Download Sharp R-1875 Service manual

Transcript

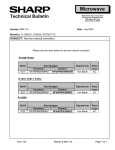

R-1875 SUPPLEMENTAL SERVICE MANUAL S01M177R1875E OVER THE RANGE MICROWAVE OVEN MODEL R-1875 This is a supplemental Service Manual for Model R-1875. This model is quite similar to Base Model R-1855A (S/M# S01M177R1875E). Use this supplemental manual together with the Base Model Service Manual for complete operation and service information In the interest of user-safety, the oven should be restored to its original condition and only parts identical to those specified should be used. WARNING TO SERVICE PERSONNEL: Microwave ovens contain circuitry capable of producing very high voltage and current, contact with following parts may result in a severe, possibly fatal, electrical shock. (High Voltage Capacitor, High Voltage Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness etc..) TABLE OF CONTENTS Page PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICE TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY ................... INSIDE FRONT COVER BEFORE SERVICING ...................................................................................................... INSIDE FRONT COVER MICROWAVE MEASUREMENT PROCEDURE .....................................................................................................2 FOREWORD ..........................................................................................................................................................5 PRODUCT SPECIFICATIONS ...............................................................................................................................6 GENERAL INFORMATION ...................................................................................................................................7 PICTORIAL DIAGRAM ..........................................................................................................................................8 CONTROL PANEL CIRCUIT ..................................................................................................................................9 PARTS LIST ........................................................................................................................................................ 10 PACKING AND ACCESSORIES ......................................................................................................................... 16 This document has been published to be used for after sales service only. The contents are subject to change without notice. (IN USA): SHARP ELECTRONICS CORPORATION Service Headquarters: Sharp Plaza, Mahwah, New Jersey, 07430-2135 OR: (IN CANADA): SHARP CORPORATION SHARP ELECTRONICS OF CANADA LTD. Head Office: 335 Britannia Road East, Mississauga, Ontario L4Z 1W9 (905) 890-2100 R-1875 PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY (a) Do not operate or allow the oven to be operated with the door open. (b) Make the following safety checks on all ovens to be serviced before activating the magnetron or other microwave source, and make repairs as necessary: (1) interlock operation (2) proper door closing, (3) seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening of hinges and latches, (5) evidence of dropping or abuse. (c) Before turning on microwave power for any service test or inspection within the microwave generating compartments, check the magnetron, wave guide or transmission line, and cavity for proper alignment, integrity, and connections. (d) Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generation and transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual before the oven is released to the owner. (e) A microwave leakage check to verify compliance with the Federal Performance Standard should be performed on each oven prior to release to the owner. BEFORE SERVICING (USA) Before servicing an operative unit, perform a microwave emission check as per the Microwave Measurement Procedure outlined in this service manual. If microwave emissions level is in excess of the specified limit, contact SHARP ELECTRONICS CORPORATION immediately @1-800-237-4277. If the unit operates with the door open, service person should 1) tell the user not to operate the oven and 2) contact SHARP ELECTRONICS CORPORATION and Food and Drug Administration's Center for Devices and Radiological Health immediately. Service personnel should inform SHARP ELECTRONICS CORPORATION of any certified unit found with emissions in excess of 4mW/cm2. The owner of the unit should be instructed not to use the unit until the oven has been brought into compliance. BEFORE SERVICING (CANADA) Before servicing an operative unit, perform a microwave emission check as per the Microwave Measurement Procedure outlined in this service manual. If microwave emissions level is in excess of the specified limit, contact SHARP ELECTRONICS OF CANADA LTD. immediately. If the unit operates with the door open, service person should 1) tell the user not to operate the oven and 2) contact SHARP ELECTRONICS OF CANADA LTD. and NHW, CANADA immediately. Service personnel should inform SHARP ELECTRONICS OF CANADA LTD. of any certified unit found with emissions in excess of 4mW/cm2. The owner of the unit should be instructed not to use the unit until the oven has been brought into compliance. R-1875 NOTES 1 R-1875 MICROWAVE MEASUREMENT PROCEDURE (USA) A. Requirements: 1) Microwave leakage limit (Power density limit): The power density of microwave radiation emitted by a microwave oven should not exceed 1mW/cm2 at any point 5cm or more from the external surface of the oven, measured prior to acquisition by a purchaser, and thereafter (through the useful life of the oven), 5 mW/cm2 at any point 5cm or more from the external surface of the oven. 2) Safety interlock switches: Primary interlock relay and door sensing switch shall prevent microwave radiation emission in excess of the requirement as above mentioned, secondary interlock switch shall prevent microwave radiation emission in excess of 5 mW/cm2 at any point 5cm or more from the external surface of the oven. B. Preparation for testing: Before beginning the actual measurement of leakage, proceed as follows: 1) Make sure that the actual instrument is operating normally as specified in its instruction booklet. Important: Survey instruments that comply with the requirement for instrumentation as prescribed by the performance standard for microwave ovens, 21 CFR 1030.10(c)(3)(i), must be used for testing. 2) Place the oven tray in the oven cavity. 3) Place the load of 275±15 ml (9.8 oz) of tap water initially at 20±5C (68F) in the center of the oven cavity. The water container shall be a low form of 600 ml (20 oz) beaker with an inside diameter of approx. 8.5 cm (3-1/2 in.) and made of an electrically nonconductive material such as glass or plastic. The placing of this standard load in the oven is important not only to protect the oven, but also to insure that any leakage is measured accurately. 4) Set the cooking control on Full Power Cooking Mode 5) Close the door and select a cook cycle of several minutes. If the water begins to boil before the survey is completed, replace it with 275 ml of cool water. C. Leakage test: Closed-door leakage test (microwave measurement) 1) Grasp the probe of the survey instrument and hold it perpendicular to the gap between the door and the body of the oven. 2) Move the probe slowly, not faster than 1 in./sec. (2.5 cm/sec.) along the gap, watching for the maximum indication on the meter. 3) Check for leakage at the door screen, sheet metal seams and other accessible positions where the continuity of the metal has been breached (eg., around the switches, indicator, and vents). While testing for leakage around the door pull the door away from the front of the oven as far as is permitted by the closed latch assembly. 4) Measure carefully at the point of highest leakage and make sure that the highest leakage is no greater than 4mW/cm2, and that the secondary interlock switch does turn the oven OFF before any door movement. NOTE: After servicing, record data on service invoice and microwave leakage report. 2 R-1875 MICROWAVE MEASUREMENT PROCEDURE (CANADA) After adjustment of the door switches are completed individually or collectively, switch test and microwave leakage test must be performed with survey instrument and test result must be confirmed to meet the requirement of the performance standard for microwave ovens as undermentioned. A. Requirements: Every microwave oven shall function in such a manner that when the oven is fully assembled and operating with its service controls and user controls adjusted to yield the maximum output, the leakage radiation, at all points at least 5 cm. from the external surface of the oven, does not exceed: 1) 1.0mW/cm2 with the test load of 275 ± 15 ml of water at an initial temperature 20 ±5oC. 2) 5.0mW/cm2 when the outer enclosure is removed with a test load of 275 ± 15 ml of water at an initial temperature 20±5oC. 3) 5.0mW/cm2 without a test load. B. Preparation for testing: Before beginning the actual measurement of leakage, proceed as follows: 1) Make sure that the actual instrument is operating normally as specified in its instruction booklet. Important: Survey instruments that comply with the requirement for instrumentation as prescribed by CSA and NHW performance standard for microwave ovens must be used for testing recommended instruments are , NARDA 8100 and NARDA 8200. 2) Place the oven tray in the oven cavity. 3) Place the load of 275±15 ml of tap water initially at 20±5oC in the center of the oven cavity. The water container shall be a low form of 600 ml beaker with an inside diameter of approx. 8.5 cm (3-1/2 in.) and made of an electrically nonconductive material such as glass or plastic. The placing of this standard load in the oven is important not only to protect the oven, but also to insure that any leakage is measured accurately. 4) Set the cooking control on Full Power Cooking Mode, Close the door and select a cook cycle of several minutes. If the water begins to boil before the survey is completed, replace it with 275 ml of cool water. C. Leakage test with enclosure installed : 1) Grasp the probe of the survey instrument and hold it perpendicular to the gap between the door and the body of the oven. 2) Move the probe slowly, not faster than 2.5 cm/sec. along the gap, watching for the maximum indication on the meter. 3) Check for leakage at the door screen, sheet metal seams and other accessible positions where the continuity of the metal has been breached (eg., around the switches, indicator, and vents). While testing for leakage around the door pull the door away from the front of the oven as far as is permitted by the closed latch assembly. 4) Measure carefully at the point of highest leakage and make sure that the highest leakage is no greater than 4mW/cm2, and that the secondary interlock switch does turn the oven OFF before any door movement. C. Leakage test without enclosure: 1) Remove the enclosure (cabinet). 2) Grasp the probe of the survey instrument and hold it perpendicular to all mechanical and electric parts of the oven that is accessible to the user of the oven including, but not limited to, the waveguide, cavity seams, magnetron gap between the door and the body of the oven. 3) Move the probe slowly, not faster than 2.5 cm/sec. along the gap, watching for the maximum indication on the meter. 4) Measure carefully at the point of highest leakage and make sure that the highest leakage is under 5mW/cm2. CAUTION: Special attention should be given to avoid electrical shock because HIGH VOLTAGE is generated during this test No Load test 1) Operate the oven without a load and measure the leakage by the same method as the above test procedure " Leakage test with enclosure installed" 2. Make sure that the highest leakage should not exceed 5mW/cm2. NOTE: After servicing, record data on service invoice and microwave leakage report. 3 R-1875 WARNING TO SERVICE PERSONNEL Microwave ovens contain circuitry capable of producing very high voltage and current, contact with following parts may result in a severe, possibly fatal, electrical shock. (Example) High Voltage Capacitor, High Voltage Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness etc.. Read the Service Manual carefully and follow all instructions. Don't Touch ! Danger High Voltage outer case. 2. Open the door and block it open. 3. Discharge high voltage capacitor. 4. Reconnect the leads to the primary of the power transformer. 5. Reinstall the outer case (cabinet). 6. Reconnect the power supply cord after the outer case is installed. 7. Run the oven and check all functions. Before Servicing 1. Disconnect the power supply cord remove outer case. 2. Open the door and block it open. 3. Discharge high voltage capacitor. , and then WARNING: RISK OF ELECTRIC SHOCK. DISCHARGE THE HIGH-VOLTAGE CAPACITOR BEFORE SERVICING. After repairing 1. Reconnect all leads removed from components during testing. 2. Reinstall the outer case (cabinet). 3. Reconnect the power supply cord after the outer case is installed. 4. Run the oven and check all functions. The high-voltage capacitor remains charged about 60 seconds after the oven has been switched off. Wait for 60 seconds and then short-circuit the connection of the high-voltage capacitor (that is the connecting lead of the high-voltage rectifier) against the chassis with the use of an insulated screwdriver. Microwave ovens should not be run empty. To test for the presence of microwave energy within a cavity, place a cup of cold water on the oven turntable, close the door and set the power to HIGH and set the microwave timer for two (2) minutes. When the two minutes has elapsed (timer at zero) carefully check that the water is now hot. If the water remains cold carry out Before Servicing procedure and reexamine the connections to the component being tested. Whenever troubleshooting is performed the power supply must be disconnected. It may in, some cases, be necessary to connect the power supply after the outer case has been removed, in this event, 1. Disconnect the power supply cord, and then remove outer case. 2. Open the door and block it open. 3. Discharge high voltage capacitor. 4. Disconnect the leads to the primary of the power transformer. 5. Ensure that these leads remain isolated from other components and oven chassis by using insulation tape. 6. After that procedure, reconnect the power supply cord. When all service work is completed and the oven is fully assembled, the microwave power output should be checked and microwave leakage test should be carried out. When the testing is completed, 1. Disconnect the power supply cord, and then remove 4 R-1875 SUPPLEMENTAL SERVICE MANUAL PRODUCT DESCRIPTION MICROWAVE OVEN R-1875 GENERAL INFORMATION FOREWORD This Manual has been prepared to provide Sharp Electronics Corp. Service Personnel with Operation and Service Information for the SHARP MICROWAVE OVEN, R-1875. OPERATION WIRING DIAGRAM The model R-1875 is quite similar to base model R-1855A (Ref.# S99M138R1855E) It is recommended that service personnel carefully study the entire text of this manual and the base model's manual so that they will be qualified to render satisfactory customer service. Check the interlock switches and the door seal carefully. Special attention should be given to avoid electrical shock and microwave radiation hazard. WARNING Never operate the oven until the following points are ensured: (A) The door is tightly closed. (B) The door brackets and hinges are not defective. (C) The door packing is not damaged. (D) The door is not deformed or warped. (E) There is no other visible damage with the oven. Servicing and repair work must be carried out only by trained service personnel. DANGER Certain initial parts are intentionally not grounded and present a risk of electrical shock only during servicing. Service personnel - Do not contact the following parts while the appliance is energized; High Voltage Capacitor, Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness; If provided, Vent Hood, Fan assembly, Cooling Fan Motor. All the parts marked “*” on parts list are used at voltages more than 250V. Removal of the outer wrap gives access to voltage above 250V. USA MODEL SHARP ELECTRONICS CORPORATION SHARP PLAZA, MAHWAH, NEW JERSEY 07430-2135 CANADIAN MODEL OSAKA, JAPAN 5 PARTS LIST R-1875 SPECIFICATION ITEM DESCRIPTION Power Requirements 120 Volts / 13.2 Amperes (Microwave), 13.2 Amperes (Convection) 60 Hertz Single phase, 3 wire grounded Power Output 850 watts (IEC-705 TEST PROCEDURE) Operating frequency of 2450MHz Convection Power Output 1400 watts Case Dimensions Width 29-15/16" Height 16-11/32" Depth 15- 9/32" Cooking Cavity Dimensions 1.1 Cubic Feet Width 17-1/8" Height 8-1/16" Depth 13-13/16" Hood lamp 2 bulbs, 30W x 2, Incandescent light bulbs Hood fan Horizontal discharge 230 C.F.M. , Vertical discharge 240 C.F.M. , Control Complement Touch Control System Clock ( 1:00 - 12:59 ) Timer (0 - 99 min. 99 seconds) Microwave Power for Variable Cooking Repetition Rate; P-HI .................................................. Full power throughout the cooking time P-90 .................................................................... approx. 90% of Full Power P-80 .................................................................... approx. 80% of Full Power P-70 .................................................................... approx. 70% of Full Power P-60 .................................................................... approx. 60% of Full Power P-50 .................................................................... approx. 50% of Full Power P-40 ..................................................................... approx. 40% of Full Power P-30 ..................................................................... approx. 30% of Full Power P-20 .................................................................... approx. 20% of Full Power P-10 ...................................................................... approx. 10% of Full Powe P-0 ...................................................... No power throughout the cooking time CUSTOM HELP pad, SENSOR COOK pad, COMPU BROIL pad, COMPU ROAST pad COMPU BAKE pad, SENSOR REHEAT pad, MINUTE PLUS pad, POPCORN pad COMPU DEFROST pad, CONVECTION pad, REHEAT pad, LOW MIX/BAKE pad HIGH MIX/ROAST pad, BROIL pad, SLOW COOK pad, KITCHEN TIMER pad Number and temperature selection pads, CLOCK pad, KEEP WARM pad TURNTABLE ON / OFF pad, POWER LEVEL pad, STOP/CLEAR pad, START / TOUCH ON pad Oven Cavity Light Yes 30W x 1 Incandescent light bulb Safety Standard UL Listed FCC Authorized DHHS Rules, CFR, Title 21, Chapter 1, Subchapter J Canadian Standards Association. Department of National Health and Welfare CANADA, Industry CANADA. Weight Approx. 71 lbs. GENERAL INFORMATION GROUNDING INSTRUCTIONS This oven is equipped with a three prong grounding plug. It must be plugged into a wall receptacle that is properly installed and grounded in accordance with the National Electrical Code and local codes and ordinances. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. WARNING: Improper use of the grounding plug can result in a risk of electric shock. 6 R-1875 Electrical Requirements The oven is equipped with a 3-prong grounding plug. DO NOT UNDER ANY CIRCUMSTANCES CUT OR REMOVE THE GROUNDING PIN FROM THE PLUG. The power supply cord and plug must be connected to a separate 120 Volt AC, 60 Hz, 15 Amp. or more branch circuit, using a grounded receptacle. The receptacle should be located inside the cabinet directly above the Microwave Oven/Hood system mounting location. Grounded Receptacle Box 3-Pronged Plug Grounding Pin 3-Pronged Receptacle OVEN DIAGRAM 12 1 11 10 3 4 5 13 9 8 6 16 2 6 7 17 14 15 CONTROL PANEL 1. 2. 3. 4. 5. Oven door with see-through window. Door hinges. Stirrer cover. Turntable motor shaft. Oven lamp. It will light when oven is operating or door is open. 6. Door latches. The oven will not operate unless the door is securely closed. 7. One touch door open button. Push to open door. 8. FAN-HI/LO button. NOTE: Push for High/Low/Off. Some one-touch cooking features 9. Light button. as "MINUTE PLUS" are disabled afPush for On/Off ter one minute when the oven is not 10. Auto-Touch control panel. used. These features are automati11. Time display: Digital display, 99 minutes 99 seconds. cally enabled when the door is 12. Ventilation openings. opened and closed or the STOP/ CLEAR pad is pressed. 13. Light Cover. 14. Grease filters. 15. Removable turntable. The turntable will rotate clockwise or counterclockwise. Only remove for cleaning. 16. Removable turntable support. 17. Plug 7 MIX CONV DEFROST SENSOR TURNTABLE ON OFF COOK LBS OZ KG HELP A B C D E F G H R-1875 AH. SENSOR HOOD FAN MOTOR CN-E 6 BLK 5 4 3 BLK 1 PNK 6 BLK WHT BRN 2 GRN YLW 5 RED BLK 3 BLK RED 4 YLW BLU 3 WHT PPL 2 BLK WHT 2 WHT 1 GRN GRY N.O. GRN TEMPERATURE FUSE (MG.) R E D BLK DOOR SENSING SWITCH WHT GRN RY2:Primary Interlock Relay Power Supply cord 120V 60Hz Y L W O R G B R N 2 2 to oven cavity front flange GRN GRN 1 BLU STIRRER MOTOR PNK COM. 1 1 3 WHT CN-F 2 RED 1 BLK THERMAL CUT-OUT CONVECTION MOTOR ORG GRN BLK COM. PPL 2 BLK 1 BLK THERMISTOR GRY WHT DAMPER SWITCH RY4 BRN BRN RY7 RY5 8 RY6 BLK WHT RY8 COM. N.O. CN-A 9 BRN MAGNETRON ORG HIGH VOLTAGE CAPACITOR BLU PPL 4 4 8 7 HIGH VOLTAGE COMPONENTS DAMPER MOTOR WHT CN-B BLK RED BLU CN-F T1 RY10 ORG WHT 3 3 N.O. ORG OVEN LAMP & SOCKET WHT COM. RY1 RY9 RED MONITOR FUSE AND FUSE HOLDER PPL BRN RY2 N.O. CN-C Blue Marking RED RY3 N.O. COM. CN-F YLW RED CN-G CN-E HEATING ELEMENT GRY IC1 6 CN-C 5 4 3 F BLU BLK GRY WHT BLK 2 1 7 BLK PNK N.C. RED N H RED POWER TRANSFORMER PPL 5 PPL 2 RED 5 CN-B WHT ORG COM. MONITOR SWITCH BLU H.V. RECTIFIER FAN MOTOR BLU GRY 6 5 4 3 FA GRY 2 GRY-GRY PNK 1 BRN-BRN 1 WHT CN-A 3 YLW 2 1 RED THIRD DOOR SWITCH N.O. 5 ORG 4 NOISE FILTER BOARD BLK COM. SECONDARY INTERLOCK SWITCH YLW ORG R E D B L K B P R N N K P N K TURNTABLE MOTOR B R N BLK COM. GRY GRY BRN BRN NOISE RESISTOR RED HOOD LAMPS & SOCKETS WHT N.O. Blue Marking 6 6 HOOD FAN THERMAL CUT-OUT Figure S-1. Pictorial Diagram A B C D E F G H C7 R7 4.7k ZD4 HZ4A2 C8 R8 4.7k R62 36kF D28 RY3 R30 15k D32 C50 Q28 KRA101M D29 NO Q60 KRC102M CF1 4MHz Q29 KRA101M (A) (B) (C) C72 330pF C71 330pF C70 330pF D30 22 23 24 25 26 27 28 29 1G 2G 3G 4G 5G 6G 7G 8G KG HELP 5 6 7 8 9 10 11 12 13 15 16 17 18 19 20 OZ P2 P3 P4 P5 P6 P7 P8 P9 P10 P11 P12 P13 P14 P15 P16 R93 100k G1 G2 G3 G4 G5 G6 R82 3.3k D76 R81 D75 3.3k D74 3.3k 3.3k R80 D73 D71 D72 R79 R78 3.3k R77 3.3k R76 3.3k C74 330pF C73 330pF D31 COM R31 4.7k C60 R70 3.3k R63 220F R64 3.9kF R51 4.7k C30 COOK LBS G7 G8 CUSTOM SENSOR HELP REHEAT COMPU SENSOR MINUTE POPCORN DEFROST PLUS COOK COMPU BROIL G9 CONVEC PREHEAT LOW MIX HIGH MIX BAKE ROAST COMPU BAKE G10 BROIL SLOW COOK G11 KITCHEN TIMER CLOCK G12 TURNTABLE POWER LEVEL ON / OFF 1 100°F 6 2 150°F 7 COMPU ROAST 3 275°F 8 4 300°F 9 5 5 R50 15k RY2 D70 Q30 KRA101M Q27 KRC243M COM COM – R91 100k R92 100k R100 330 1w C11 (J7) (J5) + (A) R74 3.3k + R73 3.3k RY1 MICRO 12 (C) (B) R72 3.3k + R65 1k C65 100µ/16v P30 P31 P32 P33 P34 P35 P36 P37 P00 P01 P02 P03 P04 P05 P06 P07 P10 P11 P12 P13 P14 P15 P16 P17 P20 P21 P22 P23 P24 P25 P26 P27 R71 3.3k – – IC1 IZA719DR Q26 KRA101M NO CONVECTION HERTER C12 10µ/35v RY10 R75 100k NO (J3) Q25 KRA101M D26 COM C9 0.1µ/50v Q24 KRA101M D27 C7 IC2 IZA495DR F 1, 2 MIX CONV F 31, 32 4 DEFROST P1 SENSOR TURNTABLE ON OFF (VP) 4 4 C5 HIGH VCC VEE AVSS VREF AN7 AN6 AN5 AN4 AN3 AN2 AN1 AN0 P55 P54 P53 P52 P51 P50 P47 P46 P45 P44 P43 P42 INT1 P40 RST P71 P70 XIN XOUT VSS RY9 HOOD MOTOR LOW 1 RY8 D65 C9 HOOD THERMO (J6) D23 Q23 KRA101M D25 C3 R40 3.3k RY7 D24 9 COM SP40 D20 – (J4) C1 + Q22 KRA101M (J2) HOOD LAMP RY6 C21 0.1µ/50v B7 Q40 KRA101M C20 10µ/35v CONVECTION MOTOR FLUORESCENT DISPLAY TUBE Q90 KRA101M RY5 D22 B5 R90 100k 3 3 DAMPER MOTOR Q21 KRA101M C10 0.1µ/50v (VP) Q3 KRA101M RY4 D21 B3 : IF NOT SPECIFIEED, 0.01µF/16v R4 510 1/2w Q1 2SB1238 R3 680 1w Q20 KRA101M : IF NOT SPECIFIEED, 1SS270A Q4 DTA123ES C5 ZD3 HZ5C2 – C4 10µ/35v C3 0.1µ/50v ZD2 HZ16-1 R1 4.3k 1/2w C100 + 2 FAN MOTOR OVEN LAMP – R2 1.5k (J1) D3 + ZD1 HZ6A3 VRS1 10G471K a D2 : IF NOT SPECIFIEED, 1/4w ± 5% D4 C1 0.1µ/50v D1 C2 1000µ/35v 3 1 2 B1 A NOTE D1-D4 : 11ES1 A3 TURNTABLE MOTOR B 6 2 4 c C 1 b A1 D CONTROL UNIT 5 1 d AC120V 60Hz MOTOR RUN CAPACITOR E F G H T1 A5 5 325°F 0 350°F 375°F 400°F 425°F 450°F KEEP WARM STOP CLEAR START TOUCH ON FAN LIGHT KEY UNIT E1 E2 E3 E5 E4 E6 F1 F2 F3 OVEN THERMISTOR DAMPER SWITCH 6 6 AH SENSOR DOOR SWITCH R-1875 Figure S-2. Touch Control Panel Circuit A B C D E F G H R-1875 PARTS LIST "§" MARK: PARTS DELIVERY SECTION. REF. NO. PART NO. § DESCRIPTION Q'TY CODE ELECTRIC PARTS 1- 1 1- 2 1- 3 1- 4 1- 5 1- 6 1- 7 1- 8 1- 9 1-10 1-11 1-12 1-13 1-14 1-15 1-16 1-17 1-18 1-19 1-20 1-21 1-22 1-23 1-24 FH-DZB017MRY0 RC-QZA234WRE0 QFS-TA013WRE0 RHET-A174WRE0 RMOTDA211WRE0 RMOTDA214WRE0 RTHM-0044MRE0 RTRN-B070MRE0 RV-MZA255WRE0 QFSHDB003MRE0 QSW-MA085WRE0 FFS-BA018/KIT FACCDB011MRE0 QSOCLB006MRE0 FH-HZA053WRE0 QSOCLB006MRE0 FMOTEA362WRK0 RMOTEA343WRE0 RMOTEB032MRE0 RLMPTA068WRE0 FDTCTA217WRKZ RMOTDA217WRE0 RR-WZA031WRE0 FPWBFB014MRK0 M M M M M M M M M M M M M M M M M M M M M M M M High voltage rectifier assembly High voltage capacitor Temperature fuse 150°C Convection heater Turntable motor Stirrer motor Thermal cut-out N.O. 60°C Power transformer Magnetron Fuse holder Secondary interlock, third door sensing and damper switches Monitor and sec. interlock switch with fuse assembly Power supply cord Hood lamp socket Thermistor Oven lamp socket Hood fan motor Convection motor Fan motor Hood lamp and oven lamp AH sensor Damper motor Noise resistor Noise filter 1 1 1 1 1 1 1 1 1 1 3 1 1 2 1 1 1 1 1 3 1 1 1 1 AM AR AG AZ AQ AQ AG BF BE AD AE AF AP AE AP AE BM AX AW AG AW AP AK AU 2 1 1 1 1 1 1 1 1 1 1 1 AF AV AL AH BC AB AM AG AH AX AL AG 1 1 1 1 1 1 1 1 1 1 1 1 2 1 1 2 2 1 1 2 2 1 5 1 1 4 13 7 BQ AC AC AC AC AD AE AV AB AB AF AB AB AB AB AH AB AB AM AH AH AH AA AM AD AB AA AA CABINET PARTS 2- 1 2- 2 2- 3 2- 4 2- 5 2- 6 2- 7 2-7-1 2-7-2 2- 8 2- 9 2-10 PFIL-B002MRE0 PDIF-B032MRF0 GDAI-B052MRP0 GDAI-B039MRP0 GCABUB106MRP0 TMAPCB063MRR0 FANGKB009MRY0 LANGQB016MRP0 PGLSPB004MRE0 PCOVPB030MRT0A HDECQB030MRF0 LSTY-B010MRP0 M M M M M M M M M M M M Grease filter Hood exhaust louver Base plate right Base plate left Outer case cabinet Schematic diagram Hood lamp glass assembly Hood lamp glass angle Hood lamp glass Base cover Sash left Rear stay 3- 1 3- 1A 3- 1B 3- 1C 3- 1D 3- 1E 3- 1F 3- 1G 3- 1H C1 C2 C3 C4,C12 C5 C6 C7-8 C9-10 C20 C21 C30,C5 C50,C11 C60 C70-74 C100 CF1 D1-4 D20-32 D70-76 DPWBFB061MRU0 QCNCMA227DRE0 QCNCMA230DRE0 QCNCMA234DRE0 QCNCMA267DRE0 QCNCMA237DRE0 QCNCWA030DRE0 RV-KXB003MRE0 PTPEHB010MRE0 RC-KZA087DRE0 VCEAB31VW108M RC-KZA087DRE0 VCEAB31VW106M RC-KZA087DRE0 VCEAB31VW106M VCKYD11CY103N RC-KZA087DRE0 VCEAB31VW106M VCEAB31HW104M VCKYD11CY103N VCKYD11CY103N VCKYD11CY103N VCKYD11HB331K RC-QZB014MRE0 RCRS-A010DRE0 VHD11ES1///-1 VHD1SS270A/-1 VHD1SS270A/-1 M J J J J J J M M J J J J J J J J J J J J J J M J J J J Control unit 3-pin connector CN-A 4-pin connector CN-B 5-pin connector CN-C 6-pin connector CN-E 3-pin connector CN-F 12-pin connector CN-G Fluorescent display tube Tape 2mm Capacitor 0.1 uF 50V Capacitor 1000 uF 35V Capacitor 0.1 uF 50V Capacitor 10 uF 35V Capacitor 0.1 uF 50V Capacitor 10 uF 35V Capacitor 0.01 uF 16V Capacitor 0.1 uF 50V Capacitor 10 uF 35V Capacitor 0.1 uF 50V Capacitor 0.01 uF 16V Capacitor 0.01 uF 16V Capacitor 0.01 uF 16V Capacitor 330 pF 50V Capacitor 7 uF 230V Ceramic resonator (CST4.00MGW) Diode (11ES1) Diode (1SS270A) Diode (1SS270A) CONTROL PANEL PARTS 10 R-1875 REF. NO. IC1 IC2 Q1 Q3 Q4 Q20-26 Q27 Q28-30 Q40 Q60 Q90 R1 R2 R3 R4 R7-8 R30 R31 R40 R50 R51 R62 R63 R64 R70-74 R75 R76-82 R90-93 R100 RY1-3 RY4-9 RY10 SP40 T1 VRS1 ZD1 ZD2 ZD3 ZD4 3- 2 3- 2-1 3- 2-2 3- 2-3 3- 2-4 3- 2-5 3- 2-6 3- 3 3- 4 PART NO. RH-IZA719DRE0 RH-IZA495DRE0 VS2SB1238//-3 VSKRA101M//-3 VSDTA123ES/-3 VSKRA101M//-3 VSKRC243M//-3 VSKRA101M//-3 VSKRA101M//-3 VSKRC102M//-3 VSKRA101M//-3 VRD-B12HF432J VRD-B12EF152J VRS-B13AA681J VRD-B12HF511J VRD-B12EF472J VRD-B12EF153J VRD-B12EF472J VRD-B12EF332J VRD-B12EF153J VRD-B12EF472J VRN-B12EK363F VRN-B12EK221F VRN-B12EK362F VRD-B12EF332J VRD-B12EF104J VRD-B12EF332J VRD-B12EF104J VRS-B13AA331J RRLY-B002MRE0 RRLY-A075DRE0 RRLY-B001MRE0 RALM-A014DRE0 RTRNPB004MRE0 RH-VZA032DRE0 VHEHZ6A3///-1 VHEHZ161///-1 VHEHZ5C2///-1 VHEHZ4A2///-1 FPNLCB377MRK0 FUNTKB324MRE0 GMADIB023MRF0 MSPRTA050WRE0 JBTN-B111MRF0 JBTN-B113MRF0 LANGQB036MRP0 PCUSUB044MRP0 XEPSD30P10XS0 § J J J J J J J J J J J J J J J J J J J J J J J J J J J J J M J M J M J J J J J M M M M M M M M M DESCRIPTION LSI IC Transistor (2SB1238) Transistor (KRA101M) Transistor (DTA123ES) Transistor (KRA101M) Transistor (KRC243M) Transistor (KRA101M) Transistor (KRA101M) Transistor (KRC101M) Transistor (KRA101M) Resistor 4.3k ohm 1/2W Resistor 1.5k ohm 1/4W Resistor 680 ohm 1W Resistor 510 ohm 1/2W Resistor 4.7k ohm 1/4W Resistor 15k ohm 1/4W Resistor 4.7k ohm 1/4W Resistor 3.3k ohm 1/4W Resistor 15k ohm 1/4W Resistor 4.7k ohm 1/4W Resistor 36k ohm 1/4W Resistor 220 ohm 1/4W Resistor 3.6k ohm 1/4W Resistor 3.3k ohm 1/4W Resistor 100k ohm 1/4W Resistor 3.3k ohm 1/4W Resistor 100k ohm 1/4W Resistor 330 ohm 1W Relay (DU24D1-1P(M)) Relay (OJE-SS-124LM) Relay (VE-24HSF-K) Buzzer (PKM22EPT) Transformer Varistor (10G471K) Zener diode (HZ6A-3) Zener diode (HZ16-1) Zener diode (HZ5C-2) Zener diode (HZ4A-2) Control panel sub. assembly Key unit Display window Open button spring Open button Select button Key fixing Cushion Screw; 3mm x 10mm Q'TY CODE 1 AW 1 AL 1 AA 1 AB 1 AA 7 AB 1 AB 3 AB 1 AB 1 AB 1 AB 1 AH 1 AA 1 AA 1 AB 2 AA 1 AA 1 AA 1 AA 1 AA 1 AA 1 AA 1 AB 1 AA 5 AA 1 AA 7 AA 4 AA 1 AA 3 AH 6 AG 1 AM 1 AG 1 AN 1 AE 1 AC 1 AA 1 AA 1 AA 1 BB 1 AX 1 AD 1 AA 1 AD 1 AC 1 AL 3 AA 3 AA OVEN PARTS 4- 1 4- 2 4- 3 4- 4 4- 5 4- 6 4- 7 4- 8 4- 9 4-10 4-11 4-12 4-13 4-14 4-15 4-16 4-17 4-18 4-19 4-20 4-21 4-22 4-23 FFTA-B004MRK0 FROLPB020MRK0 NTNT-B006MRE0 LANGKB010MRP0 FCOVPB002MRY0 FFAN-B008MRK0 ------------DHET-B001MRK0 NCPL-B007MRF0 NFANMB003MRK0 LANGQB031MRP0 PPACGB013MRE0 LBNDK0054WRE0 NFANMB004MRP0 PHOK-B013MRF0 FANGTB003MRY0 PFPF-B002MRE0 PPIPFB002MRE0 PREFHB006MRP0 PDUC-B083MRP0 NFANPB005MRE0 GBDYRB002MRP0 FDUC-B046MRK0 M M M M M M M M M M M M M M M M M M M M M M M Exhaust damper assembly Turntable support assembly Turntable tray Capacitor holder Stirrer cover assembly Stirrer fan assembly Oven cavity (not replaceable) Convection heater unit Coupling Convection motor fan Convection motor angle Turntable motor packing Heater mounting holder Convection fan Latch hook Unit mounting plate Heat protect L Coller Heater cover L Hood intake duct L Fan blade Back plate Fan duct 11 1 1 1 1 1 1 1 1 1 1 1 1 2 1 1 1 1 1 1 1 1 1 1 AM AS AZ BB AM AL AP AT AE AE AF AC AD AE AG AV AK AD AM AG AC AX AM R-1875 REF. NO. 4-24 4-25 4-26 4-27 4-28 4-29 4-30 4-31 4-32 4-33 4-34 4-35 4-36 4-37 4-38 4-39 4-40 4-41 4-42 4-43 4-44 4-45 4-46 4-47 4-48 4-49 4-50 4-51 4-52 4-53 4-54 4-55 PART NO. LBSHC0037WRE0 FDUC-B050MRK0 MLEVPB016MRF0 PCUSGB030MRP0 MCAMPB001MRF0 PCUSGB032MRP0 PFPF-B004MRE0 PFTA-B003MRP0 PREFHB004MRP0 LANGQB033MRP0 PREFHB005MRP0 LSTPPB024MRF0 PCOVPB047MRP0 PCOVPB050MRP0 PCUSGB027MRP0 PDUC-B056MRF0 PDUC-B057MRP0 PDUC-B058MRF0 PDUC-B060MRP0 PFILWA035WRE0 PFPF-B003MRE0 PCUSUB018MRP0 PCUSUB019MRP0 PCUSUB020MRP0 PCUSUB024MRP0 PCUSUB033MRP0 PCUSGB035MRP0 PCUSUB047MRP0 PCUSUB046MRP0 PFPF-B005MRE0 PFPF-B004MRE0 LANGQB025MRP0 § M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M DESCRIPTION Cord bushing Exhaust duct Open lever Cushion Damper cam Damper cushion Heat protect R Damper plate Thermal cover R Hood lamp angle Thermal cover bottom Door stopper Oven lamp cover Heat protect top sheet Cushion Hood exhaust duct Top duct Magnetron duct Hood intake duct R Oven light screen Heat protect top Exhaust cushion A Exhaust cushion B Cushion Cushion Cushion Cushion Cushion Cushion Heat protect Heat protect Noise filter angle CDORFB285MRK0 DDORFB074MRY0 GWAKPB140MRF0 PGLSPB036MRR0 GCOVHB031MRF0 LSTPPB025MRF0 LSTPPB028MRF0 MSPRTA046WRE0 PCUSUB022MRP0 XCTSD40P08000 M M M M M M M M M M Door assembly, complete Door panel assembly Door frame Door glass front Choke cover Latch head Glass stopper Latch spring Cushion Screw : 4mm x 8mm 6- 1 6-1-1 6-1-2 6-1-3 6-1-4 6-1-5 6-1-6 6-1-7 6- 2 6- 3 6- 4 6- 5 6- 6 6- 7 6- 8 6- 9 6-10 6-11 6-12 6-13 6-13 6-14 6-15 CFZK-B131MRK0 LBSHC0040MRE0 LX-BZ0195WRE0 LX-MZB001MRE0 XBRSD50P60000 XOTSD40P12000 XTSSD50P35000 XWHSD50-16300 TINSEB141MRR0 TINSEB287MRR0 TINSKB018MRR0 TINSKB019MRR0 QW-QZB011MRE0 TCADCB012MRR0 FW-VZB171MRE0 FAMI-B006MRM0 FAMI-B005MRM0 FW-VZB077MRE0 TCAUAB025MRR0 TCAUAB005MRR0 TCAUAB034MRR0 TCAUAB045MRR0 TCAUAB008MRR0 M M M M M M M M M M M M M M M M M M M M M M M Installation material assembly Grommet Toggle screw Cord holder Screw : 5mm x 60mm Screw : 4mm x 12mm Screw : 5mm x 35mm Washer Installation instruction Operation manual Top template Wall template High voltage wire A Cook book Main harness A High rack Low rack Main harness C Caution label DHHS caution label NHW caution label Monitor caution label User caution label (CANADIAN) 7- 1 XCPSD40P08000 M Screw : 4mm x 8mm Q'TY CODE 1 AB 1 AK 1 AD 1 AC 1 AC 1 AC 1 AD 1 AD 1 AK 1 AM 1 AK 1 AD 1 AD 1 AK 1 AA 1 AY 1 AN 1 AD 1 AH 1 AF 1 AE 1 AA 1 AA 1 AA 1 AA 1 AD 1 AA 1 AD 1 AE 1 AR 1 AK 1 AE DOOR PARTS 5 555555555- 1 2 3 4 5 6 7 8 9 1 1 1 1 1 1 1 1 1 6 BL BB AS AV AM AE AD AB AC AA 1 1 4 1 2 1 6 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 AN AC AC AC AC AA AA AA AD AF AD AD AD AP AY AQ AP AH AA AA AA AA AA 2 AA MISCELLANEOUS SCREWS,NUTS AND WASHERS 12 R-1875 REF. NO. 7- 2 7- 3 7- 4 7- 5 7- 6 7- 7 7- 8 7- 9 7-10 7-11 7-12 7-13 7-14 7-15 7-16 7-17 7-18 7-19 7-20 7-21 7-22 7-23 7-24 7-25 7-26 PART NO. XOTSF40P10000 XCBSD30P08000 XBTSD40P08RV0 XCBSD30P08000 XBTWW40P06000 XOTSD40P12000 XOTSF40P10000 XBTSD40P08000 LX-BZB011MRE0 LX-CZA038WRE0 XCBWW30P08000 LX-CZ0052WRE0 XCTWW40P08RV0 XRESD40-06000 XOTSD40P12000 XCTWW40P08000 LX-NZA002WRE0 XWSUW40-10000 LX-BZ0081YBE0 XWHSD50-20120 XWHUW40-08100 XWHUW50-08120 XOTSD40P08000 XOTWW40P10000 LX-CZB004MRE0 § M M M M M M M M M M M M M M M M M M M M M M M M M DESCRIPTION Screw : 4mm x 10mm Screw : 3mm x 8mm Screw : 3mm x 6mm Screw : 3mm x 8mm Screw : 4mm x 6mm Screw : 4mm x 12mm Screw : 4mm x 10mm Screw : 4mm x 8mm Unit mounting screw Special screw Screw : 3mm x 6mm Special screw Screw : 4mm x 8mm E-ring Screw : 4mm x 12mm Screw : 4mm x 8mm Nut: 4mm x 3.2mm Spring Washer Screw : 4mm x 8mm Washer : 5mm x 2mm Washer : 4mm x 0.8mm Washer : 5mm x 0.8mm Screw : 4mm x 8mm Screw : 4mm x 10mm Hood louver Screws HOW TO ORDER REPLACEMENT PARTS To have your order filled promptly and correctly, please furnish the following information. 1. MODEL NUMBER 2. REF. NO. 3. PART NO. 4. DESCRIPTION Order Parts from the authrized SHARP parts Distributor for your area. Defective parts required return should be returned as indicated in the Service Policy. 13 Q'TY CODE 4 AB 2 AA 2 AA 2 AA 2 AA 24 AA 1 AA 2 AA 2 AH 4 AA 5 AA 2 AA 2 AA 1 AA 2 AC 1 AA 1 AB 1 AA 9 AA 1 AA 2 AA 1 AA 9 AA 10 AA 2 AA R-1875 2 1 4 3 6 5 OVEN AND CABINET PARTS A A 4-52 4-52 4-50 1-17 7-25 4-1 4-50 7-24 B 4-51 4-16 B 7-7 7-24 2-10 4-39 4-46 7-11 4-36 4-25 C 7-7 7-24 7-24 4-37 1-21 4-24 7-3 4-45 2-5 1-13 4-38 7-5 7-7 2-6 1-7 D 7-5 1-16 2-9 1-6 1-20 4-54 1-3 7-1 7-20 7-4 4-4 4-19 E 7-7 7-7 4-7 1-4 4-10 4-11 7-11 7-7 D 4-18 7-14 4-22 7-20 4-44 4-8 7-21 7-14 7-15 7-23 1-18 1-15 7-1 7-25 7-12 7-19 7-6 7-22 4-14 7-26 4-13 7-12 2-2 1-20 7-20 4-33 2-4 7-5 1-24 4-23 4-26 4-15 7-25 1-19 4-48 1-11 1-7 4-28 4-2 7-7 4-30 2-3 7-10 2 7-7 7-10 2-7 6-14 4-32 4-49 4-47 G 7-20 4-42 7-7 2-1 2-7-2 H 2-7-1 7-8 1 1-22 7-7 2-1 H 4-29 4-31 2-8 7-7 1-11 1-14 1-23 4-3 F 4-50 1-14 G 4-55 7-9 1-12 7-16 1-8 7-5 4-21 1-11 4-41 1-10 4-27 1-20 7-26 4-5 6-12 1-5 7-22 1-9 4-53 4-34 E 7-16 7-13 4-9 7-18 4-6 1-2 1-1 4-43 7-12 4-17 6-13 4-12 4-13 F 7-11 4-40 7-17 4-20 C 7-2 4 3 14 5 6 R-1875 2 1 4 3 6 5 CONTROL PANEL PARTS A 3-3 A 3-2 3-4 3-1 3-2-2 3-2-6 B DOOR PARTS B 3-2-1 4-34 7-7 3-4 6-15 5-9 5-4 C 3-2-5 3-2-4 C 5-6 5-1 3-2-3 5-9 5-5 D D 5 5-7 5-8 5-3 E E MISCELLANEOUS 5-2 6-1 6-8 F 6-1-1 6-6 6-1-4 F 6-1-5 6-1-2 6-1-3 6-1-6 6-1-7 G G 6-9 6-10 6-11 H H 1 2 4 3 15 5 6 R-1875 PACKING AND ACCESSORIES 6-1 INSTALL MATERIAL ASSEMBLY 6-7 COOK BOOK 6-3 OPERATION MANUAL 6-5 WALL TEMPLATE TOP PAD DOOR PROTECTOR WRAP COVER 6-2 INSTALLATION INSTRUCTION 6-4 TOP TEMPLATE 2-1 GREASE FILTER (x 2) 6-10 LOW RACK 6-9 HIGH RACK BOTTOM PAD MILLER MAT 4-3 TURNTABLE TRAY TAPE 4-2 TURNTABLE SUPPORT ASSEMBLY PACKING CASE Non-replaceable items TRAY HOLDER DAMPER HOLDER 4-1 DAMPER ASSEMBLY '96 SHARP CORP. (8K5.550E) Printed in U.S.A 16 R-1875 NOTES 17 R-1875 COPYRIGHT © 2001 BY SHARP CORPORATION ALL RIGHTS RESERVED. No part of this publication may be reproduced, stored in retrieval systems, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without prior written permission of the publisher. '01 SHARP CORP. (10M2.60E) Printed in U.S.A 18