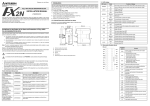

Download FX2N-10PG USER`S MANUAL

Transcript