Download MULTIQUIP DCA-15SPX3 Specifications

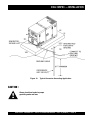

Transcript