Download Installation

Transcript

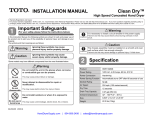

INSTALLATION MANUAL Important Safeguards It is recommended to install a circuit-breaker in the power supply Important In this Instruction Manual, the following symbols are shown for safe and proper use of your automatic faucet and in order to alert you to the possibility of personal injury and damage to your property. The symbols and their meanings are as follows. Warning Caution Ignoring these symbols may cause severe injury and/or property damage. Important Do not disassemble Failure to do this may cause damage or personal injury if it falls down. Do not! Do not place anything beneath the unit; leave a clearance of 3-15/16” (100mm). Do not install on uneven wall surface. If air flow is not good, the product may not perform well . Specification Product HDR100#GY Power Rating 120V AC, 4.25 Amps, 60 Hz, 510 W Power Connection Hardwiring Never attempt to disassemble for repair or modification. Power Saving Function Automatically turns OFF after 60 seconds of use Decibel Rating 62 dB This may cause electric shock, fire, injury or failure Air Speed 224 mph (100 meters/second) Dry Time 12 seconds Drain Tray Capacity 0.20 gal (700 ml) This may cause product failure or damage. Do not install outdoors or where it is exposed to water. Do not use in This may cause current leakage, electric shock, fire, or failure. humid area 0GU3040 2008.04 The chassis assembly must be installed on a smooth and even wall surface which has enough strength. Notice Warning Do not Failure to do this may cause electric shock during overload or short circuit. Caution *Some models may have different components from the ones illustrated below. Do not install the unit in the places where corrosive or combustible gas can be present. High Speed Hand Dryer Warning (For your safety, please follow the instructions below.) Ignoring these symbols may cause personal injury and/or property damage. Clean Dry™ Ambient temperature 32°-104°F (0°-40°C) Size 9-5/8" x 18-1/2" x 6-5/16" Weight 10 lbs (4.5kg) Set-up Drawing Before Installing Some models may have different components as illustrated below. DIA. MOUNTING HOLES (4) 5/32” (4mm) Meets the American Disabilities Act Guidelines, ANSI A117.1 and CSA B651 requirements when mounted in a recessed wall where the front surface is not more than 4” (102mm) from finished wall and max. height of air blower outlet from finished floor is 47-1/4” (1200mm). TOP COVER ASSY UNIT* 5/8” (16mm) POWER CABEL (HARDWIRING) Ø4.5X30 (mm) SCREW DRAIN TRAY ASSY* DRAIN TRAY CLEARANCE FOR DRAIN TRAY AND AIR FLOW PATH** Ø4.5X30 (mm) SCREW 7” (177mm) 4-5/16” (110mm) * 10-3/8” (263mm) 18-1/2” (470mm) *Recommended mounting bracket heights from floor are as follow: -Male/Female: 53” (1346 mm) -Children: 47” (1194 mm) -Handicapped: 45” (1143 mm) 6-5/16” (162mm) 9.5/8” (245mm) Pay special attention so that both top cover and sensor surface are not flawed or scratched. 18-1/2” (470mm) 7-1/8” (180mm) 8-7/8” (224mm) 9-5/8” (245mm) 2. Others Do not place other devices using inverter or infrared sensor near the hand dryer, this may cause malfunction. 18-1/2” (470mm) ELECTRICAL INLET 7/8” (22mm) DIA. HOLE Junction box (actual placement) 9-5/8” (245mm) 7-13/16” (199mm) It is necessary to install circuit breaker for the power supply. 9-7/16” (240mm) Mounting surface should be even and smooth. Confirmation must be made that the wall has enough strength for hand dryer installation and be sure to use all the mounting harware provided to securely install the hand dryer. 6-5/16” (162mm) 2-1/4” (57mm) 6-5/16” (160mm) Clearance for drain tray, shown in Set-up Drawing, is required for proper air flow into the unit and maintenance of the tray. 3 HOLE BRACKET DIA. 5/32” (4mm) 7-13/16” (199mm) All electrical wiring should be installed in accordance with national/local codes and regulations with an assistance from a certified electrician. 3-1/16〝 (77mm) 2-1/4” (57mm) 9-7/16” (240mm) Confirm the rough-in, major dimensions and wiring diagram before installation in order to properly install the hand dryer and electrical wiring. 6-11/16” (170mm) 1. Precautions 3-15/16” (100mm) Ø4.5X30 (mm) SCREW 5/8” (16mm) FINISHED WALL *Top Cover Assy Unit and Drain Tray Assy are two separate parts. **Clearance is required in order to take off the tray for cleaning and maintenance and have good air flow into the unit. FLOOR Installation *Some models may have different component as illustrated below. Hand Dryer Unit w/o Top Cover Sensor <Bottom view> Top cover Platform for Mounting bracket Junction box air nozzles (Connection type) Power switch Chassis Assy. ON POWER OFF △ Wall surface Filter back of Drain Tray Assy. Filter case Drain Tray Assy Drain tray Filter case <View with cover removed> Accessories ※ Model is subject to change without further notification. Mounting Bracket Screws and vandal resist Hex Wrench Installation position (φ4.5×30)X7 Owner’s and Installation manual Template Installation Procedure 1 Use template, mark the wall for locations and install the mounting bracket. STEP 1 Mark the wall with template and install the bracket STEP 1 Mounting Bracket Caution Chassis Assy. must be installed on a rigid and even surface Failure to do this may cause damage or personal injury when it falls. ・ Attach the bracket firmly on the rigid wall with three screws (φ4.5×30) provided. ・ In the case of a tile or concrete wall, please use plastic plug anchors with screws provided. 3-1/16〝 (77mm) 2-1/4” (57mm) junction box location Screw (x3) Chassis Assy. 2-1/4” (57mm) 9-5/8” (245mm) 2 Complete the electrical wiring; install the junction box,and connect the power cord using wire nuts. 3 Mount the Chassis Assembly and Drain Tray Assembly 4 Install the top cover and drain tray 7-1/8” (180mm) 8-7/8” (224mm) * 35-3/4” (907mm) 45-3/16” (1147mm) Drain Tray Junction box (actual placement) 53” (1346mm) ELECTRICAL INLET 7/8” (22mm) DIA. HOLE 46-3/4” (1186mm) Screw (x4) (φ4.5×30) DIA. MOUNTING HOLES (4) 5/32” (4mm) 18-1/2” (470mm) Drain Tray Assembly 9-7/16” (240mm) 3 HOLE BRACKET DIA. 5/32” (4mm) 7-13/16” (199mm) (φ4.5×30) 6-11/16” (170mm) Top cover Floor surface * Recommended mounting bracket heights from floor are as follow: -Male/Female: 53” (1346 mm) -Children: 47” (1194 mm) -Handicapped: 45” (1143 mm) To be continued on the back STEP 2 STEP 2 - STEP 4 Complete the electrical wiring STEP 3 ・ Use the special hex wrench provided to remove the 2 screws (φ4×10) from the top cover, then remove the cover. To remove the top cover, pull the lower part ① towards you and pull ・ the upper part ② upward, then remove it. Hang Chassis Assy. mounting platform onto mounting bracket hooks.. ・ Connect the power cord inside the main body case with the power cord ・ out of the wall and use wire nuts (certified electrician to confirm the specific wire nut to use). Vandal resist Screw for Top cover (x2) ・Put the connection point (with wire nuts) into the junction box. ・Hang the Chassis Assembly onto the mounting bracket. ・Insert the Drain Tray Assy. into the bottom of the Chassis Assembly, and attach the lower part of the Drain Tray Assy. ① to the Chassis Assy. ② with 2 screws (Ф4.5×30) provided. mounting bracket Chassis Assembly Top cover Chassis Assembly Chassis Assembly mounting platform Mount the Chassis Assembly and Drain Tray Assembly mounting bracket hooks mounting bracket Junction box (Actual Placement) STEP 4 Install the top cover and drain tray ・ ① Insert the hook of the top cover into the slot at the upper part of the Chassis Assembly, ② then put the cover down. ・ Then, fasten the cover with two screws (Ф4×10) that were previously taken out. * POWER MUST BE IN OFF POSITION DURING INSTALLATION. Connection diagram hook of Top cover Top cover Connection point Drain Tray Assembly Junction box (Actual Placement) Screw for Top cover (x2) (φ4×10) Slot at the upper part of the Chassis Assy. Chassis Assembly Drain Tray Assembly Drain tray ※ ※ Connect the cord firmly with a wire nut or equivalent. When installing the drain tray, slide it completely into its maximum depth. Drain Basin Function Test 1. Checking after installation ■ Test the product as follow after the installation is complete. Wiring Diagram Sensor Control Assembly ・First peel off the seal on the filter. (The seal is used to protect the filter from scratches during shipment; it is no longer needed.) P6 P5 P4 W Bu R Power Switch P7 W Air nozzles P1-1 W P2 Motor P3 P1-2 B Peel off the seal Power Connector 1.Check the main Power Supply Switch. W ・Turn on the main power supply switch on. 2.Check the power switch of the hand dryer ・Turn the power swtich ON. 3.Check the functionality ・Place your hand under the outlet nozzles to see if air blows out. ■ After trial run ・After you check the functionality by trial run, give the User Manual (with Warranty) to the customer, and explain how to use and maintain the product. B G Power Switch Power Fuse B Motor W B=BLACK R=RED W=WHITE Bu=BLUE G=GREEN