Download RBI Gas boilers Operating instructions

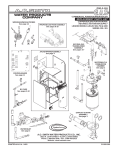

Transcript