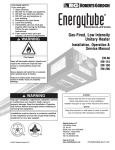

Download Roberts Gorden operation & service Service manual

Transcript