Download User`s Manual

Transcript

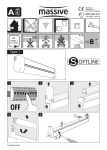

R PowderMidcap™ 811 - 821 Powdercap™ 811 - 821 02/2004 User’s Manual 1 R So m m a r y 1 Introduction page 5 2 Front control panel description page 7 3 C alibration of the “F a n F a il u r e ” indicator page 10 4 Replacement of the filter page 12 5 Replacement of the prefilter page 13 6 Exploded views of the Powdercap™ et powdermidcap™ page 14 7 The technical cases page 17 8 Electrical diagrams page 19 9 Spécifications of the Powdercap™ et powdermidcap™ page 21 3 I n tr o d ucti o n 1 W h a t m ust b e a b so l u t e ly k n o w n b e fo r e usi n g y o u r P o w d e rc a p™ ? O r h o w to m a n i p u l a t e i n tot a l s a f e ty? C ongratulations for your excellent choice, your new equipment is manufactured according to a very high standard of quality which will guarantee its safe use over the years to come. The Powdercap™ combines operator protection and protection of the environment by using a unique air recirculation system directly into the laboratory.This is being made possible by the use of highly specialized filters which trap toxic molecules. This process named chemical adsorption allows to obtain purified air at the filter exhaust that is free from chemical pollutants. The efficiency and filter lifetime directly depend on the nature of the manipulation that will be carried out in the enclosure. I m p o rt a n t n otic e fo r y o u r s a f e ty The Powdercap™ is designed to protect the user while weighing powders or powders diluted into water. In any case, the Powdercap™cannot be used for weighing powders in a boiling liquid or heated in the enclosure. The filtration system can be seriously damaged if used in inappropriate conditions and may not provide full protection to the user. A careful reading of this user's manual will insure you a worry free experience while working in total safety. 5 R 2 F r o n t co n tr o l p a n e l d e scr i p ti o n P o w d e r m i d c a p™ 8 1 1 - 8 2 1 SE 1 0 l f R P o w d e r m i d c a p™ 8 2 1 M a d e i n F r a nc e N U M BER N U M ER O N U M M ER AC 230 V 132 2003 50 Hz 47 W R PARC D’AFFAIRES DES P O RTES BP 403 - 27104 VAL DE REUIL C edex (FRAN CE) TÉL : 02 32 09 55 80 - FAX : 02 32 09 55 90 m Ri g h t h a n d si d e of t h e fr o n t p a n e l co n tr o l . f l m - Ventilator/fan on-off switch - Type label. - N ame of the manufacturer or its distributor k M i d d l e p a rt of t h e fr o n t co n tr o l p a n e l . R Le ft si d e of t h e fr o n t co n tr o l p a n e l I . 7 R 2 F r o n t co n tr o l p a n e l d e scr i p ti o n P o w d e rc a p™ 8 1 1 - 8 2 1 l f R P o w d e rc a p™8 1 1 M a d e i n F r a nc e N U M BER N U M ER O N U M M ER AC 230 V 150 2003 50 Hz 47 SE 1 0 g W R PARC D ’AFFAIRES DES P O RTES BP 4 0 3 - 2 7 1 0 4 VAL DE REUIL C edex (FRA N CE) TÉL : 0 2 3 2 0 9 5 5 8 0 - FAX : 0 2 3 2 0 9 5 5 9 0 m j Ri g h t h a n d si d e of t h e fr o n t p a n e l co n tr o l . f l m - Ventilator/fan on-off switch - Type label. - N ame of the manufacturer O r its distributor g - (Red) warning light “F a n F a il u r e ” J . - External potentiometer for the “F a n F a il u r e ” setting k M i d d l e p a rt of t h e fr o n t co n tr o l p a n e l. R Le ft si d e of t h e fr o n t co n tr o l p a n e l I . 8 R 2 1 - I d e n tific a ti o n t a g (right side of the front panel) R P o w d e rc a p™8 1 1 M a d e i n F r a nc e N U M BER N U M ER O N U M M ER 150 AC 230 V c a) b) c) d) e) 50 SE 1 0 10/2000 Make sure that your power supply complies with the actual supply voltage a of your Powdercap™. b 2003 Hz 47 d W e Powdercap™ model Serial number Actual supply voltage H e rt z frequency Total power in W a tt 2 - N a m e of t h e m a n u f a ct u r e r o r its d istr i b u to r (right side of the front panel) Label with the manufacturer or distributor contact detail label. O NE ELM S Q UARE 1980 TURNPIKE STREET N O RTH AN D O VER - MA 01845P PH O NE (978) 975-336 FAX ((978) 975-2730 3 - Sw itc h i n g o n t h e e q u i p m e n t Your Powdercap™ is equipped with 1 on-off switche - An on-off switch with a green light for the control of the fan. Before using your Powdercap™, the fan switch must be turned on “ I “Fan Failure” light will illuminate but should go out after a few seconds. “. The red If the light and the warning alarm do not stop, go to section 3. 9 R 3 C a li b r a ti o n of t h e “ F A N F A IL URE ” i n d ic a to r P o w d e rc a p™ 8 1 1 - 8 2 1 The “F a n F a il u r e ” alarm warns the user of any fan malfunction. Prior to use, it is necessary to calibrate this alarm according to the following procedure: Ext e r n a l c a li b r a ti o n p r oc e d u r e To be done when using your Powdercap™ for the first time This calibration has to be done when the fans are running, with the filters installed and only if the “fan failure” red warning light g (located on the right side of front control panel I) and alarm are active. * G ently turn with a screwdriver the potentiometer screw J located under the red warning light g towards the left or the right until the visual and audible alarm stops. If you cannot calibrate the visual and audible alarm with the potentiometer J, then follow the instructions hereunder. I n t e r n a l c a li b r a ti o n p r oc e d u r e (To be done by qualified maintenance technicians) 1 Remove the entire acrylic front panel V F (Lower door + Visor). Unlock the fasteners W which maintain the panel I. Lower the panel I. 2 With the screwdriver (provided with the unit in the technical casing), gently turn the grey potentiometer S clockwise or counter clockwise until neither of the yellow light T1or yellow light T2 remain on. Within this range, the audible alarm stops. 3 Fan failure detection: Put on a thick glove and decrease the fan rotor rotation speed by pushing on it with the palm of your hand. O ne of the 2 warning lights T1 or T2 should go on. Remove your hand. O nce the fan rotor is back to normal speed, the visual and audible alarm will stop. 4 Raise the panel I and lock the fasterns W. Replace the acrylic front panel V F. 10 R 3 P o w d e rc a p™ 8 1 1 - 8 2 1 H H VF M1 I I W W X U M1 g I T1 0 WSE 117 07/2002 j M1 : Circuit board installed in filter housing H . S : G rey multi turn potentiometer for the calibration of the “Fan Failure” indicator. S T2 T1 -T2 : Yellow warning lights located on electronic board M 1 , determines the external calibration area. U : Circuit board M 1 protection fuse 11 R 4 Re m p l a c e m e n t d u filtr e M K L H To r e p l a c e a filt e r, y o u m a y sto p y o u r P o w d e rc a p™,P o w d e r m i d c a p™. 1 Remove all 16 white plastic caps M covers located on top the filter housing H . 2 Unscrew all screws with the box spanner provided with your Powdercap™ and remove the top panel K . 3 With the help of two metal “L” shaped bars provided and remove the particulate filter L. 4 Take the new filter and place it in the filter housing H but make sure to position in the direction of the filtration flow (see directions on the information sticker found on the filter shell). 5 Place the top panel back K to its original position on the Powdercap™ filter housing H and tighten it in place with the 16 screws which were previously removed. 6 You can cover all screws with the white plastics caps M . Your Powdercap™ is now ready for use. 12 R 5 Re m p l a c e r l e p r é filtr e H VF H J M1 I I W W X U To r e p l a c e t h e p r e filt e r 1 Turn off your product. 2 Use gloves to protect your hands. 3 Remove the entire acrylic front panel V F (Lower door + Visor). 4 Unlock the fasteners W which maintain the panel I. Lower the panel I. 5 Remove the saturated prefilter J and replace it with an new prefilter. O ne your prefilter is properky in place, raise the panel I and lock the fasterns W. 6 Replace the acrylic front panel. Your Powdercap™ or Powdermidcap™ is ready. 13 Ex p l o d e d v i e w 6 P o w d e r m i d c a p™ 8 1 1 - 8 2 1 + , 3 ( * ) # " & 1 # 6 5 ' ! R 14 Ex p l o d e d v i e w 6 P o w d e rc a p™ 8 1 1 - 8 2 1 + , 3 ( * ) #1 " & 1 #2 6 5 ' ! R : 15 6 SP ARE PARTS REFEREN CE DESI G NATI O N Z Air velocity meter A: Spill tray B Back panel C 1: Side panel B C 2: Side panel P F: Visor V: Lower door for Powdercap™ or Powdermidcap™ Q : G : Two plastic hingers Side clamp b : O PTN 5SF O PTN 5S G B O PTN 5SUS Lighting option Europe 230V Lighting option UK 230V Lighting option USA 127V R Electrical Electrical Electrical Electrical S : PIDB O 086 U : PIDMSU824 PIDMS032 Six vis nylon screwsM8x25 Two screws PP M6x16 Six nuts PP black M6 L: Filter HEPA H14 753 X 403 X 62 mm H K J I Filter housing Top panel cordset cordset cordset cordset (Europe) (USA - Ja pon) (UK) (Suisse) Prefilter for Powdercap™ ou Powdermidcap™ Panel 16 El e ctr ic a l (Te c h n ic a l) p a rts 7 P o w d e r m i d c a p™ 8 1 1 - 8 2 1 < = > ? @ d < 1 2 3 4 5 A Electrical socket Fuses 5 X 20 4A Fuse holder Electrical plug Ventilator G eneral switch R 17 El e ctr ic a l (Te c h n ic a l) p a rts 7 P o w d e rc a p™ 8 1 1 - 8 2 1 < = > ? " # @ A < 1 2 3 4 5 Electrical socket Fuses 5 X 20 4A Fuse holder Electrical plug Ventilator 6 A “F a n F a il u r e ” circuit board G eneral switch B C “F a n F a il u r e ”warning light “F a n F a il u r e ” potentiometer R 18 8 El e ctr ic a l w i r i n g d i a g r a m P o w d e r m i d c a p™ 8 1 1 - 8 2 1 C ELECTRIC AL C O N N EXI O N V e n til a to r D F A N SW ITC H W IT H W AR N I N G LI G H T R 19 8 El e ctr ic a l w i r i n g d i a g r a m P o w d e rc a p™ 8 1 1 - 8 2 1 C ELECTRIC AL C O N N EXI O N L E N 4A V e n til a to r D J1 Fuse 50 m A 1 1 2 2 FA N F A IL URE CIRC U IT B O ARD 3 4 1 1 2 2 B A J2 3 1 2 J3 3 1 2 3 J4 1 2 3 4 6 5 6 J5 5 1 2 3 h i efg E ON 2 1 2a 1a OFF “ F A N F A IL URE ” F A N SW ITC H P O TE N TI O M ETER FOR & W AR N I N G LI G H T W EI G H TI N G F A N SW ITC H W IT H W AR N I N G LI G H T R 20 9 S p e c ifi c a tio n s Model P o w d e r m i d c a p™ P o w d e r m i d c a p™ 811 821 P o w d e rc a p™ P o w d e rc a p™ 811 811 799 721 555 742 496 480 799 969 622 742 749 580 799 721 555 742 496 480 799 969 622 742 749 580 1 1 1 1 1 1 1 1 “ F a n f a il u r e ” alarm - - Serial Serial Switch for weighting - - Serial Serial O ption 5S O ption 5S O ption 5S O ption 5S External dimensions m m Length Height Depth Length Internal dimensions m m Height Depth Q uantity of fans Q uantity of HEPA filters (H 1 4) 753X403X62 mm Lighting 1x11W Volume of air treated m3/ h 170 170 170 170 F a c e velo city m /s 0,55 0,55 0,55 0,55 Internal volume of enclosure m3 0,15 0,32 0,32 0,32 Ti m e / h o u r 18,9 9,9 18,9 9,9 Air exchange per hour Sound level dBA 54 54 54 54 Power consumption W a tt 47 47 47 47 Ele ctric a l volt a g e V o lt 230 230 230 230 Hz 50 50 50 50 A 0,31 0,31 0,31 0,31 Frequency Amperage absorbed R 21 9 S p e c ifi c a tio n s Model External dimensions i nc h e s Length Height Depth Length Internal dimensions i nc h e s Height Depth Q uantity of fans P o w d e r m i d c a p™ P o w d e r m i d c a p™ 811 821 31 1/2 28 1/3 21 6/7 29 19 18 7/8 31 38 1/5 24 1/2 29 29 1/2 22 4/5 P o w d e rc a p™ P o w d e rc a p™ 811 31 1/2 28 1/3 21 6/7 29 19 18 7/8 811 31 38 1/5 24 29 29 1/2 22 4/5 1 1 1 1 1 1 1 1 “ F a n f a il u r e ” alarm - - Serial Serial Switch for weighting - - Serial Serial O ption 5S O ption 5S O ption 5S O ption 5S Q uantity of HEPA filters (H 1 4) 753X403X62 mm Lighting 1x13W Volume of air treated cf m 105 105 105 105 F a c e velo city fp m 118 118 118 118 Internal volume of enclosure cf 5,3 11,3 5,3 11,3 20 10,4 20 10,4 Air exchange per minute Ti m e / m n Sound level dBA 56 56 56 56 Power consumption W a tt 50 50 50 50 Ele ctric a l volt a g e V o lt 115 115 115 115 Hz 60 60 60 60 A 0,62 0,62 0,62 0,62 Frequency Amperage absorbed R 22 P o w d e r M i d c a p™ 8 1 1 & P o w d e rc a p™ 8 1 1 799 m m 31 1/2” 9 490 m m I R 350 m m 9 5/7” 13 3/4” 721 m m 28 1/3” 246 m m O 742 m m 785 m m 29 1/4” 31” 555 m m 21 6/7” R 23 P o w d e r M i d c a p™ 8 2 1 & P o w d e rc a p™ 8 2 1 799 m m 31 1/2” 9 490 m m I R 350 m m 9 5/7” 13 3/4” 969 m m 38 1/5” O 785 m m 29 1/4” 31” 246 m m 742 m m 622 m m 24 1/2” R 24 w w w. e r l a b - d fs.c o m W o r l d Le a d e r i n m o l e cu l a r filtr a ti o n t e c h n o l o g y si nc e 1 9 6 8 E UR O PE FRA N CE : G ERM A N Y : SP A I N : IT ALY : UK : e r l a b D. F. S. S.A.S. Parc d’affaires des Portes BP 403 27104 Val de Reuil C edex Tél : Fax : + 33 (0)2 32 09 55 80 + 33 (0)2 32 09 55 90 e r l a b D. F. S. S.A.S. erla b Vertretungsbüro Deutschland G ustav-Heinemann-Ufer 54 50 968 K Ö LN Tel : Fax : e r l a b S.L.. O ficina C omercial en España Ruiz Alarcón, 7 - 1° 28014 Madrid Tel : Fax : e r l a b D. F. S. S.A.S. Ufficio di rappresentanza in Italia Via Cusani, 5 20121 Milano Tel : Fax : e r l a b D. F. S. S.A.S. UK and IRELAN D representationoffice St Thomas’s House / St Thomas’s square Salisbury - SPI IBA Wiltshire P h o n e : 01722 341 940 Fax : 01722 341 950 E- M a il : Ventes @ erlab.net 0211 / 39 50 41 0211 / 39 8 22 15 E- M a il : Verkauf @ erlab.net 91 701 02 53 91 701 02 77 E- M a il : Ventas @ erlab.net 02 89 00 771 02 72 097 812 E- M a il : Vendite @ erlab.net E- M a il : SalesUK @ erlab.net N O RT H A M ERIC A USA : ASI A M ALA YSI A : CHIN A : e r l a b ® i nc. O ne Elm Square 1980 Turnpike Street North Andover, MA 01845 e r l a b ® Asia Sdn Bhd 25 jalan Firma 2 / 1Kawasan Perindustrian - Terbrau 81 100 Johor Bahru State Malaysia ® e r l a b D. F. S. Ltd 139, Chang Jiang Rd. ( C ) Kunshan development Zone Kunshan, Jinagsu Province P.R. China 215300 P h o n e : (800) 964 - 4434 Fax : 1 (978) 975 - 2730 E- M a il : C aptairSales @ erlab.com Tél : Fax : + 60 (0) 7 3 555 724 + 60 (0) 7 3 552 810 E- M a il : erlab @ tm.net.my Tél : Fax : 86 512 573 13 701 86 512 573 13 702 E- M a il : sales.china @ erlab.net