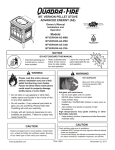

Download Quadra-Fire MTVERNON-AE

Transcript