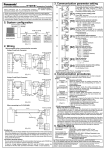

Download KT4H/B Temperature Controller User's Manual

Transcript