Download BENDIX TCH-020-007 User's Manual

Transcript

Technical Bulletin

Bulletin No.: PRO-20-07 Effective Date: 1/1/91 Cancels: N/A Page: 1 of 3

subject: Ford F Series Truck Hydraulic Parking System HR-1

Hydraulic Relay Noise

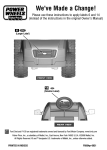

SUPPLY RESERVOIR CONTROL

DELIVERY

PORT

TW-11

DELIVERY

EXHAUST

PORT

FRONT BACK

HR-1 HYDRAULIC RELAY VALVE

While some noise is inherent in the operation of a hydraulic brake system (pump, check valves and pressure regulating

valves opening and closing) operators occasionally report hearing excessive noise emanating fromthe HR-1 hydraulic relay

valve. The HR-1 is used on Ford truck model series 600, 700, 800, 900, 7000 and 8000. Described variously as a “buzzing,

humming, popping or groaning” sound, the excessive noise is often attributed to a faulty HR-1. Because the HR-1 is mounted

on the firewall, adjacent to the Hydro-Max booster, sounds are amplified. Excessive HR-1 noise can be the result of air in

the parking brake system.

PARKING BRAKE

CONTROL VALVE (TW-44)

RESERVOIR

PARKING BRAKE PARKING BRAKE

CHAMBER CHAMBER

LT

((О)) SAGINAW BRAKE DRUM

PUMP «й ASSEMBLIES

DISC BRAKE

BRAKE .

HYDRO-MAX (PARKING) J

| BOOSTER с |

(SECONDARY) | | |

| (PRIMARY)

DISC С 1 1

BRAKE | |

PARKING |

(©) | hn | sea oo

! ı CHAMBER |

! ' {

| | |

1

CA nn J PARKING BRAKE

dh -—= CHAMBER

TYPICAL HR-1 SYSTEM

In order to eliminate the excessive HR-1 noise it is necessary to bleed the air from the spring brake actuators, using the

vehicle manufacturer's recommended procedure. Ifthe HR-1 noise is only temporarily eliminated and reappears ina short

period of time, then it is likely that an external leak exists somewhere in the Hydro-Max and/or parking brake system which

allows air to reenter the system. Check for fluid leakage and repair or replace as necessary.

POWER

FLUID

(100-150 PSI)

FROM HR-4

RELAY VALVE

CAGE

ROLLER

WEDGE TUBE

BRAKE

BACIONG

SPRING BRAKE MATE TAPPET

PARKING ACTUATOR WITH LUCAS GIRLING EXPANDER

Most fluid leaks can be found by visual inspection, however the spring brake actuators can LEAK INTERNALLY INTO THE

EXPANDER unit of the Lucas Girling A2LS drumbrake. Internal, hydraulic spring brake leakage can not be detected visually

unless the actuator is removed from the expander and checked for “wetness” inside the wedge tube.

CAUTION: Thoroughly read the vehicle manufacturer's maintenance manual before attempting removal of the hydrau-

lic spring brake actuators. A VERY HIGH SPRING LOAD IS USED AND INJURY CAN RESULT FROM IMPROPER

HANDLING.

Input Tappet/Piston

MANUAL ADJUSTOR

BACKING

ADJUSTER PLATE Seal Posili

WHEEL EXPANDER/ eal Position

CYLINDER PARKING

WHEEL

CYLINDER O-Ring

3/4" TAPERED

LINING

AND SHOE

ASSEMBLY

Roller Tappet/

LINING

INSPECTION die SHOE Piston

HOLE URN

SPRINGS

Abutment

Tappet

TYPICAL LUCAS GIRLING A2LS BRAKE ASSY. LUCAS GIRLING EXPANDER

Both actuators should be checked for internal leakage. if evidence of internal leakage is found in either of the actuators,

it may be necessary to repair or replace all components containing BRAKE FLUID SEALS, that may have been exposed

to hydraulic fluid from the leaking spring brake actuator. The affected components are the: A2LS expander unit, A2LS

wheel cylinder and possibly the master cylinder. Drain, flush and replace the brake fluid in the service brake system to

eliminate any hydraulic fluid contamination.