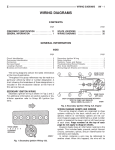

Download Transmission Diagnostic Procedures

Transcript