Download Manual BOSS Kit Pro Farina

Transcript

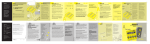

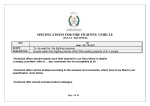

Manual BOSS Kit Pro Farina 380100 • 05/2014 INDEX: 1. Introduction�������������������������������������������������������������������������������� 1 2. Contents������������������������������������������������������������������������������������� 2 3. Important Notice������������������������������������������������������������������������ 3 4. Structure assembly ����������������������������������������������������������������������4 4.1. Elements �����������������������������������������������������������������������������������4 4.2. Assembly����������������������������������������������������������������������������������5 5. Solar panels placement����������������������������������������������������������������9 6. Photovoltaic array wiring sketch������������������������������������������������ 10 7. General wiring sketch����������������������������������������������������������������� 11 8. Stone Mill start operation����������������������������������������������������������� 12 8.1. Placement�������������������������������������������������������������������������������� 12 8.2. Parts��������������������������������������������������������������������������������������� 12 8.3. Mill operation������������������������������������������������������������������������� 13 8.4. Alternative energy source operation���������������������������������������� 15 9. General Maintenance����������������������������������������������������������������� 16 10. FAQ����������������������������������������������������������������������������������������� 16 11. Milling operation trouble chart�������������������������������������������������� 17 1. INTRODUCTION This solar milling system is a complete equipment. It offers an affordable system based on solar energy to facilitate an appropriate cereal/food processing technology for the benefit of smallholder farms, rural communities, cooperatives or projects in places where there is not electrical grid. The solar mill guarantees the possibility to obtain flour from different kinds of most common cereals (maize, wheat, barley, teff, millet, rice…) directly from the sun energy, so not electric or fuel bills are involved anymore. The equipment as a whole can be described as follows: 1. the stone mill; 2. photovoltaic array; and, 3. control panel. With our electrical stone mill, flour can be easily obtained from raw cereals. The stone mill is based on pure granite 500 mm stones and equipped with standard triphase asyn- chronous motor 230/400 V 50 Hz. This machine, made in the EU, is CE certified. The photovoltaic array supplies the necessary energy to run the stone mill. It consists of 7 solar panels (128 W each) with a total power of 896 W. A hot dip galvanized structure holds the solar panels. The control panel links the photovoltaic array to the stone mill. The equipment works without batteries. However during sunless hours the equipment is capable to work directly through single phase 230 V source, i.e. a generator (2 KVA minimum, not included). You will need little time to set up all the elements to start milling. Please follow step by step this user’s manual. Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 2 2. Items Supplied / Packing List 2. Items Supplied/Packing List 3 BOX 2 // Measures: 960x 780 x 780 x 1365mm / Volume: / Weight: 223kgs BOX 11 of of 2 Measures: 960 x 1365 mm / Volume: 1 m1m3 / Weight: 223 kgs Qty Description 1 Horizontal stone Mill, 1HP 3 x 230/400 VAC, 50 Hz. 50 mm stone diameter 1 Control panel, solar/generator/mains input, Ref. SMCP11 1 User manual 1 Wooden box, measures 960 x 780 x 1365 mm BOX 2 of 2 / Measures: 1635 x 1072 x 665 mm / Volume: 1,16 m3 / Weight: 252 kgs Qty Description 7 Solar panel, Thin-film technology, 128 Wp first quality brand 10 Horizontal rail 41/41 x 1500 mm, for structure 3 Vertical triangle rail, pre-mounted 20º, for structure 1 Vertical triangle rail, pre-mounted 20º, with electrical box fixed, for structure 8 Rail unions, for structure 12 Panel clamps, for structure 4 End panel clamps, for structure 8 Allen screw with nut rail, for structure 1 Electrical cable to Control Panel to photovoltaic array, 25 m, blue plugs 1 Electrical cable to Control Panel to Stone mill, 5 m, red plugs 1 Earth bar with earth cable 1 Pack of fuses 10amps, spare part 2 Wrench key nº17-13 mm 1 Allen key nº8 1 Allen key nº6 1 Metric tape, 5 m 1 Masonry hammer to maintain the granite stones 1 Pack of nylon cable tie, 100 units 1 Wooden box, measures 3 TOTAL WEIGHT: 475 Kgs TOTAL WEIGHT: 475 Kgs TOTAL VOLUME: 2,16 m3 TOTAL VOLUME: 2,16 m3 Total kits kits per 1010 units Total per dry dry20” 20”container: container: units Total kits kits per 2020 units Total per dry dry40” 40”container: container: units Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com Serial Number: each mill has the serial number noted above the motor. Structure Holder: Manufacturer: Solar Milling SL (Spain) 380100 • p. 3 Product description: Hot dip iron structure for 7 solar panels ref. NA-F128GK, Sharp, 20º tilt. Test Directives by Applus+: Wind resistance: up to 147 km/h. 3. Important Notice: 4. Important Notice: 1. Heavy equipment. The stone mill is heavy. Take the considerations to its placement. 2. Solar panels are sensible, handle with care. 3. Note that solar panels produces electrical energy. For your safety: All the equipment is protected against the following situations: Short-circuits. Lightings. Over/under current. Over/under voltage. Empty running mill stone. It has emergency STOP in the mill. All the equipment is connected to earth. Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 4 4. Structure assembly 5. Structure assembly 4.15.1. Elements Elements Horizontal rail 41/41x1.500mm Ref. 444242 Vertical rail, triangle Pre-mounted, 20º tilt Ref. 446451 10 units 2 units Vertical rail, triangle with electrical box Ref. 446452 Rail unions Ref. 444139 5 1 unit 8 units End Clamps Ref. 756004 Allen screw With nut rail Ref. 756005 Panel Clamps Ref. 756001 12 units 4 units 8 units Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 5 5.2. Assembly 4.2 Assembly General View Tools required: Metric tape Allen key, nº6 and nº8 Wrench key, nº13 and nº17 Compass STEP 1 Determine the orientation of the structure (north or south) Use compass 6 North hemisphere: If you are here, face the structure towards SOUTH South hemisphere: If you are here, face the structure towards NORTH Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 6 STEP 2 Place the triangles according to the sketch here below NOTE: Choose a flat and levelled place to install the structure. 2,20 m NOTE: Place the triangle with the electrical box in the right side. 2,20 m 2,20 m Use metric tape 2,20 m STEP 3 Tight the screws of the 8 jointed adjustable supports. 2,20 m 2,20 m 7 NOTE: The rear supports must be in vertical position, 90 degrees. 90º Side view Use wrench key nº 17 Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 7 STEP 4 x8 Join 2 sets of 5 horizontal rails by unions (4 unions per set) Use wrench key nº13 x5 rail 1,5 m x5 rail 1,5 m 7,5 m total length STEP 5 Place 2 horizontal rails on the vertical triangle rails NOTE: Before to go in, pay attention to this sketch with measures and… 0,45m 0,45m 90º 0,9m 90º Use metric tape Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 8 … go ahead! Upper horizontal rail 9 Use allen key nº8 Bottom horizontal rail x8 Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 9 5. Solar Panels placement 6. Solar Panels placement Place the solar panels using the clamps. NOTE: Start the operation placing the first solar panel in one of the sides (vertical position). Before placing the solar panels be aware to insert the solar panel with the label upside. 1 4 3 2 …… 7 Intermediate panel clamps End panel clamps Use allen key nº6 Upper Side Sharp NA-F128GK Maximum Power: 128Wp Open-circuit voltage: 59,8V Short-circuit current: 3,45A Voltage at point of maximum power: 45,4V Current at point of maximum power: 2,82A Made In Germany CE _ + Bottom Side Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 10 7. Photovoltaic Array wiring sketch 6. Photovoltaic Array wiring sketch 11 (Use nylon cable ties to fix the cable in the structure) Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 11 7. General Wiring Sketch x5m STONE MILL STONE MILL 8. General Wiring Sketch + PHOTOVOLTAIC ARRAY x25m + PHOTOVOLTAIC ARRAY CONTROL PANEL 12 Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 12 8. Stone Mill start operation ne Mill start 8.1. operation Placement: acement: Place indoors. Level the soil surface. Place indoors. Level the soil surface. arts: 8.2. Parts: Security Switch Electrical Plug Up / Down stone positioner Flour Outlet 13 Auto-stop device (Hopper empty) Grain drop lever Motor AC 230/400VAC (Squirrel cage) Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 13 8.3. Operation 9.3. Milling Milling Operation 1. Lift the stopper device. 2. Fill the hopper with grain. 3. Down the stopper device above the grain. 4. Press the security switch On. 5. Up the stone using the stone positioner. Starting up: 6. Select “Solar” mode in Control Panel switch. 7. When the stone rotate, lower the stone by the stone positioner. 8. Regulate the fineness of the flour desired by the dropping cereal ramp and stone position. 2 14 3 GRAIN Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 14 6 0 1 2 GENSET / MAINS SOLAR OPERATION SELECTION 8 15 The stone full down and slow grain dropping results in fine flour. To get coarser flour, lift the stone or increase the amount of grain entering the milling chamber. When the hopper is almost empty the stopper device will switch off automatically. This is to avoid stones useless friction without grain. IMPORTANT NOTICE TO RE START THE SYSTEM: 1) Switch position to 0 (control panel) 2) Lift the stone 3) Press On (mill) 4) Switch to solar or mains. 5) Operate the mill. Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 15 9.4. Alternative energy source operation 8.4. Alternative energy source operation In some cases you might need to grind after daylight time or very dark clouds can reduce the performance of the system. A single phase 230 VAC/1 KW can be connected to the Control Panel. Electrical Grid: Just plug in 230 VAC and turn the Switch to “MAINS/GENERATOR” mode. The system will start operating. Generator: A generator with 230 VAC outlet (Minimum 2 KVA) can be plugged in the Control Panel. Suggested procedure: Turn the Control Panel Switch to 0 mode. Start the generator and keep running till choke is removed (petrol engines). Then turn the Control Panel Switch to “MAINS/ GENERATOR” mode. The system will start operating. Switch OFF: Always Switch OFF the switch in Control panel, then stop the generator. OPERATION SELECTION SOLAR 0 1 2 16 GENSET or MAINS Control Panel side VIEW MAINS / GENERATOR SINGLE-PHASE 230 VAC INPUT Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 16 9.10.General Maintenance General Maintenance The installation requires no maintenance except regular array cleaning. Photovoltaic Array: 10. General Maintenance Cleaning the surface of solar panels and visual inspection. The installation requires no maintenance except regular array cleaning. Try to locate the Photovoltaic Array in a place where shadows have the lowest possible. Photovoltaic Array: Recommended fence the Photovoltaic Array for more security. Cleaning the surface of solar panels and visual inspection. Stone Mill: Try to locate the Photovoltaic Array in a place where shadows have the lowest possible. Locate the Control Panel indoors. Recommended fence the Photovoltaic Array for more security. Check the stone inside the mill if you detected low flour fineness. Stone Mill: Check the belt below the motor. If it is loose, turn the handle up to tension it. Locate the Control Panel indoors. 11. FAQ (Frequently Asked Questions) Check the stone inside the mill if you detected low flour fineness. Q: Can the buyer install himself the system? Check the belt below the motor. If it is loose, turn the handle up to tension it. A: Yes, the equipment is supplied 10. FAQ (Frequently Asked pre-mounted Questions)and can be set up easily within 1H 30m just following 11. FAQ (Frequently Asked Questions) this user manual provided. Q: Can the buyer install himself the system? Q: What is the lifespan of the solar modules? A: Yes, the equipment is supplied pre-mounted and can be set up easily within 1H 30m just following A: The solar modules are high quality brand and as per manufacturer specifications, 90% of power this user manual provided. peak performance are guaranteed at 25 years. Q: What is the lifespan of the solar modules? Q: What is the lifespan of the mill machine? A: The solar modules are high quality brand and as per manufacturer specifications, 90% of power A: Due its free maintenance the mill is a very long lasting machine. The mill itself is a very basic mapeak performance are guaranteed at 25 years. chine equipped with standard tripahse motor can be adapted and found in any market. Q: What is the lifespan of the mill machine? Q: What about the stones? A: Due its free maintenance the mill is a very long lasting machine. The mill itself is a very basic maA: The stones are made from pure granite and most probably you’ll never have to replace it. The machine equipped with standard tripahse motor can be adapted and found in any market. chine has a stopper device to avoid useless stones friction without grain. Its recommended to Q: What about the stones? work with the stopper device operating. In case of need to rough the stone faces, special masonry A: The stones are made from pure granite and most probably you’ll never have to replace it. The mahammer is provided. chine has a stopper device to avoid useless stones friction without grain. Its recommended to Q: Are the spare parts available? work with the stopper device operating. In case of need to rough the stone faces, special masonry A: Yes, all spare parts are available from the solar milling company, although some can be locally in hammer is provided. any country. Q: Are the spare parts available? Q: At night time which kind of electrical source can be used? A: Yes, all spare parts are available from the solar milling company, although some can be locally in A: Single phase 230 V - 50 Hz, capable to supply 750 W. any country. Q: is there any risk of electrical shock? Q: At night time which kind of electrical source can be used? A: No, all the connectors are isolated. You’ll never be in touch with live electrical parts. The earth rod A: Single phase 230 V - 50 Hz, capable to supply 750 W. provided is highly recommended to be installed before the operation, to keep the entire equipment Q: is there any risk of electrical shock? safe. A: No, all the connectors are isolated. You’ll never be in touch with live electrical parts. The earth rod Q: Which kind of cereals can be grinded? provided is highly recommended to be installed before the operation, to keep the entire equipment A: All dry cereals can be grinded in this mill. Wet grains can clog the stones and be not effective. safe. Q: What happens when there is not enough solar radiation? Q: Which kind of cereals can be grinded? A: The machine could not work at full performance or even stop due lack of enough power from the A: All dry cereals can be grinded in this mill. Wet grains can clog the stones and be not effective. solar modules. In this case it would be better to wait for better radiation conditions o choose electrical Q: What happens when there is not enough solar radiation? Mains. A: The machine could not work at full performance or even stop due lack of enough power from the 17 17 solar modules. In this case it would be better to wait for better radiation conditions o choose electrical Mains. Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com 380100 • p. 17 11. Milling operation trouble chart 12. Milling operation trouble chart DEFECT Will not turn MAY BE CAUSED BY REMEDY No power supply Check supply, ensure source of power is working correctly Too much fixed load Disconnect power, check to see if overfeeding has caused a jam Not enough power Check if power source is working correctly Over-feeding Reduce grain feed rate Noisy operation Worn bearing Check bearing and replace or lubricate as required Low output Caking/blockageing in the mill Dry grain it too wet Stones polished Remove for resurfacing Stones polished Remove for resurfacing Inappropriate feeding Adjust feeding device (smaller quantity) Mill will not turn fast enough Coarse grinding 18 Phaesun GmbH · Brühlweg 9 · 87700 Memmingen · Germany | Telefon +49 (8331) 990 42 0 · Telefax +49 (8331) 990 42 12 | [email protected] · www.phaesun.com