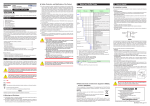

Download Autostart AS-1251 Operating instructions

Transcript