Download Kodak 6B7198 Photo Scanner User Manual

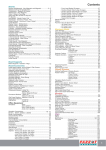

Transcript