Download Daikin FD(Y)M04FAVAL Service manual

Transcript

Si42-107

Service

Manual

Packaged Air Conditioners

Duct Connection Type

(High Static Pressure Application)

FD(Y)-K(A) Series

[Applied Models]

Cooling Only

Heat Pump

Si42-107

Packaged Air Conditioners

Duct Connection Type

(High Static Pressure

Application)

FD(Y)-K Series

Packaged Air Conditioners Duct Connection Type

(High static Pressure Application

FD-K Series — Cooling Only — ...................... 1

Part 1 Model Name and Power Supply ......................................... 3

Part 2 Functions ............................................................................ 7

Part 3 Specifications .................................................................... 9

!

!"# !

$!"# Part 4 Remote Controller (Optional Accessories)...................... 15

%

$

%& $

'()*'+,-. +

/0'()*'+,. 1

'()*'+,2.!

30/0(

Part 5 Field Piping and Wiring .................................................... 23

030 Table of Contents

i

Si42-107

$

/!-*4!*4!* /!$*4! *4!* 1

/*4!*-

'+54!!545 -1

'5!$*

'! *4'!* !

Part 6 Function and Operation ................................................... 55

% $

5$

%5 +

%6 %6)/,*7',5.

%6)/,*7'5,*.$!

- $

- 5$

- %5 $

Part 7 Troubleshooting ............................................................... 67

8

$

% $

""'98

+!

6 +!

- :;6029(+

-

-

--

-

-$

-+

-

-1

:;6029( +

9(% +

%4;( +0%;(( +

9(6/4

;'36+

9(%;0 +$

9(/

60368 ++

9(

&<6=+

9(/

60/+1

Part 8 Removal Procedure .......................................................... 81

'+5> '(0

'(%58 '(

2 '((

Part 9 Appendix........................................................................... 87

0/0(

0%

30/0( 1!

!"# 1!

$!"# 1+

ii

Table of Contents

Si42-107

Packaged Air Conditioners Duct Connection Type

(High static Pressure Application)

FDY-K(A) Series — Heat Pump —.............. 107

Part 1 Model Name and Power Supply ..................................... 109

8<(

!

"06

:!

Part 2 Functions ........................................................................ 113

Part 3 Specifications ................................................................ 115

$

*!"# $

*$!"# *!"# !

*$!"# Part 4 Remote Controller .......................................................... 125

'( $

3'(2'$

3'(2'$+

- 3'(2'$ Part 5 Field Piping and Wiring .................................................. 129

030 -!

/>!$4! 4!*). -!

/>?!*). '>!*5 $

'>!!*5?'>!*5 Part 6 Field Setting ................................................................... 151

86

)'8

?'.

0 - #@<0)A!"8%. +

0

08

52 - /

64B(2 $

- '

:;$

Table of Contents

iii

Si42-107

- (0

% $

-- 8

80$

Part 7 Function and Operation ................................................. 165

% $$

5$$

%5 $+

%

6)'>!*5. $

0?0(/% $

"0 +!

- %

6)'>!!4!*5. +

- 0?0(/% +

- "0 +

+$

5+$

%5 +1

:6(:('

:; :6(:('

:; $ / $ 5/>!$A!*).

$ %5'>!*58 $- %5'>!!C!*58 1+

Part 8 Troubleshooting ............................................................. 205

8

!+

%(% !+

""'98

!

6 !

- :;6029(

-

-

--

-

-$

-+

-

-1

-!

-

:;6029( 9(% %4;( 0?"0%;(( 9(6/4

;'36

9(%;0 +

9(%;"0 1

9(/

60368 9(

&<6=

9(/

60/'(&//D D ,/0;'( :6<:%<?::2

,/0;3'($

- '(/8

1

,/0;&/-!

:;60;&/:65E -!

:;60;&/:6%5E2 -

$ :;60;'(/?&//-

$ (;-

$ 8

&//:;--

iv

Table of Contents

Si42-107

$$

$

$$

$+

$

$1

$!

$

$

$$

$

$$

$+

$

$1

$!

$

$

52 -

8

"

60:(( -$

8

:((-+

8

'(:6( /

-1

/

!

%52 "06()".8

&()&.8

8

F /

60:(8

8

"06

6$

8

&

6 +

8

%:(( 8

/

60:((1

8

"

60:(( !

6@8

'6

8

:()2%5.8

:(

)25'(. $

$- :(28'(

;'(+

$ 0

6

Part 9 Appendix......................................................................... 261

0/0($

?%5 $

30/0($+

Index

5/>,*8 $+

5/>,*8 +

%5 +

30)/>!$?! ?!*)..+

30)/>?!*)..+1

............................................................................................. i

Drawings & Flow Charts ............................................................... iii

Table of Contents

v

Si42-107

vi

Table of Contents

Si42-107

Introduction

! 260

;

0=

! :6

(

G

HG

H:6

GH

(

(

6

6I6

:6G

H(

(

6:64;;6

(

;;

! ;6

0(

:6(;

(6

6

(;

:6

0(66(6

6(;

:6(;

6;

:66;(

66(;

:6(;

6(;=4

:6

66(;

! 6=

(4;

66

9((46

06

6

(

2

6

;0(60

=;

(;069(

3=069(6

6=

69(

6

06

4

6

60

6

9(

600

6006=4

66

60000

:600

;

36

06

606

(6

4600

(,

60(06

(4600

00(

6

6066

4

I

600=06=46:6

00

0

06

(

:6,

606,0

6

(6

2

606

(;

0=

60

6

=

/6

;0000006

;0

0000006

;069(

6

=

vii

Introduction

Si42-107

/6

(66

3=069(66

6

=

/

6

;60

36066

6

=

26006069(6(

4

6

=

26

606

;6

0

69(

:66064

I

/66(0

:66

6

2

6

=6600

6

;

0=

3=066600

6

;

56,

506

(

0

26

6

;(

=<((6

9(

:6

6

=4

60

36

069(4(=666

06660669(

66

066

=

469(

I

26

;06

(

6((

6

9(40I

26

6((

(

6

(4

I

viii

0

0

Si42-107

Introduction

2

69(46

6

6

9(460

06

(6

0

=

(

=

6

=

26

;

;6

8=6

6

;66

06

;6

(

(

60

36

06

;;64(=

66(

(;

6

;

6

(46(

6

=4

60

/(0(6

;

/(0(

;

6

=

06(6

;46006

;

(06

;

/(0666

0)'.60

(

600(4

6064

09((0I

600=4;

6=;

60060

60004(=66

0=

6=

;

6=(;4;

((,

6

4600

(=06(:6006(4;

0

06

(4

6664

0

36

06

;6(

4;

6;

6(0

66

;4

((

=0;=

(

06

64

6

=

/69(

66;

(;;0=

(;;0=(64

26

=06(

0

6

=04

6( 6

6

=(=66

;046

606

606

4

6

=

6

;6

64;

6(

/(0

;

6

=4

6

0

ix

Introduction

Si42-107

/I

;

;466(

66

4

6

=4

60

6

=6(

4

6

6

((

(

604

6

=

6((6

4

((

640

I

6

=600469(0

(00

6

=

2(6

64(=

66

86(606

6

=

2

6

=6066

0

66(6

66

(:6(0

6

;6;;J

:

(

<

/

G

H660664606

(4((09(440

6).

30

G0H660I

'

G

H066

6;

6(466?6(

GH(6;4;(

6;;64

6

=

x

Si42-107

Packaged Air Conditioners

Duct Connection Type

(High static Pressure

Application)

FD-K Series

— Cooling Only —

Model Series

Class

Indoor Units

3HP

4HP

FD03K FD04K

5HP

6HP

8HP

10HP

FD05K FD06K FD08K FD10K

15HP

20HP

FD15K

FD20K

Outdoor Units R71FU R100FU R125FU RU06K RU08K RU10K RU08K×2 RU10K×2

1

Si42-107

2

Si42-107

Part 1

Model Name and

Power Supply

Model Name and Power Supply

3

Power Supply

Si42-107

!"

!"

(;

>

4

/!-*>

%

'+5>

-φ- !AF!"#

).

/!*>

/!*>

'!!5>

'5>

/!$*>

/! *>

'5!$*>

'5! *>

/!*>

/*>

'5!*>

'5! *>K

F&

/!*>

/!-*F&

'5!*>K

'+5F&

φ!F$!"#

:&

/!*F&

/!*:&

'!!5F&

'5:&

-φ!F$!"#

/!$*:&

/! *:&

'5!$*:&

'5! *:&

/!*:&

/*:&

'5!*:&

'5! *:&K

/!*:&

'5!*:&K

Model Name and Power Supply

Si42-107

External Appearance

#$"%

#$"%

&

Model Name and Power Supply

5

External Appearance

6

Si42-107

Model Name and Power Supply

Si42-107

Part 2

Functions

Functions

7

Function

Si42-107

'

'

(

%

;%

'

I;

60&06

8

,

(

6

60

;

"J0

8

/

"06

:

/,*

"

")

608.

(

"

")*.

Functions

Si42-107

Part 3

Specifications

!

!"# !

$!"# Specifications

9

Specifications

Si42-107

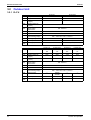

()*

&

+"

!0

0

5

%

5

&9

@

/

&9

@

/

=3

2?6

=

?6

M

((

((

((

((

((

((

/(

306

&

:

'K0K

6

:

/

'

8%

"K3K/

(P

(Q?(

(

(("%

=3

((

=0

',(-.

0'.

+4 !!

+4!!!

!!,!

φ1)2#0.

φ1)2#0.

-?2

φ1).

φ1).

φ$!)".

',(-.

KK!

!-

$

1

+

!

!K$!K !

0'.

:

(

'0

'0

%

',(-.

',(-.

(('.

'.

!

!

-+4+!!

+4$!!

14!!

4!!!

!!,!

!!,!

φ1)2#0.

φ1)2#0.

φ1)2#0.

φ1)2#0.

-?2

-?2

φ1).

φ1).

φ1).

φ1).

φ$!)".

φ$!)".

',(-.

',(-.

)3&",O:;.

KK!

KK!

!-+!

!-+!

2/

-!

$

4!1

4$!

1

1

!

!+

!K1!!K !

!K1!!K !

1

+

(('.

'.

"(

'

0:

8

<

8%

8

60

8

60

=3

"--R/2<

-!

"-$R/2<

-

=0

5<%-@

$-

:

$-

'K0K

6

(P

'0

&06

(

'0

8&06

(

8"06/

(

:

8

(Q?(

'!?$!"#

(

8%

3

K-$K!

!$

!)9&06+!(.

-!

B8

$

4$!

!

KK!

!1+1

KK!

!1+1

:;

!)9&06+!(. !)9&06+!(.

-!

-!

B8K

B8K

!

+

4 -4!+

+7-

+7$!

:6(

%84'F)(.

8

)(.%

'8

/

/(

306

/0<

"K3K/

KK!

!1

4 -$

1

!+

!K4-!K !

+1

(/-.

6

"(

:

B:!!2,>

N

'

10

"-$R/2<

',(/-.

(/-.

+

14!!

4!!!

!!,!

φ1)2#0.

φ1)2#0.

-?2

φ1).

φ1).

N

',(/-.

((

=0

$K

!K-+!

4K !K-+!

!1

/!!!-

4K !K-+!

!

! <(

0

;60

J

'(J+L/241L324%(J-L/290J(

)"#.

! 0

6

6

(6

-!)

60(.

5<%@//,*

$

)3

&",O

:;.

K$!K!

$

!)9&06+!(.

-!

B8

!

-4 7$

:6(

(%

84"06

64&

64%'

)(

8.4'6

4

4-K !K-!

/!!$ 1

(

=

?6S=3K $!

2?6S=3K-

(S(Q?(K--

Specifications

Si42-107

Specifications

&

',(-.

',-.

',(-.

(-.

(1-.2

(-.2

=3

1+

$

1!0

2?6

!4!!

$$4!!!

!4!!

=

?6

4!!

4 !!

4!!!

M

!!,!

!!,!,!

!!,!,!

Kφ+)2#0.

Kφ1)2#0.

φ1)2#0.

&9

((

Kφ)2#0.

Kφ- )2#0.

@

((

φ- )2#0.

5

/

((

-?2

2

2

0

Kφ+)2#0.

Kφ1)2#0.

φ1)2#0.

&9

((

% @

Kφ)2#0.

Kφ- )2#0.

((

φ- )2#0.

5

/

((

N

N

N

',(-.

',-.

',(-.

:

)3&",O:;.

'K0K

6

-KK!

-KK!

-K$K!

-K$K!

(P

!!

!+ !11

:

/

2/

(Q?(

$

-$

$$

'

(

4!!

41-!

4 !!

4 $!

!

!

(("%

8%

=3

-+

/(

"K3K/

((

!!K4-!K !

!!K4--!K !

$K4$!K !

$K41 !K !

306

=0

1!

$

+

&

(1-.

(-.

(1-.2

(-.2

36

:

"(

:

(

8

B:$/>,

B:--/>,

K)B:$/>,.

K)B:--/>,.

8%

=3

+

1

K+

K1!

8

'

'0

60

=0

!)60(.

$)60(.

K!)60(. K$)60(.

8

5<%@//,*

'0

%

60

K!

K!

:

)3&",O:;.

'K0K

6

K!K!

K!K!

K)K!K!.

K)K!K!.

(P

+

1+

K+

K1+

'0

:;

&06

(

'0

8&06

(

!)9&06+!(. !)9&06+!(. !)9&06+!(. !)9&06+!(.

8"06/

(

-!

-!

-!

-!

:

8

"

"

:"

:"

(Q?(

!

+

K!

K+

'!?$!"#

(

41

$4++

K41

K$4++

8%

3

-!71!

-!71!

K)-!71!.

K)-!71!.

:6(

(%84"06

64%')(

/

8.4'6

4

/(

"K3K/

((

4!K4 !K$1!

4!K4 !K$1!

K)4!K4 !K$1!.

K)4!K4 !K$1!.

306

=0

++

1!

K++

K1!

/0<

/!!$ 1

/!! $++

+"

Specifications

',(1-.

(1-.

-4!!!

!41!!

!!,!

φ+)2#0.

φ)2#0.

-?2

φ+)2#0.

φ)2#0.

N

',(1-.

! <(

0

;60

J

'(J+L/241L324%(J-L/290J(

)"#.

! 0

6

6

(6

(

=

?6S=3K $!

2?6S=3K-

(S(Q?(K--

11

Specifications

Si42-107

/()*

&

+"

!0

0

5

%

5

&9

@

/

&9

@

/

=3

2?6

=

?6

M

((

((

((

((

((

((

/(

306

&

:

'K0K

6

:

/

'

8%

"K3K/

(P

',(-3%

0'3%

$

14!!

+4!!

!!,!

φ1)2#0.

φ1)2#0.

-?2

φ1).

φ1).

φ$!)".

',(-3%

KK!

!-

(Q?(

(

(("%

=3

((

=0

$

1+

+

!

!K$!K !

0'3%

F&

:&

=3

"--R2

N

-

"-$R2

N

=0

)60(.

1)60(.

5<%-@

$-

:

(

'0

'0

%

',(-3%

',(-4%

(('3%

'4%

4-!!

4 !!

!4!!

-4-!!

!!,!

!!,!

φ1)2#0.

φ1)2#0.

φ1)2#0.

φ1)2#0.

-?2

-?2

φ1).

φ1).

φ1).

φ1).

φ$!)".

φ$!)".

',(-3%

',(-4%

)3&",O:;.

KK!

KK!

!-+!

!-+!

2/

-!

$

4!1

4$1

1

!

!+

!K1!!K !

!K1!!K !

$

+

(('3%

'4%

"(

'

0:

8

<

8%

8

60

8

60

:

-)60(.

$-

'K0K

6

(P

'0

&06

(

'0

8&06

(

8"06/

(

:

8

(Q?(

'!?$!"#

(

8%

3

K-$K!

!$

!)9&06+!(.

-!

B8

41

!

KK!

!1+1

KK!

!1+1

:;

!)9&06+!(. !)9&06+!(.

-!

-!

B8:

B8:

1

1

-4+

-41

1!7$!

1!7 !

:6(

%84'F)(.

8

)(.%,'8

/

/(

306

/0<

"K3K/

KK!

!1

4 -

1

!+

!K4-!K !

+1

(/-4%

36

"(

:

N

B:1!2

N

'

12

N

"-$R/2&

$!

',(/-4%

(/-4%

+

14!!

4!!!

!!,!

φ1)2#0.

φ1)2#0.

-?2

φ1).

φ1).

N

',(/-4%

((

=0

$K

!K-+!

+

4K !K-+!

+

/!! $!

4K !K-+!

!

! <(

0

;60

J

'(J+L/241L324%(J-L/290J(

)"#.

! 0

6

6

(6

-!)

60(.

5<%@//,*

$

)3

&",O

:;.

K$!K!

$

!)9&06+!(.

-!

B8

!

-4 !!7!!

:6(

(%

84"06

64&

64%'

)(

8.4'6

4

4-K !K-!

/!!$ !

(

=

?6S=3K $!

2?6S=3K-

(S(Q?(K--

Specifications

Si42-107

Specifications

&

',(-4%

',-4%

',(-4%

(-4%

(1-4%2

(-4%2

=3

1+

$

1!0

2?6

!4!!

$$4!!!

!4!!

=

?6

4!!

4 !!

4!!!

M

!!,!

!!,!,!

!!,!,!

Kφ+)2#0.

Kφ1)2#0.

φ1)2#0.

&9

((

Kφ)2#0.

Kφ- )2#0.

@

((

φ- )2#0.

5

/

((

-?2

2

2

0

Kφ+)2#0.

Kφ1)2#0.

φ1)2#0.

&9

((

% @

Kφ)2#0.

Kφ- )2#0.

((

φ- )2#0.

5

/

((

N

N

N

',(-4%

',-4%

',(-4%

:

)3&",O:;.

'K0K

6

-KK!

-KK!

-K$K!

-K$K!

(P

!!!

!+ !11!

:

/

2/

(Q?(

$

-$

$$

'

(

4!!

411

4 !!

4 $!

!

!

(("%

8%

=3

-+

/(

"K3K/

((

!!K4-!K !

!!K4--!K !

$K4$!K !

$K41 !K !

306

=0

1!

$

+

&

(1-4%

(-4%

(1-4%2

(-4%2

36

:

"(

:

8

B:-$/,

B:-!!/,

K)B:-$/,.

K)B:-!!/,.

(

<

N

N

N

N

8%

=3

+

K

K+

8

'

'0

60

=0

!)60(.

$)60(.

K!)60(. K$)60(.

8

5<%@//,*

'0

%

60

!

!

:!

:!

:

)3&",O:;.

'K0K

6

K!K!

K!K!

K)K!K!.

K)K!K!.

(P

+

1+

K+

K1+

'0

:;

&06

(

'0

8&06

(

!)9&06+!(. !)9&06+!(. !)9&06+!(. !)9&06+!(.

8"06/

(

-!

-!

-!

-!

:

"

"

:"

:"

8

(Q?(

$!

1!

K$!

K1!

'!?$!"#

(

4$

$4+!+

K4$

K$4+!+

8%

3

-!71!

-!71!

K)-!71!.

K)-!71!.

:6(

(%84"06

64%')(

/

8.4'6

4

/(

"K3K/

((

4!K4 !K$1!

4!K4 !K$1!

K)4!K4 !K$1!.

K)4!K4 !K$1!.

306

=0

+$

K+$

K

/0<

/!!$ !

/!! $+

+"

Specifications

',(1-4%

(1-4%

-4!!!

!41!!

!!,!

φ+)2#0.

φ)2#0.

-?2

φ+)2#0.

φ)2#0.

N

',(1-4%

! <(

0

;60

J

'(J+L/241L324%(J-L/290J(

)"#.

! 0

6

6

(6

(

=

?6S=3K $!

2?6S=3K-

(S(Q?(K--

13

Specifications

14

Si42-107

Specifications

Si42-107

Part 4

Remote Controller

(Optional Accessories)

%

$

%& $

'()*'+,-. +

/0'()*'+,. 1

'()*'+,2.!

30/0(

Remote Controller (Optional Accessories)

15

Optional accessories

Si42-107

&"

&

%

'(

'(=

8

6

:

/0:

-8:(

*

16

36-8

:(3:

;8

/!-*4!*>4F&

/!*4!$*4! *4!* /*4!*>4:&

>4:&

*'+,-

*'+,<%:.

*'+,2

<%:.

*'+,

*'+,

<%:.

N

36-8

:(

N

*:1

/:!+

!!,!M

!!,!,!M

- *'+,2&

(

4-((*:1

6

00

(

Remote Controller (Optional Accessories)

Si42-107

Optional accessories

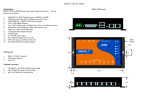

5""6-078

*'+,-

6046

=

5""

)"

Remote Controller (Optional Accessories)

17

Optional accessories

Si42-107

"969$8

150

80

15

220

4-Ø6HOLE

200

60

240

(P1392)

:"

:""; 56155!"":<":"=8

:":!#$

18

Remote Controller (Optional Accessories)

Si42-107

Optional accessories

,"5""6-078

,"5""

%>&!"":;568

Remote Controller (Optional Accessories)

19

Optional accessories

Si42-107

5""6-0798

,"5""

-079

20

Remote Controller (Optional Accessories)

Si42-107

Optional accessories

",5

-07

B C

D

A

E

~

~

~

~

B

C

A

D

~

~

~

~

B

C

A

3

THERMOSTAT

FAN

P1

FD06-10

FD03-05

N

L

(ON/OFF)

P3

FD15-20

P5

ON

ELECTRONIC

CONTROL

TEMPERATURE

CONTROL

OFF

P6

(P1256)

-07

ROOM SENSOR

P21

B

P1

FD15•20

P1

P2

P2

A

E

D

FD06~10

P1

P3

P6

C

A

P2

P6

P7

P3

P3

A

C

P10

P11

B

D

P6

C

P10

P11

B

P8

P10

P11

P12

P13

P14

P15

P16

P17

P18

DISPLAY

3

FD03~05

(P1257)

Remote Controller (Optional Accessories)

21

Optional accessories

Si42-107

-079

A

A

D

B

B

J

C

ON

OFF COOL

D

E

HEAT

F

C

G

H

FD15•20

I

H

E-F

E-G

E-H

E-I

L

H

TEMPERATURE

22

(P1258)

Remote Controller (Optional Accessories)

Si42-107

Part 5

Field Piping and Wiring

030 $

Field Piping and Wiring

/!-*4!*4!* /!$*4! *4!* 1

/*4!*-

'+54!!545 -1

'5!$*

'! *4'!* !

23

Field Piping and Wiring

Si42-107

'"

',(-?(-?(-

""

660;

=6;)0.5064

06;666;

I66606

- 8=66)0$.

I604(=6

36(=0I(4

666;

6

$ 066

@

A'?;""5"B

,5$;;;

;

"3";

;""@""

! 06;;#66

=6#60066

6;

! 5(

0

'00#

@

/!-

/!

φ1K!4&S!

φ1K!4&S!

φ1K! 4&S+

φ1K! 4&S+

/!

φ1K!4&S!

φ1K! 4&S+

)0 G&H.

24

Field Piping and Wiring

Si42-107

Field Piping and Wiring

,;;":

;"?;!

;"5:

! '(6

;

660).;606(6

0).)0+.

! ;#0660 460

6

6)01!.6

(

6;;;;

=0

! 360EI6)

((

;.4(=066

0;60)01,.

Field Piping and Wiring

25

Field Piping and Wiring

Si42-107

,@

4;5:"";!;5:"!<!5

:"@

! (;660

! :6

;6606:60

;

(

6606

! ;4=606;600

()6666:-?6.

0

! 6

! 606

66

(6(6

66

046(;

! *06;

06

(

;

! 06664

(6

6)0.

! 6(60

! 6((4

66

#"

! ((

;4(

(

(

! 5

! 0=46G30/0(H

66

! (

046(

E(

! 0(;(;6#

! ;=

;

066((;

! '6(

666#6

;

6646

6

;=?

640

A+;!

5

""

B

%6

6;

;(06

)0.

! ;66(40-

60

6

066(0

! ;6?(

40-56

0(;6

66

(

26

Field Piping and Wiring

Si42-107

Field Piping and Wiring

'6(

66(

).600(

6

! 6660660

6;(6

6;)0

-.6

4=6(66

6;

(0

%;6(;6

06(;

! /

006((

)&6

(

60.

! 36

06(004

6(

0606

06

((

;(

;

(;6

66600(

6

(

! 5""

5(

3

5&!3@ 9

#)((P.

!+

6

975"5!;;

5?;!;

55

! 6

6;

;

)0.6

;6(06

6

6;466

0666

Field Piping and Wiring

27

Field Piping and Wiring

Si42-107

,"";!

;:$;";

"6;$

;8?

;<"

";

@

:"@

! 606

6;

! (6606

66()0.

4&

! 6

=(=6

6;

(

06

(646(

! :6(

6

=6

6

660

4

6066

)-

6(.

! 606I((46

(60

28

Field Piping and Wiring

Si42-107

Field Piping and Wiring

',(/-?(1-?(-

""

660;

=6;)0.5064

06;666;

I66606

- 8=66)0$.

' I604(=(6

' 36(=0I(4

666;

6

066

Field Piping and Wiring

29

Field Piping and Wiring

Si42-107

@

A'?;""5"B

,5$;;;

;

"3";

;""@""

! 06;;#66

=6#60066

6;

! 5(

0

'00#

/!$

@

φ1K!4&S!

φ1K! 4&S+

/! /!

φK4&S

φ- K4&S

φ+K!14&S

φ1K!14&S

)0 G&H.

! '(6

;

660).;606(6

0).)0+.

! ;#0660 460

6

6)01!.60

6;;

;;=0

0)

((

;.

30

@0

((60((/! C!

Field Piping and Wiring

Si42-107

Field Piping and Wiring

,@

4;5:"";!;5:"!<!5

:"@

! (;660

! :6

;6606:60

;

(

6606

! ;4=606;600

()666:-?6.

0

! 6

! 606

66

(6(6

66

0

! *06;

06

(

;

! 06664

(6

6)0.

! 6(60

! 6((4

66

#"

! ((

;4(

(

(

! 5

! 0=46G30/0(H

66

! (

046(

E(

! 0(;(;6#

! ;=

;

066((;

! '6(

666#6

;

6646

6

;=?

640

Field Piping and Wiring

31

Field Piping and Wiring

Si42-107

A+;!

5

""

B

%6

6;

;(06

)0.

! ;66(40-

60

6

066(0

! ;6?(

40-56

0(;6

66

(

'6(

66(

).600(

6

! 6660660

6;(6

6;)0

-.6

4=6(66

6;

(0

32

%;6(;6

06(;

! /

006((

)&6

(

60.

! 36

06(004

6(

0606

06

Field Piping and Wiring

Si42-107

Field Piping and Wiring

((

;(

;

(;6

66600(

6

(

! 5""

5(

3

#)((P.

5&!3@ 9

!+

6

975"5;

5?;!;

55

! 6

6;

;

)0.6

;6(06

6

6;466

0666

,"";!

;:$;";

"6;$

;8?

;<"

";

@

:"@

! 606

6;

! (6606

66()0.

4&

! 6

=(=6

6;

(

06

(646(

! :6(

6

=6

6

660

4

6066

)-

6(.

! 606I((46

(60

Field Piping and Wiring

33

Field Piping and Wiring

Si42-107

',-?(-

""

60)

((

;.

68

606;)0$.

5064

06;666;

- I66606

8=66)0+.

' I604(=(6

' 36(=0I(4

666;

6

066

!

;:$

'(6

6;

=

:6;

=6,46

,

34

36

606

6;6(J

',6

- '(6

66;46

6;

=6,66;

;

;;!

;:$;5?:;

"

!

6+218

;;""?"

""!

Field Piping and Wiring

Si42-107

Field Piping and Wiring

@

A'?;""5"B

,5$;;;

;

"3";

;""@""

! 06;;#66

=6#60066

6;

! 5(

0

'00#

/

@

)φK4&S.K

&9

)φ+K! 4&S .K

/!

)φ- K4&S.K

)φ1K!4&S .K

)01

G&H.

,;;":

;"?;!

;"5:

! 2606(60

4(6

60)0 .

! ;#06601460

6

6)0!.

(6066

6

($6460

!,

! 360TI6)

((

;.4(=066

0;60)0!,.

Field Piping and Wiring

35

Field Piping and Wiring

Si42-107

,@

4;5:"";!;5:"!<!5

:"@

! (;660

! :6

;6606:60

;

(

6606

! ;4=606;600

()666626.

0

! 6

! 606

66

(6(6

66

046(;

! *06;

06

(

;

! 06664

(6

6)0.

! 6(60

! 6((4

66

#"

! ((

;4(

(

(

! 5

! 0=46D3'<@/@'8D

66

! (

046(

T(

! 0(;(;6#

! ;=

;

066((;

! '6(

666#6

;

6646

6

;=?

640

A+;!

5

""

B

%6

6;

;(06

)0-.

! ;6(40

66

4

606

06

0600(

! ;6?(

4056

0(;6

66

(

'6(

66(

).600(

6

36

Field Piping and Wiring

Si42-107

Field Piping and Wiring

! 6660660

6;(6

6;)0-

.

6

4=6(66

6;(0

! 50(

6(;

=

366

;460

%;6(;6

06(;

! /

006((

)&6

(

60.

! 36

06(004

6(

0606

06

((

;(

;

(;6

66600(

6

(

! 5""

5(

Field Piping and Wiring

3

#)((P.

5&!3@ 9

!+

6

37

Field Piping and Wiring

Si42-107

975"5!;;

5?;!;

55

! 6

6;

;

)0.6

;6(06

6

6;46

60666

,"";!

;:$;<"

"

;

@

:"@

! 606

6;

! (6606

66()0$.

4&

! 6

=(=6

6;

(

06

(646(

! :6(

6

=6

6

660

4

6066

)-

6(.

! 606I((46

(60

38

Field Piping and Wiring

Si42-107

Field Piping and Wiring

0'?(('?'

*5:";

(600#

).'00#

%

'00#

+

@

φ1K!

!!C

φ1K!

&9

φ1K!

);.(;006

:

8(;

006

8606

-!(

!(

! 0

;

6

! 06!(=6$((44;06=

=

((6

(

Field Piping and Wiring

! /;

666

0

6(6

0

A;"3"<B

:6,

00

6((6

:6(6606

5

66

;6)(.60

0606

- /6

66

;66) ) .

39

Field Piping and Wiring

Si42-107

A&3"<B

%0

). :6(?

=40)U.

);. 6666:6

0

). :6(?

=40)U.

);. 6666:6

)"3"<<

:6

6

;6:=

(0

064;066

:0609J1$!,!<C

()!!,!=0C

(.

)"<

3=66

60666;

6=4066

:0609

J1 !,+!<C

()!!,!=0C

(.

8=66,

0

66

(6

(

:6

0(

66

;6

(

'"

60;6

(

36

06400(

6

6).

6-

;6

- 60;60609)

060

=6.

(064

0=

60

60

6

40

0#

:0609

(

)((.

φ1

-+!A-11!<C

(

)---A!+=0C

(.

!A

φ1

$ !A+!<C

(

)$-!A++!=0C

(.

$A1!

φ1

1+!A $!<C

(

)11!A!=0C

(.

1A--

(

Field Piping and Wiring

Si42-107

Field Piping and Wiring

%

060(40

((

;

! :69

6000

0606

6

:=60

600

'00,06

'0

60(

6000

). 60

600((:;

6060

);. 8=

6

(6;6

6(6

)06.

0

:;

600(VJ=0W

:6(((;06-!(

&06

)&.

(

!(

(

!(

(

-!(

600(

N

!-

!

!-

!!

!$-

'

6000

). 3660066(4

6060

66((6(46606

(46

600(6(6

(6

600(

Field Piping and Wiring

41

Field Piping and Wiring

Si42-107

- ((6

:=60(6(

006 06

60

6

6

(;6

(

- (

0;6

(

8=669,

0,

6

=66

(

0

'6(

N

6;#

69, ;,6

(

$ 600

6!=0?

(P@4

60

6;

6(

N

:66(0

#"

"

! 0(;

;9

30

! (;

606(

(

666(

30

! 206

! /

66044060

66

! 5

! :60;6(;!F

! /6(

660

(

! :6

600(

!!6(

! 36(0

04600(6

! 56

6(6

(6

6

(

(04666

(466064

6(6

(

! (606;4=0

66

660

)

606,0.

! <

66D&D4D&DD&-D(:6(;

6D<D()>(.

! <9#6

! 360664

0606

6=

=,6)φ-((.

! (66

(66

(;

42

Field Piping and Wiring

Si42-107

Field Piping and Wiring

A)!

;!":!B

6060;46

86

0

(

8

'+5>

3)!.

"!FF,5@

'!!5>

'5>

"!FF,5@

"!FF,5@

'+5F

'!!5F

-!

-!

"!FF,5-@

"!FF,5-@

30

;6)!.

#

30#(

"!FF,5@!

(66

"!FF,5@!

;

"!FF,5@!

"!FF,5@!

"!FF,5@!

! 4

;=

/ 4&

! 269,0,6

6

(0066

4(=

6;

;(

! 4686

Field Piping and Wiring

43

Field Piping and Wiring

Si42-107

(/-

*%""!:";

*

%

'5!$*>

'5!$*:&

'0#

@

&9

φ1K!

φ1K!

! 56(;0306

)60(((

11 M.J%--$

%""!:"";

,

8((;0

06)6#0

906.

!(

8((;606

-!(

;

! /666

0(0600(

0600

! :6

06

4(==

=6;

06

)

.0φ$((

(P1454)

(P1453)

! 2

06)

.4;;660;

)6

=6

06.

(P1455)

44

Field Piping and Wiring

Si42-107

Field Piping and Wiring

A

;"<"<B

:6(6

6066

;0:6

;6(

! :066;006

;6;

=6

06/06

;666

(P1456)

&<"<

:J

:6(?

=6

06(666(

(

66<6

)'0$.

:

J

:6(?

=

06(666(

(

66<6

)'0.

(P1457)

A

;"<"<

B

66

;6:=

(0

2066

06

:0609J1$!,!<C

()!!,!=0,

(.

(P1458)

A

;"<

B

56,,

6006

2066

:0609J1 !,+!<C

(

)!!,!=0,

(.

Field Piping and Wiring

45

Field Piping and Wiring

Si42-107

A

B

6

(00

66(

6

(I66066(9666

;00

66((=66

00

66(0;6

(

6606664

6

((0

606066

;

065

6

4

((;=6

(064

(46

;66

(;

=60

(

(P1459)

A

B

! 6:;6(

0

! 36

064

6;6600

(

606;6-;060(

! 2;69

6066

0

0?(6

! 6:;60609):(

6

06006.

(P1461)

:;

0#

:0609

(

0)((.

φ1

-+!A-11!<C

(

)---A!+=0C

(.

!A

φ1

1+!A $!<C

(

)11!A!=0C

(.

1A--

6

(P1460)

! 666600;

=6

(6

09

(6(4

4

;

600

! 4""

(P1462)

46

6660666

Field Piping and Wiring

Si42-107

Field Piping and Wiring

#<

:6

6

==;6(

:60;

6

==;6

@

6

6

=

()<

(.

60<00

- =;04

6

06

/

60<0

6

=

(0

$ 6I

60606

+ &=(6<-+ ,+

(P1463)

;

:69

6000

06

06

6

:=60

600

%"

;

60

600((:;4-

60606

66

6).

0

:"%"

;5

(P1464)

(P1465)

A

B

! /=6060-(

5"

;;

3660066(4

6060

66((6(46606

(46

600((6(69

600;

6

600(

57!

:696,

6

6

(:=6

0(6(0,

Field Piping and Wiring

47

Field Piping and Wiring

Si42-107

<;7

;"!7!

;;

(

0;

6(

(6;6

690

6

=66

(

0

(

N

;#

- 69,

06(

;06

(

366,

6

N

46

=06(4

6

60

:6(

N

(P1466)

#"

"@

! 0(;(;6#

! (

6

6

(66

;

! 5

! 50!!Ω

! ;60+6

;(=

66)

606.

! >(

8=

;(

6

6469(

6066

;

)&4&4&-.

6

)6

6(0

66;

;669(4

6

(;(0;<

;6

.

! <9#;

;

! 36

;(644;

=

(P1467)

64

6

)@,

.

;66)φ-4φ+.)'0 .

! 6

00(6(

0=

! <;6

06

! *6666

6

! 2

! /6

((669(

A!";B

'(

660

4

6(

66

A!";B

'6(

66

04

6(

66

(P1468)

48

Field Piping and Wiring

Si42-107

Field Piping and Wiring

5

(P1469)

8

3)!.

'5!$*>

"!FF,5@

'5!$*:&

"!FF,5@

#

30

;6

)!.

30#(

(

66

;

"!FF,5@!

"!FF,5@!

!%

4"!+'<,6

6.5""8

! 8=666

E(

6

60!!

(P1470)

! 0

60

(06

/ 4&

6

46(

Field Piping and Wiring

49

Field Piping and Wiring

/

Si42-107

(1-?(-

/ @

! :60(

60

'00J(

066066

#

#J0;

8

'00#

@

%/K:)8.

&9

%/K:)8.

/! *

7

'5! *

φK((

φ+K!1((

/!*

7

'5!*

φ- K((

8((

;

&06

!(

0

6

'

9

&06

8((

;

"06

/

+!(

-!(

φ1K!((

! 66;460

;

(664;(

6

I

00

! ! 95

! (66090

! 56

;60 !L;6609

50

Field Piping and Wiring

Si42-107

Field Piping and Wiring

/ %;!;

4;5"

;!;;

%"!

;;!;'"!""

5;

5,

;;

5!;!;"

! (06(6

((

! :66;

6

==;6(

! '00(;

6

==;6

! @

60

6

=6

():66;

(.

606(600

- =;6I60

/

600

60

6

=6

(0

$ 6060

! 6(0

6006(;

)3606(06.

'5! *)>C:&.

'5!*)>C:&.

!=0)2

60.

$=0)2

60.

)360(6(06.

'5! *)>,:&.

:'0

()=0.

S

2

60

()=0.

7

60

()=0?(.

7

60

()=0?(.

!!

7)

:0

&06)(.

U(.

7)

:0

&06)(.

U(.

'5!*)>,:&.

:'0

()=0.

S

2

60

()=0.

!!$

! 6066(0

;

Field Piping and Wiring

51

Field Piping and Wiring

Si42-107

/ #"

@

! 0

(6

6;;

((

6

;6

06

66;0

! %

! '6G30/0(H660

! =(;(;

! :6

6(

0(6060

6(9

! :66(6

66;=6(

;

! 3

(;064;

/6066

(

?0

604

6

=?

! !";

! '686

4;!";5;<!

;!;:@;5

"

:""

"

"5;!"!!"";!:!;

!;

"55"69

"5;!8

8

52

'5! *>

-!

'5!*>

!

'5! *:&

!

'5!*:&

$!

3:

"!FF,5@

"!FF,5@

#

0

(6

6

;;

((

6

;

6

0

6

66;0

3025

3:

#

5&!

3@ 9

!+((P

6

Field Piping and Wiring

Si42-107

Field Piping and Wiring

! 660;460

;

(6406

6

6.5""8

8=66

E(

6

60

!!

! 0

60

(06

/ 4&

! %(

600660

(06

(

Field Piping and Wiring

/6686

53

Field Piping and Wiring

54

Si42-107

Field Piping and Wiring

Si42-107

Part 6

Function and Operation

% $

5$

%5 +

%6 %6)/,*7',5.

%6)/,*7'5,*.$!

- $

- 5$

- %5 $

Function and Operation

55

Function Outline

Si42-107

'

&"

',7-

(Input)

Indoor Unit

(Output)

Thermostat Control

Remote Controller with Liquid

Crystal

Fan Motor

Fan Operation

ON/OFF

Fan Operation

Cooling Operation

Malfunction Detection Function

∗ Fan Motor over Current

Thermostat

3 Minutes Timer

56

(P1259)

Funciton and Operation

Si42-107

Function Outline

&

+"

(Output)

(Input)

Outdoor Unit

Discharge Pipe Thermostat

Switch

Compressor ON/OFF Control

Compressor

Fan Motor Thermostat Switch

Malfunction Detection Function

Outdoor Fan Motor

Compressor over Current Switch

RU Model Only

High Pressure Switch

RU Model Only

Low Pressure Switch

RU06K Only

Functon and Operation

(P1260)

57

Operation Flow Chart

Si42-107

&'"!;

&'"!;6',7-C7'8

VW

Power switch on remote controller ON.

Is F1C

of indoor unit in

normal condition.

Unit does not

NO operate.

YES

Relay K1R of indoor unit is ON

Press Fan operation button.

Mgs K1M of indoor unit is ON.

Indoor unit Fan operates.

Press cooling button.

Thermostat

ON judgement.

Thermostat OFF

Thermostat ON

Mgs K1M of outdoor unit is ON,

then compressor and outdoor fans

operates.

One of safty device Q1L, Q2L and

S1B actuates.

Mgs K1M of outdoor unit is OFF.

Compressor and outdoor fans are

OFF. (Indoor fan keeps to operate.)

Safty device returns to normal.

Stop unit operation

and locate cause

of actuation of

safty device.

Manually resets the safty devices.

(P1261)

58

Funciton and Operation

Si42-107

Operation Flow Chart

VW

Power switch on remote controller ON.

Is F1C

of indoor unit in

normal condition.

Unit does not

NO operate.

YES

Relay K1R of indoor unit is ON

Press Fan operation button.

Mgs K1M of indoor unit is ON.

Indoor unit Fan operates.

Press cooling button.

Thermostat

ON judgement.

Thermostat OFF

Thermostat ON

Mgs K1M of outdoor unit is ON,

then compressor and outdoor fans

operates.

F1C of indoor unit actuates.

Relay K1R is OFF and Mgs K1M

is OFF, then Mgs K1M of outdoor

unit is OFF also.

Indoor unit Fan stops, then

compressor and outdoor unit's fan

are OFF.

F1C of indoor unit returns to

normal.

Stop unit operation

and rocate cause

of actuation of

safty device.

Manually resets the F1C relay.

(P1262)

Functon and Operation

59

Operation Flow Chart

Si42-107

&'"!;6',7-C7-8

∗ :6/!$A!*7'5!$A!*

/*?/!*;6(

VW

Power switch ON.

Is safty

device in normal

condition.

Unit does not

NO operate.

YES

Relay K1R of outdoor unit is ON.

Relay K2R, K3R of indoor

unit are ON.

Press Fan operation button.

Mgs K2M of indoor unit is ON,

and relay K2R, K4R are ON.

Indoor Fan operates.

Press cooling button.

Thermostat

ON judgement.

Thermostat OFF

Thermostat ON

Mgs K1M of outdoor unit is ON,

then compressor and outdoor fans

operates.

One of the safty device Q1RP,

F1C, S1B, S1PH, Q1L, Q2L

acutuates.

Relay K1R of outdoor unit is OFF.

Relay K2R, K3R, of indoor unit is

OFF then K2M and K1M are OFF.

Fan and compressor are OFF.

Safty device returns to normal

condition.

(P1263)

60

Funciton and Operation

Si42-107

Operation Flow Chart

VW

Power switch ON.

Is safty

device in normal

condition.

Unit does not

NO operate.

YES

Relay K1R of outdoor unit is ON.

Relay K2R, K3R of indoor

unit are ON.

Press Fan operation button.

Mgs K2M of indoor unit is ON,

and relay K2R, K4R are ON.

Indoor Fan operates.

Press cooling button.

Thermostat

ON judgement.

Thermostat OFF

Thermostat ON

Mgs K1M of outdoor unit is ON,

then compressor and outdoor fans

operates.

F2C of indoor unit actuates.

Relay K2R, K3R, are OFF and

K2M and K1M are OFF also.

Fan and compressor are OFF.

F2C returns to normal condition.

(P1264)

Functon and Operation

61

Electric Function Parts

Si42-107

#"

'

',7-.

'(

!-

8

880

6

!

*'+,-4*'+,)/0:.

:%,*

-φ- !?F!=3

&*B:"!,$

!F

:%,*

-φ- !?F!+=3

&*B:"!,$

!F

8%

'

'(

8

880

6

8%

'

!

!$

!

!

*'+,-4*'+,)/0:.

:%

:%,*

-φ- !?F!+=3

-φ- !?F=3

&*,B:"!,$

!F

&*,B:!,$

!F

-$

',7-3%

'(

!-

!

*'+,-4*'+,)/0:.

8

%5

φ!?!F!=3

&*B:"!,

!F

880

6

8%

'

-

',7-4%

'(

8

880

6

8%

'

62

!

!$

!

*'+,-4*'+,)/0:.

:%

-φ!F!+=3

!

:%,*

-φ!F=3

&*,":"!,2

!F

&*,B:"!,$

!F

&*,B:!,$

!F

-

-

$!

Funciton and Operation

Si42-107

Electric Function Parts

',7-.

'(

8

880

6

8%

'

!

*'+,-):6(.4*'+,)/0:.

*'+,2):6(.7*:1∗

:%

:%

-φ- !?F!"#=3

-φ- !?F!"#-+=3

&*,B:!,$

!F

!

&*,B:!,$

!F

!

∗ *:1J-(0(

',7-4%

'(

8

880

6

!

*'+,-):6(.4*'+,)/0:.

*'+,2):6(.7*:1∗

:%

-φ!F$!"#=3

&*,B:!,$

!F

:%

-φ!F$!"#-+=3

"%,!,:'

!F

1

8%

'

∗ *:1J-(0(

Functon and Operation

63

Electric Function Parts

Si42-107

&

>'

8

(

*8

8

80

6

%5

)5.

8

%5

)&.

%5

8

:6(

R&

R&

'+5F&

"--R2

85!,

!3

85!/

!3

N

%J-XL

%<J $XL

'

'

8

8

2

:(

6

)/

60.

0'

,5:,-*

%J-XL?%<JXL

N

$$, +<

8

0

N

N

*

-'

'4

'

8

(

*8

80

6

8

%5

)5.

%5

)&.

8

R&

R&

'

64

'+5>

"--R/2

µ

N

'!!5>

'!!5F&

'5>

'5:&

"-$R/2

85!,

"-$R2

85!/

"-$R/2

85!,

"-$R/2

&

85!/

+3

1!3

+3

1!3

-3

3

$!3

!3

%5

8

:6(

8

'

2

8

:(

6

)/

60.

*

0'

-µ

!µ7 !µ

%J-XL

%<J $XL

µ

µ

,5:,-*

%J-XL?%<JXL

N

-'

8

N

$$,

+<

!µ

'4

'

0

N

$µ7 !µ

N

N

N

N

N

N

Funciton and Operation

Si42-107

Electric Function Parts

7-.

8

(

*8

80

6

8

%'

8)5.

8

8)&.

'5!$*>

'5! *>

'5!*>

B:!!2>

-6- !,F!"#

"%$,:'

!F

B:$/,>

-6- !,F+=3

B:--/,>

-6- !,F1=3

&*,!B:,

!F

,<%:

6!,!F$ 3

"%,-,:'

!F

3$ $!!

6!,!F$-!3

8

:6(

%J-XL

%<J!L

3$ !!

6!,!F$1!3

%J-XL

%<J $XL

'

'

8

8

$µ4!!F

$µ4!!F

µ4!!F

µ4!!F

R'

'6

:6(

6

)/

60.

2

"

6)"06

.

&

6)&

.

,<%:

6!,!F$$3

'B,!!F

5:,-*

%J-XL

%<JXL

2,/2 %J17!,!8

%<J$X!8

&2,B

%J,!!-X!!8

%<J!!X!!-8

!F

7-4%

8

(

*8

80

6

8

%'

8)5.

8

8)&.

'5! *:&

'5!*:&

B:1!2

-6!F$!"#

"%,-,:'

!F

B:-$/,

-φ!!F=3

"%,-,:'

!F

B:-!!/,

-6!!F+=3

&*,!B:,

!F

-

$

,<%:

6!,!F$!!3

3$ $!!

6!,!F$-!3

,<%:

6!,!F$!!3

8

:6(

%J-XL

%<J!L

3$ !!

6!,!F$1!3

%J-XL

%<J $XL

'

'

8

8

$µ4!!F

$µ4!!F

µ4!!F

µ4!!F

R'

'6

:6(

6

)/

60.

2

Functon and Operation

'5!$*:&

"

6)"06

.

&

6)&

.

'B,!F

5:,-*

%J-XL

%<JXL

2,/2 %J17!,!8

%<J$X!8

&2,B

%J,!!-X!!8

%<J!!X!!-8

!F

65

Electric Function Parts

66

Si42-107

Funciton and Operation

Si42-107

Part 7

Troubleshooting

8

$

% $

""'98

+!

6 +!

- :;6029(+

-

-

--

-

-$

-+

-

-1

Troubleshooting

:;6029( +

9(% +

%4;( +0%;(( +

9(6/4

;'36+

9(%;0 +$

9(/

60368 ++

9(

&<6=+

9(/

60/+1

67

Maintenance Inspections

Si42-107

+

&<<!

D

&5"

&

:6060

;606

;6(

06;;'+,5

(6;

JG"H

0

"06

)8.

&

)8.

! $A1

"# )$A1.

$! +A

"# )+A!.

!-1A!1

)!A$!.

!-A!

)-A.

/

60

5

:(

J

:(

)L.

/

)L.

2

:(

/

60

:(

)L.

$!A1

!A

+!A

,A!

%5

J

/

2

:(

/

60

:(

)L.

A

+A

006=0?

(P

0%

"0%

5

%5

+L/2?1L32

L/2

-L/2

+L/2?$L32

! /0(

466;

=

(

;6G

G

6

36(0(

46(60

Indoor unit

To dedicated breaker

Transmission wiring

between indoor and

outdoor units

What about switch capacity?

What about cable thickness?

What about voltage and current?

To dedicated

breaker

Refrigerant piping

(Liquid+gas)

Drain piping

Outdoor unit

Earth

(P1667)

68

Troubleshooting

Si42-107

"%7

E

&

F

Maintenance Inspections

366

((((#6;;)8

(,!((.

)36

0.

,

0

6

5?

%?%

%50

6

%5?

%

8'0

&

&

"06

&

'0

&

&

&

&

"06

"06

"06

"06

"06

"06

"06

"06

"06

38'0

/8'0

Y&

Y&

&

&

&

&

&

='0)@.

5

(

&

Y"06

&

&

&

&

Y360#6

;4;

6(

6((

Y/60

0604;

6(6(

(

- ;606;

(06

<

Troubleshooting

69

How to Handle Request for Maintenance

Si42-107

)!)"=+

'"!;

6

060

669

(6

(

Turn the power supply

switch ON or replace

the fuse.

Wait until

power failure

is over.

YES

YES

Doesn't run at all

Is there a

power

failure?

(1) The operation circuit fuse is

disconnected or is making poor contact.

(2) The operation swich is broken or its

contact is defective.

(3) The high pressure switch is broken.

(4) The fan motor's magnetic switch is

broken.

(5) The fan motor's protection thermostat is

being actuated or is broken.

(6) The compressor's overcurrent relay is

broken.

(7) The compressor's protective thermostat

is broken.

(8) The electrical system insulation is

defective.

(9) The compressor's magnetic switch's

contact is defective.

(10) The compressor is broken.

NO

The power supply switch is NO

OFF or the switch's fuse is

burnt.

Nomal

Runs

The fan comes on

but the

compressor

doesn't run.

Set the remote

controller's temperature

setting to:

(1)When

cooling:Minimum

(2)When

heating:Maximum

(11) Thermostat is broken.

(12) The cool/heat selector is broken.

(13) The operation switch is broken.

(14) The compressor's magnetic swich is

broken.

Doesn't run

(15) Over-charged with refrigerant.

(16) Air is mixed inside the refrigerant

circuit.

(17) The pressure switch is broken.

(18) The outdoor unit fan motor's magnetic

switch is broken.

(19) The outdoor unit fan motor's auxiliary

relay is broken.

Cooling

Cooling starts but

stops right away.

(20) The outdoor unit's heat exchanger is

dirty.

(21) There is something blocking the

outdoor unit's air flow.

(22) Malfunction of the outdoor unit's fan.

Nomal

The unit won't run

again for a while

after stopping.

Try turning the

Operation switch OFF

and On.

Did you allow 3 minutes to

elapse after turning ON?

YES

NO

Runs

Operation is

normal.

Is there something causing the

indoor load to be large, such as

an open window or door?

The unit runs but

doesn't cool the

room.

Measure the suction

/disharge temperature.

YES

Temperature

differential is 8~18˚C

NO

(23) Overcurrent relay (for compressor)

(24) Compressor's protective themostat

(25) The causes for the overcurrent relay

(for compressor) being actuated are:

(26)-1 Power supply voltage is lower than

prescribed.

(26)-2 High pressure is too high.

(26)-3 The power supply cord is too small.

(26)-4 The compressor is broken.

(27) The causes for the compressor's

protective thermostat

(27)-(1) Unsatisfactory compression from

the compressor

(27)-(2) Defective refrigerant

(27)-(3) Unsatisfactory refrigerant circulation

(Temperature differential

=suction temperature - discharge temperature)

OK.We'll be right over.

(Maintenance required)

(P1268)

70

Troubleshooting

Si42-107

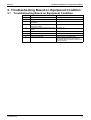

Troubleshooting Based on Equipment Condition

4:";9#=5

4:";9#=5

'(

0 +

-

4;

(

0;

((

9(64

; 0 +

6

9(; 0 +$

0

Troubleshooting

9(

9(

0 +0 +

$

+

9(

606(

0 ++

9(

6= 0 +

1

9(

60

9((

0 +1

'((

0

(6

6066

(;

71

Troubleshooting Based on Equipment Condition

Si42-107

#=5&

%"

:"+"

/,*

:"

!

!

!

!

!

!

!

!

!

!

;

6

(

606

6

(0

6(

6((

(

(

6(

(

(0

6

(

8

(

4:";

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Is power

switch OFF or fuse

for control circuit

blown?

YES

Turn on power switch or replace

fuse.

NO

Is there

power outage?

YES

Wait until power returns.

NO

Is the

power supply

between terminal C-D

(or 3) from remote

controller?

NO

Check remote controller contact

YES

Is the

power supply

on MgS "K1M or K2M"

coil of indoor

fan motor?

YES

Malfunction of MgS coil or MgS

contact replace the MgS switch.

NO

Is the

power supply

to Relay "K1R" coil of

indoor or outdoor

unit? ∗Note

NO

Is there

any malfunction

or actuation of safty

devices?

YES

∗ K1R relay rocated on indoor unit for

FD03·04·05K and outdoor unit for

FD06·08·10K

YES

NO

Is the

sufficient insulation

in electric system?

YES

Possibly faulty electric wiring

or relay etc.

72

NO

Malfunction of K1R relay and

replace it.

Malfunction or actuation of safty

device such as:

· indoor fan motor protection

thermostat or over current relay

· Compressor overload relay or

protection thermostat

· Discharge pipe thermostat switch

· High pressure switch or Low

pressure switch

Check the faulty insulation parts or

wiring.

Check electric wiring or relay etc.

(P1269)

Troubleshooting

Si42-107

Troubleshooting Based on Equipment Condition

'&?:5

%"

:"+"

/,*

:"

! (

! (0

6

(

4:";

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Make the following

temperature setting using

remote controller.

Cooling: Lowest setting

YES

Does

equipment operate?

YES

Normal.

NO

Is the

power supply

between terminal B-D

(or 3) from remote

controller?

NO

Malfunction of remote controller

contact or thermostat

YES

Is the power

supply on MgS coil for

compressor.

YES

Malfunction of MgS coil or MgS

contact.

Replace the MgS switch.

NO

Is there

any malfunction or

actuation of safty

devices?

NO

Possibly faulty electric

wiring or relay etc.

YES

Malfunction or actuation of safty

device such as:

· Discharge pipe thermostat

· Thermostat switch for outdoor

fan motor.

(In case of R71~125FU)

Check electric wiring between

indoor and outdoor unit or relay

etc.

(P1270)

Troubleshooting

73

Troubleshooting Based on Equipment Condition

Si42-107

"&:55"

%"

:"+"

/,*

:"

!

!

!

!

!

!

!

!

600

0(

6

(0

6(

(

6

60

:60(

8

4:";

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

[ Outdoor unit [

Does the

fan rotate?

NO

YES

Does the fan

overheated?

YES

Malfunction of fan

motor

Check the magnetic

switch and aux. switch

for fan motor

Replace fan motor.

NO

Is there any

item disturbing

airflow?

YES

Remove the disturbing

item

NO

Is the heat

exchanger soiled?

YES

Cleaning of the heat

exchanger

NO

Possible causes as

follows:

* Refrigerant overcharge

* Mixing of air in

refrigerant system

* Faulty pressure switch

After vacuum drying,

charge correct amount

of refrigerant

Check the pressure

switch

(S1271)

74

Troubleshooting

Si42-107

Troubleshooting Based on Equipment Condition

%#=5;,!?

:

;"

%"

:"+"

/,*

:"

! %

)

(.

! (

6(

! %

(

60

&0

606

;

8

(

! (

6((

60

(

(

0

0

4:";

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Turn the operation switch

ON and OFF, then wait at

ON side.

Does the unit

start operation after

3 minutes?

YES

[Electric system]

Power

supply voltage is

NO

within ±10 % of specified

voltage.

NO

Is the

discharge side of

compressor hot after

unit operation

stop?

YES

Check on the cause why

overcurrent relay (for

compressor) or

compressor protection

thermostat acted.

NO

Not so hot

YES

Is the size

of power cable

through total length

correct?

[Refrigerant circuit]

Normal. Unit is in 3-min standby

mode

Contact power company

Check compressor

NO

Replace power cable

YES

After vacuum drying,

charge correct amount of

refrigerant. Then, start

operation again.

Is

there any

temperature

difference between inlet

and outlet of

capillary

tube?

YES

Malfunction of

compressor

NO

Capillary tube clogged.

Check compressor

(P1272)

Troubleshooting

75

Troubleshooting Based on Equipment Condition

/

Si42-107

#=5&:<"

%"

:"+"

/,*

:"

! %

)

(.

! (

6(

! %

(

60

&0

606

;

8

(

! (

6((

60

(

(

0

0

4:";

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Measure the temperature of

suction air and discharge

air.

Temperature difference =

Suction air temp. –

Discharge air temp.

Temperature

difference for cooling

should be between

8 and 18 ˚C.

YES

YES

Normal.

NO

Possible causes as follows

* Incorrect selection of model

* Affection of direct sun

NO

Does

any frost

generate around

inlet port of indoor unit

heat exchanger or

outlet port of

capillary

tube?

Does the

heat load increase

after installation

of the unit?

YES

Is the

operation current

less than specified

level?

Additional unit installation

should be considered

YES

NO

NO

Gas shortage possibly

generates trouble.

Does indoor

unit discharge flow

rate down?

YES

NO

Is the

level of high

pressure higher than

normal level?

NO

Possible causes as follows

* Insufficient compression of

compressor

* Insufficient circulation of

refrigerant

* Faulty expansion valve

76

YES

* Clogged air filter

* Soiled heat exchanger

* Malfunction of fan motor

Possible causes as follows

* Refrigerant overcharge

* Soiled heat exchanger

* Short circuit of discharge

air

* Disturbing item in air flow

* Malfunction of fan motor of

outdoor unit

After vacuum drying, charge

correct amount of refrigerant.

Check each section

Check each item

Check each item

(P1273)

Troubleshooting

Si42-107

0

Troubleshooting Based on Equipment Condition

#=5,

;;+

%"

:"+"

/,*

:"

!

!

!

!

!

"(

6(

6

60

00

8

(

4:";

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Is the

room temperature

higher than set value in

cooling

operation?

YES

NO

Continue unit operation.

Is white fog

coming out from

the unit?

NO

Normal

YES

It may be necessary to

remove the source of

humid condition.

Is the heat

exchanger of indoor

unit soiled?

YES

Remove the source of humid

condition.

Cleaning of heat exchanger is

necessary.

NO

Is the site

dusty or with dense

oil mist?

YES

Dust or oil mists should

be removed.

Remove the source of oil mist or

dust.

NO

Is the airflow

rate too small?

YES

Possible causes as follows

* Clogged air filter

* Malfunction of fan motor

Cleaning of air filter

Check fan motor

(P1274)

Troubleshooting

77

Troubleshooting Based on Equipment Condition

1

Si42-107

#=5

;@

%"

:"+"

/,*

:"

! 600

! 0(

! 60060)6.

4:";

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Does the

noise generate with

vibration of whole

ceilings and

walls?

[Installation work side]

YES

Correction of installation

Reinforcement for ceilings or

NO

Does the

noise generate

with vibration of

unit mounting

section?

YES

Continuous

YES

slight noise of "shoo....."

during cooling

operation

NO

Is the

piping secured?

NO

YES

NO

Does the

pipe contact with

casing?

NO

Sound

of "shoo..."

generates just after

operation start

or stop.

[Power supply side] YES

Does the fan

contact with other

parts?

Insert shock absorber in

mounting section, or strengthen

the mounting section.

YES

Insert cushion materials to the

pipe support such as saddle.

YES

NO

Sound

of "shoo..." generates

during cooling or after

operation

stop.

NO

Normal. The sound is flushing

noise of gas (refrigerant) inside

air conditioning unit

Normal. The noise is a sound

generated at the time of gas

Disassemble and remove parts

contact.

YES

Normal. Operation sound of

draining device

Correct piping manually or attach

a dead weight to pipe

NO

Is

the noise

flushing sound from

pressure reducing

valve or capillary

tube?

NO

78

YES

Normal.

* Excess charge of

refrigerant

* Air intrudes into

refrigerant system

* Flushing noise due to

refrigerant shortage.

(Sound of shoo...)

After vacuum drying, charge

correct amount of refrigerant.

(P1275)

Troubleshooting

Si42-107

G

Troubleshooting Based on Equipment Condition

#=5,

;,

%"

:"+"

/,*

:"

! (

! (T6

4:";

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Does

the trouble

generate at the

time of operation start

again after extended

period of

operation?

YES

Dust collected inside the indoor

unit are blown out.

Cleaning for inside of indoor unit

is necessary.

NO

Is air filter

equipped?

NO

YES

Dust collected inside the indoor

unit are blown out.

Cleaning for inside of indoor unit

is necessary.

Install air filter.

(P1276)

Troubleshooting

79

Troubleshooting Based on Equipment Condition

80

Si42-107

Troubleshooting

Si42-107

Part 8

Removal Procedure

'+5> Removal Procedure

'(0

'(%58 '(

2 '((

81

For R71FUY1

Si42-107

'0'.

5<"#$"

-

82

9""!":5:"!@

'(61

'(6

60

'(6-

6

0

(;60

'(6 6

0

Removal Procedure

Si42-107

For R71FUY1

5<"&''+

9""!":5:"!@

! '(60

4

4

0

6

(06

0

'(6

6 ;06

6006

?;(?

064(6

600

-

'(6

;0

0

/

6(

(6

;E0

(

6

'(660

;06

(4(6

(

:6(;

;

(;

(06-

60;

Removal Procedure

83

For R71FUY1

5<"#"

"9$

-

84

9""!":5:"!@

! '(64

0

0

06

(0

'(6

(

6

60)

(04

6

.

Si42-107

'(6

;

6606

;

6

(;6

04

4(6

(

(06

04(6

6

;

'(6

;

Removal Procedure

Si42-107

For R71FUY1

5<"5

9""!":5:"!@

! '(6

04

4

0

(

'(6

(

0

/

6

(

(6

(

(

-

"6;#

6

60

4

((60

6

4

Removal Procedure

85

For R71FUY1

86

Si42-107

'(6

(E6

;

5:,;

&6

(

06

Removal Procedure

Si42-107

Part 9

Appendix

0/0(

0%

30/0( 1!

!"# 1!

$!"# 1+

Appendix

87

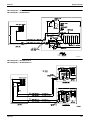

Piping Diagrams

Si42-107

,5

"&"

',(-C0'F',(-C(('F',(-C'

',(/-C(/-

88

Appendix

Si42-107

Piping Diagrams

',(1-C(1-F',(-C(-

',-C(1-2F',(-C(-2

Appendix

89

Wiring Diagram

Si42-107

,5

()*

',(H(H(-.

90

Appendix

Si42-107

Wiring Diagram

0'.

3D000995C

(('.F'.

3D001007C

Appendix

91

Wiring Diagram

Si42-107

',(/-.C(/-.

92

Appendix

Si42-107

Wiring Diagram

',(1-.C(1-.F',(-.C(-.

Appendix

93

Wiring Diagram

Si42-107

',-.C(1-.2F',(-.C(-.2

94

Appendix

Si42-107

Wiring Diagram

',(>(-.

Appendix

95

Wiring Diagram

Si42-107

',H(-.

96

Appendix

Si42-107

Wiring Diagram

/()*

',(H(-3%

Appendix

97

Wiring Diagram

Si42-107

0'3%

3D005375C

(('3%

3D005376C

98

Appendix

Si42-107

Wiring Diagram

',(-4%

Appendix

99

Wiring Diagram

Si42-107

'4%

100

Appendix

Si42-107

Wiring Diagram

',(/-4%C(/-4%

Appendix

101

Wiring Diagram

Si42-107

',(1-4%C(1-4%F',(-4%C(-4%

102

Appendix

Si42-107

Wiring Diagram

',-4%C(1-4%2F',(-4%C(-4%2

Appendix

103

Wiring Diagram

Si42-107

',(?(-3%F',(>(-4%

104

Appendix

Si42-107

Wiring Diagram

',H(-4%

Appendix

105

Wiring Diagram

Si42-107

106

Appendix

Si42-107

Packaged Air Conditioners

Duct Connection Type

(High static Pressure

Application)

FDY-K(A) Series

— Heat Pump —

Model Series

Class

Indoor Units

Outdoor Units

6HP

8HP

10HP

15HP

20HP

FDY06K(A) FDY08K(A) FDY10K(A) FDY15K(A) FDY20K(A)

RY140KU

RY200KU

RY250KU

RY200KU×2 RY250KU×2