Download Operating instructions

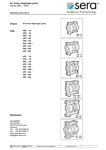

Transcript