Download BENDIX SD-01-670 User's Manual

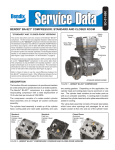

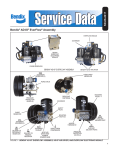

Transcript