Download Epson FX-2180 - Impact Printer Service manual

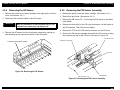

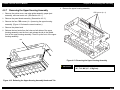

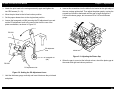

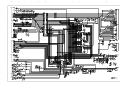

Transcript