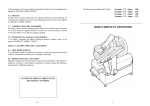

Download D:\Doc\Esplosi + tabelle\Snack\Piastre_tostiere\Piastre_old\4Q.pcx

Transcript