Download watercooled service manual

Transcript

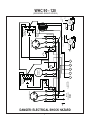

by by AITONS' Water Cooled Air Conditioners AITONS' by by AITONS' AITONS' WPC • WHC • WSC Installation, Operation And Maintenance Manual WPC • WHC • WSC ALL WIRING SHOULD COMPLY WITH LOCAL AND NATIONAL CODES. THE COMPRESSOR AND FAN MOTORS (If applicable) ARE INTERNALLY PROTECTED. INSTALLATION by AITONS' WATER VALVE The Water Regulating Valve is adjustable (by means of stem on top of valve) to control refrigerant system head pressure. Counter clockwise rotation of the handle increases head pressure and clockwise rotation decreases the head pressure. WHC Series LOCATING THE UNIT In locating the unit, consideration should be given to space requirements, floor strength, water supply, power supply, sewer for condensate and condensate drain. In addition to space required for the unit, consideration should be given for service clearance and maintenance. It will be necessary to field adjust the valve because of variance in water pressure, flow rates and temperature encountered. Fasten a service head pressure gauge to the service fitting on the compressor discharge line to determine the head pressure. The optimum condition is 230 p.s.i.a. WSC PRE-INSTALLATION The water cooled system consists of a condensing unit designed for installation with refrigerant lines and matching evaporator coil. Before beginning the installation, make certain you have received the proper system components for your requirements. by AITONS' ELECTRICAL CONNECTIONS All units are wired at the factory and require connection of the power supply to the unit control box. Power at the unit must be within 10% of rated voltage, both during normal operation and starting periods. WPC Series 2 OPERATION OF SYSTEM 6. Turn on the line voltage to the condensing unit. System is controlled by a room thermostat. Place system switch on the thermostat to the “cool” position. 7. Set the thermostat to 15°C. The compressor contactor should close and the compressor starts to work. The furnace blower should start and run on the cooling speed. Place the fan switch to the “on” position for continuous fan operation or the “auto” position to cycle the blower on and off with the compressor. 8. With the unit operating, close all the doors, windows and openings to the house. Set the thermostat to the desired setting, usually 22°C, allow the unit to condition the house. Don’t be alarmed if the unit runs several hours or even a full day to reduce the heat and moisture in the house on the initial run. This is normal for any air conditioning system. CHECK OUT OF UNIT 1. Turn the thermostat Heat/Cool switch to “off”. Turn the thermostat fan switch to “auto”. 2. Turn all power on except line voltage (230v) to condensing unit. SPECIAL NOTE 3. Turn fan switch at thermostat to “on”: blower should run on cooling speed. Reset to “auto”; blower should turn off. In the event of a compressor motor failure or burnout; normally cleaning the metering device, installing a suction line filter drier will be sufficient to remove contaminates resulting from the failure. 4. Set the room thermostat above 30°C, turn selector switch to cool. Move thermostat below indicated room temperature; the blower should run on a cooling speed and a click of the compressor contactor should be heard in the condensing unit. If the contactor cannot be heard, check visually that the contacts are closed. After a few days of operation, the drier core can be removed from the suction line filter. 5. Again, set room temperature above 30°C. Turn selector switch to heat. Furnace should start to heat. When plenum temperature reaches fan on setting, the blower should run at heating speed. turn thermostat down below 15°C, to shut off heat. After a few minutes the blower should turn off. by AITONS' WSC Series 3 GENERAL SERVICE GUIDE PROBLEM POSSIBLE REMEDY POSSIBLE REMEDY POSSIBLE REMEDY POSSIBLE REMEDY Fan and compressor will not start. CAUSE CAUSE CAUSE CAUSE PROBLEM POSSIBLE REMEDY POSSIBLE REMEDY POSSIBLE REMEDY POSSIBLE REMEDY Fan operates, but compressor will not start. CAUSE CAUSE CAUSE CAUSE POSSIBLE CAUSE REMEDY PROBLEM POSSIBLE REMEDY POSSIBLE REMEDY POSSIBLE REMEDY POSSIBLE REMEDY Incorrect thermostat setting. Adjust thermostat. Thermostat defective. Replace. Compressor overloads or thermostat open. Check reasons for overload open: excessive heat. High or low pressure control tripped. Re-set and check water regulating valve and water supply. If switch is defective, then replace. Contactor faulty. Replace. Compressor motor hums but will not start. CAUSE CAUSE CAUSE CAUSE PROBLEM POSSIBLE REMEDY POSSIBLE REMEDY POSSIBLE REMEDY POSSIBLE REMEDY Power Off. Check main circuit fuses and wiring. (a) Faulty unit wiring (b) Loose wiring connections. (a) Check wiring diagram (b) Tighten terminals and wiring connections. 24 volt supply faulty. Check transformer. Thermostat defective. Replace. Low or incorrect voltage. Check with power company for required voltage. Faulty capacitor. Replace. Faulty Hard Start Kit. Replace. Seized compressor. Replace. Fan motor starts but cuts off on internal protector. CAUSE CAUSE CAUSE CAUSE Low voltage. Check with power company. Defective bearings. Replace motor. Internal fault. Replace motor. High amp draw. Replace motor. 4 PROBLEM POSSIBLE CAUSE REMEDY POSSIBLE CAUSE REMEDY POSSIBLE CAUSE REMEDY POSSIBLE CAUSE REMEDY PROBLEM POSSIBLE CAUSE REMEDY POSSIBLE CAUSE REMEDY POSSIBLE CAUSE REMEDY High Suction Pressure. Water supply inadequate. Check water regulating valve setting or water supply. Excessive load on unit. High air flow, high inlet temperature as in initial start or pull down. Defective compressor. If head pressure is low or normal at this condition, compressor may be defective. Overcharge of refrigerant. Usually associated with high discharge pressure. Remove excess gas. High Discharge Pressure. Water supply to condenser inadequate. (a) Adjust or, if defective, replace water regulating valve. (b) Water pressure low, or supply lines too small. (c) Water temperature too high. (d) Condenser surface fouled. Recognized by low temperature water rise through condenser. Overcharge of refrigerant. Remove refrigerant, and balance to normal. Non-condensibles in system. Remove refrigerant and evacuate system. 5 WPC / WHC 12 - 60 (208/230/60/1) COMPRESSOR R SOLID STATE LOCKOUT CONTROL C LOGIC CIRCUIT S 4 1 FAULT LIGHT 3 2 CONTROL 208/230 - 24V TRANS COMP CAP HP SWITCH T2 COIL SUPPLY 208/230 V 1O L1 CONTACTOR T1 24 V TO THERMOSTAT G R Y L2 GND OPTIONAL MOTOR AND FROM WIRING L1 CAPACITOR 4 2 FROM MOTOR RELAY 5 CAPACITOR BLOWER MOTOR 1 COIL 3 BLOWER MOTOR BLOWER MOTOR RELAY DANGER: ELECTRICAL SHOCK HAZARD 6 WPC / WHC 36 - 60 (208/230/60/3) COMPRESSOR T1 SOLID STATE LOCKOUT CONTROL T3 LOGIC CIRCUIT T2 4 1 FAULT LIGHT 3 2 CONTROL 208/230 - 24V TRANS HP SWITCH T2 T3 CONTACTOR T1 COIL SUPPLY 208/230 V 3O L1 L2 24 V TO THERMOSTAT G R Y L3 GND OPTIONAL MOTOR AND FROM WIRING L1 CAPACITOR 4 2 FROM MOTOR RELAY 5 CAPACITOR BLOWER MOTOR 1 COIL 3 BLOWER MOTOR BLOWER MOTOR RELAY DANGER: ELECTRICAL SHOCK HAZARD 7 WPC / WHC 36 - 60 (575/60/3) COMPRESSOR T1 SOLID STATE LOCKOUT CONTROL T3 LOGIC CIRCUIT T2 4 1 FAULT LIGHT 3 2 CONTROL 575 - 24V TRANS HP SWITCH T2 T3 CONTACTOR T1 COIL SUPPLY 575 V 3O L1 L2 24 V TO THERMOSTAT G R Y L3 GND OPTIONAL MOTOR AND FROM WIRING L1 CAPACITOR 4 2 FROM MOTOR RELAY 5 CAPACITOR BLOWER MOTOR 1 COIL 3 BLOWER MOTOR BLOWER MOTOR RELAY DANGER: ELECTRICAL SHOCK HAZARD 8 9 GND L2 L3 T1 208-230/60/3 460/60/3 575/60/3 SUPPLY T2 T2 T3 T3 COMPRESSOR L1 T1 24 V TO THERMOSTAT COIL FAULT LIGHT LOGIC CIRCUIT HP SWITCH 2 3 1 R L1 T1 G Y1 L2 T2 BLOWER MOTOR x2 Y2 COIL C HP SWITCH T2 L2 T2 T3 L3 FAULT LIGHT CONTROL 208-230 - 24V TRANS RED YELLOW T3 BLOWER MOTOR LOW SPEED L1 BLACK COIL T1 T1 COMPRESSOR 2 SOLID STATE LOCKOUT CONTROL CONTACTOR 4 CONTACTOR LOGIC CIRCUIT SOLID STATE LOCKOUT CONTROL 3 1 4 RED HIGH SPEED BLOWER MOTOR YELLOW BLACK WHC 90 - 120 (208/230/60/3 460/60/3 575/60/3) DANGER: ELECTRICAL SHOCK HAZARD CONTACTOR 10 GND L2 L3 T1 208-230/60/3 460/60/3 575/60/3 SUPPLY T2 T2 T3 T3 COMPRESSOR L1 T1 24 V TO THERMOSTAT COIL FAULT LIGHT LOGIC CIRCUIT HP SWITCH 2 R 3 1 L1 T1 G Y1 L2 T2 BLOWER MOTOR x2 COIL Y2 C HP SWITCH T2 L2 T2 T3 L3 FAULT LIGHT CONTROL 208-230 - 24V TRANS RED YELLOW T3 BLOWER MOTOR LOW SPEED L1 BLACK COIL T1 T1 COMPRESSOR 2 SOLID STATE LOCKOUT CONTROL CONTACTOR 4 LOGIC CIRCUIT SOLID STATE LOCKOUT CONTROL 3 1 4 RED HIGH SPEED BLOWER MOTOR YELLOW BLACK WPC 90 - 120 (208/230/60/3 460/60/3 575/60/3) DANGER: ELECTRICAL SHOCK HAZARD CONTACTOR WSC 12 - 60 (208/230/60/1) COMPRESSOR SOLID STATE LOCKOUT CONTROL C S 2 4 LOGIC CIRCUIT R 1 FAULT LIGHT 3 COMP CAP T1 T2 COIL SUPPLY 208/230 V 1O L1 CONTACTOR HP SWITCH 24 V TO THERMOSTAT C L2 GND DANGER: ELECTRICAL SHOCK HAZARD 11 Y WSC 36 - 60 (208/230/60/3) COMPRESSOR 2 T1 T3 T2 4 LOGIC CIRCUIT SOLID STATE LOCKOUT CONTROL 1 FAULT LIGHT 3 T1 T2 T3 COIL SUPPLY 208/230 V 3O L1 L2 CONTACTOR HP SWITCH 24 V TO THERMOSTAT C L3 GND DANGER: ELECTRICAL SHOCK HAZARD 12 Y WSC 36 - 60 (575/60/3) COMPRESSOR 2 T1 T3 T2 4 LOGIC CIRCUIT SOLID STATE LOCKOUT CONTROL 1 FAULT LIGHT 3 T1 T2 T3 COIL SUPPLY 575 V 3O L1 L2 CONTACTOR HP SWITCH 24 V TO THERMOSTAT C L3 GND DANGER: ELECTRICAL SHOCK HAZARD 13 Y 14 Water Flow Rate – G.P.M. (U.S.) Entering Water Temperatures vs. Water Flow Rate WPC, WHC, WPCP & WSC WATER CONSUMPTION CHART 15 FB0003 FM0002 FM0010/FM0004 FM0011/FM0005 WPC/WHC120 WPC/WHC120-5 REVISED 5/02 FM0009/FM0005 FB0004 FM0005 WPC/WHC90-5 FB0004 FM0004 FB0006/FB0004 FB0006/FB0004 FB0005/FB0004 FB0005/FB0004 FB0004 FM0004 FM0008/FM0004 FB0004 FB0003 FM0004 FM0002 FB0003 FB0003 FM0002 FM0002 FB0002 FM0001 WPC/WHC90-3 WPC/WHC48 WSC * WPC/WHC60-1 WSC * WPC/WHC60-3 WSC * WPC/WHC60-5 WSC * WPC/WHC44-3 WPC/WHC44-1 FB0002 FM0001 FB0002 FB0002 FM0001 WPC/WHC15 FB0002 BLOWER WHEEL FM0001 FM0001 WPC/WHC12 WPC/WHC18 WSC * WPC/WHC24 WSC * WPC/WHC30 WSC * WPC/WHC36-1 WSC * WPC/WHC36-3 WSC * MOTOR MODEL PARTS LISTING FOR RC0021 (2) RC0013 (2) RC0020 (2) RC0012 (2) RC0021 RC0013 RC0009 RC0008 RC0011 RC0007 RC0010 RC0006 RC0005 RC0004 RC0002 8000-632 RC0001 COMPRESSOR by EO0002 EO0002 EO0002 EO0002 EO0002 EO0002 EO0000 EO0001 EO0002 EO0001 EO0002 EO0001 EO0001 EO0001 EO0001 EO0001 EO0001 CONTACTOR COMFORT-AIRE AITONS' EC0015 EC0015 EC0015 EC0015 EC0015 EC0001 EC0001 EC0001 EC0001 EC0001 EC0001 EC0001 EC0001 EC0001 EC0011 EC0010 EC0010 EC0010 EC0007 EC0007 EC0007 EC0007 EC0005 MOTOR CAPACITOR COMP WPC/WHC/WSC 12 THRU 120-5 REVISED 08/14/01 VW0002 VW0002 VW0002 VW0002 VW0002 VW0002 VW0002 VW0002 VW0001 VW0001 VW0001 VW0001 VW0001 VW0001 VW0001 VW0001 VW0001 WATER VALVE Parts Listing for WPC/WHC/WSC 12 THRU 120-5 www.comfort-aire.com LIMITED WARRANTY Water Cooled Equipment AITONS’ EQUIPMENT INC. warrants for one year its products to be free from defects in material and workmanship when installed and operated pursuant to manufacturers instructions. In addition, the compressor is warranted for an additional 4 years. If, upon examination by AITONS’ EQUIPMENT INC., a part is deemed to be defective under this warranty, we will repair or replace that part F.O.B. Guelph, Ontario free of charge, exclusive of labour. This warranty is to the exclusion of any statutory warranty expressed or implied. The PURCHASER FILLS IN AND RETAINS THIS WARRANTY (The Serial Number of your unit is recorded on computer when shipped.) MODEL SERIAL number DATE OF INSTALLATION INSTALLER’S NAME AITONS’ EQUIPMENT INC. Guelph, Ontario www.aitons.com [email protected] 16