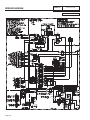

Download Carrier 2.4L 45kW Repair manual

Transcript