Download User Manual - Bezares USA

Transcript

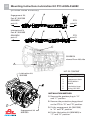

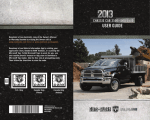

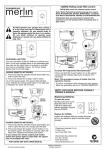

Hot Shift PTO 3000, 3100 and 3300 Series ser Manual Hydraulic Systems 3000 series 3300 SAE output 3100 series Building our world +1 888 663 1786 • pto-usa.com • [email protected] 3300 series ES 0303/1998 ES 2001/0353 2 Contents SAFETY INFORMATION ............................................................................................................................ 3 FOREWORD ............................................................................................................................................... 4 APPLICATION QUESTIONS ........................................................................................................................ 5 1- P.T.O 3100 FOR WORLD TRANSMISSION SERIES BREAK UP VIEW ....................................................................................................................... 6 MOUNTING PTO TO TRANSMISSION ....................................................................................... 7 MOUNTING PTO TO TRANSMISSION ....................................................................................... 8 SHIFTER COMPONENT INSTALLATION SKETCH....................................................................... 9 PRESSURE PORT AND OPENING IDENTIFICATION ................................................................. 10 LUBRICATION KIT MOUNTING INSTRUCTION ....................................................................... 11 2- P.T.O 3000 SERIES AT, MT, HT BREAK UP VIEW ...................................................................................................................... 12 MOUNTING PTO TO TRANSMISSION ..................................................................................... 13 MOUNTING PTO TO TRANSMISSION ..................................................................................... 14 AUTOMATIC TRANSMISSION PRESSURE LUBE HOSE CONNECTION .................................... 15 SHIFTER COMPONENT INSTALLATION SKETCH..................................................................... 16 PRESSURE PORT AND OPENING IDENTIFICATION ................................................................. 17 LUBRICATION KIT MOUNTING INSTRUCTION AT500/MT 600/HT 700........................ 18,19,20 3- P.T.O 3300 SERIES ALLLISON / AISIN BREAK UP VIEW ...................................................................................................................... 21 SHIFTER COMPONENT INSTALLATION SKETCH..................................................................... 22 AISIN- LUBRICATION KIT MOUNTING INSTRUCTION ............................................................ 23 AISIN AS69RC- LUBRICATION KIT MOUNTING INSTRUCTION .............................................. 24 ALLISON 1000, 2000, 2400 TRANSMISSION SERIES ............................................................... 25 PTO SHIFTING PROCEDURE & PRECAUTIONS ........................................................................................ 26 NOTES ...................................................................................................................................................... 27 Safety Information 3 CAUTION: TO PREVENT POSSIBLE INJURY OR DEATH: DO NOT go underneath the vehicle with the engine running. DO NOT attempt to work on an installed Power Take-Off with the engine running. DO NOT operate the controls of the Power Take-Off or other driven equipment from underneath the vehicle with the engine running. DO NOT operate the controls of the Power Take-Off or other driven equipment in any position that could result in getting caught in the moving machinery. CAUTION: Make sure to block any moving or raised device that may injure a person working on or under the truck. A lever or its linkage may be accidentally moved causing movement of the device which could cause injury to a person near the device. IMPORTANT: Because most of our Bezares Power Take–Offs and P.T.O. drive lines are sold through distributors, the product applications and the resulting degree of exposure to danger of the operators are beyond the knowledge and controls of BZ U.S.A. Therefore, the proper installation of the P.T.O. and its associated equipment, and the decisions of whether to install guards and/or warning signs shall be the responsibility of the designers or installers. ! DANGER NEVER GET UNDER THE TRUCK IF THE ENGINE IS RUNNING! You may be hurt or killed. ! PELIGRO ¡NUNCA SE META DEBAJO DEL CAMIÓN CUANDO EL MOTOR ESTÉ EN MARCHA! 4 Foreword Since it is our major objective to show you how to get additional and more profitable miles from truck, tractor and trailer components, we want to provide you with information on the installation of 3000, 3100, and 3300 Series. We all realize that an inadequate transmission will overwork any Power Take–Off in a very short period of time. In addition, a mismatched transmission/P.T.O. combination can result in unsatisfactory performance of the equipment right from the start. P.T.O. 3100 SERIES P.T.O. 3000 SERIES P.T.O. 3300 SERIES Before you order new trucks be sure that you’re getting the right transmission/P.T.O. combination. It is of vital importance for efficient performance to have adequate power. To help you select the proper type, size and design of P.T.O. it is advisable to discuss your specific requirements with a Bezares P.T.O. specialist. They know their products and Power Take–Offs. They can inform you about everything you need to know about power, at the right time, before you specify components. Aplication Questions 5 Here are some of the questions that are relevant to the Proper Selections of a Transmission mounted Power Take–Offs. 1. What is the make and model of your transmission? 2. Which P.T.O. opening will be used? 3. What accessory is to be driven? 4. How much horsepower is required to drive the accessory? 5. What is the required rotation of the P.T.O.? 6. What is the required P.T.O. output shaft speed as a percent of engine speed? Once all of the answer to these questions have been determined, a transmission mounted P.T.O. can be selected to meet the horsepower, speed and rotation that you require. Having made the selection of a P.T.O. you are ready to start the installation. 55 54 53 51 52 50 49 48 18 47 19 46 20 45 21 44 22 43 23 24 42 25 41 26 40 2 27 57 3 28 4 37 5 30 38 29 39 6 56 31 36 7 32 33 8 34 35 9 57 10 11 12 13 14 15 16 17 6 1. P.T.O. 3100 For World Transmission Mounting P.T.O. To Transmission 1 7 2 1. Drain the oil from the transmission and the PTO aperture cover plate. 2. Discard the cover plate and cover plate gasket, then clean the aperture pad using a putty knife or wire brush. Note: Stuff a rag in the aperture opening to prevent dirt from entering the transmission while you are cleaning it. 3 4 3. Install the proper studs and pins (furnished with the PTO) in the pto aperture pad. (See also specific mounting instruction furnished with the PTO). 4. Place the steel gasket over studs using grease, if necessary, to keep it in place. The ribbed surface should face towards the installer. Fit at least 4 nuts in each corner before checking the backlash. Check the suitable backlash. It should be between 0,006” and 0,015”. 8 Mounting P.T.O. To Transmission 5. Fasten the PTO to the transmission by means of the bolts and remaining nuts. 6 6. Install the lubrication and engagement hoses (see specific mounting instructions pag. 11) 7. Fasten the high pressure line to the transmission and checking for proper oil level and signs of oil leakage, the best check is conducted with the transmission at operating temperature. 8. Finally install the electrical connection. 7 White Fuse holder 8/10 Amp Switch P/N 9058799 Grommet P/N-9059299 Red Light Indicator P/N 12V-903013 24V-902913 Bracket P/N-200105021 Drill 11/4” Pass the cable through partition connector grommet Red Blue Positive terminal (ignation or battery) INSTALLATION SKETCH HOT SHIFT PTO’S 24V 9058999 Pressure switch P/N-905999 12V INSTALLATION KIT P/N 9058899 Electrical ground (instrument panel) Black Valve Connection Electrovalve P/N 12V-9067290 24V-9067390 Shifter Component 3100 Series Installation Sketch 9 10 Pressure Port and Aperture Identification THESE DRAWINGS REPRESENT LEFT AND RIGHT VIEWS OF THE MD AND HD PRESSURE PORT ON THE TRANSMISION. MD ALLISON 10 BOLT PAD MAIN PRESS. PORT .438-20 UNF-2A 175 TO 255 P.S.I. BOTH SIDES 68-TEETH 10.16 PITCH 20° P.A. 19.2654° HELIX L.H. MAIN PRESS. PORT .438-20 UNF-2A 175 TO 255 P.S.I. BOTH SIDES HD ALLISON 10 BOLT PAD 97-TEETH 10.16 PITCH 20° P.A. 19.2654° HELIX L.H. MAIN PRESS. PORT .438-20 UNF-2A LEFT SIDE ONLY Mounting Instruction Lubrication Kit PTO 3100 11 Shifting Kit Part Nº 900899 GEARBOX point A PTO point B LIST OF CONTENT Lubrication Kit Item 1 2 3 4 Description Fitting Hose Fitting Washer Part Nº 9018699 PTO point C PTO point D 9018699 9018699 900899 To main pressure port 3100 Series 3250 Series 900899 To main pressure port INSTALLATION METHOD 1. Remove the gearbox plug in position (A) and fit the fitting available in the kit (1) 2. Remove the protection plug placed on the PTO (B). 3. Fit the pressure Hose (900899) on the (A) and (B) position by means of the hose and fitting (3). 4. Fit the Lube hose (9018699) on the (C) and (D) position with the fitting (3) and washers (4) SERIES HD Rear View 45 44 oil return line port from cooler 43 42 41 40 46 39 1 47 38 2 48 37 35 3 49 36 6 50 34 7 51 33 8 52 32 53 31 9 54 30 55 4 56 10 29 28 57 5 11 58 27 12 13 main pressure port 26 14 59 15 18 19 25 16 20 21 22 23 24 17 12 2. P.T.O. 3000 Series AT, MT, HT Mounting P.T.O. To Transmission 13 1. Discard the cover plate and cover plate gasket, then clean the aperture pad using a putty knife or wire brush. Note: Stuff a rag in the aperture opening to prevent dirt from entering the transmission while you are cleaning it. 2. Install the proper studs (furnished with the PTO) in the PTO aperture pad. See also specific mounting instructions (furnished with the PTO). DO NOT USE SEALING COMPOUNDS IN AUTOMATIC TRANSMISSIONS 3. Place the correct number of gaskets over studs. Do not use paste between because you may want to add or subtract gasket to obtain proper backlash. Do not use more than 3 gaskets together, Usually one gaskets 0.020” (0.5 mm) will be required. 4. Install the lubrication and engagement hoses (specific instructions for each transmission pag. 18, 19, 20). Lubrication hose is connected to point coming from cooler. 14 Mounting P.T.O. To Transmission 5. Install the PTO to the transmission by means of the bolts and remaining nuts. Torque to 30-35 lb-ft (41-47Nm). (See specific mounting instructions). 6. After fastening the high pressure line to the transmission, circuit need to be checked for proper oil level and signs of oil leakage. The best check is conducted with the transmission at operating temperature. 7. Finally install the electrical circuit. Automatic Transmission’s Pressure Lube Hose Connection 15 Tee Connection To Idler pin in PTO Pressure Lube Hose (9018399) To cooler Return TRANSMISSION AT - 500 MT - 600 HT - 700 “T” CONNECTION P/N FI511 FI511 FI521 TRANSMISSION “T” CONNECTION P/N 1000 / 2000, 2400 FI831 FI401 White Fuse holder 8/10 Amp Red Positive terminal ignition or battery Switch P/N 9058799 Blue Drill 1 1/4” Red Light Indicator 12V 903013 24V 902913 Bracket P/N 200105021 Grommet P/N 9059299 Electrical ground (instrument panel) Black Pass the cable through partition connector grommet Pressure switch P/N 905999 Valve connection Electrovalve P/N 12V - 9067290 24V - 9067390 16 Shifter Component 3000 Series Installation Sketch Pressure Port And Aperture Identification 17 THESE DRAWINGS REPRESENT LEFT AND RIGHT VIEWS OF THE AT-500, MT-600 AND HT/CLT-700 PRESSURE PORT ON THE TRANSMISSION Oil return line from cooler AT-540 4 Speed Main pressure 1/8 N.P.T. 90 - 150 PSI 6.3 - 10.5 Kg / cm2 MT-640 MT-650 4&5 Speed Oil return line from cooler Main pressure 1/8 N.P.T. 125 - 217 P.S.I. 8.7 - 15.2 Kg / cm2 HT-740 HT-750 D Oil return line from cooler Main pressure CLT-750 Oil return line from cooler Main pressure HT-700 Oil return line from cooler Main pressure Mounting Instructions Lubrication Kit PTO AT500 18 Oil From Cooler 2 1 3 4 3 6 PTO point B Lubrication Kit Part Nº 9018399 3 4 5 LIST OF CONTENT Description “T”Description Fitting “T” Fitting O-ring O-ring Fitting Fitting Hose Hose Fitting Fitting Washer Washer Oil Return Line From Cooler 6 PTO, point D Gearbox point C Gearbox point A Item Item 1 21 32 3 44 55 66 6 Shifting Kit Part Nº 9019499 A INSTALLATION METHOD 1. Install the “T” fitting (1) into the oil line returning to the transmission from cooler (A) position. 2. Connect the lubrication hose (9018399) to the “T” fitting (1) by means of fitting (3). 3. Connect the lubrication hose to the PTO (B) position by means of the fitting (3) C Main Pressure Rear view 4. Fit the Pressure hose (9019499) into the main pressure to the transmission (C) position, with the fitting (3). 5. Fit the Pressure hose on the (D) position with the fitting (5) and washers (6). * After installation of the PTO the transmission should be carefully checked for proper oil level and signs of oil leakage. The best check is conducted with the transmission at operating temperature. Mounting Instructions Lubrication Kit PTO MT600 19 Oil From Cooler 1 2 3 4 3 6 PTO, point B Lubrication Kit Part Nº 9018399 GEARBOX point A 3 4 5 GEARBOX point C LIST OF CONTENT Item Item 1 1 2 3 3 4 4 5 5 6 6 6 6 PTO, point D Shifting Kit Part Nº 9019499 Description Description “T” Fitting “T” Fitting O-ring O-ring Fitting Fitting Hose Hose Fitting Fitting Washer Washer D B INSTALLATION METHOD 1. Install the “T” fitting (1) into the oil line returning to the transmission from cooler (A) position. 2. Connect the hose (9018399) to the “T” fitting (1) by means of fitting (3). 3. Connect the lubrication hose to the PTO (B) position by means of the fitting (3) C MAIN PRESSURE Oil Return Line From Cooler Rear view A 4. Fit the Pressure hose (9019499) into the main pressure to the transmission (C) position, with the fitting (3). 5. Fit the Pressure hose on the (D) position with the fitting (5) and washers (6). * After installation of the PTO the transmission should be carefully checked for proper oil level and signs of oil leakage. The best check is conducted with the transmission at operating temperature. 20 Mounting Instructions Lubrication Kit PTO HT700 Oil From Cooler 1 2 3 4 3 6 PTO point B Lubrication Kit Part Nº 9018399 GEARBOX point A 3 4 5 GEARBOX point C LIST OF CONTENT Item Item 1 1 22 33 44 55 6 6 6 6 PTO point D Shifting Kit Part Nº 9019499 Description Description “T” Fitting “T” Fitting O-ring O-ring Fitting Fitting Hose Hose Fitting Fitting Washer Washer D B A INSTALLATION METHOD 1. Install the “T” fitting (1) into the oil line returning to the transmission from cooler (A) position. 2. Connect the lubrication hose (9018399) to the “T” fitting (1) by means of fitting (3). 3. Connect the lubrication hose to the PTO (B) position by means of the fitting (3) C Oil return line from cooler Main Pressure 4. Fit the Pressure hose (9019499) into the main pressure to the transmission (C) position, with the fitting (3). 5. Fit the Pressure hose on the (D) position with the fitting (5) and washers (6). Rear view * After installation of the PTO the transmission should be carefully checked for proper oil level and signs of oil leakage. The best check is conducted with the transmission at operating temperature. oil return line port from cooler 62 66 30 29 61 28 60 59 58 32 55 10 56 31 63 57 64 34 53 11 12 13 14 35 52 main pressure port 33 54 INPUT GEAR "A" AND "Z " RATIO INPUT GEAR "B" RATIO ONLY 68 67 65 15 36 51 16 17 37 50 48 38 49 46 2 18 39 1 47 3 19 40 45 4 41 44 5 20 7 21 6 42 43 8 9 22 23 24 25 26 27 3. PTO 3300 SERIES 21 White Fuse holder 8/10 Amp Red Positive terminal ignition or battery Switch P/N 9058799 Blue Drill 1 1/4” Pressure switch P/N 905999 Electrical ground (instrument panel) Black Wire connections P/N 9059199 Red Light Indicator 12V 903013 24V 902910 Bracket P/N 200105021 Grommet P/N 9059299 Pass the cable through partition connector grommet Valve connection Electrovalve P/N 12V - 9067290 24V - 9067390 22 Shifter Component 3300 Series Installation Sketch Shifter Instructions Lubrication Kit PTO AISIN 23 1 2 3 4 Engagement Kit Part Nº 9041399 GEARBOX, point A PTO point B Lubrication Kit Part Nº. 9041499 1 5 6 4 PTO point D GEARBOX, point C C A GEARBOX Viewed from top side GEARBOX Viewed from left side LIST OFOF CONTENT LIST CONTENT Item Item 11 22 3 34 45 56 6 Lubrication Kit 9041499 Description Description Fitting 1/2” UNF Fitting 1/2” UNF Engagement hose Engagement hose Fitting M10x1 Fitting M10x1 Washer Washer Lubrication hose Fitting 1/8” BSP Lubrication hose Fitting 1/8” BSP B INSTALATION METHOD INSTALLATION 1.- Remove the METHOD gearbox plug “A” and the “C” position. 1. in Remove gearbox plug in “A” and 2.- Remove the protection “C” position plugs placed on the PTO in “B”, 2. Remove the protection plugs placed on and “D” position. the PTO “B” and “D” 3.- Fit thein engagement kit position. (9041399) in “A” and “B” position. 3. Fit engagement 4.- the Fit the lubrication kitkit (9041399) in “A” and “B” position (9041499) in “C” and “D” position. 4. Fit the lubrication kit (9041499) in “C” and “D” position. D PTO Engagement kit 9041399 24 Mounting Instructions Lubrication Kit PTO AISIN AS69RC (DODGE RAM Vehicles) Engagement Kit Part Nº 9041399 PTO point B GEARBOX point A Lubrication Kit Part Nº 9041499 PTO point D GEARBOX point C C GEARBOX viewed from left side A Lubrication kit 9041499 LIST OF CONTENT Item 1 2 3 4 5 6 Description Fitting 1/2” UNF Engagement hose Fitting M10x1 Washer Lubrication hose Fitting 1/8” BSP INSTALLATION METHOD 1. Remove the gearbox plug in “A” and “C” position 2. Remove the protection plugs placed on the PTO in “B” and “D” position. Engagement kit 9041399 3. Fit the engagement kit (9041399) in “A” and “B” position 4. Fit the lubrication kit (9041499) in “C” and “D” position. Mounting Instructions Lubrication Kit PTO 25 Allison/1000/2000/2400 Oil from cooler PTO point A Lubrication Kit part Nº 9019199 Option 1 (3/4" - 16 UNF) Option 2 (7/8" - 14 UNF) Option 3 (1 1/16" - 12 UNF) GEARBOX point D GEARBOX point C LIST OF CONTENT Item 1 2 3 4 5 6 PTO point B Engagement Kit part Nº 900899.1 Description “T” Fitting O-ring Fitting Hose Fitting Washer Lubrication Kit 9019199 INSTALLATION METHOD 1. Install the “T” fitting (1) into the oil line returning to the transmission from cooler (point C). 2. Connect the hose (9019199) to the “T” fitting (1) by means of fitting (3). 3. Connect the lubrication hose to the PTO (A) position by means of the fitting (5) and washers (6). 4. Fit the Pressure hose (900899.1) into the main pressure to the transmission (D) position, with the fitting (3). Engagement Kit 900899.1 5. Fit the Pressure hose on the (B) position with the fitting (5) and washers (6). PTO * After installation of the PTO the transmission should be carefully checked for proper oil level and signs of oil leakage. The best check is conducted with the transmission at operating temperature. (Main pressure port 0,438-20UNF) Gearbox, bottom view 26 P.T.O. Shifting Procedure & Precautions CAUTION: This vehicle is equipped with a Power Take-Off. Shut engine off before working on the Power Take-Off or getting below the vehicle. Consult the operating instructions before using the P.T.O. (see sun visor) POWER TAKE-OFF OPERATION - VEHICLE STATIONARY Automatic Transmission with Power Shift P.T.O.’s Engage the P.T.O. with the engine at idle speed. NOTE: Power Shift P.T.O.´s: The engine must be at idle or below 1000 RPM when the P.T.O. is engaged. See the transmission manufacturer’s instructions for special procedures. IMPORTANT: Failure to follow the proper shifting or operating sequences will result in premature P.T.O. failure with possible damage to other equipment. Warning: Cold Weather Operation of Power Shift P.T.O.´s During extreme cold weather operation [32°F (0°C) and lower], a disengaged Power Shift Power Take-Off can momentarily transmit high torque that will cause unexpected output shaft rotation. This is caused by the high viscosity of the transmission oil when it is extrememly cold. As slippage occurs between the Power Take-Off clutch plates, the oil will rapidly heat up and the viscous drag quickly decreases. The Power Take-Off output shaft rotation could cause unexpected movement of the driven equipment, resulting in serious personal injury, death, or equipment damage. To avoid personal injury or equipment damage: - Driven equipment must have separate controls. - Driven equipment must be left in the disengaged position when not in operation. - Driven equipment must not be operated until the vehicle is allowed to warm up. Notes 27 28 Notes 27634 Commerce Oaks Drive Oak Ridge north, Texas 77385 +1 888 663 1786 [email protected] BZUM3000-07/2015