil (Al/Cu) and indoor coil (Al/Cu)

X

E--- Coat outdoor coil (Al/Cu)

X

E--- Coat outdoor coil (Cu/Cu)

X

Pre--- Coated Aluminum condenser fins

X

Condenser Coil Grille

Condenser

Protection

Dehumidification

and IAQ

X

High Pressure/ Loss of Charge Switch

X

Low Pressure/ Loss of Charge Switch

X

Evaporator Freeze Protection Switch

X

Slide Out, Rust Proof, Sloped Condensate Pan

X

Foil Faced, Cleanable Insulation

X

Demand Control Ventilation CO2 Sensors

Economizer Sensors

X

X

MERV--- 8 Filters

X

EconoMi$er --- OA Temperature (includes barometric relief)

X

X

EconoMi$er --- Single Enthalpy (includes barometric relief)

X

X

100% Two--- Position Damper (motorized)

X

25% Two--- Position Damper (motorized)

X

Manual Outdoor--- Air Damper

X

Power Exhaust (prop fan)

X

Return Air Temperature Sensor

X

Return Air Enthalpy Sensor

X

Outdoor Air Differential Temperature Sensor

X

Outdoor Air Differential Enthalpy Sensor

X

Return Air CO2 Sensor (duct mounted)

X

Space CO2 Sensor (wall mounted)

X

ComfortLink Communicating Controller

Electrical and

Controls

X

X

HACR Breaker

X

Unit--- Mounted Non--- Fused Disconnect

X

Powered Convenience Outlet (load or line side powered)

X

Non--- Powered Convenience Outlet

X

Fan/Filter Status Switches

X

Stainless Steel Heat Exchanger

Gas Heat Exchanger

X

Flue Discharge Deflector

X

Low NOx Heat Exchanger

X

LP (liquid propane) Conversion Kit

Indoor Motor and

Drive

Low Ambient Control

Roof Curbs

X

Standard Static Indoor Fan Drive

X

High--- Static Indoor Fan Drive

X

Included with ComfortLink™ DDC Communicating Controller

X

X

Roof Curbs 14” (Vertical or Horizontal Supply/Return)

X

Roof Curbs 24” (Vertical or Horizontal Supply/Return)

X

Burglar Bars

X

Thermostats are not applicable to this product

Thermostats and

Sensors

X

X

Ultra--- Violet Lights

4--- Inch Filter Capability

Economizers and

Outdoor Air

ACCESSORY{

X

Thru--- the--- Bottom Connections Electrical

Coil Options

STANDARD

FEATURE

N/A

N/A

N/A

Communicating Space Temperature Sensors with/without over--- ride

X

Relative Humidity Sensor (space, duct or outdoor)

X

* Factory Installed

{ Field Installed

9

ACCESSORY WEIGHT ADDERS

OPTION/ACCESSORY WEIGHTS

ACCESSORY WEIGHTS

2--- Position Damper

4--- in Filter Capability

Barometric Relief Damper

CO2 Sensor

Cu Condenser and Evaporator Coils

Cu Condenser Coils

Differential Enthalpy Sensor

Economizer Horizontal

Economizer Vertical

Enthalpy Sensor

Fan Status

Gas Heat --- Low

Gas Heat --- Medium

Gas Heat --- High

HACR Breaker

Hail Guard

Manual Damper

Non--- Fused Disconnect

Non--- Powered Convenience Outlet

Plugged Filter Indicator

Power Exhaust

Powered Convenience Outlet

Return Smoke Detector

Roof Curb (14 in.)

Roof Curb (24 in.)

Supply Smoke Detector

05

lb

30

06

kg

lb

14

30

NO ADDITIONAL WEIGHT

NO ADDITIONAL WEIGHT

2

5

79

175

45

100

1

3

23

50

25

55

1

2

1

2

NO ADDITIONAL WEIGHT

7

15

14

30

9

20

23

50

14

30

7

15

9

20

1

2

14

30

16

35

2

5

66

145

70

155

2

5

5

175

100

3

50

55

2

2

15

30

20

50

30

15

20

2

30

35

5

145

155

5

NOTE: All weights do NOT include packaging.

10

kg

14

2

79

45

1

23

25

1

1

7

14

9

23

14

7

9

1

14

16

2

66

70

2

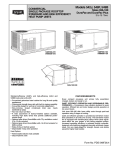

BASE UNIT DIMENSIONS

C08493

11

48PD

05-06

48PD

05-06

ROOF CURB

C07313

12

SELECTION PROCEDURE

I.

S

S

S

S

IV.

Determine cooling and heating requirements at design

conditions.

Given the following data:

Vertical or horizontal supply/return configuration

Evaporator air quantity (CFM)

External duct static pressure (in.wg)

Electrical characteristics (Volts--Ph--Hz)

Cooling

. . . Required gross cooling capacity (TC)

. . . Gross sensible capacity (SHC)

. . . Condenser entering air temperature (OATc)

. . . Indoor air (return air) temperature (RATc)

S

Heating

. . . Required heating capacity (HC)

. . . Ambient air temperature (OATh)

. . . Condenser entering air temperature (OATh)

. . . Indoor air (return air) temperature (RATh)

II.

Select unit size.

The unit size should be based on required cooling capacity

at design conditions.

1. Using the design cooling data, enter the cooling capacity

table (or software selection program) and determine the

unit Total Cooling and Sensible Cooling Capacities.

2. Compare unit performance to required TC and SHC

values.

S

NOTE: Unit ratings are gross capacities and do not include the effect of indoor fan motor heat. To calculate net

capacities, see Step V.

III. Select heating capacity

The unit heat option should be chosen to meet the heating

requirements at the design conditions.

1. For gas heat units, utilize heat output values from the

Gas Heating Capacities and Efficiencies table. Compare

the heating output value to the design criteria. Calculate

the heating leaving air temperature value using the formula:

EAT = (% RA)(RATh) + (%OA)(OATh)

Heat Output in BTU = (CFM)(1.08)(EAT – LAT)

S

V.

VI.

Determine fan speed and power requirements at design

conditions.

48PD units use the same fan performance tables as the

similar size PG units. The variable fan system for a PD unit

uses the 100% fan speed to satisfy the design cooling &

heating capacities (same fan speed). The unit will modulate

the fan system to lower speeds from that setting. See unit

Application Data and Sequence of Operation sections of this

manual for additional information.

1. Before entering the Fan Performance tables, calculate the

total static pressure required due to duct design and any

selected options/accessories.

2. Tabulated fan performance includes unit casing, filters,

and wet evaporator coil. User only has to add effect of

duct static pressure and options/accessories added to base

unit. If using the software selection program, the

options/accessory static pressure effects are automatically

added in the selection software, so user only has to

determine the appropriate duct static pressure.

3. Enter Fan Performance tables for the appropriate unit

and determine the fan speed (RPM) and horsepower

(bhp).

4. Compare fan speed and motor horsepower to speed

ranges of each drive per the fan tables. If using the

software selection program and more than one option is

compatible with the desired operating point, the program

will automatically default to the lower cost option.

Determine net cooling capacities.

Listed cooling capacities are gross capacities and do not

include indoor fan motor (IFM) heat. When desired,

calculate the net cooling capacity as follows:

1. Determine input power to the motor, by entering the Fan

Performance tables and determining the motor calculated

input watts:

Input Watts = (746 x Bhp)/(motor eff)

2. Determine net cooling capacity and net sensible cooling

capacity using the following formulas:

IFM Heat = Input Watts x 3.412 Btuh/Watt

Net Capacity = Gross Capacity -- IFM Heat

Select compatible controls and sensors.

The 48PD units cannot be operated using a conventional

Y1/Y2 thermostat. A space temperature sensor must be used

with or without a humidity or CO2 input.

NOTE:

1. Unit design selection should be chosen with consideration for

the design maximum cooling & heating conditions. Because the

PD units use a modulating fan and modulating compressor system,

an infinite range of part--load cooling performance is available.

The part--load cooling capacity will modulate to the specific

requirements of the zone as called for by the zone requirements.

2. The unit selection and initial unit configuration must be made

with the unit’s 100% airflow configuration in the nominal unit

range of 300--500 cfm/nominal ton. This is necessary to in order

for the ComfortLinkt control logic to properly control the unit.

3. Economizer minimum damper position is automatically adjusted

by the unit’s ComfortLink controls as the indoor fan speed

changes, in order to ensure the Outdoor Ventilation Air does not

fall below the desired setpoint.

13

MAXIMUM COOLING CAPACITY

48PD05

Temp (F)

Air Entering Evaporator — Cfm

Air Ent

1200

1600

Air Entering Evaporator — Ewb (F)

Condenser

(Edb)

TC

SHC

60

BF

TC

SHC

70

BF

TC

SHC

75

BF

TC

SHC

85

BF

TC

SHC

95

BF

TC

SHC

105

BF

TC

SHC

115

BF

TC

125

SHC

BF

2000

80

76

72

67

62

58

54

80

76

72

67

62

58

54

80

76

72

67

62

58

54

66.6

18.3

0.00

64.4

17.6

0.00

63.2

17.2

0.00

60.6

16.3

0.00

57.9

15.5

0.00

54.8

14.5

0.00

51.3

13.5

0.00

47.4

12.3

0.00

62.4

23.4

0.00

60.3

22.6

0.00

59.1

22.2

0.00

56.7

21.3

0.00

54.2

20.1

0.00

51.4

19.1

0.00

48.2

18.3

0.00

44.5

17.2

0.26

58.4

27.8

0.00

56.4

27.2

0.36

55.4

26.9

0.29

53.1

26.1

0.26

50.7

25.2

0.23

48.0

24.3

0.21

45.2

23.2

0.19

41.9

22.1

0.18

53.6

33.8

0.24

51.8

33.2

0.22

50.8

32.8

0.22

48.8

32.0

0.20

46.6

31.2

0.19

44.2

30.2

0.18

41.6

29.2

0.18

38.7

28.0

0.17

49.1

39.6

0.22

47.5

38.9

0.20

46.6

38.6

0.20

44.7

37.7

0.19

42.7

36.8

0.19

41.9

31.0

0.18

38.3

34.9

0.18

35.7

33.5

0.18

45.7

43.4

0.23

44.1

42.3

0.24

43.4

41.8

0.24

41.7

40.3

0.27

39.9

39.9

0.24

38.3

38.3

0.27

36.6

36.6

0.30

34.6

34.6

0.34

44.5

44.5

0.37

43.3

43.3

0.39

42.7

42.7

0.40

41.3

41.3

0.41

39.9

39.9

0.43

38.3

38.3

0.45

36.6

36.6

0.48

34.6

34.6

0.50

70.5

18.6

0.00

67.9

17.8

0.00

66.4

17.4

0.00

63.5

16.5

0.00

60.4

15.6

0.00

57.0

14.6

0.00

53.2

13.5

0.00

48.9

12.3

0.00

66.2

24.3

0.00

63.6

23.7

0.00

62.3

23.4

0.00

59.5

22.6

0.00

56.5

21.7

0.36

53.4

20.8

0.28

50.0

19.7

0.24

46.0

18.6

0.22

61.9

31.0

0.27

59.5

30.2

0.25

58.3

29.8

0.24

55.7

28.9

0.23

53.1

28.0

0.22

50.2

27.0

0.21

47.1

25.9

0.21

43.4

24.7

0.20

57.0

38.6

0.23

54.8

37.8

0.22

53.7

37.3

0.22

51.4

36.5

0.21

48.9

35.5

0.21

46.3

34.5

0.21

43.5

33.4

0.20

40.3

32.2

0.20

52.3

45.8

0.23

50.4

45.1

0.22

49.4

44.7

0.22

47.2

43.6

0.22

44.9

42.4

0.22

42.6

41.0

0.23

40.2

39.3

0.26

37.5

37.5

0.27

49.2

49.2

0.30

47.8

47.8

0.31

47.0

47.0

0.33

45.4

45.4

0.35

43.7

43.7

0.37

41.9

41.9

0.40

39.9

39.9

0.42

37.5

37.5

0.46

49.2

49.2

0.47

47.8

47.8

0.49

47.0

47.0

0.50

45.4

45.4

0.51

43.7

43.7

0.53

41.9

41.9

0.55

39.9

39.9

0.57

37.5

37.5

0.59

72.9

18.7

0.00

70.0

17.9

0.00

68.4

17.5

0.00

65.3

16.6

0.00

62.0

15.7

0.00

58.3

14.7

0.00

54.3

13.6

0.00

49.9

12.4

0.01

68.3

26.1

0.00

65.6

25.3

0.36

64.1

24.9

0.33

61.2

24.0

0.30

58.1

23.1

0.27

54.8

22.1

0.26

51.2

21.0

0.24

47.0

19.8

0.23

64.1

33.7

0.26

61.6

32.8

0.25

60.2

32.4

0.25

57.5

31.4

0.24

54.6

30.5

0.23

51.6

29.5

0.23

48.3

28.3

0.23

44.5

27.1

0.22

59.1

42.7

0.24

56.8

41.9

0.24

55.6

41.4

0.24

53.1

40.5

0.23

50.5

39.5

0.23

47.7

38.4

0.23

44.7

37.3

0.23

41.3

35.9

0.23

54.3

51.0

0.25

52.1

49.7

0.26

51.1

49.1

0.27

49.0

47.6

0.28

46.6

46.6

0.28

44.5

44.2

0.32

42.2

42.2

0.34

39.5

39.5

0.38

52.7

52.7

0.39

51.1

51.1

0.41

50.3

50.3

0.42

48.5

48.5

0.44

46.5

46.5

0.46

44.5

44.5

0.48

42.2

42.2

0.51

39.5

39.5

0.54

52.7

52.7

0.55

51.1

51.1

0.56

50.3

50.3

0.57

48.5

48.5

0.58

46.6

46.6

0.60

44.5

44.5

0.61

42.2

42.2

0.63

39.5

39.5

0.66

LEGEND

BF --- Bypass Factor

Edb --- Entering Dry--- Bulb

Ewb --- Entering Wet--- Bulb

kW --- Compressor Motor Power Input

Idb --- Leaving Dry--- Bulb

Iwb --- Leaving Wet--- Bulb

SHC --- Sensible Heat Capacity (1000 Btuh) Gross

TC --- Total Capacity (1000 Btuh) Gross

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

tldb = tedb –

sensible capacity (Btuh)

1.10 x cfm

3. The SHC is based on 80_F edb temperature of air entering evaporator coil

Below 80_F edb, subtract (corr factor x cfm) from SHC.

Above 80_F edb, add (corr factor x cfm) to SHC.

BYPASS

FACTOR

(BF)

.05

.10

.20

.30

.76 1.53

2.29

3.05 3.82

Interpolation is permissible.

Correlation Factor = 1.09 x (1--- BF) x (edb --- 80).

4. Cooling capacities for 48PG03--- 16 units with Humidi--- MiZer system in Cooling

mode are the same as standard units.

tlwb = Wet--- bulb temperature corresponding to enthalpy of air leaving

evaporator coil (hlwb)

hlwb = hewb –

ENTERING AIR DRY-BULB TEMP (F)

78

77

76

75

under 75

82

83

84

85

over 85

Correction Factor

1.04 2.07 3.11 4.14 5.18

.98 1.96 2.94 3.92 4.90 Use formula

.87 1.74 2.62 3.49 4.36 shown below.

79

81

total capacity (Btuh)

4.5 x cfm

Where: hewb = Enthalpy of air entering evaporator coil

14

MAXIMUM COOLING CAPACITY (CONT)

48PD06

Temp (F)

Air Ent

Condenser

(Edb)

TC

SHC

60

BF

TC

SHC

70

BF

TC

SHC

75

BF

TC

SHC

85

BF

TC

SHC

95

BF

TC

SHC

105

BF

TC

SHC

115

BF

TC

125

SHC

BF

1200

80

83.9

23.0

0.00

81.1

22.1

0.00

79.9

21.7

0.00

76.9

20.8

0.00

73.6

19.7

0.00

69.8

18.6

0.00

65.6

17.3

0.00

60.8

15.9

0.00

72

73.6

35.7

0.17

71.3

34.9

0.16

70.1

34.4

0.16

67.5

33.5

0.15

64.5

32.4

0.15

61.3

31.2

0.15

57.8

30.0

0.15

53.8

28.5

0.15

67

67.9

43.4

0.16

65.8

42.6

0.16

64.7

42.1

0.16

62.2

41.1

0.15

59.5

40.1

0.15

56.6

38.9

0.15

53.4

37.7

0.14

49.7

36.1

0.14

62

62.6

51.1

0.16

60.6

50.1

0.16

59.5

49.4

0.16

57.2

48.7

0.15

54.8

47.4

0.16

52.1

46.2

0.15

49.0

44.8

0.15

45.7

42.9

0.17

58

58.8

55.7

0.20

56.7

54.2

0.21

55.6

53.6

0.21

53.7

52.0

0.23

51.5

51.4

0.23

49.4

49.3

0.26

47.0

47.0

0.30

44.5

44.4

0.34

54

57.3

57.2

0.37

55.7

55.6

0.39

54.8

54.8

0.40

53.3

53.2

0.42

51.5

51.4

0.44

49.3

49.3

0.46

47.1

47.0

0.49

44.5

44.5

0.51

LEGEND

BF --- Bypass Factor

Edb --- Entering Dry--- Bulb

Ewb --- Entering Wet--- Bulb

kW --- Compressor Motor Power Input

Idb --- Leaving Dry--- Bulb

Iwb --- Leaving Wet--- Bulb

SHC --- Sensible Heat Capacity (1000 Btuh) Gross

TC --- Total Capacity (1000 Btuh) Gross

Air Entering Evaporator — Cfm

2000

Air Entering Evaporator — Ewb (F)

80

72

67

62

58

54

88.6

78.1

72.0

66.7

63.2

63.2

23.4

39.9

49.6

59.3

63.1

63.1

0.00

0.17

0.17

0.18

0.29

0.47

85.4

75.4

69.4

64.4

61.4

61.5

22.5

38.8

48.6

58.1

61.4

61.4

0.00

0.17

0.17

0.18

0.31

0.49

83.8

73.9

68.1

63.2

60.6

60.6

22.0

38.3

48.1

57.5

60.5

60.5

0.00

0.17

0.17

0.18

0.32

0.50

80.3

70.9

65.4

60.6

58.6

58.6

21.0

37.2

46.8

56.0

58.5

58.6

0.00

0.17

0.18

0.19

0.34

0.52

76.4

67.7

62.4

57.9

56.5

56.5

19.8

36.1

45.9

54.6

56.4

56.4

0.00

0.17

0.17

0.20

0.37

0.53

72.1

64.2

59.2

55.0

54.1

54.1

18.6

34.8

44.6

52.8

54.1

54.1

0.00

0.17

0.17

0.21

0.39

0.55

67.4

60.3

55.8

51.8

51.5

51.4

17.3

33.5

43.2

50.5

51.4

51.4

0.00

0.17

0.17

0.23

0.42

0.57

62.0

56.0

51.7

48.4

48.4

48.4

15.8

32.0

41.6

47.8

48.3

48.3

0.00

0.18

0.17

0.27

0.46

0.60

80

91.2

23.5

0.00

87.8

22.6

0.00

85.9

22.0

0.00

82.0

20.9

0.00

77.9

19.8

0.00

73.3

18.5

0.00

68.3

17.2

0.00

62.6

15.6

0.00

72

80.8

43.2

0.20

78.0

42.2

0.20

76.4

41.7

0.20

73.2

40.6

0.20

69.7

39.4

0.20

66.0

38.1

0.20

61.9

36.7

0.20

57.4

35.0

0.21

67

74.9

55.3

0.19

72.2

54.2

0.19

70.8

53.6

0.19

67.8

52.3

0.20

64.6

51.2

0.19

61.2

49.9

0.20

57.5

48.4

0.20

53.3

46.7

0.20

62

69.4

65.6

0.22

67.0

64.1

0.23

65.7

63.3

0.24

63.0

61.4

0.25

60.1

60.0

0.26

57.7

56.2

0.31

54.5

54.5

0.33

51.0

51.0

0.38

58

67.6

67.5

0.39

65.8

65.7

0.41

64.8

64.7

0.42

62.5

62.5

0.44

60.1

60.0

0.46

57.4

57.4

0.48

54.6

54.5

0.51

51.1

51.0

0.54

54

67.6

67.5

0.55

65.7

65.7

0.56

64.8

64.7

0.57

62.5

62.5

0.58

60.1

60.1

0.60

57.5

57.4

0.62

54.6

54.5

0.64

51.1

51.0

0.66

3. The SHC is based on 80_F edb temperature of air entering evaporator coil

Below 80_F edb, subtract (corr factor x cfm) from SHC.

Above 80_F edb, add (corr factor x cfm) to SHC.

ENTERING AIR DRY-BULB TEMP (F)

BYPASS

FACTOR

(BF)

NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

sensible capacity (Btuh)

1.10 x cfm

tlwb = Wet--- bulb temperature corresponding to enthalpy of air leaving

evaporator coil (hlwb)

tldb

2500

= tedb –

79

78

77

76

75

under 75

81

82

83

84

85

over 85

Correction Factor

.05

1.04 2.07

3.11

4.14 5.18

.10

.98 1.96

2.94

3.92 4.90

.20

.87 1.74

2.62

Use formula

3.49 4.36 shown below.

.30

.76 1.53

2.29

3.05 3.82

Interpolation is permissible.

Correlation Factor = 1.09 x (1--- BF) x (edb --- 80).

total capacity (Btuh)

4.5 x cfm

Where: hewb = Enthalpy of air entering evaporator coil

hlwb = hewb –

15

FAN PERFORMANCE

Vertical Supply/Return

48PD05 (High Heat Units)

AIRFLOW

(Cfm)

1200

1300

1400

1500

1600

1700

1800

1900

2000

Rpm

520

545

570

596

623

650

677

705

734

0.2

Bhp

0.17

0.20

0.24

0.28

0.32

0.37

0.43

0.50

0.57

Rpm

628

648

668

691

714

737

762

787

813

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

0.4

0.6

0.8

Bhp

Rpm

Bhp

Rpm

0.24

723

0.33

811

0.28

739

0.37

823

0.32

756

0.41

837

0.37

775

0.46

853

0.42

795

0.52

870

0.48

816

0.58

889

0.54

838

0.65

909

0.61

861

0.72

929

0.68

884

0.80

951

Bhp

0.41

0.46

0.51

0.56

0.62

0.69

0.76

0.84

0.93

Rpm

892

902

913

927

942

958

976

994

1014

Rpm

1040

1046

1054

1063

1074

1087

1100

1116

1132

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.4

1.6

1.8

Bhp

Rpm

Bhp

Rpm

0.71

1108

0.82

1172

0.77

1112

0.88

1176

0.83

1119

0.95

1181

0.90

1127

1.02

1188

0.97

1136

1.09

1196

1.05

1147

1.17

1205

1.13

1159

1.26

1216

1.22

1173

1.36

1229

1.32

1188

1.46

1242

Bhp

0.93

1.00

1.07

1.14

1.22

1.31

1.40

1.50

1.61

Rpm

1233

1237

1241

1247

1254

1262

1272

1283

1295

48PD05 (High Heat Units) (cont)

AIRFLOW

(Cfm)

1200

1300

1400

1500

1600

1700

1800

1900

2000

Rpm

968

976

985

996

1009

1024

1039

1056

1074

1.2

Bhp

0.61

0.66

0.72

0.78

0.85

0.92

1.00

1.09

1.19

48PD06 (High Heat Units)

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

Rpm

620

648

677

707

737

767

798

829

861

893

925

0.2

Bhp

0.30

0.35

0.40

0.47

0.54

0.61

0.70

0.79

0.89

1.00

1.12

Rpm

711

736

762

788

815

843

871

900

929

959

989

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

0.4

0.6

0.8

Bhp

Rpm

Bhp

Rpm

0.39

794

0.49

871

0.45

816

0.55

890

0.51

838

0.61

910

0.58

862

0.69

931

0.65

887

0.77

954

0.73

912

0.85

977

0.82

938

0.95

1001

0.92

965

1.05

1026

1.03

992

1.17

1052

1.15

1020

1.29

1078

1.27

1048

1.42

1105

Bhp

0.59

0.65

0.72

0.80

0.89

0.98

1.08

1.19

1.31

1.43

1.57

Rpm

944

960

978

997

1017

1039

1061

1084

1108

1133

1158

Rpm

1078

1091

1105

1120

1137

1155

1174

1195

1216

1238

1261

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.4

1.6

1.8

Bhp

Rpm

Bhp

Rpm

0.92

1141

1.05

1202

1.00

1152

1.13

1211

1.08

1165

1.21

1222

1.18

1179

1.31

1235

1.27

1194

1.41

1249

1.38

1210

1.52

1264

1.49

1228

1.64

1280

1.62

1247

1.77

1298

1.75

1267

1.90

1317

1.89

1288

2.05

1336

2.04

1309

2.20

1357

Bhp

1.17

1.25

1.35

1.44

1.55

1.67

1.79

1.92

2.06

2.21

2.37

Rpm

1260

1269

1278

1290

1302

1316

1331

1348

1365

1384

—

48PD06 (High Heat Units) (cont)

AIRFLOW

(CFM)

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

LEGEND

Bhp --- Brake Horsepower

Rpm

1013

1027

1043

1060

1078

1098

1119

1140

1163

1186

1210

1.2

2.0

Bhp

0.51

0.56

0.61

0.67

0.73

0.80

0.88

0.97

1.06

Bhp

1.04

1.11

1.19

1.27

1.35

1.44

1.54

1.64

1.75

NOTES:

1. Motor drive range is 596 to 910 rpm for low range motor/drive and 828 to 1173 rpm

for high range motor/drive. All other rpms require a field-supplied drive.

2. Maximum continuous bhp is 0.85 for low range motor/drive and 1.60 (single phase)

and 2.40 (3 phase) for high range motor/drive.

3. See General Fan Performance Notes.

LEGEND

Bhp --- Brake Horsepower

High Range Motor/Drive Required

AIRFLOW

(Cfm)

1.0

Bhp

0.81

0.88

0.96

1.05

1.14

1.24

1.35

1.47

1.60

1.73

1.88

1.0

2.0

Bhp

0.70

0.76

0.84

0.92

1.01

1.11

1.21

1.33

1.45

1.58

1.72

Bhp

1.30

1.39

1.48

1.59

1.70

1.81

1.94

2.08

2.22

2.37

—

NOTES:

1. Motor drive range is 690 to 978 rpm for low range motor/drive and 929 to 1261 rpm

for high range motor/drive. All other rpms require a field-supplied drive.

2. Maximum continuous bhp is 0.85 (single phase) and 2.40 (3 phase) for low range

motor/drive and 1.60 (single phase) and 2.40 (3 phase) for high range motor/drive.

3. See General Fan Performance Notes.

16

FAN PERFORMANCE (CONT)

Horizontal Supply/Return

48PD05 (High Heat Units)

AIRFLOW

(Cfm)

1200

1300

1400

1500

1600

1700

1800

1900

2000

Rpm

456

477

500

524

550

576

604

633

662

0.2

Bhp

0.13

0.16

0.18

0.22

0.26

0.30

0.35

0.41

0.47

Rpm

574

591

610

630

652

675

699

724

750

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

0.4

0.6

0.8

Bhp

Rpm

Bhp

Rpm

0.20

675

0.28

766

0.23

688

0.32

776

0.27

703

0.36

788

0.31

720

0.40

802

0.35

739

0.45

819

0.40

759

0.50

836

0.46

781

0.57

856

0.52

804

0.63

876

0.59

828

0.71

898

Bhp

0.37

0.41

0.45

0.50

0.55

0.61

0.68

0.75

0.83

Rpm

850

857

867

879

893

908

925

944

964

Rpm

1003

1006

1012

1020

1029

1041

1054

1070

1086

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.4

1.6

1.8

Bhp

Rpm

Bhp

Rpm

0.66

1073

0.76

1139

0.71

1075

0.82

1140

0.76

1079

0.87

1143

0.82

1085

0.94

1148

0.89

1093

1.01

1155

0.96

1103

1.08

1163

1.04

1115

1.16

1174

1.12

1129

1.25

1186

1.21

1144

1.35

1199

Bhp

0.87

0.93

0.99

1.06

1.13

1.21

1.30

1.39

1.49

Rpm

1202

1202

1204

1208

1214

1221

1230

1241

1253

48PD05 (High Heat Units) (cont)

AIRFLOW

(Cfm)

1200

1300

1400

1500

1600

1700

1800

1900

2000

Rpm

929

934

941

951

963

976

991

1008

1026

1.2

Bhp

0.56

0.60

0.65

0.71

0.77

0.84

0.91

0.99

1.08

48PD06 (High Heat Units)

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

Rpm

551

579

608

638

668

700

732

765

799

833

867

0.2

Bhp

0.24

0.28

0.33

0.39

0.45

0.52

0.60

0.68

0.78

0.88

1.00

Rpm

653

676

701

727

755

783

812

842

873

904

936

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

0.4

0.6

0.8

Bhp

Rpm

Bhp

Rpm

0.33

741

0.42

821

0.38

761

0.48

839

0.43

783

0.54

858

0.49

807

0.60

879

0.56

831

0.68

902

0.64

857

0.76

925

0.72

884

0.85

950

0.81

912

0.95

976

0.92

940

1.05

1002

1.03

969

1.17

1030

1.15

999

1.30

1058

Bhp

0.52

0.58

0.64

0.71

0.79

0.88

0.97

1.08

1.19

1.31

1.44

Rpm

896

912

929

948

968

990

1013

1037

1062

1087

1114

Rpm

1035

1047

1060

1075

1092

1110

1129

1150

1172

1195

1219

AVAILABLE EXTERNAL STATIC PRESSURE (in. wg)

1.4

1.6

1.8

Bhp

Rpm

Bhp

Rpm

0.85

1100

0.97

1162

0.92

1110

1.04

1171

0.99

1121

1.12

1181

1.08

1135

1.21

1193

1.17

1150

1.30

1206

1.27

1166

1.41

1221

1.38

1185

1.52

1238

1.50

1204

1.64

1256

1.62

1225

1.77

1275

1.76

1246

1.92

1296

1.91

1269

2.07

1317

Bhp

1.09

1.16

1.25

1.34

1.44

1.55

1.67

1.79

1.93

2.07

2.23

Rpm

1222

1229

1238

1248

1261

1275

1290

1307

1325

1344

1365

48PD06 (High Heat Units) (cont)

AIRFLOW

(Cfm)

1500

1600

1700

1800

1900

2000

2100

2200

2300

2400

2500

LEGEND

Bhp --- Brake Horsepower

Rpm

968

981

996

1013

1031

1051

1072

1094

1118

1142

1168

1.2

2.0

Bhp

0.46

0.50

0.55

0.60

0.66

0.72

0.79

0.87

0.95

Bhp

0.98

1.05

1.11

1.18

1.26

1.34

1.43

1.53

1.63

NOTES:

1. Motor drive range is 596 to 910 for low range motor/drive and 828 to 1173 rpm for

high range motor/drive. All other rpms require a field-supplied drive.

2. Maximum continuous bhp is 0.85 for low range motor/drive and 1.60 (single phase)

and 2.40 (3 phase) for high range motor/drive.

3. See General Fan Performance Notes.

LEGEND

Bhp --- Brake Horsepower

High Range Motor/Drive Required

AIRFLOW

(Cfm)

1.0

Bhp

0.73

0.80

0.87

0.95

1.04

1.14

1.24

1.35

1.48

1.61

1.75

1.0

2.0

Bhp

0.62

0.69

0.76

0.83

0.91

1.01

1.11

1.21

1.33

1.46

1.60

Bhp

1.21

1.29

1.38

1.48

1.58

1.69

1.82

1.95

2.09

2.24

2.40

NOTES:

1. Motor drive range is 690 to 978 for low range motor/drive and 929 to 1261 rpm for

high range motor/drive. All other rpms require a field-supplied drive.

2. Maximum continuous bhp is 0.85 (single phase) and 2.40 (3 phase) for low range

motor/drive and 1.60 (single phase) and 2.40 (3 phase) for high range motor/drive.

3. See General Fan Performance Notes.

17

GENERAL NOTES FOR FAN PERFORMANCE DATA TABLES

1. Static pressure losses from accessories and options

4. Extensive motor and drive testing on these units ensures

(Humidi-MiZer™ system, economizer, etc.) must be added

that the full horsepower range of the motor can be utilized

to external static pressure before entering Fan Performance

with confidence. Using your fan motors up to the bhp rating

table.

shown will not result in nuisance tripping or premature

motor failure. Unit warranty will not be affected.

2. Interpolation is permissible. Do not extrapolate.

5.

Use

of a field-supplied motor may affect wire size.

3. Fan performance is based on wet coils, clean filters, and

Recalculate the unit power supply MCA and MOCP if

casing losses. See Accessory/FIOP Static Pressure informarequired. Contact your Carrier representative for details.

tion.

6. Use the following formula to calculate input watts:

Input Watts = Bhp x (746/Motor Eff)

18

INDOOR FAN DATA

48PD Fan Motor and Drive Data --- Vertical Supply/Return

48PD Fan Motor and Drive Data --- Horizontal Supply/Return

UNIT SIZE

UNIT SIZE

Voltage

05

06

208/230 and

460

208/230 and

460

2.4

2.4

LOW STATIC DRIVE OPTION

Motor HP

Motor Nominal RPM

Voltage

05

06

208/230 and

460

208/230 and

460

2.4

2.4

1725

1725

LOW STATIC DRIVE OPTION

Motor HP

1725

1725

Maximum Continuous BHP

2.0

2.0

Maximum Continuous BHP

2.0

2.0

Maximum Continuous Watts

2000

2000

Maximum Continuous Watts

2000

2000

Motor Frame Size

56HZ

56HZ

Motor Frame Size

56HZ

56HZ

5/8

5/8

5/8

5/8

1.9 --- 2.9

2.4--- 3.4

596--- 910

690--- 978

5.5

6.0

16.2--- 20.2

16.2--- 20.2

Motor Shaft Diameter (in.)

Motor Nominal RPM

Motor Shaft Diameter (in.)

Motor Pulley Pitch Diameter

Min--- Max (in.)

1.9 --- 2.9

2.4--- 3.4

Motor Pulley Pitch Diameter

Min--- Max (in.)

Fan RPM Range

596--- 910

690--- 978

Fan RPM Range

Blower Pulley Pitch Diameter

(in.)

Pulley Center Line Distance (in.)

Belt Quantity--- Type--- Pitch

Length (in.)

5.5

6.0

16.2--- 20.2

16.2--- 20.2

1--- AX48--- 49.3 1--- AX48--- 49.3

Blower Pulley Pitch Diameter

(in.)

Pulley Center Line Distance (in.)

Belt Quantity--- Type--- Pitch

Length (in.)

1--- AX48--- 49.3 1--- AX48--- 49.3

Speed Change per Turn of

Adjustable Pulley (RPM)

63

58

Speed Change per Turn of

Adjustable Pulley (RPM)

63

58

Moveable Pulley Maximum Full

Turns

5

5

Moveable Pulley Maximum Full

Turns

5

5

596

690

596

690

Factory Speed Setting (RPM)

HIGH STATIC DRIVE OPTION

Motor HP

Motor Nominal RPM

Maximum Continuous BHP

Factory Speed Setting (RPM)

HIGH STATIC DRIVE OPTION

2.4

2.4

1725

1725

Motor HP

2.0

2.0

Maximum Continuous BHP

Motor Nominal RPM

2.4

2.4

1725

1725

2.0

2.0

Maximum Continuous Watts

2000

2000

Maximum Continuous Watts

2000

2000

Motor Frame Size

56HZ

56HZ

Motor Frame Size

56HZ

56HZ

5/8

5/8

5/8

5/8

2.4--- 3.4

2.8--- 3.8

828--- 1173

929--- 1261

5.0

5.2

16.2--- 20.2

16.2--- 20.2

Motor Shaft Diameter (in.)

Motor Pulley Pitch Diameter

Min--- Max (in.)

Fan RPM Range

Blower Pulley Pitch Diameter

(in.)

Pulley Center Line Distance (in.)

Belt Quantity--- Type--- Pitch

Length (in.)

2.4--- 3.4

2.8--- 3.8

828--- 1173

929--- 1261

5.0

5.2

16.2--- 20.2

16.2--- 20.2

1--- AX48--- 49.3 1--- AX48--- 49.3

Motor Shaft Diameter (in.)

Motor Pulley Pitch Diameter

Min--- Max (in.)

Fan RPM Range

Blower Pulley Pitch Diameter

(in.)

Pulley Center Line Distance (in.)

Belt Quantity--- Type--- Pitch

Length (in.)

1--- AX48--- 49.3 1--- AX48--- 49.3

Speed Change per Turn of

Adjustable Pulley (RPM)

69

67

Speed Change per Turn of

Adjustable Pulley (RPM)

69

67

Moveable Pulley Maximum Full

Turns

5

5

Moveable Pulley Maximum Full

Turns

5

5

828

929

828

929

Factory Speed Setting (RPM)

Factory Speed Setting (RPM)

19

ELECTRICAL DATA

48PD05--06 Without Powered Convenience Outlet

48PD

UNIT

SIZE

NOMINAL

POWER

SUPPLY

V- PH- HZ

VOLTAGE

RANGE

Min

Max

COMPRESSOR

RLA

LRA

OFM

Qty

FLA

(ea)

COMBUST.

FAN

MOTOR

FLA

CONV

OUTLET

POWER

EXH

FLA (ea)

—

208/230-- 3-- 60

187

253

16.1

110

1

1.0

0.52

None

1.4

05

—

460-- 3-- 60

414

506

7.8

52

1

0.5

0.30

None

0.6

—

208/230-- 3-- 60

187

253

17.9

110

1

1.5

0.52

None

1.4

06

—

460-- 3-- 60

414

506

7.8

52

1

0.8

0.30

None

0.6

IFM

TYPE

IFM

FLA

STD

ALT

STD

ALT

STD

ALT

STD

ALT

STD

ALT

STD

ALT

STD

ALT

STD

ALT

5.2

5.2

5.2

5.2

2.6

2.6

2.6

2.6

5.2

5.2

5.2

5.2

2.6

2.6

2.6

2.6

IFM

TYPE

IFM

FLA

STD

ALT

STD

ALT

STD

ALT

STD

ALT

STD

ALT

STD

ALT

STD

ALT

STD

ALT

5.2

5.2

5.2

5.2

2.6

2.6

2.6

2.6

5.2

5.2

5.2

5.2

2.6

2.6

2.6

2.6

POWER SUPPLY

DISCONNECT SIZE

MCA

MOCP

FLA

LRA

26.3/26.3

26.3/26.3

27.7/27.7

27.7/27.7

12.9

12.9

13.5

13.5

29.1/29.1

29.1/29.1

30.5/30.5

30.5/30.5

13.2

13.2

13.8

13.8

40/40

40/40

40/40

40/40

20

20

20

20

45/45

45/45

45/45

45/45

20

20

20

20

26/26

26/26

27/27

27/27

13

13

13

13

28/28

28/28

30/30

30/30

13

13

14

14

142/142

142/142

144/144

144/144

68

68

69

69

143/143

143/143

145/145

145/145

69

69

70

70

48PD05--06 With Powered Convenience Outlet

48PD

UNIT

SIZE

NOMINAL

POWER

SUPPLY

V- PH- HZ

VOLTAGE

RANGE

Min

Max

COMPRESSOR

RLA

LRA

OFM

Qty

FLA

(ea)

COMBUST.

FAN

MOTOR

FLA

CONV

OUTLET

POWER

EXH

FLA (ea)

—

208/230-- 3-- 60

187

253

16.1

110

1

1.0

0.52

Yes

1.4

05

—

460-- 3-- 60

414

506

7.8

52

1

0.5

0.30

Yes

0.6

—

208/230-- 3-- 60

187

253

17.9

110

1

1.5

0.52

Yes

1.4

06

—

460-- 3-- 60

414

506

7.8

52

1

0.8

0.30

Yes

0.6

20

POWER SUPPLY

DISCONNECT SIZE

MCA

MOCP

FLA

LRA

31.1/31.1

31.1/31.1

32.5/32.5

32.5/32.5

15.1

15.1

15.7

15.7

33.9/33.9

33.9/33.9

35.3/35.3

35.3/35.3

15.4

15.4

16.0

16.0

45/45

45/45

45/45

45/45

20

20

20

20

50/50

50/50

50/50

50/50

20

20

20

20

31/31

31/31

33/33

33/33

15

15

16

16

34/34

34/34

35/35

35/35

15

15

16

16

147/147

147/147

149/149

149/149

70

70

71

71

148/148

148/148

150/150

150/150

71

71

72

72

WIRING DIAGRAMS

C10046

21

C10053

22

SEQUENCE OF OPERATION

Cooling Mode Using Space Temperature Sensors:

T55, T56, or T58 (No Economizer)

General

The 48PD rooftop units use Puronr (R--410A) refrigerant and

ComfortLinkt DDC controls. The PD units are intended to be

used in a either a displacement ventilation or a single--zone variable

air volume application. The PD unit includes a factory installed

variable capacity compressor and variable frequency drive indoor

fan motor. The unit is controlled by space temperature via space

temperature sensor such as a T--55, T--56 or T58. The unit will not

operate with a conventional R, Y1, Y2, W1, W2, G, C thermostat.

When a space temperature sensor is connected to the low voltage

terminal board as shown in the Installation Instructions Manual, the

unit will try to maintain the Space Temperature (SPACE_T) at one

of four set points:

S Occupied Cool Set Point (OCSP)

S Unoccupied Cool Set Point (UCSP)

S Occupied Heat Set Point (OHSP)

S Unoccupied Heat Set Point (UHSP)

The building’s occupancy is affected by a number of different

factors (see Controls and Troubleshooting Guide for details).When

the building is in occupied mode, the occupied set points are

active. When the building is in unoccupied mode, the unoccupied

set points are active. The unit controls will switch automatically