Download Mitsubishi Electric VS-45605 Service manual

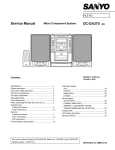

Transcript