Download Evenflo R-1851A Service manual

Transcript

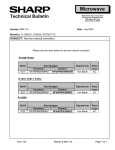

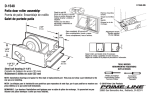

SUPPLEMENTAL R-l 850A R-1851A R-l852A SERVICE MANUAL S98M121 R1850A ------ OVER THE RANGE MICROWAVE OVENS R-l 850A/R-1851 A/R-l 85249 R-1851A Model In the interest of user-safety the oven is to be restored to its original condition and only the parts identical to those specified should be used. This is a supplemental Service Manual for Models R-l 850A/R-1851A/R-1852A. This model is quite similar to the Base Model R-l 850 (S/M# S6804R185OXDJ Use this supplemental manual togetherwith the Base Model Service Manualsforcomplete operation and service information. TABLE OF CONTENTS PAGE SECTION PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICE TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY. ........... Before Servicing ............................................................. Warning ............................................................ Forewordand Warning to Service Personnel ...................................................... Microwave Measurement Procedure ........................................................... ................................................................... Wiring/SchematicDiagram Parts ...................................................................................... .................................................................... PackingandAccessories SHARP ELECTRONICS Inside Front Cover Inside Front Cover 1 2 3 4 6 13 CORPORATION Service Headquarters: Sharp Plaza, Mahwah, New Jersey, 07430-2135 R-1850A R-185lA R-l 852A (a) Do not operate or allow the oven to be operated with the door open. 04 Make the following safety checks on all ovens to be serviced before activating the magnetron or other microwave source, and make repairs as necessary: (1) Interlock operation, (2) proper door closing, (3) seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening of hinges and latches, (5) evidence of dropping or abuse. (d Before turning on microwave power for any service test or inspection within the microwave generating compartments, check the magnetron, waveguide or transmission line, and cavity for proper alignment, integrity, and connections. (4 Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generation and transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual before the oven is released to the owner. 03 A microwave leakage check to verify compliance with the Federal should be performed on each oven prior to release to the owner. performance standard (RD21101U Before servicing an operative unit, perform a microwave emission check as per the Microwave Measurement Procedure outlined in the base model service manual. If microwave emissions level is in excess of the specified limit, contact SHARP ELECTRONICS CORPORATION immediately Q l-800-237-4277. If the unit operates with the door open, service person should 1) tell the user not to operate the oven and 2) contact SHARP ELECTRONICS CORPORATION and DHHS immediately. Service personnel should inform SHARP ELECTRONICS CORPORATION of any certified unit found with emissions in excess of 4mW/cm2. The owner of the unit should be instructed not to use the unit until the oven has been brought into compliance. I (RD81001 U) SERVICE MANUAL SHARC, Over The Range Microwave Ovens R-l 850A/R-1851 A/R-l 852A Foreword This manual has been prepared to provide Sharp Electronics Corporation personnel with complete operation and service information for Sharp microwave oven models R-l 850A/R-1851 AIR-1 852A It is recommended that service personnel carefully study the entire text of this manual so they will be qualified to render satisfactory customer service. Check interlock switches and the door seal carefully. Special attention must be given to avoid electrical shock and microwave radiation hazards. This supplemental service manual contains update information only. Please refer to base model service manual (R-1850) for complete service information. WARNING Never operate the oven until the following ensured: points are (A)The door is tightly closed. (B)The door brackets and hinges are not defective. (C)The door packing is not damaged. (D)The door is not deformed or warped. (E)There are no other visible signs of damage to the oven. DANGER Certain initial parts are intentionally not grounded and present a risk of electrical shock only during servicing. Service personnel - Do not contact the following parts while the appliance is energized; High Voltage Capacitor, Power Transformer, Magnetron, High Voltage Rectifier Assembly and High voltage Harness. If provided, Vent Hood, Fan Assembly and Cooling Fan motor. All of the parts marked “*I’ on parts list are used at voltages more than 250V. Removal of the outer case cabinet voltage above 25OV. gives access to All of the parts marked “A” on parts list may cause undue microwave exposure, by themselves, or when they are damaged, loosened or removed. Sharp Electronics Corporation Sharp Plaza Mahwah, New Jersey 07430-2135 I WARNING TO SERVICE PERSONNEL Microwave ovens contain circuitry capable of producing very high voltage and current. Contact with following parts may result in a severe, possibly fatal, electrical shock. (EXAMPLE) High Voltage Capacitor, High Voltage Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness etc.. Read the Service Manual carefully and follow all instructions. Don’t Touch ! Danger High Voltage Before Servicing 1, Disconnect the power supply cord and then remove outer case cabinet. 2. Open the door and block it open. 3. Discharge the high voltage capacitor. WAl?NING:RISK OF ELECTRICAL THE HIGH VOLTAGE CAPACITOR When the testing is completed 1. Disconnect the power supply cord and then remove outer case cabinet. 2. Open the door and block it open. 3. Discharge the high voltage capacitor. 4. Reconnect the leads to the primary of the power transformer. 5. Re-install the outer case cabinet. 6. Reconnect the power supply cord after the outer case cabinet is installed. 7. Start the oven and check all functions. SHOCK. DISCHARGE BEFORE SERVICING. The high-voltage capacitor remains charged about 60 seconds after the oven has been switched off. Wait for 60 seconds and then short-circuit the connection of the high voltage capacitor (that is the connecting lead of the high voltage rectifier) against the chassis with the use of an insulated screwdriver. After repairing Whenever troubleshooting is performed, the powersupply must be disconnected. In some cases it may be necessary to connect the power supply after the outer case has been removed, in this event: 1. Reconnect all Lads removed from components during testing. 2. Re-install the outer case (cabinet). 3. Reconnect the power supply cord after the outer case is installed. 4. Reconnect the power supply cord after the outer case is installed. 5. Run the oven and check all functions. Microwave ovens should not be operated empty. To test for the presence of microwave energy within a cavity, place a cup of cold water on the oven turntable, close the door and set the power to HIGH and set the microwave timer for two (2) minutes. When the two minutes has elapsed (timer at zero), carefully check to see if the water is hot. If the water remains cold, carry out Before Servicing procedure and re-examine the connection to the component being tested. 1. Disconnect the power supply cord and then remove outer case cabinet. 2. Open the door and block it open. 3. Discharge the high voltage capacitor. 4. Disconnect the leads to the primary of the power transformer. 5. Ensure that the leads remain isolated from other components and oven chassis by using insulation tape. 6. After the above procedure, reconnect the power supply cord. When all service work is completed and the oven is fully assembled, the microwave power output should be checked and the microwave leakage test should be carried out. 2 R-l 85OA ;:;gs MICROWAVE MEASUREMENT After adjustment of the door, interlock and monitor switches are completed individually or collectively, a INTERLOCK SWITCH TEST and MICROWAVE LEAKAGE TEST must be performed to assure compliance with DHHS (CDRH) Performance Standards for Microwave Ovens. Interlock Switch Test Make sure that the door sensing switch, secondary interlock switch and monitor switch are operating properly by checking with an ohmmeter. Refer to the “Test Procedure” of the door sensing switch, secondary interlock switch and monitor switch. 2. Place the oven tray in the oven cavity. 3. Place the load of 275 & 15ml(9.8 oz.) of tap water initially at 20 z!z5OC (68OF) in the center of the oven cavity. The water container shall be a low form of 600 ml (20 oz.) beaker with an inside diameter of approximately 8.5 cm (3 % in.) and made of an electrically nonconductive material such as glass or plastic. The placing of this standard load in the oven is important not only to protect the oven, but also to insure that any leakage is measured accurately. 4. Set the cooking control on Full power cooking mode. 5. Close the door and put the oven into a cook cycle for several minutes. If the water begins to boil before the survey is completed, replace it with 275ml of cool water. Microwave Leakage Test Requirements 1. Microwave leakage limit (Power density limit). The power density of microwave radiation emitted by a microwave oven shall not exceed 1mW/cm* at any point 5cm or more from the external surface of the oven, measured prior to acquisition-by the purchaser, and thereafter (through the useful life of the oven) 5mW/cm* at any point 5cm or more from the external surface of the oven. 2. Safety interlock switches. Primary interlock relay and door sensing switch will prevent microwave radiation emissions in excess of the requirement as above mentioned, secondary interlock switch shall prevent microwave radiation emission in excess of 5 mW/cm* at any point 5cm or more from the external surface of the oven. Preparation PROCEDURE For Testing Leakage Test Closed-door leakage test (microwave measurement). 1. Grasp the probe of the survey instrument and hold it perpendicular to the gap between the door and the body of the oven. 2. Move the probe slowly, not faster than lin./sec (2.5cm/sec.) along the gap, watching for the maximum indication of the meter. 3. Check for leakage at the door screen, sheet metal seams and other accessible positions where the continuity of the metal has been breached (eg., around switches, indicator and vents). While testing for leakage around the door pull the door away from the front of the oven as far as is permitted by the closed latch assembly. 1. Make sure that the actual instrument is operating normally as specified in its instruction booklet. 4. Measure carefully at the point of the highest leakage and make sure that the highest leakage is no greater than 4 mW/cm* to allow for measurement uncertainty, and that the secondary interlock switch does turn the oven OFF before any door movement. Note: Survey instruments Note: After servicing, Before beginning the actual measurement proceed as follows: of leakage, that comply with the requirement for instrumentatoin 21 CFR1030.1 O(c)(3)(i), as prescribed by the performance standard for microwave ovens must be used for testing. and microwave record data on service leakage report. invoice R-l 850A R-l85lA R-1852A A BJ n-m n-w n Gz n-la LHM KUMS C 1 I Dl E tlOLoyy NOl133ANO3 =-@zG 378VJNWlL AMO ---I I i F G H' I- MOLOW tl3dVWCl R-l 85OA R-1851A R-l 852A 31 )I 1 I 2 3 4 5 5 6 PARTS LIST Contact your nearest SHARP Parts Distributor to order. For location of SHARP Parts Distributor, Please call Toll-Free; 1-800-BE-SHARP “ Q ” MARK - Spare [ REF NO. PART NO. r * t * *A section. parts delivery DESCRIPTION /§) ELECTRICAL l- 1 FH-DZBOlOMRYO M H.V. Rectifier l- 2 RC-QZBOllMREO M H.V. Capacitor QFS-TA013WREO M Oven l- 4 RHET-A174WREO M Convection l- 5 RMOTDAl82WREO M Turntable l- 6 RMOTDAZlIWREO M Stirrer motor l- 7 RTHM-0044MRE0 M Thermal cut-out l- 8 RTRN-BO49MREO Power l- 9 RV-MZA255WREO l-10 QFSHDBOO3MREO M M M 1-11 QSW-MAllOWREO 1-12 FFS-BAOl6/KIT 1-13 FACCDBOllMREO l-14 1-15 QSOCLB006MREO FH-HZAO53WREO l-16 QSOCLB006MREO l-17 FMOTEA362WRKO 1-18 RMOTEA343WREO l-19 RMOTEA344WREO l-20 RLMPTA077WREO 1-21 FDTCTA171WRKO l-22 RMOTDA217WREO l-23 RR-WZA031WREO temperature CODE PARTS assembly l- 3 M M M M M - Q’N fuse heater motor N.O. 1 1 (15O'C) 60°C transformer AM 1 AR 1 AG 1 1 AZ AQ 1 AQ 2 AG 1 BF Magnetron 1 BE Fuse holder 1 AD Secondary Monitor Power Hood interlock, Door sensing & damper switches switch supply AE and fuse assembly AF cord lamp socket AP & Oven lamp socket AE Thermistor AP M M M M M Oven lamp socket AE Hood fan motor M M M - AH Convection BM motor Ax Fan motor Hood AW lamp & Oven lamp AG 1 1 1 sensor Damper Noise motor Resistor CABINET AW AP AK 1 PARTS 2- 1 PFIL-BOO2MREO E- Grease 2- 2 PDIF-BOllMRFO 2- 2 PDIF-BO12MRFO M M M M M M M exhaust louver R-1850A Hood exhaust louver R-1851A Hood exhaust louver R-1852A Base plate left Outer case cabinet Outer case cabinet R-1850A R-1851A BE BE M M Outer case cabinet R-1852A BE AB AM AM 2- 2 PDIF-BO13MRFO 2- 3 GDAI-BO52MRPO 2- 4 GDAI-B039MRPO 2- 5 GCABUB065MRPO GCABUB066MRPO 2- 5 2- 5 2- 6 2- 7 2- 7 2- 7 2-7-l 2-7-l 2-7-l 2-7-2 2- 8 2- 9 2-10 GCABUB079MRPO TMAPCBO56MRRO FANGKBOO9MRYO FANGKBOIOMRYO FANGKBOllMRYO LANGQB016MRPO LANGQBOZOMRPO LANGQBO27MRPO PGLSPBOO4MREO PCOVPB051MRPO HDECQBOl6MRFO LSTY-BOlOMRPO M M M M M M M M M M - filter AF Hood Base plate Schematic Hood lamp Hood lamp Hood lamp Hood lamp Hood lamp 1 right diagram glass assembly R-1850A glass assembly R-1851A glass assembly R-1852A glass angle R-l850A glass angle R-1851A AV AV AV 1 AL 1 AH Sash left AM AG AG AG AG AY AL Rear AG Hood lamp glass Hood lamp glass Base cover angle stay 6 R-1852A REF NO. PART NO. I§ DESCRIPTION ( CONTROL Q’TY CODE 1 1 1 1 1 BQ AC AC AC AC 1 1 1 1 AD AE AV AB PANEL PARTS 3-l 3-1A 3-1B 3-1c 3-1D DPWBFB061MRUO QCNCMA227DREO QCNCMA23ODREO QCNCMA234DREO QCNCMA267DREO M J J J J Control unit 3-pin connector 4-pin connector 5-pin connector 6-pin connector 3-1E 3-1F 3-1G 3-1H QCNCMA237DREO QCNCWA030DREO RV-KXBOO3MREO PTPEHBOlOMREO J J M M 3-pin connector (CN-F) 12-pin connector (CN-G) Fluorescent display tube Tape 2mm (CN-A) (CN-B) (CN-C) (CN-E) Cl RC-KZAO87DREO J Capacitor 0.1 PF 5OV 1 AB c2 VCEAB31VW108M J Capacitor 1000 PF 35V 1 AF c3 RC-KZA087DREO J Capacitor 0.1 PF 50V 1 AB c4 VCEAB31W106M J Capacitor 10 PF 35V 1 AB c5 RC-KZA087DREO J Capacitor 0.1 PF 50V 1 AB C6 VCEAB31W106M J Capacitor 10 PF 35V 1 AB :7-8 VCKYDllCY103N J Capacitor 0.01 PF 16V 2 AH :9-10 RC-KZA087DREO J Capacitor 0.1 PF 50V 2 AB C20 VCEAB31W106M J Capacitor 10 PF 35V 1 AB "21 VCEAB31HW104M J Capacitor O.lpF 5OV 1 AM 230 VCKYDllCY103N J Capacitor 0.01 FF 16V 1 AH 350 VCKYDllCY103N J Capacitor 0.01 PF 16V 1 AH 160 VCKYDllCY103N J Capacitor 0.01 PF 16V 1 AH "70-74 VCKYDllHB331K J Capacitor 330 OF 50V 5 AA 2100 RC-QZBOl4MREO M Capacitor 7 PF 230V 1 AM :Fl RCRS-AOlODREO J Ceramic 31-4 VHDllESl///-1 J Diode (llES1) 320-32 VHDlSS27OA/-1 J Diode (lSS270A) 13 AA (lSS270A) 7 AA AW resonator (CSTI.OOMGW) 1 AD 4 AB 370-76 VHDlSS27OA/-1 J Diode [Cl RH-IZA719DREO J LSI 1 1c2 RH-IZA495DREO J IC 1 AL AA 21 VS2sB1238//-3 J Transitor (2SB1238) 1 23 VSKRAlOlM//-3 J Transitor (KRAlOlM) 1 AB 14 VSDTAl23ES/-3 J Transistor (DTAl23ES) 1 AA 220-26 VSKRClOlM//-3 J Transistor (KRClOlM) 1 AB 227 VSKRC243M//-3 J Transistor (KRC243M) 1 AB 128-30 VSKRAlOlM//-3 VSKRAlOlM//-3 J Transistor (KRAlOlM) 1 AB 240 J Transistor (KRAlOlM) 1 AB 260 VSKRAlOlM//-3 J Transistor (KRAlOlM) 1 AB 190 VSKRAlOlM//-3 J Transistor (KRAlOlM) 1 AB il VRD-B12HF432J J Resistor 4.3m l/zw 1 AH ?2 VRS-B12EF152J J Resistor 1.5m 1/4w 1 AA 13 VRD-B13AA681J J Resistor 680521.OW 1 AA 51oa l/zw 1 AB 1/4w 2 AA 1/4w 1 AA 1/4w 1 AA <4 VRD-BlZHF511J J Resistor 17-8 VRD-Bl2EF472J J Resistor <30 VRD-B12EF153J J Resistor 131 VRD-B12EF472J J Resistor 4.7m 4.7m 15kR 140 VRD-Bl2EF332J J Resistor 3.3m 1/4w 1 AA 150 VRS-B12EF153J J Resistor 15m 1/4w 1 AA 4.7m 151 VRD-Bl2EF472J J Resistor 1/4w 1 AA 162 VRN-B12EK363F J Resistor 36w2 1/4W 1 AA 163 VRN-B12EK221F J Resistor 22oa 1/4w 1 AB 7 REF NO. PART NO. DESCRIPTION )§I CONTROL R64 VRN-BlZEK362F J R70-74 VRD-B12EF332J R75 VRD-BlZEFlO4J R76-82 Q’TY CODE 1 PANEL PARTS Resistor 3.61dl 1/4W 1 AA J Resistor 3.31d2 1/4w 5 AA J Resistor 1ooldz 1/4w 1 AA VRD-B12EF332J J Resistor 3.3kf2 1/4w 7 AA R90-93 VRD-B12EF104J 1ookR 1/4w 4 AA VRS-B13AA331J J J Resistor RlOO Resistor 1w 1 AA RYl-3 RRLY-A113WREO M Relay 3300 (DU241-lP(M)) 3 AH RY4-9 RRLY-A080DREO J Relay (OJE-SS-124LM) 6 AG RYlO RRLY-112MREO M Relay (VE-24HS5-K) 1 AM SP40 RALM-A014DREO J Buzzer (PKM22EPT) 1 AG I?1 RTRNPB004MREO M Transformer 1 AN VRSl RH-VZA032DREO J Varistor 1 AE ZDl VHEHZ6A3///-1 J Zener diode (HZ6A-3) 1 AC ZD2 VHEHZ161///-1 J Zener diode (HZ16-1) 1 AA ZD3 VHEHZ5CZ///-1 Zener diode (HZ5C-2) 1 AA ZD4 VHEHZ4A2///-1 J J Zener diode (HZ4A-2) 1 AA 3-2 FPNLCB153MRKO M Control panel with key unit R-1850A 1 BB 3-2 FPNLCB154MRKO M Control panel with key unit R-1851A 1 BB 3-2 FPNLCB170MRKO M Control panel with key unit R-1852A 1 BB 3-2-l FUNTKB108MREO Key unit R-1850A 1 AX 3-2-l FUNTKB109MREO M M Key unit R-1851A 1 AX 3-2-l FUNTKBl25MREO M Key unit R-1852A 1 AX 3-2-2 GMADIBO23MRFO M Display 1 AD 3-2-3 MSPRTA050WREO M 3pen button 1 AA 3-2-4 JBTN-B053MRFO M Dpen button R-1850A 1 AD 3-2-4 JBTN-B054MRFO M 3pen button R-1851A 1 AD 3-2-4 JBTN-B066MRFO M 3pen button R-1852A 1 AD 3-2-5 JBTN-B067MRFO M Select buttonR-1850A 1 AC 3-2-5 JBTN-B056MRFO M Select buttonR-1851A 1 AC 3-2-5 JBTN-B055MRFO M Select buttonR-1852A 1 AC 3-2-6 LAIiGQBO36MRPO M Key fixing 1 AA 3-3 XEPSD30PlOXSO M - Screw; 5 AA 1 AM r (104G471K) window spring 3mmxlOmm 1 OVEN PARTS 4- 1 4- 2 FROLPB020MRKO M Turntable support 1 AS 4- 3 NTNT-B006MREO M Turntable tray 1 AZ 4- 4 LANGKBOlOMRPO M Capacitor holder 1 BB 4- 5 FCOVPB002MRYO Stirrer cover 1 AM FFAN-B003MRKO -__--__----_-- M M Stirrer fan assembly 1 M Oven AL -- FFTA-B003MRKO M Exhaust damper assembly assembly 4- 6 4- 7 4- a DHET-BOOlMRKO M Convection 4- 9 NCPL-B007MRFO M Coupling 4-10 NFANMB003MRPO M Convection Motor 4-11 LANGQB031MRPO M Convection Motor cavity 4-12 PPACGB013MREO M Turntable 4-13 LBNDK0054WREO M Heater 4-14 NFANMB004MRPO M Convection 4-15 PHOK-B013MRFO M - Latch assembly (Not a renlaceble motor motor 1 1 BL 1 AE fan 1 AE angle 1 AF heater mounting nart) unit packing 1 AC holder 2 AD fan hook 8 1 AE 1 AG REF NO. PART NO. DESCRIPTION I§1 OVEN - -. 4-16 Q’TY CODE PARTS ~~ 4-17 4-18 FANGTBOO3MRYO PFPF-B002MREO PPIPFB002MREO M M M Unit mounting angle Heat protect L Caller 1 2 1 4-19 4-20 4-21 4-22 PREFHBOO6MRPO PDUC-BO83MRPO NFANPBOO5MREO GBDYRB002MRPO M M M M Heater Cover L Hood intake duct Fan blade Back plate 4-23 4-24 4-25 4-26 4-27 4-28 4-29 FDUC-BO25MRKO LBSHCOO37WREO FDUC-BO22MRKO MLEVPBOl6MRFO PCUSGB03OMRPO MCAMPBOOlMRFO PCUSUBO32MRPO M M M M M M M Fan duct Cord bushing Exhaust duct Open lever cushion Damper cam Damper cushion 4-30 4-31 PFPF-BOOlMREO PFTA-BOO3MRPO M M Heat protect Damper plate 1 1 1 1 1 1 1 1 1 1 1 1 AV AK AD AM AG AD AX AM AB AK AD AC AC AC AD 4-32 4-33 4-34 4-35 PREFHBOO4MRPO LANGQB033MRPO PREFHBOOSMRPO LSTPPBO24MRFO M M M M Thermal cover R Hood lamp angle Thermal cover bottom Door stopper 1 1 1 1 1 AD AK AM AK AD 4-36 4-37 4-38 PCOVPB047MRPO PCOVPBOSOMRPO PCUSGB027MRPO M M M Oven lamp cover Heat protect top sheat cushion 4-39 4-40 M M Hood exhaust Top duct 4-41 PDUC-B056MRFO PDUC-BO57MRFO PDUC-B058MRFO M Magnetron 4-42 4-43 4-44 4-45 PDUC-B060MRPO PFILWA035WREO PFPF-B003MREO PCUSUB018MRPO M M M M Hood intake duct R Oven light screen Heat protect top Exhaust cushion A 4-46 4-47 4-48 4-49 4-50 PCUSUB019MRPO PCUSUB02OMRPO PCUSUB024MRPO PCUSUB033MRPO PCUSGBO35MRPO M M M M M Exhaust cushion cushion cushion cushion 4-51 4-52 PCUSUBO47MRPO PCUSUB046MRPO M M 5- 0 5- 0 CDORFB166MRKO M CDORFB167MRKO M L R 1 AD 1 1 1 1 AK AA AY AN 1 1 1 1 1 AD AH AF AE AA 1 1 1 1 2 AA AA AA AA AA cushion cushion 1 2 AA AA DOOR PARTS Door assemblyR-1850A Door assemblyR-185lA 1 BL 1 BN 1 BN duct duct cushion B 5- 0 CDORFB19OMRKO M Door 5- 1 FDORFBO53MRTO M Door panel 5- 2 GWAKPBO58MRFO M Door frame R-1850A frame R-1851A assemblyR-1852A 1 BB 1 AX 5- 2 GWAKPBO76MRFO M Door 5- 2 5- 3 GWAKPBO58MRFO PGLSPB008MRRO M M Door frame Door glass R-1852A front R-1850A 5- 3 1 PGLSPBOlOMRRO BD M Door glass front R-1851A 1 BD front R-1852A 5- 3 PGLSPBOllMRRO M Door 5- 4 GCOVHB031MRFO M Choke cover LSTPPB025MRFO LSTPPB028MRFO M Latch 5- 6 M Glass 5- 7 MSPRTA046WREO M Latch XCTSD40P08000 M Screw 5- 5 5- 8 glass 1 AX 1 AX 1 BD 1 AM head 1 AE stopper 1 AD spring 1 AB 6 AA 9 REF NO. PART NO. DESCRIPTION 101 Q’TY CODE 1 1 4 1 2 AM AC AC AC AC 1 CFZK-B131MRKO LBSHCOO4OMREO LX-BZ0195WREO LX-MZBOOlMREO XBRSD50P60000 Installation material Gromment Toggle screw Cord holder Screw; 5mm x 6Omm 6-l-5 XOTSD40P12000 M Screw; 4mm x 12mm 1 AA 6-l-6 6-l-7 6- 2 XTSSD50P35000 XWHSDSO-16300 TINSEB141MRRO TINSEB199MRRO M M M M Screw; 5mmx 35mnl Washer Installation instructions Operation manual 6 2 1 1 AA AA AD AE TINSKB018MRRO TINSKB019MRRO QW-QZBOllMREO TCADCB012MRRO FW-VZB166MREO M M M M M Top Wall High Cook Main 1 1 1 1 1 AD AD AD AP AY High rack Low rack Main harness C Caution label DHHS caution label 1 1 1 1 1 AQ AP AH AA AB Monitor 1 AA UAMI-B007MRMO UAMI-B008MRMO FW-VZB077MREO TCAUAAO25WRRO TCAUAB005MRRO ( assembly 6-14 TCAUABO15MRRO 777777- 1 2 2 3 4 5 xCPSD40P08000 XOTSF40PlOOOO XOTSE40PlOOOO XCBSD30P08000 XBTSD40P08RVO XCBSD30P08000 7- 6 7- 7 7- 8 7- 8 7- 9 7-10 XBTWW40P06000 XOTSD40P12000 XOTSF40P12000 XOTSE40P12000 LX-BZO208WREO LX-BZBOllMREO 7-11 7-12 7-13 7-14 7-15 1M w template template voltage wire A book wire harness A caution label FASTENERS x x x x x x 8mm 1Omm R-1850A 1Omm R-1851A, R-1852A 8mm 6mm 8mm 2 3 3 2 2 2 AC AC AA AA AA M M M M M M Screw; 4mm x Screw; 4mm x Screw; 4mm x Screw; 4mm x Screw; 4mm x Unit mounting 8mm 12mm 1Omm R-1850A 1Omm R-1851A, R-1852A 8mm screw 2 26 3 3 2 2 AA AA AA AA AA AH LX-CZA038WREO xcBWW30P08000 LX-CZOO52WREO XCTWW4OPO8RVO XRESD40-06000 M M M M M Special screw Screw; 3mm x 6mm Special screw Screw; 41~n x 8mm E-ring 4 8 2 2 1 AA AA AA AC AA 7-16 7-17 7-18 7-19 7-20 XOTSD40P12000 XCTWW40P08000 XOTWW4OP10000 xwsUW40-10000 LX-BZ0081YBEO M M M M M Screw; Screw; Screw; Spring Screw; 2 3 8 1 9 AC AA AA AA AA 7-21 7-22 7-23 7-24 XWHSD50-20120 XWHUWIO-08100 XWHUWIO-08120 XOTSD40P08000 M M M -M Washer; 5mmx 2INn Washer; 4mm x 0.8mn Washer; 511m x 0.8mm Screw; 4mm x 8mm 1 2 1 8 AA AA AA AA M M M M M Screw; Screw; Screw; Screw; Screw; Screw; 4mm 4mm 4mm 3mm 3mm 3mm 4mm x 4mm x 4m-1 x Washer 4mm x 12mm 8mm 8mm 8mm 10 AA A IA B IC C t ID D c E E F IF 3 L 1 E G It Ii I 1 2 4 3 11 5 6 R-l 850A Fb1851A R-l 852A 1 I 3 I 3 4 5 6 Control Panel Assembly B C L , IE ‘1 / I I I I I I I I I I I \ I I I I I I I I I I F L / / / / / lc t 1 2 __-l 3 4 12 5 6 r 1 I I 2 3 I 4 5 6 Miscellaneous A I’ I I I _I I I I I B l I I l I ---------_________ --I C -1 Packing and Accessories D OPERATION MANUAL E F \. PACKING CASE _ G 0 Non-replaceable items SHARF? ‘980 SHARP CORP. (9M2.70E) Printed in U.S.A.