Download Craftsman 917.292350 Owner`s manual

Transcript

OWNER'S

MANUAL

Caution:

Read and follow

all Safety Rules

and instructions

Before Operating

This Eqmpment

5,0 HP

24

CH TUNEW_DTH

FRONT TiNE T_LLER

o AssembUy

Operation

Customer Responsibilities

Service and Adjustments

- Repair Parts

Sears, Roebuck

and Co., Hoffman

Estates,

UL 60179 U.S.A.

Safe Operation

SAFETY

RULES PoweCed

for Walk-Behind

Practices

TRAINING

=

•

=

Read the Owner's Manual carefully. Be thoroughly

familiar with the controls and the proper use of the

equipment, Know how to stop the unit and disengage

the controls quickly,

Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

,

o

=

o

o

o

Thoroughfy inspect the area where the equipment is to

be used and remove a{I foreign objects_

Disengage all clutches and shift into neutral before

starting the engine (motor).

Do not operate the equipment without wearing adequate outer garments. Wear footwear that wi{l improve footing on slippery surfaces.

Handle fuet with care; it is high{y flammable,

Use an approved fuel container_

Never add fuel to a running engine or hot engine

Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors.

Repiace gasoline cap securely and clean up spilled

fuel before restarting.

Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors

Never attempt to make any adjustments while the

engine (motor) is running (except where specifically

recommended by manufacturer).

OPERATION

°

•

-

o

•

°

,

o

o

o

Do not put hands or feet near or under rotating parts.

Exercise extreme caution when operating on or crossing gravel drives, walks, or roads Stay alert for hidden

hazards or traffic.. Do not carp/passengers,.

After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly inspect the tiller for any damage, and repair the damage

before restarting and operating the tiller,

Exercise caution to avoid slipping or falting_

tf the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

Stop the engine (motor) when leaving the operating

position.

Take all possible precautions when leaving the machine unattended,

Disengage the fines, shift into

neutral, and stop the engine.

Before cleaning, repairing, or inspecting, shut off the

engine and make certain a!t moving parts have stopped.

DisconneCt the spark plug wire, and keep the wire

away from the plug to prevent accidental starting.

Disconnect the cord on electric motors.

Do not run the engin e indoors; exhaust fumes are

dangerous.

Never operate the tiiler without proper guards, plates,

or other safety protective devices in place=

Tillers

•

o

Keep children and pets away..

Do not overload the machine capacity by attempting to

til! too deep at too fast a rate,

o

Never operate the machine at high speeds on slippery

surfaces. Look behind and use care when backing.

Never allow bystanders near the unit,.

o

o

Keep the area of operation clear of att persons, particufarly small children, and pets

PREPARATION

Rotary

o

o

Use only attachments and accessories approved by

the manufacturer of the tiller (such as wheel weights,

counterweights, cabs, and the like).

Never operate the tiller without good visibility or light

Be careful when tilling in hard ground. The tines may

catch in the ground and propel the tilter forward_ If this

occurs, let go of the handlebars and do not restrain the

machine,

MAINTENANCE

•

o

o

o

AND STORAGE

Keep machine, attachments, and accessories in safe

working condition.

Check shear pins, engine mounting bolts, and other

bolts at frequent intervals for proper tightness to be

sure the equipment is in safe working condition°

Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present, such as

hot water and space heaters, clothes dryers, and the

like. Allow the engine to coot before storing in any

enclosure.

Always refer to the operator's guide instructions for

important details if the tiller is to be stored for an

extended period.

- iMPORTANT

-

CAUTIONS, IMPORTANTS, AND NOTES ARE A MEANS

OF ATTRACTING ATTENTION TO IMPORTANT OR

CRITICAL INFORMATION IN THIS MANUAL

IMPORTANT: USED TO ALERT YOU THAT THEREIS A

POSSIBILITY OF DAMAGING THIS EQUIPMENT

NOTE:

Gives essential information that will aid you to

better understand, incorporate, or execute a particular set

of instructions.

portant

precautions.

means

Look for safety

this symbol

to point It out

imCAUTION!!! BECOME ALERT!!! YOUR

SAFETY IS INVOLVED.

CAUTION:

Always disconnect

spark

plug wire and place wire where it cannot contact spark plug in order to prevent accidental starting when setting

up, transporting,

adjusting or making

repairs.

,,;;,,,_

.........

,.....

....

i

,,

,i ¸¸

WARNING

The engine exhaust

from this product

contains criemicals

known to the State of California to cause cancer,

birth defects,

or other

reproductive

harm.

........

_1,,,,

,,, ,,, ,,,,,

,,,_

PRODUCT

CONGRATULATIONS

on your purchase of a Sears Tiller,

It has been designed, engineered and manufactured to

give you the best possible dependability and perfoi'mance.

Should you experience any problems you cannot easily

remedy, please contact your nearest authorized Sears

Service CentedDepartment.

They have competent, welltrained technicians and the proper tools to service or repair

this unit,

Please read and retain this manual The instructions will

enable you to assembfe and maintain your tiller properly.

Always observe the "SAFETY RULES".

MODEL

NUMBER

917.292350

SPECIFICATIONS

HORSEPOWER:

50 HP

DISPLACEMENT:

I2.57cu. in (206cc)

GASOLINE CAPACITY:

3 Quarts

Unleaded Regular

OIL TYPE (APFFGISG):

(CAPACITY: X oz.)

SAE 30W (Above 32°F)

SAE 5W-30 (Below 32°F)

SPARK PLUG :

(GAP: .030")

Champion

RJ19LM (STD361458)

SERIAL

NUMBER

MAINTENANCE

DATE OF

PURCHASE

A Sears Maintenance Agreement is available on this product Contact your nearest Sears store for details

CUSTOMER

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON THE MODEL PLATE ATTACHED TO

THE RIGHT HAND ENGINE BRACKET.

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

AGREEMENT

RESPONSIBILITIES

•

Read and observe the safety rules,

=

Follow a regular schedule in maintaining, caring for and

using your tiller.

Follow the instructions

under the "Customer

Responsibilities" and "Storage" sections of this Owner's

Manual.

•

IMPORTANT:

THIS UNIT IS EQUIPPED WITH AN INTERNAL COMBUSTION

ENGINE AND SHOULD NOT BE USED ON

OR NEAR ANY UNIMPROVED

FOREST-COVERED,

BRUSH-COVERED

OR GRASS COVERED

LAND UNLESS THE

ENGINE'S EXHAUST

SYSTEM IS EQUIPPED WITH A SPARK ARRESTER

MEETING APPLICABLE

LOCAL OR STATE

LAWS (tF ANY), tFASPARKARRESTERISUSED,

IT SHOULD BE MAfNTAtNED

iN EFFECT1VE WORKfNG ORDER BY

THE OPERATOR.

IN THE STATE OF CALIFORNIA

THE ABOVE IS REQUIRED

BY LAW (SECTION 4.442 OF THE CALIFORNIA

PUBLIC

RESOURCES

CODE).

OTHER STATES MAY HAVE SIMILAR LAWS.

FEDERAL LAWS APPLY ON FEDERAL

LANDS.

SEE YOUR SEARS AUTHORIZED

SERVICE

CENTER FOR SPARK ARRESTER,

REFER TO THE REPAIR

PARTS

SECTION OF TH1S MANUAL FOR PART NUMBER

iii

..ql.l...

i _1._.:.._

LIMITED

n

ONE YEAR WARRANTY

.

uulln .....................

IT.i i lol

ON CRAFTSMAN

TILLER

For one (1) year from date of purchase, when this Craftsman Tiller is maintained, lubricated, and tuned up according

to the operating and maintenance instructions in the owner's manual, Sears will repair free of charge any defect in

material or workmanship.

This Warranty does not cover:

o

Expendable items which become worn during normal use, such as tines, spark plugs, air cleaners and belts,

o

Repairs necessary because of operator abuse or negligence, including bent crankshafts

maintain the equipment according to the instructions contained in the owner's manual.

•

If this Craftsman Tiller is used for commercial or rental purposes, this Warranty applies for only thirty (30) days

from the date of purchase.

and the failure to

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN TILLER TO THE NEAREST SEARS

SERVtCE CENTER/DEPARTMENT

IN THE UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS

PRODUCT lS IN USE IN THE UNITED STATES.

This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL 60179

,

,,,., ....

. ii.

. i.i,

.

.nil

irl

SAFETYRULES...........................................................

2

CUSTOMER RESPONSIBILITIES ..................... 3, 12.,14

PRODUCT SPECIFICATIONS ...................................... 3

WARRANTY ............... ...................................................

3

ACCESSORIES .............................................................

5

ASSEMBLY ................................................................

6-7

OPERATION .............................................................

8-11

MAINTENANCE SCHEDULE ......................................

t2

SERVICE & ADJUSTMEI_JTS ................................. 14-17

STORAGE ...................................................................

18

TROUBLESHOOTING .................................................

19

REPAIR PARTS-TILLER ........................................

20-25

REPAIR PARTS-ENGINE ......................................

26-30

SERVICE/PARTS ORDERING .................... Back Cover

BNDEX

A

Oil Type ................................ 10,t3

Repair Parts ........................ 26-30

Spark Plug ...................................14

Starting ..................................... 10

Stopping .........................................g

Storage ..........................................18

Winter Operation ..................... 13

Accessories ............................................5

Adjustments:

Carburetor ...................................17

Depth Stake ................................ 9

Handle Height ........................... 14

Tines ....................................... 14-15

V-Belt ............................................16

Wheels ......................................... 9

Air Cleaner ....................................... 13

B

Belt, V-:

Belt Guard ............................... 17

Repair Parts ............................ 21

V-Belt Replacement ................. 16

C

Cooling System ..................................13

Controls:

Choke ............................................ 8

Throttle ....................................... 8

Tines ................................................8

Cultivating ..............................................

11

Customer Responsibilities:

Air Cleaner ....................................13

Cooling System ...................... 13

Finish ....................................... 14

Maintenance Schedule ............ '12

Muffler ....................................... 14

Oil Change .................................. 13

Spark Plug ................................ 14

Transmission ........................... 14

F

Fuel:

Filling Tank .............................. t 0

Storage ................................

18

Type ........................................... 10

Finish:

Maintenance ............................... 14

H

Handle:

Height Adjustment ..................... 14

Repair Parts ......................................

20

L

Lubrication:

Lubrication Chart .................. 12

Engine ............................................

13

M

Muffler:

Maintenance ..........................

14

Spark Arrester .......................... 3

O

Oil:

R

Repair Parts

Tiller .........................................20-24

Engine .................................. 26-30

Rules for Safe Operation ................... 2

S

Service & Adjustments:

Carburetor ...........................

t7

Handle Height ..............................14

Tines ..................................... 14,-15

V-Belt ......................................

16

Wheels ........................................... 9

Service:

Repair Parts ........................ 20-30

Service Record ....................... 12

Spark Plug:

Gap ..................................................3

Maintenance ..........................

14

Storage:

Fuel System .....................................

18

Tiller ......................................

18

T

Tilling ......................................................

9,11

Tines:

Arrangement ........................ 14-15

Operation .........................................9

Repair Parts ............................... 23

Replacement ...............................15

Transmission:

Maintenance ........................... 14

Repair Parts .............................. 24

Troubleshooting ............................... 19

Transporting ....................................... 10

Level ...................................................

10

Type ...................................... 10,13

Operation:

Depth Stake:

Cultivating .....................................11

Adjustment .......................................9

W

Fill Fuel Tank ................................10

Re#air Parts ..........................................

22

Warranty

.........................................................

3

Starting Engine .......................... 10

E

Stopping Tines & Engine .......... 9

Wheels:

Tilling ...............................................9

Adjustments ...................................9

Engine:

Tilling Hints ...................................11

Repair Parts,: .................................

22

Air Cleaner ............................... 13

Tine Operation ......................................

9

Cooling System .............................

13

Transporting Tiller ........................10

Fuel Type ...............................

10

Winter Operation ...................... 13

Lubrication .............................. 13

Oil Level ,.:................................ 10

D

4

i......

=,,,,==,,,

_

i

_L,I._

ill,

i

ACCES$ORUE$

These accessories

were available when the tiller was purchased.

They are also available at most Sears Retail

outlets, Catalog and Service Centers. Most Sears Stores can order repair parts for you when you provide the model

number of your tiller.

ENGINE

,

, i

SPARK

.............

PLUG

MUFFLER

AIR FILTER

GAS CAN

,T_,,

,,,,, ........

TILLER

,,,

ENGINE

OIL

STABILIZER

, i, ,,,,,,_,,

,

MAINTENANCE

BELT

CLEVIS PIN

TINES

HAIRPIN

, ,,,

5

,

CLIP

,,,_,,,,_,,J

.......

....

• :

.........

,,,,===

=......

.,,

.

•

ASSEMBLY

Your new tiller has been assembled at the factory with exception of those parts left unassembled for shipping purposes,, To

ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely° Use the

correct tools as necessary to insure proper tightness,

TOOLS REQUIRED

FOR ASSEMBLY

OPERATOR'S

POSITION

(See Fig. 1)

When right or left hand is mentioned in this manual, it

means when you are in the operating position (standing

behind tiller handles)_

A socket wrench set wilt make assembly easier° Standard

wrench sizes are listed.

(1) Utility knife

(1) Screwdriver

FRONT

(1) Pair of pliers

(2) 1/2" wrenches

LEFT

IGHT

OPERATOR'S

POSITION

FIG. 1

CONTENTS

OF HARDWARE

(1) Manual

PACK

(1) Plastic Cable Clip

1,1 t

i, J J

i J _,JJ,

itui

0

(2) Flange Locknuts 5/16-18 UNC

(2) Cardage Bolts 5116-18 UNC x 2_3/8 Gr. 5

©

(2) Hex Bolts 5/16-18 x 1-1/4

(2) Hex Nuts 5/I6-t8

6

(2) Lock Washers 5/16

........

=, , i,

u ,,,i,

i,l_[j_

,

u

=....

i

ASSEMBLY

i, = ,i,,=,,,i....

UNPACK

CARTON

& INSTALL

HANDLE

(See

Fig, 2)

i, =, i,=,=

I

&

i=

, i,,i,i ....

=

H

staples when handling or disposing of

|

CAUTION_

Be

careful

cartoning

material.

I'

i

of

expOsed

H,I..

o

Slowly lift handle column up and slip over handle

mount._ -

,

,

Remove packing from carton.

Secure handle column to handle mount using two (2)

carriage bolts and two (2) flange lecknuts Tighten both

flange locknuts securely.

Insert plastic cable dip into hole in handle column_

.

Route tine control cable through plastic cable clip on

handle celumn_

,

Remove packing material from handle assembly.

,

Cut cable ties securing tiller to skid

•

Cut away carton and remove tiller from skid by pulling

backwards°

STAKE

= ,, ,i, ,=m

ASSEMBLY

Insert stake support between engine bracket halves

with stake spring down.

NOTE: it may be necessary to Ioosen nut "A"o

IMPORTANT:

WHEN UNPACKING AND ASSEMBLING

TILLER. BE CAREFUL NOT TO STRETCH OR KINK

CABLE(S).

= Cut cabte ties securing handle cotumn.

•

...................

INSTALL DEPTH

(See Fig. 3)

-

Bolt stake support to engine brackets with bolts, lock

washers and nuts, Tighten securely. Also tighten nut

"A" if it was necessary to loosen.

•

Depth stake must move freely. If it does not, !oosen

support boll

ENGINE

BRACKET

NUT"A"

DEPTH STAKE

_ORT

DEPTH

STAKE

TINECONTROL

SUPPORT

BOLT

HEXBOLTS,

LOCK WASHERS,

AND HEX NUTS

FIG. 3

HANDLE

MOUNT

HANDLE

TINECONTROL

CABLE

o

-HANDLE

COLUMN

Hand!e height may be adiusted to better suit operator_

(See HANDLE HEIGHT in the Service and Adjustments section of this manual).

TILLING

.

HEIGHT

WIDTH

Tilling width may be adjusted to better handle your

tilling conditions (See "TINE ARRANGEMENT" in the

Service and Adjustments section of this manual),

TINE OPERATION

o

BOLT

FLANGE

LOCKNUT

CABLE

CLiP

FIG. 2

7

Check tine operation before first use

(See 'q'INE

OPERATION CHECK" in the Service and Adjustments

section of this manual).

OPERATHO

KNOW YOUR TILLER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR TILLER.

Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

, ,

These symbols

meaning.

i'n

,

may appear on your Tiller or in literature

supplied

with the product.

,...................

Learn and understand

&

FORWARD

TINE

i,i

i

their

R0.H

TILUNG FORWARD NEUTRAL REVERSE CAUTION ENGINE

ORWARNING ON

i,,,

' .....

ENGINE

OFF

FUEL

FAST

OIL

STOP0

,,,u

CONTR_

CHOKE CONTROL

- THROTTLE

_=_/_

CONTROL

'"

p

DEPTH5

RECOIL STARTER

HANDLE

FIG. 4

MEETS

ANSI SAFETY

REQUIREMENTS

Sears tillers conform to the safety standards of the American National Standards Institute,,

DEPTH STAKE - Controls forward speed and the depth at

which the tiller will dig.

RECOIL STARTER HANDLE - Used to start the engine,,

FORWARD TINE CONTROL - Engages tines in forward

direction.

CHOKE CONTROL - Used when starting a cold engine.

THROTTLE CONTROL - Controls engine speed,

8

,' ,, .................

_,r,.,

OPERATION

The operation of any tiller can result in foreign objects thrown into the eyes, which can

result in severe eye damage. Always wear safety glasses or eye shields before starting

your tiller and while tilling. We recommend a wide vision safety mask over the spectacles

or standard safety glasses.

STOPPING

TILLING

(See Fig. 5)

The speed and depth of tilling is regulated by the position

of the depth stake and wheel height.

TINES

•

Release tine control to stop movement,

The depth stake should always be below the wheels for

digging. It serves as a brake to slow the tilter's forward

motion to enable the tines to penetrate the ground. Also,

the more the depth stake is lowered into the ground the

deeper the tines will dig,

ENGINE

o

Move throttle control to "STOP" position,

•

Never use choke to stop engine..

DEPTH STAKE (See Fig. 6)

TINE CONTROL

"OFF" (UP) POSITION

Adjust depth stake by removing the hairpin clip and clevis

pin,. Change depth stake to desired position. Replace the

clevis pin and hairpin clip,

°

For normal tilling, set depth stake at the second or third

hole from the top,

WHEELS (See Fig. 6)

Adjust wheels by removing the hairpin clip and clevis pin,

Change wheel position,, Replace the hairpin clip and clevis

pin.

TINE CONTROL

"ON" (DOWN) POSITION

CHOKE

•

For normal tilting, set wheels at the second or third hole

from the top,

HAIRPIN CLIP

AND CLEVIS PIN

CONTROL

DEPTH

STAKE

FIG. 5

TINE

OPERATION

(See

HAIRPIN CLIP

AND CLEVIS PIN

Fig. 5)

Start engine and move throttle control to desired speed.

•

FIG. 6

Squeeze line control to handle.

9

OPERATHON

......

TO TRANSPORT

,LI_

.....

__

......

ADD GASOLINE

o

ing, allow tiller engine and muffler to

CAUTION: Before lifting or transportcool. Disconnect sparkplugwire.

Drain

gasoline from fuel tank,

AROUND THE YARD

=

Tip depth stake forward until it is held by the stake

spring.

°

Push tiller handles down, raising tines off the ground.

=

Push or pull tiiler to desired Iocation_

AROUND TOWN

•

o

Disconnect spark plug wire.

Drain fuel tank.

o

Transport in upright position to prevent oil feakage.

BEFORE STARTING

ENGUNE

Fill fuel tank_ Use fresh, clean, regular unleaded

gasoline. (Use of leaded gasotine wil_increase carbon

and lead oxide deposits and reduce valve tife)

IMPORTANT: WHEN OPERATING iN TEMPERATURES

BELOW 32°F (0°C), USE FRESH, CLEAN, WINTER GRADE

GASOLINE TO HELP iNSURE GOOD COLD WEATHER

STARTING.

WARNING:

Experience indicates that alcohol blended

fuels (called gasoho! or using ethanol or methanol) can

attract moisture which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before

storage of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty Use fresh fuel next season. See Storage section

of this manual for additional information, Never use engine

or carburetor cleaner products in the fuel tank or permanent

damage may occur.

IMPORTANT;

BE VERY CAREFUL NOT TO ALLOW DIRT

TO ENTER THE ENGINE WHEN CHECKING OR ADDING

OIL OR FUEL. USE CLEAN OiL AND FUEL AND STORE

IN APPROVED,

CLEAN, COVERED CONTAINERS.

USE

CLEAN FILL FUNNELS.

FILL ENGINE

WITH OIL (See Fig. 7)

=

With engine level, remove engine oil filler plug

.

Fill engine with oil to point of overflowing. For approxi*

mate capacity see "PRODUCT SPECIFICATIONS" on

page 3 of this manual

Tilt tiller back on its wheels and then re-leveL

o

=

With engine level, refill to point of overflowing {fnecessary_ Replace oil filler pfugo

o

For cold weather operation you should change oil for

easier starting (See "OIL VISCOSITY CHART" in the

Customer Responsibilities section of this manuat)_

.

of fuel tank to prevent spills and to

allow

for fuel

If gasoline

is

CAUTION:

Fillexpansion.

to within 1/2

inch of top

accidentally

spilled,

move machine

away from area of spill. Avoid creating

any source of ignition until gasoline

vapors have disappeared.

To change engine oil, see the CtJstomer ResponsibiiF

ties section of this manual.

OIL

OIL

FILLER

PLUG

FIG. 8

Do not overfill, Wipe off any spilled oil

or fuel. Do not store, spill or use gasoline near an open flame.

TO START

t

_

U_jtion

ENGINE

CAUTION:

(See Fig. 8)

Keeptine control

when starting

in "OFF"

engine.

When starting engine for the first time or if engine has run

out of fuel, itwill take extra pulls of the recoil starter to move

fuel from the than to the engine.

= Make sure spark plug wire is properly connected

= Ptace throttle control in "FAST" position.

= Move choke control to full "CHOKE" position Grasp

recoil starter handle with one hand and grasp tiller

handle with other hand. Pul! rope out slowly until

engine reaches start of compression cycle (rope wili

pull slightly harder at this point)

= Pull recoil starter handle quickly. Do not let starter

handle snap back against starter_ Repeat if necessary_

•

If engine fires but does not start, move choke control to

half choke position. Pull recoil starter handle until

engine starts°

°

When engine starts, slowly move choke control to

"RUN" position as engine warms up_

NOTE: A warm engine requires Iess choking to start°

o Move throttle control to desired running position_

= Allow engine to warm up for a few minutes before

engaging tines.

NOTE: If at a high altitude (3000 feet) or in cold temperatures (below 32°F), the carburetor fuel mixture may need to

be adjusted for best engine performance. See "TO ADJUST CARBURETOR" in the Service and Adjustments

section of this manual

10 NOTE: If engine does not start, see troubleshooting points°

_, ,

r ..........

I ........

,,,,H=I=,

,m

OPERATIO

.

You will find tilling much easier if you leave a row

untilled between passes. Then go back over the entire

area at right angles (See Fig 9)There are two reasons

for doing this.. First, wide turns are much easier to

negotiate than about-faces. Second, the tiller won't be

pulling itself, and you, toward the row next to it.

.

Set depth stake and wheel height for shallow tilling

when working extremely hard soil or sod. Then work

across the first cuts at normal depth.

SPARK

PLUG

CONTROL

CONTROL

CTI I 13I !,!'1 I. 1

RECOILSTARTER

HANDLE

_, ÷

FIG. 8

BREAKING

i_

u

HINTS

handling your tiller, start actual field

CAUTION:

Until you

are accustomed

to

use

with throttle

in slow

position.

....

,=

i =1,1...........

=,,mr,

I

÷

÷._

_

<-

.<-

÷

<-

_

<--..._j

<--

"<-

÷

"<-

<-

<-

_-

L/

Cultivating is destroying the weeds between rows to prevent them from robbing nourishment and moisture from

the plants At the same time, breaking up the upper layer

of soil crust will help retain moisture in the soil. Best

digging depth is 1"-3"..

. You wilt probably not need to use the depth stake.

Begin by tipping the depth stake forward until it is held

by the stake spring

o Cultivate up and down the rows at a speed which will

allow tines to uproot weeds and leave the ground in

rough condition, promoting no further growth of weeds

and grass (See Fig. 10).

lfyou are straining or tilter is shaking, the wheels and depth

stake are not set properly in the soil being tilledo The proper

setting of the wheels and depth stake is through trial and

error and depends upon the soil condition_ (The harder or

wetter the ground, the slower the engine and tine speed

needed. Under these poor conditions, at fast speed the tiller

will run and jump over the ground)

",_J i

A properly adjusted tiller wit! dig with little effort from the

operator.

.

_

CULTIVATING

To help tiller move forward, lift up the handles slightly (thus

lifting depth stake out of ground). To slow down the tiller,

press down on handles

-

_

FIG. 9

Check tine operation and adjust if necessary. See

_ T NE OPERATION

CHECK _ In the Servce an d Adjustments section of this manual.

TILLING

÷

IN YOUR TILLER

Break-in your belt(s), pulleys and fine control before you

actually begin tilling.

o Start engine, tip tines off ground by pressing handles

down and engage tine control to start tine rotation_

Allow tines to rotate for five minutes.

-

t, 1

_

_J

fx

Tilling is digging into, turning over, and breaking up

packed soil before planting

Loose, unpacked soil

helps root growth. Best tilling depth is 4"-6". A tiller will

also clear the soil of unwanted vegetation. The decomposition of this vegetable matter enriches the soil.

Depending on the climate (rainfall and wind), it may be

advisable to tilt the soil at the end of the growing season

to further condition the soil

A

\J

\.J

Soil conditions are important for proper tilting. Tines witi

not readily penetrate dry, hard soil which may contribute to excessive bounce and difficult handling of your

tiller. Hard soil should be moistened before rifling;

however, extremely wet soil will "ball-up" or clump

during tilling. Wait until the soil is less wet in order to

achieve the best results.. When tilling in the fall, remove

vines and long grass to prevent them from wrapping

around the tine shaft and slowing your tilling operation.

FIG. 10

11

v

CUSTOMER

RESPONS BmL TSES

----

i,,

, ......

i

,,

..........

MAINTENANCE

SCHEDULE

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

SERVICE

DATES

Check Engine Oil Le,2el

Change Engine Oil

......

i

,, i,i

u,i

O11Pivot Points

6'/

inspect Spark Arrester Muffler

illU,i n u, ll_

i:_,_

Inspect Air Screen

6/

Clean or Replace Air Cleaner Cartridge

Clean Engine Cylinder Fins

Replace Spark Plug

t - Change more often when operating under a heavy load or in high ambient temperatures

2 - Service more often when operating In dirty or dusty conditions

GENERAL

RECOiVliViENDATaONS

LUBRICATION

CHART

The warranty on this tiller does not cover items that have

been subjected to operator abuse or negligenceo To

receive full value from the warranty, operator must maintain ti{Eeras instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your tiller°

** ENGINE

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each

season.

o

* TINE CONTROL

Once a year you should replace the spark plug, clean

or replace air filter, and check tines and belt for wear.

A new spark plug and clean air filter assure proper airfuel mixture and help your engine run better and last

longer.

BEFORE

EACH USE

°

Check engine oil level

o

*,

Check tine operation..

Check for !oose fasteners.

" IDLER

ARM

LUBRICATION

Keep unit well lubricated (See "LUBRICATION

* SAE 30 OR 10W30 MOTOR OIL

REFER TO CUSTOMER RESPONSIBILITIES

CHART") •

12

ENGINE

SECTION.

CUSTOME

..............

,

...........

LLmES

i,H

I AL

.........

.....

..............

..........

,,

•

IA

,i,,,

Disconnect spark plug wire before performing any maintenance (except carburetor adjustment) to prevent

accidental starting of engine°

Prevent fires! Keep the engine free of grass, leaves, spilled oil, or fuel. Remove fuel from tank before tipping

unit for maintenance. Clean muffler area of all grass, dirt, and debris.

Do not touch hot muffler or cylinder fins as contact may cause burns.

ENGINE

AIR CLEANER

LUBRICATION

Service air cleaner cartridge every twenty-five hours, more

often if engine is used in very dusty conditions.

Use on y high quality detergent oil rated with API service

classification SF, SG or SHo Select the oil s SAE viscos ty

grade according to your expected temperature.

SAE VISCOSITY GRADES

_

(See Fig. 13)

.

Loosen air cleaner screws, one on each side of cover°

°

Remove air cleaner cover.

o

Carefully remove air cleaner cartridge. Be careful Do

not allow dirt or debris to fan into carburetor.

o

Clean by tapping gently on a flat surface.

.

If very dirty or damaged, replace cartridge.

-

Clean and replace cover° Tighten screws secureiy_

......:

FIG. 11

CAUTION:

NOTE: Although multi-viscosity oils (5W-30, 10W-30, etco)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F (0°C), Check your engine oil level more frequently to

avoid'possible engine damage from running low on oil

Change the oil after every 25 hours of operation or at least

once a year if the tractor is not used for 25 hours in one year.

Check the crankcase oil level before starting the engine

and after each five (5) hours of continuous use° Add SAE

30 motor oil or equivalent. Tighten oil filler plug securely

each time you check the oil level.

......

,',

Petroleum

solvents,

such

cartridge.

They may cause deterioraas kerosene,

tion

of the cartridge.

are notto be

Doused

not to

oilclean

cartridge.

Do not use pressurized

air to

clean or dry cartridge.

, ,,, ,, ,,, ....

: H,i

COVER

AIR

Cl

SCREW

TO CHANGE ENGINE OIL (See Figs. 11 and 12)

Determine temperature range expected before oil change.

All oil must meet API service classification SF, SG or SHo

.

Be sure tiller is on level surface.

•

Oil will drain more freely when warm.

o Catch oil in a suitable container.

o Remove drain plug.

°

Tip tiller forward to drain oil.

•

After oil has drained completely, replace o11drain plug

and tighten securely.

Remove oil filler plug Be careful not to allow dirt to

enter the engine.

.

Refill engine with oil. See "FILL ENGINE WITH OIL"

in the Operation section of this manual.

AIR

CLEANER

CARTRIDGE

!

FIG. 13

COOLING

SYSTEM

(See Fig. 14)

Your engine is air cooled. For proper engine performance

and long life keep your engine clean.

o

Clean airscreen

frequently using a stiff-bristfedbrush.

o

Remove blower housing and clean as necessary

o

Keep cylinder fins free of dirt and chaff.

CYLINDER

FINS

MUFFLER

OIL

DRAIN

PLUG

OIL FILLER

PLUG

',"

J

OIL LEVEL

FIGo 14

FIG.12

13

HOUSING

CUSTOME

.................

,,,

RESPONSgBBL T ES

, lu

....

MUFFLER

i ......

TRANSIVtlSS_ON

Your transmission is sealed and will not require lubrication

unless serviced.

Do not operate tiller without muffler. Do not tamper with

exhaust system. Damaged mufflers or spark arresters

could create a fire hazard. Inspect periodically and replace

if necessary. If your engine is equipped with a spark

arrester screen assembly, remove every 50 hours for

cleaning and inspection. Replace if damaged.

SPARK

,....................

CLEANUNG

PLUG

Replace spark plugs at the beginning of each tilling season

or after every 50 hours of Use, whichever comes first. Spark

plug type and gap setting are shown in"PRODUCT SPECIFICATIONS" on page 3 of this manual.

=

Clean engine, wheels, finish, etc. of all foreign matter.

o

Keep finished surfaces and wheels free of all gasoline,

oil, etc_

o

Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean your

unit unless the muffler, air filter and carburetor are covered

to keep water ouL Water in engine can result in a shortened

engine life.

SERVNCE AND ADJUSTMENTS

CAUTION:withDisconnect

contact

plug.

spark plug wire from spark plug and place wire where it cannot come into

....................

,

_

,

,,

,,

,,,,

.....

,

......

TINE ARRANGEMENT

TILLER

TO ADJUST

,

HANDLE

HEIGHT

Your outer tines can be assembled in several different ways

to suit your filling or cultivating needs,

(See Fig. 15)

CAOTION: Ti.es.,

Factory assembly has provided lowest handle height. SeIe_:t handle height best suited for your tiIling conditions

Handle height witi be different when tiller digs into soil.

•

If a higher handle height is desired, loosen the four nuts

securing handle panel to engine brackets,

o

Slide handle panel to desired tocation_

°

Tighten the four nuts securely

gloves or other protection when han-

i

d"ngt!"es,

......

NORNIAL TILLING - 24" PATH (See Fig, 16)

o Assemble holes "A" in fine hubs to holes "B" in tine

shaft..

CLEVIS

OUTER

ENGINE

BRACKETS

HANDLE

PANEL

NUTS (ALSO 2

ON LEFT SiDE

OF TILLER)

HAIRPIN CLIP

INNER TINE

FIG, 16

FIG. t5

14

SERVmCE AN

ADJUSTMENTS

FINAL CHECK "ON"

MID-WIDTH TILLING - 22" PATH (See Fig. 17)

°

Assembte holes "A" in tine hubs to holes "C" in tine

shaft.

A

C

!

C

•

Withtine control"ON" (held down to handle) push down

on handle to raise tines off the ground_

,

Slowly pull recoil starter handle while observing tines.

Tines should rotate forward_

,

If tines do not rotate, inner wire of control cable is too

loose Loosen cable clip and pull cable up to remove

slack and retighten clip,

,

Recheck in "ON" position and adjust if necessary.

A_-_._

NOTE: If "ON" position check required adjustment, recheck "OFF" position adjustment to insure tines do not

rotate when control is "OFF" (up).

FIG. 17

NARROW TILLING/CULTIVATING

Fig. t8)

•

Remove outer tines..

TINE CONTROL

- 12-3/4" PATH (See

"OFF"

POSITION

"_

"ON" POSITION

o

oil

o

POSITION

CABLE

CLIP

ool

i lO

r_uuT

/

FIG. 18

NOTE: When reassembling outer tines, be sure right tine

assembly (marked "R") and left tine assembly (marked "L")

are mounted to correct side of tine shall

i

....

i i iii ...11

....

from

I

_

WARNING_

CHECK

(See Fig. 19)

FIG. 18

ll...,i...r.lf_.l_

spark

phlg to prevent

Disconnect

spark

starting

PIL_g

while checking fine operation,

wire

I

I

I

For proper tine operation, tine control lever must be against

control body and a!l slack removed from inner wire of

control cable when control is in the "OFF" (up) position..

If lever and cable are loose, loosen cable clip at lower end

of cable.

Pull up on cable to remove slack, without

extending spring on end of cable, and retighten cable clip.

FINAL CHECK "OFF" POSITION

,

With tine control "OFF" (up), push down on handle to

raise tines off the ground.

•

Slowly pull recoil starter handle while observing tines.

Tines should not rotate

o

If tines rotate, inner wire of control cable is too tight

which is extending lower spring and engaging tines.

Loosen cable clip and push down on cable only enough

to relieve spring tensionr. Tighten cable clipo

o

Recheck in "OFF" position and adjust if necessary.

15

\

CONTROL

CABLE

INNER TINES ONLY

TINE OPERATION

'k_

TO REPLACE V-BELT (See Fig. 20)

Replace V-belt if it has stretched considerably

cracks or frayed edges.

TO REMOVE

or if it has

Beit guard must be removed to service belt. See "TO

REMOVE BELT GUARD" in this section of manual.

BELT REMOVAL

o

Remove V_belt from transmission pulley first and then

from engine pulley,,

(See Fig. 21)

°

Remove cap nut and washer from side of belt guard,,

°

Loosen (do not remove) tine shield nut on underside of

tine shield and cap nut on top of belt guard°

o

Pull belt guard out and away from unit°

°

Replace belt guard by reversing above procedure, Be

sure slot in bottom of belt guard is under head of fine

shield bolt and all nuts are tightened securely.

BELT REPLACEMENT

°

BELT GUARD

BELT GUARD

CAP NUT

CAP NUT

AND WASHER

Install new V-belt to engine pultey first then to transmission pulley,, Be sure belt is positioned on inside groove

of both pulleys, inside air belt guides and rests on idler

pulley,

CHECK TINE OPERATION

o

See "TINE OPERATION

manual,

CHECK"

in this section of

REPLACE BELT' GUARD

SHIELD

NUT

_.,

T]NE

SHIELD

FIG. 21

BELT

GUARD

BOLT

TRANSMISSION

PULLEY

FiG. 20

16

SERVICE AND ADJUSTMENTS

ENGINE

TO ADJUST

THROTTLE

CARBURETOR

LINKAGE

THROTTLE

STOP

(See Fig. 22)

The carburetor has a high speed fixed jet and has been

preset at the factory and adjustment should not be necessary. However, minor adjustments may be required to

compensate for differences in fuel, temperature, altitude or

Ioad_ If the carburetor does need adjustment, proceed as

fotlows_

In general, turning the idle needle valve in (clockwise)

decreases the supply of fuel to the engine giving a leaner

fuel/air mixture.. Turning the needle valve out (counterclockwise) increases the supply of fuel to the engine giving

a ricl_er fuel!air mixture.

IDLE SPEED

ADJUSTING SCREW

IMPORTANT:

DAMAGE TO THE NEEDLES AND THE

SEATS IN CARBURETOR MAY RESULT IF SCREWS ARE

TURNED 1N TOO TIGHT.

PRELIMINARY

FIG. 22

SETTING

o

Air cleaner assembly must be assembled to the carburetor when making carburetor adjustments°

•

With engine off, turn idle needle vatve in (clockwise)

closing it finger tight and then turn valve out (counterclockwise) 1-1/2 turns.

FINAl, SETTING

-

Start engine and allow to warm for five minutes. Make

final adjustments with engine running at idle and tine

control lever in "OFF" position.

o

With throttle control in"SLOW" position, turn idle needle

valve in (clockwise) until engine begins to die, then turn

out (counterclockwise) until engine runs rough. Turn

valve to a point midway between those two positions..

IDLE RPM ADJUSTMENT

o

IDLE NEEDLE VALVE

To adjust !dEe RPM, rotate throttle linkage counterclockwise and hold against stop while adjusting idle

speed adjusting screw to obtain 1750 RPM Release

throttle linkage.

ACCELERATION TEST

o Move throttle control lever from "SLOW" to "FAST"

position° If engine hesitates or dies, turn idre needle

valve out (counterclockwise) 1/8 turn.. Repeat test and

continue to adjust, if necessary, until engine accelerates smoothly.

High speed stop is factory' adjusted.

Do not adjust or

damage may result.

IMPORTANT:

NEVER "TAMPER WITH THE ENGINE

GOVERNOR, WHICH iS FACTORY SET FOR PROPER

ENGINE SPEED. OVERSPEEDING THE ENGINE ABOVE

THE FACTORY

HIGH SPEED SETTING

CAN BE

DANGEROUS. tF YOU THINK THE ENGINE-GOVERNED

HIGH SPEED NEEDS ADJUSTING, CONTACT YOUR

NEAREST

AUTHORIZED

SERVICE

CENTER/

DEPARTMENT, WHICH HAS THE PROPER EQUIPMENT

AND EXPERIENCE

TO MAKE ANY NECESSARY

ADJUSTMENTS

'17

....... ' ....

i

I ....

,

i,,i

,,, ,.....

,-i-,_

..................

STORAGE

ENGINE

Immediately prepare your tiller for storage at the end of the

season or if the unit will not be used for 30 days or more.

Drain oil (with engine warm) and replace with clean oil.

(See "ENGINE" in the Customer Responsibilities section of

this manual).

gasoline in the tank inside a building

where fumes may reach an open flame

or

spark.

Allow

to cool

CAUTION:

Never the

storeengine

the tiller

with

before storing in any enclosure.

i_

,

,, i ,,,,r.........

TILLER

u,

OIL

CYLINDERS

, i,i ,,,

-.,

o

Remove spark plug,,

o

o

Pour '1ounce (29 rot) of oil through spark plug hole into

cylinder,,

Pull starter handle slowly several times to distribute oil.,

Replace with new spark plug.

o

Clean entire tiller (See "CLEANING" in the Customer

Responsibilities section of this manual).

o

o

Inspect and replace belts, if necessary (See belt replacement instructions in the Service and Adjustments

section of this manual),,

OTHER

o

Do not store gasoline

.

Lubricate as shown in the Customer Responsibilities

section of this manual°

.

Replace your gasoline can if your can starts to rusL

Rust and/or dirt in your gasoline will cause problems,

o

Be sure that all nuts, bolts and screws are securely

fastened° Inspect moving parts for damage, breakage

and wear° Replace if necessary,

o

If possible, store your unit indoors and cover it to give

protection from dust and dirt.,

o

•

Cover your unit with a suitable protective cover that

does not retain moisture. Do not use plastic. Plastic

cannot breathe which allows condensation to form and

will cause your unit to rust.

IMPORTANT:

NEVER COVER TILLER WHILE ENGINE

AND EXHAUST AREAS ARE STILL WARM.

Touch up all rusted or chipped paint surfaces; sand

iightly before painting.

ENGINE

FUEL SYSTEM

IMPORTANT:

IT IS IMPORTANT TO PREVENT GUM

DEPOSITS FROM FORMING IN ESSENTIAL FUEL

SYSTEM PARTS SUCH AS THE CARBURETOR, FUEL

FILTER, FUEL HOSE, OR TANK DURING STORAGE

ALSO, EXPERIENCE

INDICATES

THAT ALCOHOL

BLENDED FUELS (CALLED GASOHOL OR USING

ETHANOL OR METHANOL) CAN ATTRACT MOISTURE

WHICH LEADS TO SEPARATION AND FORMATION OF

ACIDS DURING STORAGE. ACIDIC GAS CAN DAMAGE

THE FUEL SYSTEM OF AN ENGINE WHILE IN STORAGE

o

Drain the fuel tank_

o

Start the engine and let it run until the fuel lines and

carburetor are empty°

.

Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur.

Use fresh fuel next season.

o

from one season to another,

NOTE: Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits during storage, Add stabilizer to gasoline in fuel tank or storage

container. Always follow the mix ratio found on stabilizer

container. Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the carburetor. Do

not drain the gas tank and carburetor if using fuel stabilizer

18

=FROUBLESHOO=NNG POINTS

PROBLEM

CAUSE

Will not start

CORRECTION

!

Out of fuel

2

3

4

5

Engine not "CHOKED"

Engine flooded.

Dirty air cleaner

Water tn fuel

6

7

8

9

Clogged fuel tank

Loose spark piug wire,

Bad spark plug or improper gap,

Carburetor out of adjustment

Hard to start

t

2

3

4.

5

6

Loss of power

1

Fill fuel tank

2

3

4

5

6,

See'q_o START ENGINE" in the Operation section

Wait several minutes before attempting to start

Clean or replace air cleaner cartridge,

Drain fuel tank and carburetor, and refill tank with fresh

gasotine

Remove fuel tank and clean,

7

8

9

Make sure spark plug wire is seated properly on plug,

Replace spark plug or adjust gap

Make necessary adjustments

Throttle control not set pmper_y

Didy air cleaner

Bad spark plug or improper gap

Stale or dirty fuel.

Loose spark plug wire

Carburetor out of adjustment

1

2

3

4

5

6

Place throttle controlin "FAST" position

Clean or replace air cleaner cartridge.

Replace spark plug or adjust gap.

Drain fueEtank and refiI] with fresh gasoline.,

Make sure spark plug wire is seated properly on plug

Make necessary adjustments.

1

2

3

4

5,

Engine is overloaded,

Dirty air cieaner

Low oil ]evel/dirty olt

Faulty spark plug

Oil in fuel

6

7

State or dirty fuel

Water in fuel

1

2

3

4

5

6

7

Set depth stake and wheels for shallower tilling

Clean or replace air cleaner cartridge

Checkoit level/change oil

Clean and regap or change spark plug

Drain and clean fuel tank and refill, and dean carburetor

Drain fue! tank and refill with fresh gasoline,

Drain fuel tank and carburetor, and refill tank with fresh

8

9

10

tl

12.

13.

Engine overheats

properfy

Clogged fuel tank

Spark p/ug wire loose

Dirty engine air screen.

Dirty/clogged muffler,

Carburetor out of adjuslment

Poor compression

8

9

10

11

12

13

gasoline

Remove fuellank and c_ean_

Connect and tighten spark plug wire

Clean engine air screen

Clean/replace muffler

Make necessary adjustments

Contact an authorized Sears Service

Center/Department

1

2

3,

4.

5

Low oti level/dirty oil

Dirty engine air screen

Dirty engine,

Partially plugged muffter

Improper carburetor adjustment

1

2

3

4

Check oil level/change eli

Clean engine air screen

Clean cytinder fins. air screen, muffler are a

Remove and clean muffter

5

Adjust carburetor

1

Ground toe dry and hard.

1

2

Wheels and depth stake incorrectly adiusted

2

Moisten ground or wait for more favorab]e soil

conditions

Adjust wheels and depth stake

Sotl balls up or clumps

f

Ground toowet

t

Wait for more favorable

Engine runs but tiller

won't move

t

2

3

Ttne control ts not engaged

V-belt not correctly adjusted

Vobelt is off pulley(s)

t

2,

3

Engageline control

Inspect/adjust V-belt

Inspect V-belt,

t

2

3

Til_ing too deep

Throttle centre! not propedy adjusted

Carburetor out of adjustment

1

2

3

Set depth stake for shallower tilling

Check throttle control setting

Make necessary adjustments,

Excessive bounce/

difficult handling

=

=

to richer position.

soif conditions,

=

Engine runs but

when tilling

labors

19

REPAIR PARTS

TILLER = - MODEL

HANDLE

NUMBER

917;292350

ASSEMBLY

2

13

KEY

NO.

PART

NO.

1

72010520

2 '137118

3 152094

4 9266R

5 3066J

6 151229

7 12000027

8 154805

9 73970500

KEY

NO.

10

11

12

13

14

DESCRIPTION

Boit 5!16-18 x 2-1/2

Panel, Control

Assembly, Handle Column

Grip, Handle

Cable, Tine Control

Lever, Control, Tine

Ring, Clip

Pin, Pivot

Locknut, Flange 5/16-18 UNC

PART

NO.

121145X

110514X

98000129

STD533107

12000059

NOTE:

2O

DESCRIPTION

Clip, Cable

Assembly, Panel and Tube

Nut, Flange

Bolt, Carriage 5/16-18 x 3/4

Retainer, Ring

All component dimensions given in U IS, inches..

I inch = 25.4 mm

REPAIR PARTS

TILLER

BELT GUARD

AND PULLEY

- - MODEL

NUMBER

917:292350

ASSEMBLY

8

\

7

25

26

22

21

14

t7

KEY

NO.

1

2

3

PART

NO,

121313X

9484R

86777

4

5

6

7

8

9

10

11

12

74770812

72140404

121463X

104213X

STD551025

131158X417

72140405

9180R

23230506

13

14

12000028

151223

DESCRIPTION

KEY

NO,

PART

NO,

Assembly, Bracket, Belt Guard

CNp, CabIe

Screw, Hex Washer Head, Slotted,

Thread Cutting #10-24 x 1/2 Type D

Bolt, Hex Head 1/2-20 x 3/4

Bolt, Carriage 1/4-20 x 1/2

Keeper, Belt

Nut, Cap 1/4- 20

Washer 9/32 x 5/8 x 16 Gauge

Guard, Belt

Bolt, Carriage 1/4-20 x 5/8

v-Belt

Screw, Set, Socket, Headless

C.P. 5/16_18 x 3/8

Ring, Retainer

Sheave, Transmission

15

16

't7

18

19

20

21

22

23

24

25

26

110528X

12000036

STD541237

9178R

674A30

STD523712

106968X

73350500

STD541025

STD551125

109227X

130812

NOTE:

21

DESCRIPTION

Bolt, BeltGuard

Ring, Klip

Nut, Hex, Jam 3/8-16

Pulley, Idler

Arm, ldfer

Bolt, Hex Head 3/8-16 x 1_1/4

Shaft, Idler Arm

Nut, Hex, Jam 5/16-18

Nut, Hex 1/4-20

Washer, Lock 1/4

Pad, Idler

Sheave, Engine

AI1component dimensions given in U.S. inches.

1 inch = 254 mm

REPAIR PARTS

"TILLER - - MODEL

WHEEL

AND DEPTH

STAKE

NUMBER

917_292350

ASSEMBLY

7

4

7

16

17

KEY

NO.

PART

NO.

1

2

3

4

5

6

7

8

9

10

1t

12

t3

9194R

74780520

STD523107

STD541031

STD551131

73800600

4921H

1952J

122233X

328J

74780628

74760524

1951J

DESCRIPTION

KEY

NO.

PART

NO.

Pin, Clevis

Bolt, Hex Head 5/18-18 x I-I/4

Bott, HexHead 5/16-18x3/4

Nut, Hex 5/16-18

Washer, Lock 5/16

Locknut, w/washer 3/8-16

Clip, Hairpin

Support, Depth Stake, R.H.

Stake, Depth

Pin, Clevis

Bolt, Fin, Hex 3/8-16 x 1-3/4

Bolt, Hex 5/16-t8 x 1-1/2 Grade 2

Support, Depth Stake, L.H.

14

15

16

17

18

19

20

21

22

120958X

5388J

121t17X

9188R

STD551037

9190R

STD541437

74760516

73800500

NOTE:

22

DESCRIPTION

Washer

Spring, Stake

Bolt, Shoulder

Wheel

Washer 13/32 x 13/16 x '1t Gauge

Bracket, Wheel

Locknut, Crown 3/8-16

Bolt, Hex Head 5/t6-18 x 1

Locknut, w/insert 5/16-18

AII component dimensions

t inch = 25.4 mm

given in U.S. inches.

REPAIR PARTS

TILLER-

- MODEL

NUMBER

917_292350

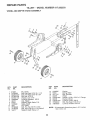

TINE ASSEMBLY

2

1

"

/

2

,4

2

/

6

I

6

KEY

NO,

PART

NO.

1

2

3

674A66

STD624008

674A64

KEY

NO,

DESCRIPTION

4

5

6

Tine, Outer, R.t4..

Clip, Hairpin

Tine, Inner, R.H.

23

PART

NO.

674A63

674A65

4929H

DESCRIPTION

Tine, Inner, LH_

Tine, Outer, LH°

Pin, Clevis

REPAIR PARTS

TILLER

- = MODEL

NUMBER

917:292350

TRANSMISSION

t

20

3

5

6

7

8

14

10

14

15

11

12

KEY

NO.

PART

NO.

1

2

3

5

6

7

8

9

10

11

12

74760524

74780652

STD551037

73800600

9056R417

1949J

110519X

STD551131

STD541031

74760544

151222

DESCRIPTION

KEY

NO.

PART

NO.

Bolt, Hex 5/t6-18 x 1-1/2 Grade 2

Bolt, Fin, Hex 3/8-16 x 3-1/4

Washer 13/32 x '13/16 x 11

Locknut, w/washer 3/8d 6

Shield, TLne

Bracket, Engine, RH

Bracket, Engine, L.H..

Washer, Lock 5/t6

Nut, Hex 5/16-18

Boft, Hex Head 5/16-18 x 2-3/4.

Transmission

14

15

16

17

18

19

20

9173R

STD54143I

19091412

19092016

STD551125

74610412

......

DESCRIPTION

Spacer, Split

Nut, Hex, Keps 5/16-18 UNC

Washer 9/32 x 7/8 x 12 Gauge

Washer 9/32 x 1-1/4 x 16 Gauge

Washer, Lock 1/4

Bott, Hex 1/4-28 x 3/4 Grade 5

Engine, (See Breakdown) Briggs &

Stratton, ModeF No: 137202, Type

0116-01

NOTE: All component dimensions given in U.S. inches,

1 inch = 2&4 mm

24

REPAIR PARTS

TILLER

- - MODEL

NUMBER

917.292350

DECALS

7

31

!

KEY

NO.

2

3

4

5

6

7

8

9

10

---

PART

NO.

158094

158093

1580O5

158006

137539

120431X

t10719X

120075X

272931

272630

158120

158121

DESCRIPTION

Decal, Logo

Decal, Logo

Decal, Logo

Decal, 5HP/24 Sears

Decal, Caution, Tine Control

Decal, Hand Placement

Decal, Operation and Lubrication

Decal, Warning, Rotating Tines

Decal, Engine

Decal, 5HP

Manual, Owner's(English)

Manual, Owner's(Spanish)

25

REPABRPARTS

TILLER

BRIGGS & STRATTON

- - MODEL

NUMBER

ENGtNE - - MODEL

917.292350

NUMBER

137202,TYPE

NO. 0116-01

3O7

10

529

527

15

528

613

81

616

21

22

REPAUR PARTS

TILLER

BRIGGS

& STRATTON

- - MODEL

NUMBER

ENGINE -- MODEL

917,292350

NUMBER

137202,TYPE

NO. 0116-01

203

205

127

127A

149

118

i

i,iii1,,

ii

iiii

i

_;¢_ 124

611 I

,

, u,,

969

190A

209

191

208

916

181

526

27

i

REPAHF_PARTS

TILLER

BRIGGS

& STRATTON

- o MODEL

NUMBER

ENGINE - - MODEL

REQUIRES SPECIAL TOOLS

TO INSTALL. SEE REPAIR

INSTRUCTION MANUAL.

334

917.292350

NUMBER

137202, TYPE NO. 01 !6-01

23

52

332_

455

305

$5

59_

459 _:_

689 O

456

28

f

REPAIR PARTS

TILLER

BRIGGS

KEY PART

NO, NO.

1

2

3

5

7

8

9

10

11

12

497144

399268

299819

214040

272157

495774

27549

94621

66578

270080

270125

270126

13 94221

14 94679

15 94.916

16 492088

94388

!8

494044

19 495660

20 294606

21 66768

22 94980

23 297229

24 222698

25 298904

298905

298906

298907

26 298982

299742

298983

298984

298985

27 26026

28 298909

298908

29 299430

390459

30

32

33

34

35

36

37

221890

94745

211119

261044

260552

26478

222443

& STRATTON

- - MODEL

NUMBER

ENGINE - - MODEL

917;292350

NUMBER

KEY PART

NO. NO.

DESCRIPTION

CyfinderAssembly

Bushing, Cylinder

* Seal, Oil

Head, Cylinder

* Gasket, Cylinder Head

Breather Assembly

* Gasket, Valve Cover

Screw, Breather Mounting

Grommet, Breather Tube

* Gasket, Crankcase, Standard _015"

* Gasket, Crankcase 005" Thick

*Gasket, Crankcase ,009" Thick

Screw, Cylinder Head 2-3/32"

Screw, Cylinder Head 2-15/32"

Plug, Pipe, Hex Socket

Crankshaft

Gear Key, Crankshaft

Cover Assembly, Crankcase

Bushing, Crankcase Cover

* Seal, Oil

Plug, Oil Filler

Screw, Cover Mounting

Flywheel, Magneto

Key, Flywheel

Piston Assembly, Standard Size

Piston Assembly .010" Oversize

Piston Assembly .020" Oversize

Piston Assembly .030" Oversize

Ring Set, Piston, Standard Size

Ring Set, Piston, Standard, Chrome

Ring Set, Piston .010" Oversize

Ring Set, Piston °020" Oversize

Ring Set, Piston .030" Oversi]ze

Lock, Piston Pin

Pin Assembly, Piston, Standard

Pin Assembly, Piston .005" Over

Rod Assembly, Connecting

Rod Assembly, Connecting

.020" Undersize Crankpin Bore

Dipper, Connecting Rod

Screw, Connecting Rod

Valve, Exhaust

Valve, Intake

Spring, Intake Valve

Spring, Exhaust Valve

Guard, Flywheel

40

93312

45

46

51

55

56

57

58

260642

212733

273113

497442

498144

263074

280399

59

60

65

69

69A

73

81

90

95

96

97

108

118

121

124

127

127A

149

152

154

'162

163

'180

181

190

190A

191

200

202

396892

393152

94686

280973

224322

225178

222263

495428

93499

223793

497600

497230

231533

495606

94913

220352

223789

26336

260575

93527

490589

271935

495405

494559

94.924

94.919

272489

223886

262280

*

**

***

Inctudedin

Included in

Included in

Carburetor

NOTE:

29

137202, TYPE NO. 0116-01

DESCRIPTION

Retainer, intake Valve and Exhaust

Spring

Tappet, Valve

Gear, Cam

*** Gasket, Carburetor Mounting (2)

Housing, Rewind Starter

Pulley, Rewind Starter

Spring, Rewind Starter

Rope, Rewind Starter

(Out to Required Length)

Insert, Starter Handle

Handle, Rewind Starter

Screw, Housing Mounting

Washer

Washer

Screen, Rotating

Lock, Screw

Carburetor Assembly

Screw, Throttle Valve to Shaft

Throttle, Carburetor

Shaft and Lever, Throttle

Valve and Shaft Group, Choke

Valve, Needle

Carburetor Overhaul Kit

Screw, Hex Head

Plug, Welch

Plug, Welch

Spring, Needle Valve

Spring, Throttle Adjustment

Screw, Machine, Round Head

Screw and Collar

* Gasket, Air Cleaner Mounting

Tank Assembly, Fuel

Cap, Fuel Tank

Screw, Fuel Tank

Screw, Fuel Tank Mounting 1-3/4"

*** Gasket, Fuel Tank to Carburetor

Guide, Air

Link, Mech. Governor

Gasket Set (495603)

Carburetor Overhaul Kit (495606)

both Gasket Set (495603), and

Overhaul Kit (495606)

All component dimensions

1 inch = 2&4 mm

given in U.S inches

REPAIR PARTS

TILLER

BRIGGS

KEY PART

NOo NO.

203

205

208

209

212

216

219

220

222

227

230

256

300

304

305

306

307

308

332

333

334

337

346

356

358

363

373

383

392

394

4t4

432

433

434

435

455

456

459

461

467

515

526

527

280720

231520

262279

262283

262270

262359

494845

221551

49064.9

490374

94927

223813

393615

495759

94619

224820

94680

224738

94877

397358

93414

802592

94896

398808

495603

19069

94908

89838

262328

272538

220982

221377

93265

2'13963

93141

225121

281503

281505

262626

280715

262625

94914

223786

& STRATTON

- o MODEL

NUMBER

ENGmNE -- MODEL

917.292350

NUMBER

KEY PART

NO. NO.

DESCRIPTION

Bell Crank

Screw, Shoulder

Rod, Speed Control

Spring, Governor

Link, Throttle

Link, Choke

Gear, Governor

Washer, Thrust

Panel, Control

Lever Assembly, Governor

Washer, Governor Lever

Ci-ank, Beli

Muffler, Exhaust

Housing, Blower

Screw, Blower Housing Mounting

Shield, Cylinder

Screw, Cylinder Shield

Cover, Cylinder Head

Nut, Flywheel

Armature Group

Screw, Armature Mounting

Plug, Spark

Screw, Seres

Wire, Ground

Gasket Set

Flywheel Puller

Nut, Hex

Wrench, Spark Pfug

Spring, Fuel Pump Diaphragm

**Diaphragm

Washer

Cap, Spring

Pin, Diaphragm Cover

Cover, Diaphragm

Screw, Diaphragm Cover

Cup, Starter

Retainer

Pawl, Starter

Pin, Spring

Knob, Control

Spring

Screw, Seres, Tank Bracket Mount

Clamp, Breather Tube

528

529

535

536

542

552

562

592

608

611

613

614

615

616

621

623

634

635

676

679

680

689

741

779

851

869

870

87't

916

966

967

968

969

971

987

995

1012

10t6

231550

67838

49'1435

494279

94897

231079

94907

231978

495766

391813

93935

93306

93307

495243

396847

94943

271853

66538

393757

270382

221839

263073

262992

262570

493880

211787

211172

262001

63709

280321

492797

491588

495872

490073

94902

398970

225057

490507

224278

RPM Settings:

*

**

***

Included in

Included in

Included in

Carburetor

137202,TYPE

NO. 0116-01

DESCRIPTION

Tube, Breather

Grommet, Breather Tube

Filter, Air

Cleaner, Air

Screw

Bushing, Governor Crank

Bolt, Governor' Lever

Nut, Hex

Starter Assembly, Rewind

Fuel Pipe and Clip Assembly

Screw, Hex Head, Shoulder

Pin, Cotter

Retainer, E-Ring

Crank, Governor

Switch, Stop

Screw, Shoulder

Washer, Throttle Shaft, Foam

Elbow, Spark Plug

Deflector, Exhaust, Side Outlet

Washer, Foam

Washer, Brass

Spring, Friction

Gear, Timing

Link, Speed Control

Cable Terminal, Ignition

Seat, intake Valve, Standard

Seat, Exhaust Valve, Standard

Guide, Exhaust Valve

Guide, Intake Valve

Rack, Gear Control

Base, Air Cleaner

Filter, Air Cleaner

Cover, Air Cleaner

Screw, Air Cleaner

Screw, Hex Head

Seal, Throttle Shaft

Lever, Bracket Assembly

Retainer, Link

Spacer

Low Speed: 1750-1950

High Speed: 3400-3600

Gasket Set (495603)

Carburetor Overhaul Kit (495606)

both Gasket Set (495603), and

Overhaul Kit (495606)

NOTE: All component dimensions given in tJ.S. inches

1 inch = 25.4 mm

3O

SERVICE

31

NOTES

®

5.0 P

24

CH TINE WIDTH

FRONT TgNE TroLLER

MODEL NO.

917.292350

Each tiller has its own model number,

number.

Each engine has its own model

The model number for your filler will be found on a plate attached to the

right hand engine bracket.

The model number for your engine will be found on the blower housing of

the engine,

All parts listed herein may be ordered from any Sears, Roebuck and COr.

Service Center/Department and most Retail Stores•

iF YOU NEED

REPAIR SERVICE

OR PARTS:

WHEN ORDERING REPAIR PARTS, ALWAYS

ING INFORMATION:

FOR REPAIR SERVICE, CALL

THIS TOLL FREE NUMBER:

= PRODUCT-

o ENGINE MODEL NUMBER - 137202_ TYPE NUMBER 0116_01

(1-800-473-7247)

,, PART NUMBER

° PART DESCRIPTION

FOR REPLACEMENT PARTS

INFORMATION AND

ORDERING, CALL THIS

TOLL FREE NUMBER:

Your Sears merchandise has added value when you consider Sears has

service units nationwide staffed with Sears trained technicians_, professional technicians specifically trained to insure that we meet our pledge

to you, we service what we sell,,

1-800-FON-PART

(1-800-366-7278)

........

t_

, ,,

•Sears, Roebuck

........

158'120

,,1_1,

Rev. 1 4.14.97

FRONT TINE TILLER

o MODEL NUMBER - 917.292350

t -800-4-REPAIR

i

GIVE THE FOLLOW-

i,

TR

.,,,,, ,,,,,lU,,

and Co., Hoffman

,

i,

i,

i,

,i,,,,11,,,,,11,

i

i

Estates,

,r,,ll

,,,

;,

.....

PL 60179 U.S.A.

,i

PRINTED

IN THE USA°