Download Sony MZ-300 User's Manual

Transcript

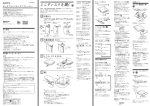

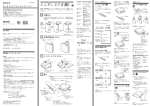

MZ-E300 SERVICE MANUAL US Model Canadian Model AEP Model E Model Chinese Model Ver 1.2 2001.12 US and foreign patents licensed from Dolby Laboratories Licensing Corporation Model Name Using Similar Mechanism NEW MD Mechanism Type MT-MZE300-176 Optical Pick-up Mechanism Type LCX-4E SPECIFICATIONS System Audio playing system MiniDisc digital audio system Laser diode properties Material: GaAlAs Wavelength: λ = 790 nm Emission duration: continuous Laser output: less than 44.6 µW* * This output is the value measured at a distance of 200 mm from the objective lens surface on the optical pick-up block with 7 mm aperture. Revolutions Approx. 700 rpm to 1,500 rpm Error correction ACIRC (Advanced Cross Interleave Reed Solomon Code) Sampling frequency 44.1 kHz Coding ATRAC (Adaptive TRansform Acoustic Coding) Modulation system EFM (Eight to Fourteen Modulation) Number of channels 2 stereo channels 1 monaural channel Frequency response 20 to 20,000 Hz ± 3 dB Wow and Flutter Below measurable limits Power requirements One LR6 (size AA) battery (not supplied) Battery operation time Battery life Battery LR6 (SG) Sony Alkaline dry battery 2) (EIAJ1)) Playback Approx. 33 hours 1) Measured in accordance with the EIAJ (Electronic Industries Association of Japan) standard (using a Sony MDW-series Mini-disc). 2) When using a Sony LR6 (SG) “STAMINA” alkaline dry battery (produced in Japan). Note The effective battery life may be shorter than that indicated above, depending on operating conditions, the surrounding temperature, and the battery type. Dimensions Approx. 83.0 x 26.7 x 76.5 mm (w/h/d) (3 3/8 x 1 1/16 x 3 1/8 in.) (not including projecting parts and controls) Mass Approx. 83.0 g (3.0 oz) (the player only) Supplied accessories Headphones/earphones (1) Design and specifications are subject to change without notice. PORTABLE MINIDISC PLAYER 9-873-064-13 Sony Corporation 2001L0200-1 © 2001.12 Personal Audio Company Published by Sony Engineering Corporation MZ-E300 SECTION 1 SERVICING NOTE TABLE OF CONTENTS Specifications ........................................................................... 1 1. SERVICING NOTE ...................................................... 2 When repairing this device with the power on, if you remove the main board, this device stops working. In this case, you work without the device stopping by fastening the hook of the Open/Close detection switch (S808). 2. GENERAL Preparing a Power Source .................................................. 3 To Connect the Headphones/Earphones ............................ 3 Playing an MD ................................................................... 3 3. DISASSEMBLY 3-1. “Lid ASSY, Upper”, Holder ASSY ............................ 3-2. Mechanism Deck ........................................................ 3-3. Main Board ................................................................. 3-4. Optical Pick-up ASSY ................................................ 4 4 5 5 Open/Close detection switch (S808) 4. TEST MODE .................................................................. 6 Note on IC replacement 5. DIAGRAMS 5-1. Explanation of IC Terminals ..................................... 5-2. Block Diagram .......................................................... 5-3. Printed Wiring Boards – Main Section (1/2) – ......... 5-4. Printed Wiring Boards – Main Section (2/2) – ......... 5-5. Schematic Diagram – Main Section (1/3) – ............. 5-6. Schematic Diagram – Main Section (2/3) – ............. 5-7. Schematic Diagram – Main Section (3/3) – ............. 13 18 19 20 21 22 23 6. EXPLODED VIEWS 6-1. Main Section ............................................................. 29 6-2. Mechanism Deck Section ......................................... 30 7. ELECTRICAL PARTS LIST ................................... 31 CAUTION Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure. Flexible Circuit Board Repairing • Keep the temperature of the soldering iron around 270°C during repairing. • Do not touch the soldering iron on the same conductor of the circuit board (within 3 times). • Be careful not to apply force on the conductor when soldering or unsoldering. Notes on chip component replacement • Never reuse a disconnected chip component. • Notice that the minus side of a tantalum capacitor may be damaged by heat. SAFETY-RELATED COMPONENT WARNING!! COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. ATTENTION AU COMPOSANT AYANT RAPPORT À LA SÉCURITÉ! LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY. 2 If using flux on replacing IC801 etc., clean it with alcohol or equivalent, and after that, check carefully there are no dust or rags in between pins. Especially, be sure to check between pins 4 and 5. SECTION 2 GENERAL MZ-E300 This section is extracted from instruction manual. 3 MZ-E300 SECTION 3 DISASSEMBLY • The equipment can be removed using the following procedure. Set “Lid ASSY, Upper”, Holder ASSY Main board Mechanism deck Optical pick-up ASSY Note : Follow the disassembly procedure in the numerical order given. 3-1. “LID ASSY, UPPER”, HOLDER ASSY Note : Holder ASSY installation 1. Attach the holes on Holder ASSY to the projections on right and left sides. 2. Attach Spring (POP/L) as shown in the figure. 3 Lid ASSY , Upper 1 Screws (1.4),MI 2 Move it away from projection Holder ASSY Reinforcement 4 Move it away from projection Spring (POP/L) 5 Holder ASSY 4 Move it away from projection Case ASSY 3-2. MECHANISM DECK 1 Screw (MD), step Mechanism deck 2 5 Motor flexible board 6 OP flexible board 7 Screws, tapping (1.7) 4 8 Reinforcement 3 Claw Case ASSY 4 MZ-E300 3-3. MAIN BOARD Note : On installation of main board, adjust the position of both switch (S809) and knob (HOLD). 1 Screws, tapping (1.7) Main board 3 Knob (HOLD) 2 Claw 3-4. OPTICAL PICK-UP ASSY Optical pick-up ASSY (LCX-4E) 1 Washer 2 Gear (SA) 5 3 Screw (MI 1.4) 4 Spring, thrust detent 5 MZ-E300 SECTION 4 TEST MODE 4-1. GENERAL Lead wires: 4 leads • When entered in the TEST MODE, this set provides the Overall Adjustment mode which allows CD and MO discs to be automatically adjusted. In the Overall Adjustment mode, performs adjustments in sequence automatically, and displays the faulty location if any fault is found. In the Manual mode, selected adjustments can be performed automatically. • Operations in the Overall Adjustment mode can be performed either via the main unit, or the keys of a remote control unit. Note that this device does not include a remote control unit. Therefore, since no connection terminals for a remote control are provided either, a connection device must be used in order to allow a suitable remote control unit to be connected. 4-2. SETTING THE TEST MODE BP801 (TEST) C806 TP809 C8 R830 C810 MAIN BOARD (SIDE A) 15 R803 FB801 Connection Following parts are required Remote commander: RM-MZ2N (1-418-493-71) After RM-MZE1 applicable to 2.4V (Not applicable to remote commanders before RM-MZE1). Jack: 7 poles jack for phones/remote commander (1-793-288-61) 4-2-1. How to set the TEST MODE To set the TEST MODE, three methods are available. 1 Solder bridge and short BP801 (TEST) on the main board. Then turn on the power. TP808 R907 20 21 C80 X801 TP816 C805 R82 R_VDD R_DATA R_KEY R_GND JACK: 1-793-288-61 4 3 2 1 MAIN BOARD (SIDE A) 1 2 TP804 3 BP801 OPEN : Normal mode SHORT : Test mode 2 Using a pair of tweezers or similar tool short-circuit TP804 and TP805 on the main board and turn on the power. 4 TP803 TP802 TP801 TP805 TP806 TP951 MAIN BOARD (SIDE A) TP804 TP805 TP804 TP803 TP802 TP801 TP805 TP806 TP951 3 In the normal mode, operate the keys on the set and those on the remote control as specified below: Turn on HOLD switch on the set. Holding down x (STOP) key on the set, press the keys on the remote control in the following sequence: >N t >N t . t . t >N t . t >N t . t X t X 6 MZ-E300 Ver 1.2 2001.12 4-2-2. Operations when the TEST MODE is set When the TEST MODE is entered, the system switches to the display check mode within the TEST MODE. From this mode, the other Test modes can be accessed. When the TEST MODE is set, the LCD repeats a cycle of the following displays: Main unit LCD 4-3. TEST MODE STRUCTURE * Manual mode operation can only be performed via the remote control unit. Use the connection tool to connect the remote control unit. The display of the main unit shows “Adj”. Test Mode (Display Check Mode) F 1SHUFF AVLS BASS + key u 888:88 Manual Mode (Remote control only) x All on key + key Servo Mode Audio Mode All off Power Mode 130 key Microprocessor version display OP Alignment Mode Press and hold down x key Display segment check mode (Main unit only) Remote control LCD Release 888 F 1SHUFF PGM u SOUND 1 2 BASS 1 2 . or x key key Overall Adjustment Mode All on x key 4-4. MANUAL MODE All off 4-4-1. Outline of the function 008 V1.300 Microprocessor version display The remote control display varies with the type of remote control unit used. (Example shown: RM-MC10L) • The current display is retained as long as either the PLAY MODE/DISPLAY key on the main unit or the PLAY MODE key on the remote control unit is pressed and held. 4-2-3. How to release the TEST MODE When method 1 was used: Turn off the power and open the solder bridge on BP801 on the main board. Note: The solder should be removed clean. The remaining solder may make a short with the chassis and other part. When method 2 or 3 was used: Turn off the power. Note: If electrical adjustment (see page 8) has not been finished completely, always start in the test mode. (The set cannot start in normal mode) The Manual mode is designed to perform adjustments and operational checks on the set’s operation according to each individual function. Usually, no adjustments are made in this mode. However, the Manual mode is used to clear the memory before performing automatic adjustments in the Overall Adjustment mode. * Manual mode operation can only be performed via the remote control unit. Use the connection tool to connect the remote control unit. The display of the main unit shows “Adj”. 4-4-2. How to set the Manual mode 1. Set the TEST MODE and press + key to set the Manual mode. Remote control LCD display 000 AAAS CC 2. When the test mode display shows “100”, “200”, “300”, “500”, “600”, “700”, “800”, or “900”, the optical pickup can be moved inside and outside of the SLED perimeter by continuously pressing the ( > N or . keys on the main unit. 7 MZ-E300 3. Each test item is assigned with a three-digit item number. The 100th place is a major item, 10th place is a middle item, and unit place is a minor item. Change Major Item > N key x x 4-5-1. Outline of the function + key : 100th place of mode number increase key : 100th place of mode number decrease This mode is designed to adjust the servo system automatically by going through all the adjustment items. Usually, this mode is used to perform automatic adjustments when servicing the set. + key : 10th place of mode number increase key : 10th place of mode number decrease 4-6. NV RESET key Change Middle Item > N key 4-5. OVERALL ADJUSTMENT MODE key > N key : Unit place of mode number Change Minor Item increase . key : Unit place of mode number Power: Connect the battery terminals to a stable DC 1.5V power supply, or insert fresh batteries (size “AA”, IEC “LR6”). Two different methods apply for NV reset, depending on whether the main unit or a remote control unit is used. NV reset via main unit 1. Enter test mode. decrease Change Adjustment Value + key : Up key : Down 2. Use the – key or the . key to set the device to Overall Adjustment mode. Write Adjustment Value ASS X key : When adjusted value is changed : Adjusted value is written. When adjusted value is not changed : That item is adjusted automatically. 4. During each test mode, the display is changed from one to another each time DISPLAY key is pressed (Remote control only). 3. Press the PLAY MODE/DISPLAY key. “CL” starts to flash. AdJ cL 4. Press the PLAY MODE/DISPLAY key once more. “CL” stops flashing and remains lit, thus concluding NV reset. Address Value & Adjustment Value AdJ cL LCD display 011 XXXSXX 5. Press the x key to return to test mode. Block Error Value & Adjustment Value LCD display 011 XX BXX ADIP Error Value & Adjustment Value LCD display 011 XX AXX Jitter Value & Adjustment Value LCD display * Functions are displayed, but cannot be used via this unit. 011 XXXJXX NV reset via remote control 1. Set the TEST MODE. 2. Set the Manual mode and set the item No. 021, Reset NV. LCD display 021 AAAS CC 3. Press X key on the remote control. LCD display Power Adjustment Value 021 AAAS CC LCD display 731 XX VXX 4. Press X key on the remote control again. After the voltage indicator appears, press the DISPLAY key twice. Memory Monitor Mode LCD display XXX: Each Value XX: Adjustment Value for Item number Note: In the Power mode, the item title display is only displayed. 5. To terminate the Manual mode and return to the TEST MODE, press x key. 8 Flash CC 021 AAAS CC 5. Press x key to terminate the Manual mode and return to the TEST MODE. MZ-E300 4-6-1. Electrical offset adjustment method Note: Doing adjustment by the state that a disc does not enter. 1. Confirm the power voltage is 1.5V. 2. Set to the test mode. 3. Press the – key of main unit activates the overall adjustment mode. Main unit LCD display 4-7. OVERALL ADJUSTMENT MODE 4-7-1. Overall adjustment mode structure TEST MODE (Display Check Mode) VOL – key or . key ASS Overall Adjustment Title Display(ASSY**) . key 4. Press the + key. x CD overall Adjustment > N key Main unit LCD display > N key MO overall Adjustment 5. Press the + key once more. Adjustment is complete when the adjustment value appears in the “XX” position. VOL + key Electrical offset Adjustment key 4-6-2. Display segment check mode 1. Enter test mode. Display continuously alternates between the following three conditions: entire LCD is lit, entire LCD is extinguished, version info is shown, and so on. PLAY MODE/DISPLAY key 035: XX 2. Press and hold the x key on the main unit to enter display segment check mode. * Should segments not be displayed correctly at this point, a shortcircuited COM terminal and/or SEG terminal on the microprocessor chip (IC801) are possible causes. 3. Display returns to condition “1” as soon as the x key is released. key x x NV reset key x key key Perform overall adjustments according to the following procedures (procedures may differ depending on the microprocessor chip version used). For Ver. 1.10, if it is no good in the overall adjustment, please repeat the overall adjustment several times. Microprocessor Version 1.10 1 Clear NV. 2 Electric offset adjustment. 3 Rewriting of RAM 633h 1. switch to manual mode No. 100. 2. Press the DISPLAY key on the remote control unit 6 times consecutively to enter RAM mode. 3. Change the RAM address to 633h. Use the following keys on the remote control unit to change the digits of the RAM address: “The DISPLAY key for the first digit (hundreds), the x key for the second digit (tens) and the >B key or the . key for the third digits (units).” 4. Use the + and – keys on the remote control unit to set the adjustment value of No.633h to 03h and press once the pause key on the remote control unit to write this value to NV. “(If NV is cleared, the value is 00h.) 5. Press the DISPLAY key once more to change the display to “address and adjustment value display”. 6. Switch to the overall adjustment. 4 CD overall adjustment * (Not to turn off the power between the items 3 and 4 .) 9 MZ-E300 Ver 1.1 2001.03 5 Rewriting of the adjustment value. 1.After CD overall adjustment, switch to manual mode No. 321 in the condition the disc is in. 2.Press – key on the remote control unit to set 1 step down the adjustment value of No. 321, and press the pause key on the remote control unit to write this value to NV. 3.Press the >B key on the remote control unit to switch to manual mode No. 323. 4.Press the pause key on the remote control unit to set to the automatic adjustment. During adjusting automatically, the adjustment value turns on and off, so wait for the time the adjustment value is on. 5.Press the >B key on the remote control unit to switch to manual mode No. 345. 6.Note down the current adjustment value of No. 345 (value X). Use the + and – keys on the remote control unit to set the adjustment value of No. 345 to the value (Y) determined by the formula below, and press the pause key on the remote control unit to write this value to NV. Formula: X x 1.18 = Y * Since X and Y are 2’sC, attention must be paid to codes. And the maximum value of Y must be 7Fh. (Never set it to the negative value.) Example: Since X = 2Bh, Y = 2Bh x 1.18 = 33h 6 Change the disc to MO overall adjustment disc (GA1 disc). Switch to manual mode No.114. Press the pause key on the remotecontrol unit to set to the automatic adjustment. After adjustment, pull out the battery from the set to turn off the power. Then insert the battery again. 7 MO overall adjustment. Microprocessor Version 1.20 and higher 5 Change the disc to MO overall adjustment disc (GA1 disc). Switch to manual mode No.114. Press the pause key on the remotecontrol unit to set to the automatic adjustment. After adjustment, pull out the battery from the set to turn off the power. Then insert the battery again. 6 MO overall adjustment. 4-7-2. Overall CD and MO adjustment method 1. Set the TEST MODE and press VOL – key or . key to set the Overall Adjustment mode. Main unit LCD display ASS 2. Insert CD disc in the set, and press . key to set the Overall CD Adjustment mode. Automatic adjustments are made. Main unit LCD display XXX: XXX: Item No. for which an adjustment is being executed. YY: Adjustment Value 3. If NG in the overall CD adjustments, return to Reset NV and perform from the electrical offset adjustment again. The NG item and “ng” alternately flash on the main unit LCD display. 1 Clear NV. 2 Electric offset adjustment. XXX: 3 CD overall adjustment. 4 Rewriting of the adjustment value. 1.After CD overall adjustment, switch to manual mode No. 321 in the condition the disc is in. 2.Press – key on the remote control unit to set 1 step down the adjustment value of No. 321, and press the pause key on the remote control unit to write this value to NV. 3.Press the >B key on the remote control unit to switch to manual mode No. 323. 4.Press the pause key on the remote control unit to set to the automatic adjustment. During adjusting automatically, the adjustment value turns on and off, so wait for the time the adjustment value is on. 5.Press the >B key on the remote control unit to switch to manual mode No. 345. 6.Note down the current adjustment value of No. 345 (value X). Use the + and – keys on the remote control unit to set the adjustment value of No. 345 to the value (Y) determined by the formula below, and press the pause key on the remote control unit to write this value to NV. Formula: X x 1.18 = Y * Since X and Y are 2’sC, attention must be paid to codes. And the maximum value of Y must be 7Fh. (Never set it to the negative value.) Example: Since X = 2Bh, Y = 2Bh x 1.18 = 33h n XXX: NG item No. YY: Adjustment Value 4. If OK through the overall CD adjustments, then perform overall MO adjustments. Main unit LCD display End:cd 5. Insert MO disc in the set, and press > N key to set the Overall MO Adjustment mode. Automatic adjustments are made. Main unit LCD display XXX: XXX: Item No. for which an adjustment is being executed. YY: Adjustment Value 10 MZ-E300 6. If NG in the overall MO adjustments, return to Reset NV and perform the adjustment again. The NG item and “ng” alternately flash on the main unit LCD display. XXX: n XXX: NG item No. YY: Adjustment Value 7. If OK through the overall MO adjustments, press x key to return to the TEST MODE and terminate the Overall Adjustment mode. Main unit LCD display 11 MZ-E300 4-7-3. Overall CD and MO adjustment items 1. Overall offset adjustment Item No. Description Item No. Description 100h GRV setting servo off 030h GRV setting servo off 112h ALFA offset adjustment 035h Laser ON/OFF Electric offset differential measurement 113h IJ offset adjustment 114h FE offset adjustment 118h AW_DW_OFFSET 200h LPIT setting servo off 2. CD overall adjustment Item No. 300h Description HPIT setting servo off 312h ALFA offset adjustment 313h IJ offset adjustment 314h FE offset adjustment 571h CLV start 561h Move to inside of SLED perimeter 562h Move to outside of SLED perimeter 320h Focus on 323h TE offset adjustment 321h TE gain adjustment 328h TWPP gain adjustment 829h TWPP gain [LPIT] adjustment value write 323h TE offset adjustment 324h OFTRK adjustment 330h Tracking ON 336h ABCD gain adjustment 337h KF gain adjustment 338h RF gain adjustment 344h FOCUS gain adjustment 345h Tracking gain adjustment 521h Twin axis sensitivity compensation (inside perimeter) 571h CLV START 561h Move to inside of SLED perimeter 220h Focus on 223h TE offset adjustment 221h TE gain adjustment 223h TE offset adjustment 226h Tracking Drive Voltage = “00h” setting 230h Tracking ON 236h ABCD gain adjustment 237h KF gain adjustment 238h RF gain adjustment 244h Focus gain adjustment 245h Tracking gain adjustment 110h GRV setting servo off (CLV remains as is) 562h Move to outside of SLED perimeter 120h Focus on 122h TE offset adjustment (TON) 121h TE gain adjustment 122h TE offset adjustment (TON) 123h TE offset adjustment (TEIN) 124h TE offset adjustment (TWPP) 125h OFTRK adjustment 130h Tracking ON 522h Twin axis sensitivity compensation (outside perimeter) 341h Field of vision oscillation check 144h Focus gain adjustment HPIT setting servo OFF 145h Tracking gain adjustment 139h bpf f0 adjustment 131h TE offset adjustment (TWPP/RF) 132h TE offset adjustment (TWPP/DSP) 136h ABCD gain adjustment 137h KF gain adjustment 134h TWPP gain adjustment 131h TE offset adjustment (TWPP/RF) 132h TE offset adjustment (TWPP/DSP) 138h RF gain adjustment 141h Field of vision oscillation check 100h GRV setting servo OFF 300h 12 3. MO overall adjustment MZ-E300 SECTION 5 DIAGRAMS 5-1. EXPLANATION OF IC TERMINALS • IC601 LC89642-8B-E (DIGITAL SIGNAL PROCESSOR, DIGITAL SERVO SIGNAL PROCESSOR, ATRAC ENCODER/DECODER, 8MBIT D-RAM, D/A CONVERTER) Pin No. Pin name I/O Description 1 FR I Connected to Bias resistor for VTEC oscillating frequency 2 ISET I Connected to Bias resistor for VTEC current charge pump 3 VCVDD — Power supply for VTEC 4 PDD O VTEC current charge pump output 5 TEST3 I Input for test 6 TEST2 I Input for test 7 SLCO O Slice level output for HF signal 8 SLCIST I Connected to Bias resistor for the slice level adjusting amplifier 9 EFMIN I HF signal input 10 RESETB I System reset 11 TEST1 I Input for test 12 HFL I Track detection signal input 13 VDD2 — Power supply 14 VSS — Ground 15 VDD1 — Internal power supply 16 AVSS1 — Ground for digital servo 17 PEAK I PEAK signal input 18 BOTTOM I BOTTOM signal input 19 ABCD I Main beam quantity signal input 20 TE I Tracking error signal input 21 FE I Focus error signal input 22 VC I Center potential input 23 AVDD1 — Power supply for digital servo 24 MAD9 O* Address output to DRAM (NC) 25 DSW1 O* Disc mode select output 26 MAD8 O* Address output to DRAM (NC) 27 DSW0 O* Disc mode select output 28 MAD7 O* Address output to DRAM (NC) 29 SGC O* AGC control signal output 30 MAD6 O* Address output to DRAM (NC) 31 AOFFSET O* ABCD offset control signal output 32 MAD5 O* Address output to DRAM (NC) 33 FOFFSET O* Focus offset control signal output 34 TOFFSET O* Tracking offset control signal output 35 MAD4 O* Address output to DRAM (NC) 36 TBAL O* Tracking balance control signal output 37 LDREF O* Laser control signal output 38 FBAL O* Focus balance control signal output 39 VDD1 — Internal power supply 40 VSS — Ground 41 VDD2 — Power supply 42 MAD3 O* Address output to DRAM (NC) 43 SPPWMF O* Spindle PWM output 44 SPPWMR O* Spindle PWM output 45 SLPWMF O* Sled PWM output 13 MZ-E300 Pin No. Pin name I/O 46 MAD2 O* 47 SLPWMR O* Sled PWM output 48 MAD1 O* Address output to DRAM (NC) 49 FOPWMF O* Focus PWM output 50 MAD0 O* Address output to DRAM (NC) 51 FOPWMR O* Focus PWM output 52 TRPWMF O* Tracking PWM output 53 TRPWMR O* Tracking PWM output 54 MAD10 O* Address output to DRAM (NC) 55 AVDD — Power supply for 1bit DAC 56 OUTL O 1bit DAC L channel output 57 OUTR O 1bit DAC R channel output 58 AVSS — Ground for 1bit DAC 59 VDD2 — 60 XIN I 16.9344MHz oscillation input 61 XOUT O 16.9344MHz oscillation output 62 VSS — Ground 63 VDD1 — Internal power supply 64 F16M O* 16.9344MHz output 65 ENH O* De-emphasis instruction output 66 LRCO O* LR clock output 67 DDATA O* Audio expansion data output 68 BCO O* Bit clock output 69 DDOUT O* Digital audio output 70 SMON3 O* Monitor signal output 71 SMON2 O* Monitor signal output 72 SMON1 O* Monitor signal output 73 SMON0 O* Monitor signal output 74 FSEQ O* Frame sync. detection signal output 75 VP O* CLV servo lock decision output 76 MRASBT O* Output for test 77 MRASB O* RAS signal output to DRAM (NC) 78 FOK O* Focus OK signal output 79 NWEB O* WE signal output to DRAM (NC) 80 DEFECT O* Defect signal output 81 MD1 I/O Data input/output to/from DRAM 82 FG I Speed pulse input 83 CL I Data transferring clock input for CPU interface 84 CE I Chip enable signal input for CPU interface 85 MDO I/O 86 DI I 87 VDD1 — power supply 88 DO O Data output for CPU interface 89 VDD2 — Power supply 90 VSS — Ground 91 MD3 I/O Data input/output to/from DRAM 92 WRQB O Interruption output for CPU interface 93 INTB O Interruption output for CPU interface 94 ADIPWO I Wobbly signal input 14 Description Address output to DRAM (NC) Power supply Data input/output to/from DRAM Data input for CPU interface MZ-E300 Pin No. Pin name I/O Description 95 MD2 I/O Data input/output to/from DRAM 96 SHOCK O* SHOCK/RFNG output 97 MCASB O* CAS signal output to DRAM (NC) 98 PCK O VTEC system clock signal output 99 MOEB O* OE signal output to DRAM (NC) 100 VCVSS — Ground for VTEC * : I/O on the test mode. 15 MZ-E300 • IC801 RU6615MF-0003 (SYSTEM CONTROL) Pin No. Pin name I/O Description 1 UNREG_MON I 2 RF_VCMON I Reference voltage (1.2V) for adjusting power supply voltage input (A/D input) 3 RMC_KEY I Remote commander with phones key input (A/D input) 4 SET_KEY I 5 OPEN_CLS_SW I Upper panel open/close detection switch (S808) input L: Close, H: Open 6 RF_SMON I S-MON level input from SN761057DBT (IC501) (A/D input) 7 DSP_SMON3_LP — 8 VL_MON I 9 XRESET I 10 AVDD — Power supply (2.48V) (For A/D conversion) 11 AVSS — Ground (For A/D conversion) UNREG voltage monitor input (A/D input) Key on the set itself input (A/D input) S801-807 (STOP, FF/PB, REW/PB, VOL+, VOL-, PLAY MODE, DBB/AVLS key input Not used (Fixed to L) VL voltage monitor input from XPC18A32FCR2 (IC901) (A/D input) System reset signal input from XPC18A32FCR2 (IC901) (A/D input) L: Reset L is in while 500-600 msec after power turns on, and then turns to H. 12, 13 TYPE0, 1 I Initial setting for the model decision input (Bit 0, 1) Fixed to L. 14 XADJUST I Test mode setting input L: Test mode (Fixed to H normally) 15 HOLD_SW I HOLD switch (S809) input L: Off, H: On 16 XOUT O Main system clock (16.9344MHz) output 16 17 XIN I Main system clock (16.9344MHz) input 18 HP_MUTE O Muting on/off control signal output to phones amplifier (IC301) H: Muting on 19 HP_STBY O Standby on/off control signal output to phones amplifier (IC301) L: Standby, H: Amp. on 20 XCLK O Clock (16.9344MHz) output to LC89642-8B-E (IC601) 21 VDD — Power supply (+2.1V) (Digital system) 22 VSS — Ground (Digital system) 23 DSP_WRQB I SUBQ/ADIP read out request input from LC89642-8B-E (IC601) L: Request 24 DSP_INTB I SPP, servo status read out request input from LC89642-8B-E (IC601) L: Request 25 DSP_SMON3 I Monitor signal 3 input from LC89642-8B-E (IC601) 26 DSP_CE O Chip enable output to LC89642-8B-E (IC601) H: Enable 27 PWR_FFCLR O Latch clear signal for start up signal to XPC18A32FCR2 (IC901) output H: Clear 28 PWR_SLEEP O System sleep control signal to XPC18A32FCR2 (IC901) output H: Sleep on 29 PWR_VLON O VL voltage control signal to XPC18A32FCR2 (IC901) output H: VL out on 30 PWR_CLKSEL O 31 SBUS_CLK O 32 SBUS_DATA I/O 33 PD_S1 O PD-IC mode select signal output L: PIT, H: GRV 34 SLD_1_MON I Sled servo timing signal input from SC111257FCR2 (IC551) 35 SLD_2_MON I Sled servo timing signal input from SC111257FCR2 (IC551) 36 CLV_VCON O Spindle servo drive voltage control signal output to SC111257FCR2 (IC551) 37 SLD_VCON O Sled servo external voltage control signal output to SC111257FCR2 (IC551) 38 VC_VCON O PWM signal for VC voltage control signal to XPC18A32FCR2 (IC901) output 39 CLV_U_MON I Spindle servo (U) timing signal input from SC111257FCR2 (IC551) 40 VDD — Power supply (+2.1V) (Digital system) 41 VPP — Test (Fixed to L) External sync. 2 division circuit control signal to XPC18A32FCR2 (IC901) output L: 2 division, H: No division SSB serial clock signal output to SN761057DBT (IC501) SSB serial data signal input/output to SN761057DBT (IC501) 42 CLV_V_MON I Spindle servo (V) timing signal input from SC111257FCR2 (IC551) 43 CLV_W_MON I Spindle servo (W) timing signal input from SC111257FCR2 (IC551) 44 CLV_U_CON O Spindle servo (U) drive signal output to SC111257FCR2 (IC551) 45 CLV_V_CON O Spindle servo (V) drive signal output to SC111257FCR2 (IC551) MZ-E300 Pin No. Pin name I/O Description 46 CLV_W_CON O 47 SLED_1R_CON O Sled motor control signal output to SC111257FCR2 (IC551) 48 SLED_1F_CON O Sled motor control signal output to SC111257FCR2 (IC551) 49 SLED_2R_CON O Sled motor control signal output to SC111257FCR2 (IC551) 50 SLED_2F_CON O Sled motor control signal output to SC111257FCR2 (IC551) Spindle servo (W) drive signal output to SC111257FCR2 (IC551) 51 BEEP O Beep sound drive signal output to phones amplifier (IC301) 52 NV_XCS O Chip select signal output to EEPROM (IC802) 53 RMC_DTCK I/O 54 SIO2_CLK O TSB serial communication data input/output to/from remote commander with phones Serial clock signal output to LC89642-8B-E (IC601) and EEPROM (IC802) 55 SIO3_DI I Read data input from LC89642-8B-E (IC601) and EEPROM (IC802) 56 SIO3_DO O Write data output to LC89642-8B-E (IC601) and EEPROM (IC802) 57 DSP_VP I CLV servo lock decision signal input from LC89642-8B-E (IC601) 58 VL_VCON O PWM signal for VL voltage control signal to XPC18A32FCR2 (IC901) output 59 PWR_CLK O External sync. clock (176.4kHz) signal to XPC18A32FCR2 (IC901) output 60 SEG0 O LCD segment output 61 VSS — Ground (Digital system) 62-72 SEG1-11 O LCD segment output 73-76 COM0-3 O LCD common output 77-79 VL1, 2, LVDD I LCD drive level power supply input 80 VSS — Ground (Digital system) 17 17 MZ-E300 5-2. BLOCK DIAGRAMS MAIN BOARD Iy 6 VREF DIGITAL SIGNAL PROCESSOR, DIGITAL SERVO SIGNAL PROCESSOR, ATRAC ENCODER/DECODER, 8M BIT D-RAM, D/A CONVERTER HEADPHONE AMP IC601 IC301 4 VREF RCH Iy 8 9 10 11 12 14 5 6 9 Ix 10 Jx 14 Jy 15 A 16 B 17 C 7 8 D Jy Jx Jy Jx A Ix Iy Ix B Iy Ix Jx Jy A B C D A-C 13 D-C 7 C 18 D MON 18 PD-I RF OUT RF AMP, FOCUS ERROR, TRACKING ERROR PEAK PEAK /BOTM BOTM ABCD 33 9 EFMIN 29 28 17 PEAK 18 BOTTOM 41 19 ABCD 42 21 FE 1 ADIP IN 44 20 TE FE TE TPP/WPP PD-NI 37 LDREF 19 VC 31 VIF PD 2 RFVC MON OFTRK 26 22 DVDD 5 12 LD LASER AUTO POWER CONTROL Q501 20 S-MONITOR PD-O S MON 10 RESET B S1 AVCC 43 2 VOUT VIN 3 2 DO 88 20 23 24 25 26 57 XIN 60 92 93 70 84 75 WRQB INTB SMON3 CE VP 38 41 40 FOCUS COIL 3 DSP WRQB DSP INTB DSP SMON3 DSP CE DSP VP 34 SLD1MON 37 39 4 PRE DRIVER 24 25 HI-BRIDGE CONTROL EEPROM BEEP 51 HP STB 19 MUTE 18 NV XCS 52 S102 CLK 54 S102 DO 56 S102 DI 55 SEG0 60 LIQUID CRYSTAL DISPLAY SEG11 72 COM0 73 HOLD SW 15 SET KEY 4 OFF ON OPEN CLS SW 5 X801 16.9344MHz BIAS FCS+ S809 HOLD S807 DIGITAL MEGABASS/ AVLS S806 S805 PLAY MODE VOLUME /DISPLAY – FCS- IC901 44 VD PRE DRIVER HI-BRIDGE CONTROL 19 18 5 XWK4 2 XWK1 RMC KEY 3 UNREG MON 1 5 7 SLED2+ 6 SLED2- 8 28 29 31 1 PRE DRIVER PRE DRIVER HI-BRIDGE CONTROL HI-BRIDGE CONTROL 54 51 47 SLED 1R CON 48 SLED 1F CON 37 SLD VCON 16 17 20 26 27 50 SLED 2F CON 49 SLED 2R CON XCS NV SI0 39 CLV U MON SCK0 1 52 56 42 CLV V MON S00 55 43 CLV W MON 2 3 4 5 6 46 CLV W CON 45 CLV V CON 44 CLV U CON 36 CLV VCON UNREG PWR CLK PWR VLON PWR SLEEP PWR FFCLR XRST AVDD VL MON 59 29 28 27 9 10 8 7 4 6 3 VRMC XWK3 VSTB XWK2 26 INM1 27 RF1 23 RF2 VC VCOM 38 VL VCOM 58 VL S804 VOLUME -+ S803 . 53 22 56 1 55 54 46 36 34 INM2 CLK VLON SLEEP FFCLR XRST VC VC 45 VC2 VCO 35 VIF 42 VC VIF AVDD VA 41 VG 19 VG D903 LG 18 UNREG VL 9 VL 11 D902 L2 16 L2 12 VB 50 L1 32 L1 28 CLVU CLVV CLVW 48 2 45 46 49 44 3 4 PRE DRIVER 3 PHASE CONTROL 52 CLK SEL VC OUT 33 PWR CLKSEL 30 S801 x VL VLO 10 D901 M901 (SPINDLE) S802 >N POWER SUPPLY 16 XOUT DVDD 14 15 12 SLED1- IC803 IC802 17 XIN CN551 SLED1+ 3 STATE BUFFER S808 (OPEN/CLOSE) 35 36 11 10 7 REFERENCE VOLTAGE SWITCHING Q301 VREF IN 13 35 SLD2MON 8 MINIDISC MECHANISM BLOCK M902 (SLED) BEEP COM3 76 42 1 XCLK 32 S BUS DATA 31 S BUS CLK 6 RF SMON IC551 TRK- 24 23 4 IC801 49 FOPWMF 51 FOPWMR 33 32 BEEP OUT B 15 18 STB 17 MUTE 3 13 41 59 89 33 PD S1 TRK+ BEEP OUT A VC VA VCVDD VDD2 VDD2 VDD2 VDD2 1 +B 20 VCC SYSTEM CONTROL 52 TRPWMF 53 TRPWMR MINIDISC OPTICAL PICK-UP BLOCK (LCX-4E) TRACKING COIL VIF IC602 FOCUS/TRACKING COIL DRIVE, SPINDLES/SLED MOTOR DRIVE 2 UNREG REGULATOR 19 S1 J301 i RCH VD VDD1 15 VDD1 63 VDD1 87 22 VC 20 11 S0 4 OUT B IN B Q801 AVCC AVCC S0 21 OUT R 57 1 13 LD-K LCH DI 86 XRST 25 SBUS 23 SCK 24 SERIAL I/F LD-A 12 HFL 2 RCH AVDD 55 94 ADIPWO ADIP 21 APC 22 OUT L 56 1 XCS 2 SK 3 DI 4 DO Jx F IC501 CN501 Ix a bc d RF AMP,FOCUS/TRACKING ERROR AMP DRY BATTERY SIZE "AA" (IEC DESIGNATION LR6) 1PC, 1.5V BP801 (TEST) XADJUST 14 UNREG • Signal path. F : Analog J : Digital 18 18 MZ-E300 5-3. PRINTED WIRING BOARDS – MAIN SECTION (1/2) – Refer to page 24 for Notes. 3 2 1 z 4 5 6 8 7 9 DRY BATTERY SIZE "AA" (IEC DESIGNATION LR6) 1PC, 1.5V A z MAIN BOARD (SIDE B) Ref. No. C608 C607 C951 D 5 4 15 TP516 20 20 TP817 R605 90 80 C302 76 10 IC601 15 TP612 TP611 TP610 60 55 25 26 30 35 45 TP806 51 50 C513 C515 C516 TP531 C606 D101 TP302 TP103 C609 TP521 R517 R804 R808 R807 R806 TP811 TP575TP574 TP522 1 1 75 42 40 IC801 35 10 15 20 C552 30 29 14 TP816 C801 X801 20 21 C803 C805 R821 61 TP203 60 55 TP812 50 15 R803 TP808 R907 IC551 L552 L554 C554 5 BP801 (TEST) C806 TP809 65 5 FB801 1 R830 C555 45 43 C551 50 L551 L553 C553 56 55 70 10 R802 TP551 F 80 TP810 TP814 C810 E TP807 M901 SPINDLE MOTOR 45 25 30 35 41 40 C813 R822 Q801 BCE 1-679-460- 25 28 19 19 D351 20 C510 C-9 C-9 A-2 IC501 IC551 IC601 IC801 C-6 F-3 C-8 D-8 Q801 F-9 S808 (OPEN/CLOSE) TAP502 40 Location D101 D351 D903 C303 65 R805 2 C301 TP618 75 70 25 23 22 R301 R609 TP610 TP504 C519 30 TP519 3 C517 IC501 15 95 C601 35 1-679-187-11 OPTICAL PICK-UP BLOCK LCX-4E 5 R607 100 C811 40 10 10 C618 1 C804 8 7 6 M TP507 5 5 R608 C511 MOTOR FLEXIBLE BOARD M902 SLED MOTOR C615 C505 44 TP506 1 C614 TP530 1 CN501 TP901 TP616 C620 C619 85 TP617 TP618 TP529 C611 C602 TP920 TP576 C503 TP572 TP573 TP905 R501 TP907 C501 C502 1 C508 8 TP571 TP577 TP917 C TP570 C504 TP904 R506 CN551 TP909 TP910 C613 TP911 TP908 R611 TAP501 C509 TP527 C851 TP903 C305 C306 C616 TP912 B TP954 R615 R951 R810 TP924 R820 R809 C906 R614 R910 C910 R905 TP953 D903 C907 Semiconductor Location 11 (11) MZ-E300 5-4. PRINTED WIRING BOARDS – MAIN SECTION (2/2) – Refer to page 24 for Notes. 3 2 1 z 4 5 6 8 7 z A MAIN BOARD (SIDE A) TP803 TP802 7 19 R949 C617 C908 45 R946 R948 S802 >N R811 C351 L904 1 56 R906 C915 C913 C903 1 5 10 16 5 C807 Q501 L502 S809 HOLD. OFFtON S801 x S807 DIGITAL MEGABASS S806 PLAY MODE R816 AVLS(2SEC) DISPLAY(2SEC) RB551 RB553 C558 C557 C527 E B C C530 R521 8 RB552 C556 4 R815 C524 R519 IC802 C529 R516 1 LCD801 LIQUID CRYSTAL DISPLAY S805 VOL– S803 . C808 R827 S804 VOL+ R814 CN805 R812 J301 i D201 E 5 50 42 C917 R947 R936 R813 R303 C621 C301 D IC901 R901 C304 C B E 10 35 C911 IC602 C919 C605 C604 R602 C 3 C603 C953 15 14 40 41 R912 C101 R302 C610 C622 2 C920 R903 C902 R603 D901 C202 L902 20 29 30 C909 C901 C905 R909 C204 R202 R201 R101 R102 C104 C102 L903 R203 1 C921 28 25 24 C201 B L901 TP805 TP806 TP951 D902 1 C103 R104 C952 C904 18 R103 R106 C203 IC301 TP801 TP804 R204 6 13 L905 R206 12 C559 C802 1 R824 R826 IC803 4 C561 3 F 5 1-679-460- 20 20 11 (11) Semiconductor Location Ref. No. Location D201 D901 D902 E-1 B-7 B-8 IC301 IC602 IC802 IC803 IC901 B-2 C-2 E-2 F-2 B-7 Q301 Q501 D-1 E-5 MZ-E300 5-5. SCHEMATIC DIAGRAM – MAIN SECTION (1/3) – z Refer to page 24 for Notes. z Refer to page 26 – 28 for IC Block Diagrams. IC B/D 21 21 z Refer to page 25 for Waveforms. MZ-E300 5-6. SCHEMATIC DIAGRAM – MAIN SECTION (2/3) – z Refer to page 24 for Notes. z Refer to page 26 – 28 for IC Block Diagrams. z Refer to page 25 for Waveforms. IC B/D IC B/D 22 22 MZ-E300 5-7. SCHEMATIC DIAGRAM – MAIN SECTION (3/3) – z Refer to page 24 for Notes. z Refer to page 26 – 28 for IC Block Diagrams. z Refer to page 25 for Waveforms. IC B/D 23 23 MZ-E300 Note on Printed Wiring Boards: MAIN SECTION • X : parts extracted from the component side. • : Pattern from the side which enables seeing. (The other layers' patterns are not indicated.) Caution: Pattern face side: Parts on the pattern face side seen from the (Side B) pattern face are indicated. Parts face side: Parts on the parts face side seen from the (Side A) parts face are indicated. Note on Schematic Diagram: MAIN SECTION • All capacitors are in µF unless otherwise noted. pF: µµF 50 WV or less are not indicated except for electrolytics and tantalums. • All resistors are in Ω and 1/4 W or less unless otherwise specified. f : internal component. • Note: The components identified by mark 0 or dotted line with mark 0 are critical for safety. Replace only with part number specified. • : B+ Line. • Power voltage is dc 1.5V and fed with regulated dc power supply from battery terminal. • Voltages and waveforms are dc with respect to ground under no-signal conditions. no mark : PLAY • Voltages are taken with a VOM (Input impedance 10 MΩ). Voltage variations may be noted due to normal production tolerances. • Waveforms are taken with a oscilloscope. Voltage variations may be noted due to normal production tolerances. • Circled numbers refer to waveforms. • Signal path. F : Analog J : Digital 24 24 MZ-E300 • Waveforms 1 IC501 1 (TE), IC601 w; (TE) (PLAY Mode) 200 mV/DIV, 1 µs/DIV 9 IC551 ta, ts, td, tf (COM, CPWI, CPVI, CPUI) 400 mV/DIV, 5 µs/DIV 5 IC601 y; (XIN) 400 mV/DIV, 20 ns/DIV 1.1 Vp-p Approx. 396 mVp-p 1.1 Vp-p 16.34MHZ 11.5 µs 2 IC501 8, 9, 0, qa (IY, IX, JX,JY) (PLAY Mode) 200 mV/DIV, 500 ns/DIV 0 IC801 qh (XOUT) 1 V/DIV, 20 ns/DIV 6 IC551 5 (PWM), IC801 eh (CLV V CON) (PLAY Mode) 1 V/DIV, 2 µs/DIV 2.2 Vp-p Approx. 540 mVp-p 3 Vp-p 16.934MHz 5.3 µs 3 IC501 ed (RF), IC601 9 (EFMIN) (PLAY Mode) 400 mV/DIV, 1 µs/DIV qa IC901 th (CLK) 1 V/DIV, 2 µs/DIV 7 IC551 2, 3, 4 IC801 rf, rg, rh (CLV U CON, CLV V CON, CLV W CON) (PLAY Mode) 1 V/DIV, 5 ms/DIV 2.2 Vp-p Approx. 1.1 Vp-p 2.8 Vp-p 5.76 µs 11.1 ms 4 IC501 rs (FE), IC601 wa (FE) (PLAY Mode) 200 mV/DIV, 1 µs/DIV 8 IC551 1, tg, th (CPUO, CPWO, CPVO) IC801 el, rs, rd (CLV U MON, CLV V MON, CLV W MON) 1 V/DIV, 5 ms/DIV Approx. 416 mVp-p 2.8 Vp-p 11.8 ms 25 MZ-E300 • IC BLOCK DIAGRAMS GND VREF IN 18 17 16 15 14 13 PW SW MT SW BST SW BEEP STB MUTE BEEP IN BST SW IC301 TA2131FL-EL 12 VREF V REF 11 LPF1 TC MT 19 VCC 20 ADD INR 21 10 BST NF1 BST1 INL 22 9 LPF2 PW A BEEP 23 OUTB PW B BST2 8 BST NF2 7 BST OUT BEEP 24 OUTA 2 3 4 5 6 +B OUTL PWR GND OUTR DET AGC IN BST AGC 1 IC501 SN761057DBT 44 ADIP-IN 43 S-MON A+B+C+D I+J NPP TON CSL Aw+Dw TON Peak TON Botm ADIP TE TE 1 REXT 2 Wpp-LPF 3 VREF 4 C 5 D 6 TE TWpp PK/BTM Aw CSLO VREF075 A-C D-C Malfa Mij AwBPF Dw DwBPF S-MONITOR TEMP D-C 7 Tpp/Wpp RF Iy 8 Ix 9 FE Jx 10 Jy 11 ABCD A 12 A-C 13 PEAK/BOTM B 14 TON-C 15 CIG 16 CDN 17 PD-NI 18 PD-I 19 PD-O 20 ADFG 21 DVDD 22 26 42 41 40 39 38 FE 37 36 35 34 PS 33 32 31 30 29 28 RF CCSL2 VC VREF075 ABCD AVCC OFC-1 OFC-2 LP EQ AGND PEAK BOTM 27 DGND T-ON 26 OFTRK SERIAL I/F 25 XRST 24 SCK 23 SBUS APC ADIP MZ-E300 36 35 34 33 FO4 VM3 37 PGND4 CPB0 38 VM34 CPAO 39 RO4 CPBIM 40 FO3 CPBIP 41 RO3 CPAIM 42 PGND3 CPAIP IC551 SC111257FCR2 32 31 30 29 28 VM4 VC VG VC VG VC VG PRE DRIVER PGNDW 43 PRE DRIVER VC WO 44 H-BRIDGE CONTROL PRE DRIVER VMVW 45 VO 46 PGNDUV 47 VC 27 R14 26 F14 H-BRIDGE CONTROL 25 R13 UO 48 24 F13 VMU 49 VG 23 VG GND2 50 VC 22 VC CPW1 51 21 GND1 CPV1 52 20 PWM24 19 F11 CPU1 53 18 R11 VC COM 54 VC H-BRIDGE CONTROL H-BRIDGE CONTROL VC VG CPWO 55 VC 3 PHASE CONTROL VC VG PRE DRIVER PRE DRIVER BIAS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 W1 V1 U1 PWM OE VM1 RO1 PGND1 FO1 VM12 RO2 PGND2 FO2 15 VM2 CPUO CPVO 56 17 F12 16 R12 27 MZ-E300 VAFB VDFB VIFFB GND VC VCO VC VCOUT L1 NC PGND1 PGND1 42 41 40 39 38 37 36 35 34 33 32 31 30 29 VIF VA IC901 XPC18A32FCR2 NC 43 VG SERIAL PASS REGULATOR VA VD 44 STEP-UP PRE DRIVEER POWER SWITCH 1 28 L1 VG VG STEP-UP PRE DRIVEER 27 RF1 SERIAL PASS REGULATOR VD VC2 45 SERIAL PASS REGULATOR VIF 26 INM1 XRST (INT) XRST 46 25 DTC1 VC VC VC 24 DTC2 PWM CRST 47 VC RSTREF 48 23 RF2 VC BANDGAP REFERENCE VREF 49 22 INM2 VG VC VB 50 21 PWM1 VG GND 51 VC 20 PWM2 VSTB VC VB VB VC VG VG 19 VG CLKSEL 52 VAIFON 53 VB FFCLR 54 START-UP CONTROL STEP-UP DC/DC CONVERTOR 18 LG SLEEP 55 17 PGND2 CLK 56 VSTB VG STEP-UP PRE DRIVEER PWER SWITCH 2 16 L2 VC VB 28 1 2 3 4 5 6 7 8 9 10 11 12 13 14 VLON XWK1 XWK2 XWK3 XWK4 VSTV VRMC GND VL VLO VL L2 PGND2 PGND2 15 NC MZ-E300 SECTION 6 EXPLODED VIEWS NOTE : • -XX, -X mean standardized parts, so they may have some difference from the original one. • Color indication of Appearance Parts Example : KNOB, BALANCE (WHITE) ••• (RED) ↑ ↑ Parts color Cabinet's color • Items marked “ * ”are not stocked since they are seldom required for routine service. Some delay should be anticipated when ordering these items. • The mechanical parts with no reference number in the exploded views are not supplied. • Hardware (# mark) list and accessories and packing materials are given in the last of this parts list. The components identified by mark 0 or dotted line with mark 0 are critical for safety. Replace only with part number specified. Les composants identifiés par une marque 0 sont critiques pour la sécurité. Ne les remplacer que par une pièce portant le numéro spécifié. 6-1. MAIN SECTION 6 7 8 11 10 18 8 5 9 12 not supplied LCD801 13 15 16 8 17 1 3 2 14 4 Ref. No. 1 1 2 2 3 4 4 5 6 6 Part No. Description Remark X-3380-002-1 CASE ASSY (S)...(SILVER) (CND,AEP,FR,EE,E,CH) X-3380-005-1 CASE ASSY (L)...(BLUE) 4-225-572-03 KNOB (HOLD)...(SILVER) (CND,AEP,FR,EE,E,CH) 4-225-572-11 KNOB (HOLD)...(BLUE) 3-226-517-01 WINDOW (LCD) 3-226-512-01 LID, BATTERY CASE...(SILVER) (CND,AEP,FR,EE,E,CH) 3-226-512-11 LID, BATTERY CASE...(BLUE) X-3379-511-1 HOLDER ASSY X-3380-003-1 LID ASSY (S), UPPER...(SILVER) (CND,AEP,FR,EE,E,CH) X-3380-006-1 LID ASSY (L), UPPER...(BLUE) Ref. No. Part No. Description 7 8 9 10 * 11 4-218-233-25 3-375-114-41 3-226-522-01 4-223-906-01 A-3323-668-A SCREW (1.4), MI SCREW, TAPPING (1.7) SPRING (POP/L) SCREW (MD), STEP MAIN BOARD, COMPLETE 12 * 13 14 15 16 1-694-743-11 3-226-523-01 X-3380-004-1 3-226-518-01 3-226-520-01 CONDUCTIVE BOARD, CONNECTION HOLDER, LCD PLATE ASSY, FULCRUM BUTTON (CONTROL) SPRING, TERMINAL COIL Remark 17 3-226-519-01 TERMINAL (PLUS), BATTERY 18 3-229-530-01 SHEET, SHIELD LCD801 1-804-162-11 DISPLAY PANEL, LIQUID CRYSTAL 29 MZ-E300 6-2. MECHANISM DECK SECTION (MT-MZE300-176) 65 55 54 53 56 57 M902 M901 61 59 58 60 62 64 63 51 52 The components identified by mark 0 or dotted line with mark 0 are critical for safety. Replace only with part number specified. Ref. No. Part No. Description 51 52 53 54 55 1-679-187-11 3-222-392-01 3-223-833-01 3-224-779-01 4-222-216-01 MOTOR FLEXIBLE BOARD SCREW (M1.4), TAPPING CHASSIS SPRING, THRUST DETENT GEAR (SA) 56 57 58 59 3-338-645-51 4-218-233-13 4-218-233-01 4-222-208-01 WASHER SCREW (1.7), MI SCREW (1.4), MI GEAR (SB) 30 Remark Les composants identifiés par une marque 0 sont critiques pour la sécurité. Ne les remplacer que par une pièce portant le numéro spécifié. Ref. No. Part No. Description 60 61 0 62 63 64 4-222-204-01 4-222-203-01 X-3379-869-1 3-222-391-01 3-225-278-11 BEARING (N) SCREW, LEAD OPTICAL PICK-UP ASSY (LCX-4E) SPRING (M), RACK SCREW, TAPPING 65 M901 M902 Remark X-3379-529-1 BASE ASSY, MOTOR 8-835-706-01 MOTOR, DC SSM18A (SPINDLE) 1-763-399-11 MOTOR, DC (SLED) (INCLUDING PULLEY GEAR) MZ-E300 SECTION 7 ELECTRICAL PARTS LIST MAIN NOTE : • Due to standardization, replacements in the parts list may be different from the parts specified in the diagrams or the components used on the set. • -XX, -X mean standardized parts, so they may have some difference from the original one. • RESISTORS All resistors are in ohms METAL : Metal-film resistor METAL OXIDE :Metal oxide-film resistor F : nonflammable • Items marked “ * ”are not stocked since they are seldom required for routine service. Some delay should be anticipated when ordering these items. Ref. No. Part No. * A-3323-668-A MAIN BOARD, COMPLETE ********************* Description Remark 1-694-743-11 CONDUCTIVE BOARD, CONNECTION 3-226-523-01 HOLDER, LCD 3-229-530-01 SHEET, SHIELD * The components identified by mark 0 or dotted line with mark 0 are critical for safety. Replace only with part number specified. • SEMICONDUCTORS In each case, u : µ , for example : uA.... : µ A.... , uPA.... : µ PA.... uPB.... : µ PB.... , uPC.... : µ PC.... uPD.... : µ PD.... • CAPACITORS uF : µ F • COILS uH : µ H • Abbreviation CND : Canadian FR : French EE : East European CH : Chinese < CAPACITOR > C101 C102 C103 C104 C201 1-109-982-11 1-119-944-22 1-115-467-11 1-162-962-11 1-109-982-11 CERAMIC CHIP ELECT CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 1uF 470uF 0.22uF 470PF 1uF 10% 20% 10% 10% 10% 10V 4V 10V 50V 10V C202 C203 C204 C301 C302 1-119-944-22 1-115-467-11 1-162-962-11 1-135-259-11 1-164-156-11 ELECT CERAMIC CHIP CERAMIC CHIP TANTAL. CHIP CERAMIC CHIP 470uF 0.22uF 470PF 10uF 0.1uF 20% 10% 10% 20% 4V 10V 50V 6.3V 25V C303 C304 C305 C306 C351 1-109-982-11 1-135-210-11 1-125-838-11 1-104-847-11 1-164-156-11 CERAMIC CHIP TANTALUM CHIP CERAMIC CHIP TANTAL. CHIP CERAMIC CHIP 1uF 4.7uF 2.2uF 22uF 0.1uF 10% 20% 10% 20% 10V 10V 6.3V 4V 25V C501 C502 C503 C504 C505 1-162-964-11 1-164-677-11 1-162-967-11 1-162-967-11 1-162-970-11 CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 0.001uF 0.033uF 0.0033uF 0.0033uF 0.01uF 10% 10% 10% 10% 10% 50V 16V 50V 50V 25V C508 C509 C510 C511 C513 1-162-965-11 1-162-967-11 1-162-915-11 1-162-919-11 1-162-915-11 CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 0.0015uF 0.0033uF 10PF 22PF 10PF 10% 10% 0.5PF 5% 0.5PF 50V 50V 50V 50V 50V C515 C516 C517 C519 C524 1-164-156-11 1-107-826-11 1-162-970-11 1-162-968-11 1-117-920-11 CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP TANTAL. CHIP 0.1uF 0.1uF 0.01uF 0.0047uF 10uF 10% 10% 10% 20% 25V 16V 25V 50V 6.3V C527 C529 C530 C551 C552 1-165-176-11 1-117-920-11 1-162-966-11 1-104-912-11 1-104-912-11 CERAMIC CHIP TANTAL. CHIP CERAMIC CHIP TANTAL. CHIP TANTAL. CHIP 0.047uF 10uF 0.0022uF 3.3uF 3.3uF 10% 20% 10% 20% 20% 16V 6.3V 50V 6.3V 6.3V Ref. No. Les composants identifiés par une marque 0 sont critiques pour la sécurité. Ne les remplacer que par une pièce portant le numéro spécifié. When indicating parts by reference number, please include the board. Part No. Description C553 C554 C555 C556 C557 1-135-211-11 1-135-211-11 1-107-826-11 1-107-826-11 1-110-563-11 TANTAL. CHIP TANTAL. CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 6.8uF 6.8uF 0.1uF 0.1uF 0.068uF 20% 20% 10% 10% 10% Remark 6.3V 6.3V 16V 16V 16V C558 C559 C561 C601 C602 1-110-563-11 1-110-563-11 1-164-156-11 1-164-156-11 1-107-826-11 CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 0.068uF 0.068uF 0.1uF 0.1uF 0.1uF 10% 10% 10% 16V 16V 25V 25V 16V C603 C604 C605 C606 C607 1-164-156-11 1-164-156-11 1-164-156-11 1-164-156-11 1-135-259-11 CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP TANTAL. CHIP 0.1uF 0.1uF 0.1uF 0.1uF 10uF 20% 25V 25V 25V 25V 6.3V C608 C609 C610 C611 C613 1-135-259-11 1-164-156-11 1-164-156-11 1-164-227-11 1-107-826-11 TANTAL. CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 10uF 0.1uF 0.1uF 0.022uF 0.1uF 10% 10% 6.3V 25V 25V 25V 16V C614 C615 C616 C617 C618 1-107-826-11 1-107-826-11 1-164-156-11 1-164-156-11 1-162-969-11 CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 0.1uF 10% 0.1uF 10% 0.1uF 0.1uF 0.0068uF 10% 16V 16V 25V 25V 25V C619 C620 C621 C622 C801 1-164-156-11 1-164-156-11 1-131-862-91 1-131-862-91 1-164-156-11 CERAMIC CHIP CERAMIC CHIP TANTAL. CHIP TANTAL. CHIP CERAMIC CHIP 0.1uF 0.1uF 47uF 47uF 0.1uF 25V 25V 4V 4V 25V C802 C803 C804 C805 C806 1-164-156-11 1-164-156-11 1-164-156-11 1-165-176-11 1-165-176-11 CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 0.1uF 0.1uF 0.1uF 0.047uF 0.047uF C807 C808 C810 C811 C813 1-162-962-11 1-164-156-11 1-162-964-11 1-162-970-11 1-164-156-11 CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 470PF 0.1uF 0.001uF 0.01uF 0.1uF C851 C901 C902 1-164-156-11 CERAMIC CHIP 1-104-752-11 TANTAL. CHIP 1-119-749-11 TANTAL. CHIP 0.1uF 33uF 33uF 20% 20% 20% 10% 10% 10% 10% 10% 20% 20% 25V 25V 25V 16V 16V 50V 25V 50V 25V 25V 25V 6.3V 4V 31 MZ-E300 Ver 1.2 2001.12 MAIN Ref. No. Part No. Description Remark C903 C904 1-104-752-11 TANTAL. CHIP 1-119-749-11 TANTAL. CHIP 33uF 33uF 20% 20% 6.3V 4V C905 C906 C907 C908 C909 1-107-826-11 1-162-970-11 1-109-982-11 1-107-826-11 1-109-982-11 CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 0.1uF 0.01uF 1uF 0.1uF 1uF 10% 10% 10% 10% 10% 16V 25V 10V 16V 10V C910 C911 C913 C915 C917 1-162-964-11 1-107-811-11 1-107-826-11 1-107-826-11 1-107-826-11 CERAMIC CHIP TANTAL. CHIP CERAMIC CHIP CERAMIC CHIP CERAMIC CHIP 0.001uF 47uF 0.1uF 0.1uF 0.1uF 10% 20% 10% 10% 10% 50V 4V 16V 16V 16V C919 C920 C921 C951 C952 1-135-259-11 1-135-259-11 1-107-826-11 1-164-156-11 1-113-690-11 TANTAL. CHIP TANTAL. CHIP CERAMIC CHIP CERAMIC CHIP ELECT CHIP 10uF 10uF 0.1uF 0.1uF 220uF 20% 20% 10% 6.3V 6.3V 16V 25V 4V C953 1-164-156-11 CERAMIC CHIP 0.1uF Ref. No. L903 L904 L905 Part No. Description Remark 1-414-398-11 INDUCTOR 10uH 1-414-398-11 INDUCTOR 10uH 1-412-032-11 INDUCTOR CHIP 100uH < LIQUID CRYSTAL DISPLAY > LCD801 1-804-162-11 DISPLAY PANEL, LIQUID CRYSTAL < TRANSISTOR > Q301 Q501 Q801 8-729-037-52 TRANSISTOR 8-729-922-10 TRANSISTOR 8-729-037-52 TRANSISTOR 2SD2216J-QR(TX).SO 2SA1577-QR 2SD2216J-QR(TX).SO < RESISTOR > 20% < CONNECTOR > * CN501 * CN551 1-778-168-11 CONNECTOR, FFC/FPC (ZIF) 20P 1-815-284-21 CONNECTOR, FPC (ZIF) 8P < DIODE > D101 D201 D351 D901 D902 8-719-056-72 8-719-056-72 8-719-017-58 8-719-081-33 8-719-081-33 DIODE DIODE DIODE DIODE DIODE UDZ-TE-17-2.4B UDZ-TE-17-2.4B MA8068 MA2YD1500LS0 MA2YD1500LS0 D903 8-719-049-09 DIODE 1SS367-T3SONY < FERRITE BEAD > FB801 1-414-226-21 FERRITE 0uH < IC > IC301 IC501 IC551 IC601 IC602 8-759-598-15 8-759-689-67 8-759-698-62 8-759-697-82 8-759-834-07 IC IC IC IC IC TA2131FL(EL) SN761057DBT SC111257FCR2 LC89642-8B-E XC62FP2302MR IC801 IC802 IC803 IC901 6-700-663-01 8-759-468-72 8-759-592-49 8-759-698-61 IC IC IC IC RU6615MF-0005 AK6420AM-E2 TC7SZ125FU(TE85R) XPC18A32FCR2 < JACK > J301 1-216-839-11 1-216-843-11 1-216-829-11 1-216-797-11 1-216-831-11 METAL CHIP METAL CHIP METAL CHIP METAL CHIP METAL CHIP 33K 68K 4.7K 10 6.8K 5% 5% 5% 5% 5% 1/16W 1/16W 1/16W 1/16W 1/16W R201 R202 R203 R204 R206 1-216-839-11 1-216-843-11 1-216-829-11 1-216-797-11 1-216-831-11 METAL CHIP METAL CHIP METAL CHIP METAL CHIP METAL CHIP 33K 68K 4.7K 10 6.8K 5% 5% 5% 5% 5% 1/16W 1/16W 1/16W 1/16W 1/16W R301 R302 R303 R501 R506 1-216-803-11 1-216-831-11 1-216-849-11 1-216-839-11 1-216-864-91 METAL CHIP METAL CHIP METAL CHIP METAL CHIP SHORT 33 6.8K 220K 33K 0 5% 5% 5% 5% 1/16W 1/16W 1/16W 1/16W R516 R517 R519 R521 R602 1-218-855-11 1-218-855-11 1-216-845-11 1-218-446-11 1-216-801-11 METAL CHIP METAL CHIP METAL CHIP METAL CHIP METAL CHIP 2.2K 2.2K 100K 1 22 0.5% 0.5% 5% 5% 5% 1/16W 1/16W 1/16W 1/16W 1/16W R603 R605 R607 R608 R609 1-216-797-11 1-216-833-11 1-216-831-11 1-216-831-11 1-216-839-11 METAL CHIP METAL CHIP METAL CHIP METAL CHIP METAL CHIP 10 10K 6.8K 6.8K 33K 5% 5% 5% 5% 5% 1/16W 1/16W 1/16W 1/16W 1/16W R611 R614 R615 R802 R803 1-216-821-11 1-216-797-11 1-216-797-11 1-216-841-11 1-216-833-11 METAL CHIP METAL CHIP METAL CHIP METAL CHIP METAL CHIP 1K 10 10 47K 10K 5% 5% 5% 5% 5% 1/16W 1/16W 1/16W 1/16W 1/16W R804 R805 R806 R807 R808 1-218-895-11 1-218-895-11 1-216-845-11 1-216-845-11 1-216-845-11 METAL CHIP METAL CHIP METAL CHIP METAL CHIP METAL CHIP 100K 100K 100K 100K 100K 0.5% 0.5% 5% 5% 5% 1/16W 1/16W 1/16W 1/16W 1/16W R809 R810 R811 R812 R813 1-216-809-11 1-216-809-11 1-216-825-11 1-216-829-11 1-216-831-11 METAL CHIP METAL CHIP METAL CHIP METAL CHIP METAL CHIP 100 100 2.2K 4.7K 6.8K 5% 5% 5% 5% 5% 1/16W 1/16W 1/16W 1/16W 1/16W R814 R815 R816 R820 R821 1-216-835-11 1-216-839-11 1-216-847-11 1-216-857-11 1-216-827-11 METAL CHIP METAL CHIP METAL CHIP METAL CHIP METAL CHIP 15K 33K 150K 1M 3.3K 5% 5% 5% 5% 5% 1/16W 1/16W 1/16W 1/16W 1/16W 25V 1-794-084-31 JACK < COIL > L502 L551 L552 L553 L554 1-469-570-21 1-410-389-31 1-410-389-31 1-414-400-41 1-414-400-41 L901 L902 1-419-258-21 INDUCTOR 1-419-646-21 INDUCTOR 32 R101 R102 R103 R104 R106 INDUCTOR INDUCTOR CHIP INDUCTOR CHIP INDUCTOR INDUCTOR 10uH 47uH 47uH 22uH 22uH 68uH 47uH MZ-E300 MAIN Ref. No. Part No. Description R822 R824 R826 R827 R830 1-216-821-11 1-216-845-11 1-216-864-91 1-216-857-11 1-216-833-11 METAL CHIP METAL CHIP SHORT METAL CHIP METAL CHIP 1K 100K 0 1M 10K 5% 5% Remark 1/16W 1/16W 5% 5% 1/16W 1/16W R901 R903 R905 R906 R907 1-218-871-11 1-216-825-11 1-216-825-11 1-216-847-11 1-216-833-11 METAL CHIP METAL CHIP METAL CHIP METAL CHIP METAL CHIP 10K 2.2K 2.2K 150K 10K 0.5% 5% 5% 5% 5% 1/16W 1/16W 1/16W 1/16W 1/16W R909 R910 R912 R936 R946 1-216-827-11 1-216-827-11 1-218-907-11 1-218-744-11 1-218-895-11 METAL CHIP METAL CHIP METAL CHIP METAL CHIP METAL CHIP 3.3K 3.3K 330K 150K 100K 5% 5% 0.5% 0.5% 0.5% 1/16W 1/16W 1/16W 1/16W 1/16W R947 R948 R949 R951 1-218-911-11 1-218-907-11 1-218-911-11 1-216-864-91 METAL CHIP METAL CHIP METAL CHIP SHORT 470K 330K 470K 0 0.5% 0.5% 0.5% 1/16W 1/16W 1/16W < COMPOSITION CIRCUIT BLOCK > RB551 RB552 RB553 1-233-959-21 RES, NETWORK (CHIP TYPE) 470 1-233-979-11 RES, NETWORK (CHIP TYPE) 1M 1-233-967-11 RES, NETWORK (CHIP TYPE) 10K < SWITCH > S801 S802 S803 S804 S805 1-786-033-21 1-786-033-21 1-786-033-21 1-786-033-21 1-786-033-21 S806 1-786-033-21 SWITCH, TACTILE (PLAY MODE/DISPLAY(2SEC)) 1-786-033-21 SWITCH, TACTILE (DIGITAL MEGABASS/AVLS(2SEC)) 1-786-061-21 SWITCH, PUSH (1 KEY) (OPEN/CLOSE) 1-762-078-11 SWITCH, SLIDE (HOLD .) S807 S808 S809 SWITCH, TACTILE (x) SWITCH, TACTILE (> N) SWITCH, TACTILE (.) SWITCH, TACTILE (VOL+) SWITCH, TACTILE (VOL–) Ref. No. Part No. Description Remark MISCELLANEOUS *************** 12 51 0 62 LCD801 M901 M902 1-694-743-11 1-679-187-11 X-3379-869-1 1-804-162-11 8-835-706-01 1-763-399-11 CONDUCTIVE BOARD, CONNECTION MOTOR FLEXIBLE BOARD OPTICAL PICK-UP ASSY (CLX-4E) DISPLAY PANEL, LIQUID CRYSTAL MOTOR, DC SSM18A (SPINDLE) MOTOR, DC (SLED) (INCLUDING PULLEY GEAR) ************************************************************** ACCESSORIES & PACKING MATERIALS ******************************** 3-021-018-11 LABEL, FRANCE (FR) 3-224-084-11 MANUAL, INSTRUCTION (ENGLISH,FRENCH,SPANISH,PORTUGUESE) (US,CND,AEP,FR,E) 3-224-084-21 MANUAL, INSTRUCTION (GERMAN,ITALIAN,DUTCH,SWEDISH) (AEP) 3-224-084-31 MANUAL, INSTRUCTION (ENGLISH,RUSSIAN,HUNGARIAN, CZECH,FINNISH) (AEP,EE) 3-224-084-41 MANUAL, INSTRUCTION (ENGLISH,SIMPLIFIED CHINESE, POLISH,SLOVAK) (EE,CH) 3-224-084-51 MANUAL, INSTRUCTION (TRADITIONAL CHINESE,KOREAN) (E) 8-953-301-92 RECEIVER,EAR MDR-E805LP (CND,AEP,FR,EE,E,CH) 8-953-775-95 HEAD SET MDR-026LP (US) < VIBRATOR > X801 1-781-575-21 VIBRATOR, CERAMIC (16.9344MHz) ************************************************************** The components identified by mark 0 or dotted line with mark 0 are critical for safety. Replace only with part number specified. Les composants identifiés par une marque 0 sont critiques pour la sécurité. Ne les remplacer que par une pièce portant le numéro spécifié. 33 MZ-E300 REVISION HISTORY Clicking the version allows you to jump to the revised page. Also, clicking the version at the upper right on the revised page allows you to jump to the next revised page. Ver. Date Description of Revision 1.2 2001.12 Change of microprocessor (IC801 : Ver 1.3). 1.1 2001.03 Correction of Overall Adjustment Mode. Correction of Electrical Parts List. 1.0 2001.02 New (SPM-01052)