Download GE Roots Universal RAI blowers Brochure

Transcript

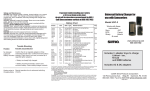

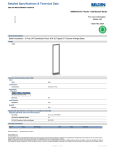

SPECIFICATIONS ROOTS™ UNIVERSAL RAI-G® Rotary Positive Gas Blowers Frames 32 thru 615 BASIC BLOWER DESCRIPTION Universal RAI-G® gas blowers are heavy duty rotary blowers designed with mechanical seals and rugged steel mounting feet. Optional feet are available for horizontal installations. The compact, sturdy design is engineered for continuous service when operated in accordance with speed and pressure ratings. The basic model consists of a cast iron casing, carburized and ground alloy steel spur timing gears secured to steel shafts with a taper mounting and locknut, and cast iron involute impellers. Oversized anti-friction bearings are used, with a cylindrical roller bearing at the drive shaft to withstand V-belt pull. The Universal RAI-G® features splash oil lube on the gear end and grease lube on the drive end. ROOT’s exclusive “figure-eight” gearbox design improves oil distribution to maximize gear and bearing life. Each unity is mechanically tested and given a 15 psig static leak test. A 1/8” NPT purge port is provided at each seal for buffer gas application as required. After testing, the unit is sprayed with a protective paint, and boxed or skid mounted for delivery. Accessories are available through our distributors. ROOTSTM Synthetic Oil and grease is recommended to maintain warranty. DESIGN AND CONSTRUCTION FEATURES 1. 2. 3. 4. 5. 6. 7. 8. Mechanical seals Rigid one-piece cast iron casing Anti-friction bearings Splash oil lubricated spur timing gears Connections in standard pipe sizes Straight, precision machined two-lobe impellers Ground steel shafts Detachable steel mounting feet OPERATING PRINCIPLE OUTLINE DRAWING & DIMENSIONAL TABLE INLET & DISCHARGE CONNECTIONS TOP DISCHARGE P C P M AX AX TOP SHAFT O' D1 O D2 R 000 U -+001 D BOTTOM DISCHARGE A LEFT DISCHARGE RIGHT DISCHARGE VERTICLE CONFIGURATION Frame 32 33 36 42 45 47 53 56 59 65 68 615 A 7.25 7.25 7.25 8.00 8.00 8.00 10.50 10.50 10.50 11.00 11.00 11.00 A’ B 7.25 7.25 7.25 8.00 8.00 8.00 10.50 10.50 10.50 11.00 11.00 11.00 6.75 7.63 10.00 7.25 10.00 11.75 8.38 11.00 14.00 10.00 13.00 20.00 S-60A01 rev.0608 C 11.25 12.13 14.63 13.00 15.50 17.63 15.38 18.00 21.18 18.38 21.38 28.38 Two figure-eight lobe impellers mounted on parallel shafts rotate in opposite directions. As each impeller passes the blower inlet, it traps a definite volume of gas and carries it around the case to the blower outlet, where the gas is discharged. With constant speed operation, the displaced volume is essentially the same regardless of pressure, temperature or barometric pressure. A BOTTOM SHAFT B HORIZONTAL CONFIGURATION D D1 5.00 5.00 5.00 6.25 6.25 6.25 6.25 6.25 6.25 8.75 8.75 8.75 8.50 8.50 8.50 10.25 10.25 10.25 11.25 11.25 11.25 14.75 14.75 14.75 D2 M O O’ P 5.00 5.81 12.81 8.88 7.75 5.00 6.25 12.81 8.88 7.75 5.00 7.56 12.81 8.88 7.75 6.25 6.86 15.06 10.63 8.75 6.25 8.00 15.06 10.63 8.75 6.25 9.25 15.06 10.50 8.50 6.75 8.18 17.38 11.88 10.25 6.75 9.19 17.38 12.25 11.00 6.75 11.19 17.38 12.25 11.00 8.75 9.19 21.63 15.13 12.75 8.75 10.82 21.63 15.13 12.75 8.75 14.32 21.63 16.25 15.00 INLET DISCH. AX 12.13 6.75 .750 1.25 NPT 12.13 6.75 .750 2.0 NPT 12.13 6.75 .750 2.5 NPT 13.63 8.25 .875 1.5 NPT 13.63 8.25 .875 2.5 NPT 13.63 8.25 .875 3.0 NPT 17.25 8.75 1.125 .2.5 NPT 17.25 8.75 1.125 4.0 NPT 17.25 8.75 1.125 4.0 NPT 19.75 11.75 1.375 3.0 NPT 19.75 11.75 1.375 5.0 NPT 19.75 11.75 1.375 .6.0 FLG 1.75 1.75 1.75 2.00 2.00 2.00 2.50 2.50 2.50 3.00 3.00 3.00 P’ R U WGT 69 74 102 88 109 128 143 170 204 245 285 425 Timing gears control the relative position of the impellers to each other and maintain small but definite clearances. This allows operation without lubrication being required inside the gas casing. Dresser Roots Houston, Texas Headquarters • U.S. Toll Free Phone: 1-877-363-ROOT(S) (7668) • Direct Phone: +1 832-590-2600 Connersville, Indiana Operations • U.S. Toll Free Phone: 1-877-442-7910 • Direct Phone: +1 765-827-9285 United Kingdom Operations • Phone: +44 (0) 1484 422 222 USA/Canada Sales • Phone: +1 773-444-3360 Houston, Texas Factory Service • Phone: +1 713-896-4810 Mexico City Sales and Factory Service • Phone: +52 55 5889 5811 Dubai Sales and Factory Service • Phone: +971 4-8830831 Malaysia Sales • Phone: +60 3 2163 0480 China Sales • Phone: +86 10 8486 2440 Shanghai Factory Service • Phone: +86 21 5858 7638 ©2007 Dresser, Inc. all rights reserved. • Printed in the U.S.A. • All information subject to change without notice. • Universal RAI and EasyAir are registered trademarks of Dresser, Inc. • ROOTS, RAM X, and WHISPAIR, are trademarks of Dresser, Inc. S-60A01 rev.0608 www.dresser.com NOTES: 615U 68U 65U 59U 56U 53U 47U 45U 42U 36U 33U 41 95 122 58 132 169 109 231 292 64 136 172 136 281 354 183 375 470 92 168 313 164 292 536 259 447 802 190 333 481 305 535 772 572 1001 1445 1.7 37 3.0 91 3.7 118 2.4 54 4.1 128 5.0 165 3.9 102 6.8 224 8.3 286 2.4 59 4.1 132 5.1 168 4.7 129 8.2 274 10.1 346 6.2 174 10.8 366 13.3 461 3.4 86 5.2 163 9.1 308 5.7 155 8.7 283 15.0 527 8.4 248 12.8 436 22.0 791 6.4 181 9.9 324 13.9 471 10.3 291 15.7 520 21.8 757 19.1 544 29.1 973 40.0 1417 2.1 3.6 4.4 2.9 4.9 6.0 4.7 8.1 9.9 2.8 4.9 6.0 5.6 9.8 12.0 7.4 12.9 15.8 4.1 6.2 10.7 6.9 10.4 17.7 10.0 15.2 26.0 7.7 11.8 16.4 12.3 18.7 25.9 22.9 34.7 47.6 5 PSI 6 PSI CFM BHP CFM BHP 34 88 115 49 123 160 96 218 279 56 128 165 122 267 340 166 357 453 81 157 302 147 275 518 238 425 780 172 315 463 277 506 743 519 948 1392 10.2 15.6 21.5 16.3 24.8 34.0 5.4 8.2 14.0 9.1 13.8 23.2 3.7 6.5 7.9 7.5 12.9 15.7 2.8 4.7 5.8 3.8 6.5 7.9 157 300 447 252 481 718 71 147 292 132 260 503 49 122 158 110 255 328 28 82 109 41 115 152 11.5 17.4 24.0 18.3 27.8 38.0 6.1 9.2 15.6 10.2 15.5 26.0 4.2 7.2 8.8 8.4 14.4 17.6 3.1 5.3 6.5 4.3 7.3 8.8 8 PSI 9 PSI CFM BHP CFM BHP 2.4 31 4.2 85 5.1 112 3.3 45 5.7 119 6.9 1156 5.5 9.4 11.5 3.3 52 5.7 125 7.0 161 6.6 116 11.3 261 13.9 333 8.6 14.9 18.3 4.8 76 7.2 152 12.3 297 8.0 139 12.1 267 20.5 511 11.7 17.7 30.0 8.9 164 13.7 307 19.0 455 14.3 264 21.8 493 29.9 703 26.7 40.4 55.2 7 PSI CFM BHP 150 293 426 241 470 707 66 143 288 125 253 496 46 119 155 104 249 322 25 79 106 38 112 149 12.7 19.3 26.5 20.3 30.8 42.1 6.8 10.3 17.2 11.4 17.2 28.7 4.7 8.0 9.8 9.3 16.0 19.5 3.5 5.9 7.2 4.7 8.1 9.8 10 PSI CFM BHP 7.1 8.6 72 99 137 279 427 219 470 707 134 279 112 241 484 15.2 23.1 31.6 24.4 36.8 50.2 12.3 20.5 13.6 20.5 34.2 130 273 421 210 439 676 235 478 130 275 113 9.6 11.0 149 11.6 146 105 9.7 142 11.7 74 101 16.5 24.9 34.1 26.4 39.8 54.2 22.2 37.0 13.3 22.1 10.3 12.6 7.6 9.3 12 PSI 13 PSI CFM BHP CFM BHP 1. Performance based on inlet methane at standard pressure of 14.7 psia, standard temperature of 68°F, and specific gravity of 0.55. 2. Vacuum ratings based on inlet methane at standard temperature of 68°F, discharge pressure of 30” Hg and specific gravity of 0.55. 1.4 2.4 3.0 1.9 3.3 4.1 3.2 5.5 6.7 1.9 3.3 4.1 3.8 6.7 8.2 5.0 8.8 10.9 2.7 4.2 7.4 4.6 7.0 12.2 6.7 10.3 18.0 5.2 8.0 11.4 8.3 12.7 17.8 15.4 23.2 32.4 45 99 126 64 138 174 116 238 300 68 141 177 144 289 362 193 385 480 99 175 320 174 302 546 272 459 815 201 343 491 322 551 788 603 1032 1476 32U 1750 2950 3550 1750 2950 3550 1750 2950 3550 1750 2950 3550 1750 2950 3550 1750 2950 3550 1170 1750 2850 1170 1750 2850 1170 1750 2850 1170 1750 2350 1170 1750 2350 1170 1750 2350 4 PSI CFM BHP Frame Speed Size RPM PERFORMANCE TABLE: ROOTS Universal URAI-G 429 666 267 415 127 272 10.8 144 69 96 42.9 58.3 26.8 36.6 14.3 23.8 11.1 13.5 8.2 10.0 261 409 268 105 141 67 94 28.7 39.1 25.4 11.9 14.4 8.8 10.6 12 15 16 12 15 15 13 15 15 14 16 16 13 16 16 14 15 15 12 15 16 13 15 16 14 15 15 14 16 16 14 16 16 11 12 12 26 68 90 39 97 134 74 181 243 42 101 137 98 218 291 126 307 402 67 124 262 117 225 468 188 363 718 132 252 400 211 405 642 483 885 1329 2.0 4.3 5.6 2.8 5.9 7.2 5.0 9.8 11.9 3.0 6.2 7.6 5.9 12.5 15.2 8.4 15.4 18.8 4.3 7.5 13.4 7.2 12.6 21.0 11.4 18.4 30.8 8.7 15.1 20.6 13.9 24.0 32.8 20.5 33.7 46.0 14 PSI 15 PSI VACUUM DATA CFM BHP CFM BHP INHGV CFM BHP