Download user manual - Agromehanika

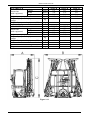

Transcript