Download Atdec TH-30-50-RW flat panel wall mount

Transcript

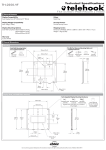

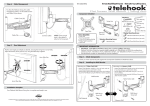

C Attaching the Display to the Wall Plate Installation Instructions C.1. Attaching the Display to the Wall Plate TELEHOOK C.2. Pivot Head Load Capacity Adjustment Note: This procedure will require two persons M12 Hex Nut 30”-50” UNIVERSAL ROTATING WALL MOUNT Tighten Important Notes The Telehook 30-50 Universal Rotating Wall Mount supports flat panel displays from 30” (76cm) to 50” (127cm) and supports a maximum load of 85kgs (187lbs). Adjusting the Pivot Head to suit the weight of the Display Back Plate Mounting Slots Note: For demonstration purposes, the wall has been omitted from the above image. With the mount attached to the display, lift the display and slide the Back Plate into the Mounting slots to ensure a secure connection. D The Pivot head is factory set to hold approximately 35kgs (77lbs). If the display is not holding its position when placed on the wall it may be necessary to remove the display from the wall and tighten the M12 Hex Nut on the back of the Pivot Head using a 17mm (11/16”) socket wrench or shifter. To achieve a one-touch effortless adjustment setting it is advised that the nut be tightened at half turns and re-tested, until the desired friction is achieved. Alternatively the M12 Hex Nut can be over tightened in order to lock the display in position. This product is factory set to support 35kgs (77lbs), and will need to be adjusted if the display is heavier or lighter. The manufacturer does not accept responsibility for incorrect installation. Component Checklist Bits Box Extension Plate For additional security, it is suggested that a Padlock be attached to the Back plate as shown. The Padlock (not supplied) should have a shackle diameter no larger than 4mm ( 3/16”). Coach Screw (x4) Masonry Wall Plug (x4) Spacer Bush (x4) Large Washer (x4) Allen Key M6x16mm Socket Drive Screw (x12) Bracket Plate (x2) TOOLS REQUIRED: Power Drill 12mm or 8mm Drill Bit Phillips Head Screw Driver Spirit Level 17mm (11/16”) Socket Wrench or Shifter A Bracket (x2) Small Washer (x4) Wall Plate M6x16mm Phillips Head Screw (x6) M5x16mm Phillips Head Screw (x6) M4x16mm Phillips Head Screw (x6) Multi Washer (x4) Mounting the Wall Plate Masonry Wall Masonry Wall Plug Timber Stud Wall TIP: Use a spirit level to ensure the wall plate is horizontal 12mm (1/2 ”) Hole Mounting Slot Wall Plate Note: It is recommended to mount the Wall Plate by firmly fixing the four Coach Screws into two studs. However, if the weight of the display is less than 50kgs (110lbs), it is possible to mount the Wall Plate to one stud by fixing the two Coach Screws through the two Centre holes. TIP: Use a spirit level to ensure the wall plate is horizontal Timber Stud 8mm ( 5 /16”) Hole Centre Holes Shackle 4mm ( 3 /16”) diameter or less Back plate M8x20mm Phillips Head Screw (x4) Pivot Head Security Option Note: For demonstration purposes, the display has been omitted from the image below. Mounting Screws Padlock Note: Ensure the Wall Plate is mounted with the narrow end of the Mounting Slot at the bottom. Coach Screw Due to continuing product development, the manufacturer reserves the right to alter specifications without notice. Published: 18.04.07 © Large Washer Note: Ensure the Wall Plate is mounted with the narrow end of the Mounting Slot at the bottom. Large Washer Coach Screw B Choosing and Assembling the Correct Mounting Configuration Measure the mounting hole pattern on the back of the display. Select the appropriate configuration (either 1, 2 or 3) that best suits the mounting hole pattern of the display then attach the product to the display as shown. Configuration 3: 260mm to 660mm (101/4 ”-26”) x 200mm to 400mm (8”-153/4 ”) Mounting Hole Patterns M6 Screw Hole 100mm (4”) Back of Display Top of Display 400mm (153 /4”) 200mm (8”) ii Multi Washer 200mm (8”) Note: The 100mmx200mm mounting configuration is shown. For mounting displays with 100mmx100mm mounting hole patterns, use the 100mmx100mm holes in the Pivot Head. 100mm (4”) M8 Screw Hole M4 & M5 Screw Hole Mounting Screw Pivot Head 100mm (4”) Attaching the Bracket to the Display 260mm (101/4”) Configuration 1: VESA Compliant 100mmx100mm (4”x4”) & 100mmx200mm (4”x8”) Mounting Hole Patterns Slot In order to ensure the display is securely attached to the bracket it is recommended that the bracket be fastened with the mounting screws aligned along the bottom edge of the slots. It is also important that you use the supplied Multi Washer and ensure that the tightest fitting hole in the washer is used for the specific size screw 660mm (26”) M6 Socket Drive Screw Pivot Head Configuration 2: 200mmx200mm to 400mm (8”x8”-153/4 ”) Mounting Hole Patterns Note: If the display has a vertical mounting distance of 200mm and requires the use of the M6 Mounting Screws, it will be necessary to substitute the MuIti Washers for the small washers provided. 200mm 400mm (153 /4”) (8”) Pivot Head Bracket Plate Extension Plate Multi Washer M6 Mounting Screw Small Washer M6 Socket Drive Screw Top of Display 200mm (8”) Note: When assembling the product, ensure the Telehook Badges are positioned towards the bottom of the display Telehook Badge Mounting Screw Multi Washer Spacer Bush Mounting Screw Spacer Bush Assembly Back of Display Multi Washer If the mounting holes are recessed into the back of the display, use the supplied Spacer Bushes to pack the recessed hole and ensure that the bracket is securely fixed to the display. Telehook Badge Bracket Bracket Bracket Plate Note: When assembling the product, ensure the red Telehook Badges are positioned towards the bottom of the display Mounting Screw Spacer Bush Top of Display Back of Display Recessed Hole