Download OPERATING INSTRUCTIONS AND SYSTEM DESCRIPTION OF

Transcript

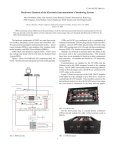

OPERATING INSTRUCTIONS AND SYSTEM DESCRIPTION OF THE PDES-02TX PNEUMATIC DRUG EJECTION SYSTEM (with analog timers and analog manometers – PDES-02TX-LA) VERSION 2.0 npi 2013 npi electronic GmbH, Bauhofring 16, D-71732 Tamm, Germany Phone +49 (0)7141-9730230; Fax: +49 (0)7141-9730240 [email protected]; http://www.npielectronic.com PDES-02TX User Manual ___________________________________________________________________________ Table of Contents 1. Safety Regulations .............................................................................................................. 3 2. PDES System...................................................................................................................... 4 2.1. System Description...................................................................................................... 4 2.2. Description of the Front Panel..................................................................................... 5 2.3. Description of the Rear Panel...................................................................................... 7 3. External Valve .................................................................................................................... 8 Remote Valve Plate ..................................................................................................... 8 microJECT micro Valve Pipette Holder...................................................................... 9 4. Operation ............................................................................................................................ 10 5. Literature............................................................................................................................. 13 Microinjection into Oocytes ........................................................................................ 14 Fast drug application with microJECT (EHM) ........................................................... 14 6. Technical Data .................................................................................................................... 15 ___________________________________________________________________________ version 1.6 page 2 PDES-02TX User Manual ___________________________________________________________________________ 1. Safety Regulations VERY IMPORTANT: Instruments and components supplied by npi electronic are NOT intended for clinical use or medical purposes (e.g. for diagnosis or treatment of humans) or for any other life-supporting system. npi electronic disclaims any warranties for such purpose. Equipment supplied by npi electronic must be operated only by selected, trained and adequately instructed personnel. For details please consult the GENERAL TERMS OF DELIVERY AND CONDITIONS OF BUSINESS of npi electronic, D-71732 Tamm, Germany. 1) 2) 3) 4) 5) GENERAL: This system is designed for use in scientific laboratories and must be operated by trained staff only. General safety regulations for operating electrical devices should be followed. AC MAINS CONNECTION: While working with the npi systems, always adhere to the appropriate safety measures for handling electronic devices. Before using any device, please read manuals and instructions carefully. The device is to be operated only at 115/230 Volt 60/50 Hz AC. Please check for appropriate line voltage before connecting any system to mains. Always use a three-wire line cord and a mains power-plug with a protection contact connected to ground (protective earth). Before opening the cabinet, unplug the instrument. Unplug the instrument when replacing the fuse or changing line voltage. Replace fuse only with an appropriate specified type. STATIC ELECTRICITY: Electronic equipment is sensitive to static discharges. Some devices such as sensor inputs are equipped with very sensitive FET amplifiers, which can be damaged by electrostatic charge and must therefore be handled with care. Electrostatic discharge can be avoided by touching a grounded metal surface when changing or adjusting sensors. Always turn power off when adding or removing modules, connecting or disconnecting sensors, headstages or other components from the instrument or 19” cabinet. TEMPERATURE DRIFT / WARM-UP TIME: All analog electronic systems are sensitive to temperature changes. Therefore, all electronic instruments containing analog circuits should be used only in a warmed-up condition (i.e. after internal temperature has reached steady-state values). In most cases a warm-up period of 20-30 minutes is sufficient. HANDLING: Please protect the device from moisture, heat, radiation and corrosive chemicals. HIGH PRESSURE PRECAUTIONS: When working with PDES systems and components always adhere to the appropriate safety measures for handling high pressure pneumatic systems. Before using the PDES or any external pneumatic device please read manuals and instructions carefully. Always turn off pressure source before connecting or disconnecting the PDES system. Any component used (tubes, fittings etc.) must be specified for the maximum possible pressure. Do not use any aggressive, combustible or explosive gases. Only gases such as air, nitrogen, carbon dioxide, helium, etc. are allowed. Use only dry, oil free, filtered gases (max. 5 µm filter is allowed). Maximum input pressure must be below 5 bar (1 bar = 100,000 Pa). npi recommends an input pressure of 1 bar more than the maximum output pressure. ___________________________________________________________________________ version 1.6 page 3 PDES-02TX User Manual ___________________________________________________________________________ 2. PDES System 2.1. System Description Pressure ejection is a convenient method for applying both ionic and non-ionic solutions from micropipettes. This method is popular for two reasons. First, it can apply to almost all solutions. Second, the amount of solution ejected can be monitored by viewing the tip of the micropipette under a microscope. npi PDES units are designed for pressure ejection of drugs in physiological and pharmacological studies. PDES systems can be equipped with high pressure outputs (up to Pmax = 4 bar / 58 psi) for drug application with fine-tipped micropipettes or with low-range pressure output (Pmax = 2 bar / 29 psi) for controlled droplet application. Analog or digital timers and a remote control unit facilitate the use of these instruments. Each PDES system is housed in a 19" cabinet that can be mounted in a rack. It comprises of one or two channels. Each channel consists of a precision pressure regulator, an analog (or digital) pressure display, electronically controlled valves, control electronics and a regulated power supply. Ejection of drugs can be activated manually or via a TTL input. The operational status is indicated by a red / green LED. Each channel can be equipped with an "EXHAUST" coupling whereby a low "retain" pressure can be applied (analogous to the "retaining" current used in iontophoretic systems). In order to speed up drug ejection, PDES systems are available with the microJect option. These systems are equipped with a micro valve located in an injection holder. The micro valve has a switch time of less than 1 ms and a very small volume that has to be controlled, resulting in application times in the ms range. Mode of operation and timing is selected by controls at the front panel. If the internal timers are used the eject time is preset by a control and the time base can be selected by a toggle switch. Each channel can be turned off by using a switch which is combined with the timing control. The operational status is indicated by a red/green LED. No light indicates that the channel has been turned off, red means that the channel has been turned on, green indicates that injection takes place. The remote control unit is housed in a small box. For each channel it has a red LED that indicates if the respective channel is turned on and a toggle switch with a temporary and a fix position for starting drug application. The pressure connectors (quick connect type) are located at the rear panel of the instrument. Each channel is equipped with an INPUT coupling where the pressure source is connected, an OUTPUT coupling where the injection pipette is connected and an EXHAUST coupling where a low "retain" pressure can be applied in order to avoid capillary effects at the tip of the injection pipette (analogous to the "retaining" current used in iontophoretic systems). This pressure must be generated by an additional pneumatic device. Please contact npi electronic for details. The injection pressure is preset by a precision pressure regulator. The pressure is displayed on an analog (standard) or digital (option) manometer. Additional pneumatic devices (tubes, fittings connectors, filters etc.) are available. Please contact npi electronic for details. A calibration procedure allowing quantitative drug application is described by Hofmeier and Lux (1981) (see chapter 5). ___________________________________________________________________________ version 1.6 page 4 PDES-02TX User Manual ___________________________________________________________________________ 2.2. Description of the Front Panel Figure 1: PDES-2TX front panel view (the numbers are related to those in the text below) ___________________________________________________________________________ version 1.6 page 5 PDES-02TX User Manual ___________________________________________________________________________ PDES systems are available with one or two channels. Since both channels are identical only channel A is described. (1) POWER switch Switch to turn POWER on or off (2) Pressure regulator Rotary knob for regulating the pressure of channel A. (3) Manometer Display indicating pressure at channel A (4) ON / EJECT LED Indicates the operational status of channel A. red light: channel has been turned on, valve is closed green light: valve is open (5) TIME BASE switch Switch to set the TIME BASE of channel A (see also #7). The total ejection time is the reading of this potentiometer multiplied by the reading of the TIMER A potentiometer (#7). (6) Operation mode switch CONT.: TIMER: EXTERN: OFF: The valve is continuously open The internal timer is used. The timer can be started via a TTL HIGH signal at #9 or by pushing a pushbutton connected to #8 The valve is open as long as the input signal at #9 is high. The PDES module is turned OFF, the valve is closed. LED (#4) is also off. The source pressure value is still shown at the manometer #3, but opening of the valve is disabled in OFF position. (see also chapter 3). (7) Timer potentiometer Potentiometer to set the ejection time of channel A. The total ejection time is the reading of this potentiometer multiplied by the reading of the TIME BASE switch (#5). Note: Due to tolerances of resistors and capacitors the time preset with the analog timer may vary up to 20%! (8) START button Push button for starting operation of channel A in TIMER or EXTERNAL mode (9) TTL INPUT connector BNC connector for external operation of channel A with a TTL HI signal (+ 5V). In TIMER mode the internal timer is triggered by the TTL signal. In EXTERN mode the valve is open as long as the TTL signal is HI. (10) TIMING MONITOR BNC connector providing a TTL signal that indicates the status of the regulated injection valve of channel A (HI = valve open, LO = valve closed) ___________________________________________________________________________ version 1.6 page 6 PDES-02TX User Manual ___________________________________________________________________________ (11) REMOTE CONTROL connector Connector for the REMOTE CONTROL unit (see Figure 5) 2.3. Description of the Rear Panel Figure 2: PDES-2TX rear panel view (the numbers are related to those in the text below) The following connectors are located at the rear panel. Connectors are mentioned only for CHANNEL A. Since both channels are identical, only one channel is described. (1) VALVE connector (optional) Connector for the electrical connection of the VALVE located in a remote valve box or in the microJECT. Important: This connector is not used for systems without a remote valve or microJECT. (2) OUT connector Connector for connecting the injection micropipette or for connecting the pressure tubing of the external valve on the remote valve plate. The EJECT pressure is supplied to this connector. (3) EXHAUST connector (optional) Connector for connecting the HOLD pressure source. If no HOLD pressure is connected, the system is exhausted as long as no pressure is applied to the pipette. (4) SOURCE IN connector Connector for connecting the filtered, dry and oil-free gas source (5 bar max.). Note: npi recommends an input pressure of 1 bar more than the maximum output pressure. (5) CHASSIS This connector is linked to chassis. (6) GROUND This connector is linked to the internal system ground. (7) POWER IN connector Jack for connecting the external power supply. Minimum: 12 V / 0.5 A for one channel and 12 V / 1 A for two channel instruments, inner pin positive. ___________________________________________________________________________ version 1.6 page 7 PDES-02TX User Manual ___________________________________________________________________________ 3. External Valve External valve(s) for the PDES system are either mounted on a remote valve plate or in the microJECT micro valve pipette holder. Remote Valve Plate The valves which are controlled by the PDES-02DX are located on the remote valve plate (see Figure 3). Tubing and cable of the external valves are connected at the rear panel of the PDES system (refer to chapter 2.3). Exhaust is usually not connected. Figure 3: external valves on remote valve plate 1: electrical connection (black) 2: EJECT pressure tubing (red) 3: connector for ejection pipette 4: exhaust connector (optional) ___________________________________________________________________________ version 1.6 page 8 PDES-02TX User Manual ___________________________________________________________________________ microJECT micro Valve Pipette Holder The valve which is controlled by the PDES-02DX is located in the micro valve pipette holder, called microJECT (see Figure 4). Tubing and cable of the microJECT are connected at the rear panel of the PDES system (refer to chapter 2.3). Exhaust is usually not connected. Figure 4: microJECT 1: pipette connector 2: connector for EJECT pressure 3: connector for EXHAUST pressure (optional) 4: electrical connection Important: In experiments with high pressures (> 1 bar) it might be necessary to insert 2 seals in the pipette connector in order to prevent the pipette from moving in any direction. Caution:Pipettes that are not rigidly fixed in the pipette connector might be pressed out of the connector by high pressure. Always adhere to the appropriate safety measures. ___________________________________________________________________________ version 1.6 page 9 PDES-02TX User Manual ___________________________________________________________________________ 4. Operation o Connect the gas source to the INPUT connector at the rear panel. The gas source must be filtered by a 5 µm filter element. Important: Do not connect sources of OXYGEN or COMBUSTIBLE gases!! The gas source MUST be dry and oil free!! Please use a degreaser and filter the gas source by a 5 µm filter element. o Connect injection micropipette to the OUTPUT connector at the rear panel. or (external valve) o Connect the pressure tubing of the external valve to the OUT connector and the electrical connector to the VALVE connector at the rear panel. o Connect your ejection pipettes to the external valve using tubing and an ejection pipette holder. o Turn on pressure and adjust the pressure to the desired value using the pressure regulator. o Connect a digital timing unit to the INPUT BNC connector at the front panel. o For remote operation connect the remote control unit to the REMOTE CONTROL connector. o Turn channel on (TIMER control). o The LED is red when no ejection occurs and green when the pressure is applied to the pipette. o Select the operation mode using the respective toggle switch at the front panel. In the CONT. position the application can be controlled manually. In the EXT. position the duration of the application is determined directly by the duration of the TTL pulse applied to TTL INPUT. In the TIMER position the duration is preset by the timer control and time base of the PDES. o REMOTE control: The selected operating mode determines the way the REMOTE control (see Figure 5) works. In the CONTINUOUS mode the remote control unit is disabled. In the EXTERN mode the valve is open as long the REMOTE control switch is activated (cont. = continuous, = temporarily). In the TIMER mode the internal timer is triggered by activation of the REMOTE control switch. The red LED indicates the channel that has been turned on. ___________________________________________________________________________ version 1.6 page 10 PDES-02TX User Manual ___________________________________________________________________________ Figure 5: PDES remote control Note: Green LED indicates that the valve is not connected properly or continuous operation. ___________________________________________________________________________ version 1.6 page 11 PDES-02TX User Manual ___________________________________________________________________________ Figure 6: Operation modes of the PDES-2TX ___________________________________________________________________________ version 1.6 page 12 PDES-02TX User Manual ___________________________________________________________________________ 5. Literature o Bickmeyer, U., Heine, M., Manzke, T., & Richter, D. W. (2002). Differential modulation of Ih by 5-HT receptors in mouse CA1 hippocampal neurons. Eur.J.Neurosci. 16, 209-218. o Eggermann, E. & Feldmeyer, D. (2009). Cholinergic filtering in the recurrent excitatory microcircuit of cortical layer 4. Proc.Natl.Acad.Sci.U.S.A. 106, 11753-11758. o Garaschuk, O., Milos, R. I., & Konnerth, A. (2006). Targeted bulk-loading of fluorescent indicators for two-photon brain imaging in vivo. Nat.Protocols 1, 380-386. o Guzman, J. N., Hernandez, A., Galarraga, E., Tapia, D., Laville, A., Vergara, R., Aceves, J., & Bargas, J. (2003). Dopaminergic modulation of axon collaterals interconnecting spiny neurons of the rat striatum. J Neurosci. 23, 8931-8940. o Hanganu, I. L. & Luhmann, H. J. (2004). Functional Nicotinic Acetylcholine Receptors on Subplate Neurons in Neonatal Rat Somatosensory Cortex. Journal of Neurophysiology 92, 189-198. o Kilb, W., Hanganu, I. L., Okabe, A., Sava, B. A., Shimizu-Okabe, C., Fukuda, A., & Luhmann, H. J. (2008). Glycine receptors mediate excitation of subplate neurons in neonatal rat cerebral cortex. J.Neurophysiol. 100, 698-707. o Kolbaev, S. & Draguhn, A. (2008). Glutamine-induced membrane currents in cultured rat hippocampal neurons. Eur.J Neurosci. 28, 535-545. o Langer, J. & Rose, C. R. (2009). Synaptically induced sodium signals in hippocampal astrocytes in situ. J Physiol. 587, 5859-5877. o Lin, B. J., Chen, T. W., & Schild, D. (2007). Cell type-specific relationships between spiking and [Ca2+]i in neurons of the Xenopus tadpole olfactory bulb. Journal of Physiology 582, 163-175. o Marandi, N., Konnerth, A., & Garaschuk, O. (2002). Two-photon chloride imaging in neurons of brain slices. Pflugers Arch. 445, 357-365. o Partridge, L.D., H.U. Zeilhofer and D. Swandulla (1998) Combined Whole-Cell and Single-Channel Current Measurement with Quantitative Ca2+ Injection or Fura-2 Measurement of Ca2+, in P.M. Conn (Ed.) Ion Channels Part B, Methods in Enzymology Vol. 293, Academic Press SanDiego. o Ponimaskin, E., Dumuis, A., Gaven, F., Barthet, G., Heine, M., Glebov, K., Richter, D. W., & Oppermann, M. (2005). Palmitoylation of the 5-Hydroxytryptamine4a Receptor Regulates Receptor Phosphorylation, Desensitization, and {beta}-Arrestin-Mediated Endocytosis. Molecular Pharmacology 67, 1434-1443. o Qiu, J., Yao, S., Hindmarch, C., Antunes, V., Paton, J., & Murphy, D. (2007). Transcription factor expression in the hypothalamo-neurohypophyseal system of the dehydrated rat: upregulation of gonadotrophin inducible transcription factor 1 mRNA is mediated by cAMP-dependent protein kinase A. J Neurosci. 27, 2196-2203. o Stepanyan, R. & Frolenkov, G. I. (2009). Fast adaptation and Ca2+ sensitivity of the mechanotransducer require myosin-XVa in inner but not outer cochlear hair cells. Journal of Neuroscience 29, 4023-4034. o Wolfram, V. & Juusola, M. (2004). The Impact of Rearing Conditions and Short-Term Light Exposure on Signaling Performance in Drosophila Photoreceptors. Journal of Neurophysiology 92, 1918-1927. ___________________________________________________________________________ version 1.6 page 13 PDES-02TX User Manual ___________________________________________________________________________ Microinjection into Oocytes o Wetzel, C. H., Oles, M., Wellerdieck, C., Kuczkowiak, M., Gisselmann, G., & Hatt, H. (1999). Specificity and sensitivity of a human olfactory receptor functionally expressed in human embryonic kidney 293 cells and Xenopus Laevis oocytes. J.Neurosci. 19, 74267433. Fast drug application with microJECT (EHM) o Courjaret, R., Troger, M., & Deitmer, J. W. (2009). Suppression of GABA input by A1 adenosine receptor activation in rat cerebellar granule cells. Neuroscience. 162, 946-958. o Heck, N., Kilb, W., Reiprich, P., Kubota, H., Furukawa, T., Fukuda, A., & Luhmann, H. J. (2007). GABA-A receptors regulate neocortical neuronal migration in vitro and in vivo. Cereb Cortex. 17, 138-148. ___________________________________________________________________________ version 1.6 page 14 PDES-02TX User Manual ___________________________________________________________________________ 6. Technical Data Source gas: air, nitrogen, helium etc. no aggressive, combustible or explosive gases, filtered by a 5 µm filter element. Pressure range: input pressure: max. 5 bar (1 bar = 105 Pa) pressure control range: 0-4 bar or 0-2 bar; display range 0-4 bar or 0-2 bar Input and output couplings: quick connect type Tubes: input: output: 6 mm OD 4 mm OD Status / EJECT time indicator: red/green LED red light: channel has been turned on, valve is closed green light: valve is open Mode selection: three position toggle switch, (TIMER, CONTINUOUS, EXTERN (TTL)) Minimum pressure pulsed width: 100 ms Analog timer (standard version): 0.001 - 0.1, 0.01 - 1 s, 0.1 - 10 s and 1 - 100 s linear control, range set by toggle switch time base selector (0.01, 0.1 s, 1 s, 10 s) Pulse input: standard BNC connector, TTL (LO = 0-2.5 V, HI = 3-5 V), input impedance 10 k Timing output: standard BNC connector, TTL (LO = 0-2.5 V, HI = 3-5 V) Power requirements: 1 channel: 2 channels: DC, 12 V, 0.5 A min. DC, 12 V, 1.0 A min. Remote control (option): Toggle switch and status LED for each channel, size 2.5x4x10 cm ___________________________________________________________________________ version 1.6 page 15