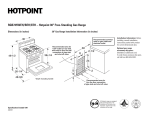

Download Hotpoint RGB744 Range User Manual

Transcript