Download American-Lincoln 4366XP Operating instructions

Transcript

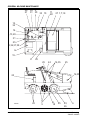

3366XP / 4366XP POWER SWEEPER For American-Lincoln MODELS 579-546, 579-547, 579-548, 579-549, 579-550, 579-551 579-546CE, 579-548CE, 579-550CE, 579-551CE Instructions for Use READ THIS BOOK This book has important information for the use and safe operation of this machine. Failure to read this book prior to operating or attempting any service or maintenance procedure to your machine could result in injury to you or to other personnel; damage to the machine or to other property could occur as well. You must have training in the operation of this machine before using it. All directions given in this book are as seen from the operator’s position at the rear of the machine. Form Number 56041668 Revised 1/07 English TABLE OF CONTENTS revised 1/07 INTRODUCTION ............................................................................................................................................................... 3 MACHINE OPERATION ................................................................................................................................................... 3 CAUTIONS AND WARNINGS .......................................................................................................................................... 4 CONSIGNES DE PRUDENCE ET DE SÉCURITE ........................................................................................................... 5 OPERATION OF CONTROLS AND GAUGES ................................................................................................................. 6 WATER TEMPERATURE GAUGE ........................................................................................................................... 6 HOUR METER ......................................................................................................................................................... 6 FUEL GAUGE ........................................................................................................................................................... 6 OIL PRESSURE GAUGE ......................................................................................................................................... 6 VOLT METER ........................................................................................................................................................... 6 BROOM & FAN SWITCH ......................................................................................................................................... 7 SHAKER MOTOR SWITCH ...................................................................................................................................... 7 TIMED SHAKER MOTOR SWITCH (OPTION) ......................................................................................................... 7 HYDRAULIC FLUID SIGHT GLASS ......................................................................................................................... 7 RIGHT SIDE BROOM LIFT AND POWER CONTROL.............................................................................................. 8 IGNITION SWITCH .................................................................................................................................................. 8 WET-SWEEP BYPASS SWITCH - (OPTION) .......................................................................................................... 8 TURN SIGNALS - 4 WAY (OPTION) ........................................................................................................................ 9 FOOT BRAKE .......................................................................................................................................................... 9 ACCELERATOR and DIRECTIONAL CONTROL PEDAL ........................................................................................ 9 BACKUP ALARM (OPTION) ..................................................................................................................................... 9 SEAT ADJUSTMENT ................................................................................................................................................ 9 PARKING BRAKE .................................................................................................................................................. 10 CIRCUIT BREAKERS ............................................................................................................................................. 10 GLOW PLUG (DIESEL) ........................................................................................................................................... 10 HOPPER LIFT/SIDE BROOM LEVER .................................................................................................................... 11 HOPPER DUMP/RETURN CONTROL LEVER....................................................................................................... 11 THROTTLE CONTROL ........................................................................................................................................... 11 CHECK ENGINE LIGHT .......................................................................................................................................... 12 MAIN BROOM LIFT ................................................................................................................................................ 12 WORK LIGHT SWITCH - (OPTION) ....................................................................................................................... 12 LIGHT SWITCH - (OPTION).................................................................................................................................... 12 HORN BUTTON ..................................................................................................................................................... 12 CAB - (OPTION) - NOT SHOWN ........................................................................................................................... 12 LOW OIL SHUTDOWN ........................................................................................................................................... 12 OPERATING INSTRUCTIONS ...................................................................................................................................... 13 PRE-START CHECK LIST ...................................................................................................................................... 13 TO START ENGINE ............................................................................................................................................... 13 POST-START CHECK LIST ................................................................................................................................... 13 TO OPERATE SWEEPER ...................................................................................................................................... 13 TO STOP SWEEPER ............................................................................................................................................. 13 POST-OPERATION CHECK LIST .......................................................................................................................... 15 TO EMPTY DEBRIS HOPPER ................................................................................................................................ 15 TOWING INSTRUCTIONS ...................................................................................................................................... 16 DUST FILTERS ...................................................................................................................................................... 16 DUST CONTROL SYSTEM ..................................................................................................................................... 16 GENERAL MACHINE MAINTENANCE .....................................................................................................................17-21 TECHNICAL SPECIFICATIONS ..................................................................................................................................... 22 2 - FORM NO. 56041668 American-Lincoln Technology 3366XP / 4366XP revised 1/07 INTRODUCTION This manual will help you get the most from your Nilfisk-Alto™ 3366XP / 4366XP. Read it thoroughly before operating the machine. References to “right” and “left” in this manual mean right or left as seen from the driver’s seat. PARTS AND SERVICE Repairs, when required, should be performed by your Authorized Nilfisk-Alto Service Center, who employs factory trained service personnel, and maintains an inventory of Nilfisk-Alto original replacement parts and accessories. Call the NILFISK-ALTO INDUSTRIAL DEALER named below for repairs or service. Please specify the Model and Serial Number when discussing your machine. NAMEPLATE The Model Number and Serial Number of your machine are shown on the Nameplate, located on the wall of the operator’s compartment. This information is needed when ordering repair parts for the machine. Use the space below to note the Model Number and Serial Number of your machine for future reference. MODEL ________________________________________________ SERIAL NUMBER ________________________________________ Note: Reference the separately supplied engine manufacture’s maintenance and operator manual for more detailed engine specification and service data. UN-CRATING Upon delivery, carefully inspect the shipping crate and the machine for damage. If damage is evident, save all parts of the shipping crate so that they can be inspected by the trucking company that delivered the machine. Contact the trucking company immediately to file a freight damage claim. MACHINE OPERATION YOUR MODEL 3366XP / 4366XP SWEEPER HAS BEEN SHIPPED COMPLETE, BUT DO NOT ATTEMPT TO OPERATE WITHOUT READING THE FOLLOWING INSTRUCTIONS: 1. 2. 3. Uncrate the machine and carefully remove from skid to prevent damage. Connect and tighten battery cables. Fill tank with UNLEADED gasoline or Diesel Fuel. WARNING! Never fill fuel tank while the engine is running. Always be sure gasoline container and sweeper are electrically connected before pouring gas. This can be easily done by providing an insulated wire (permanently attached to the container) with battery clip on the other end. 4. 5. 6. Check engine crankcase oil level. Although properly lubricated at factory, check before starting engine. No special break-in oil is used and recommended number of operating hours before the initial oil change is the same as normal. See American-Lincoln Service Manual. Check radiator coolant level. Permanent type antifreeze is added at the factory to provide protection to approximately -35° F (-37° C). To retain this protection level, always add one part water to one part antifreeze. Check oil level in the hydraulic reservoir located at center of machine beside the engine. The hydraulic reservoir is full, if oil can be seen in the sight glass with the hopper in “DOWN” position. If oil is required, add HYDRAULIC FLUID ONLY, automatic transmission fluid FORD type “F” ATF. NOTE After the first 50 operating hours, service must be performed on your engine to insure future high performance and trouble free operation. See Maintenance. American-Lincoln Technology 3366XP / 4366XP FORM NO. 56041668 - 3 CAUTIONS AND WARNINGS SYMBOLS Nilfisk-Alto uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and take the necessary steps to protect personnel and property. DANGER ! Is used to warn of immediate hazards that will cause severe personal injury or death. WARNING ! Is used to call attention to a situation that could cause severe personal injury. CAUTION ! Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property. Read all instructions before using. GENERAL SAFETY INSTRUCTIONS Specific Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm. • • • • • • • • • • • • • • • • • • • • • • • • • • WARNING! This machine shall be used only by properly trained and authorized persons. While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only while ascending (driving up) the ramp. To avoid hydraulic oil injection or injury always wear appropriate clothing and eye protection when working with or near hydraulic system. Turn the key switch off (O) and disconnect the battery before servicing electrical components. Never work under a machine without safety blocks or stands to support the machine. Do not dispense flammable cleaning agents, operate the machine on or near these agents, or operate in areas where flammable liquids exist. Do not clean this machine with a pressure washer. This machine emits exhaust gases (carbon monoxide) that can cause serious injury or death, always provide adequate ventilation when using machine. Do not dump the hopper over an open pit or dock. Do not dump the hopper when positioned on a grade (ramp). The machine must be level (horizontal). Operate only when lids, doors, and access panels are securely closed. Never travel with the hopper in the raised position. Watch out for obstructions, especially overhead. Carry no passengers on the machine. Report damage or faulty operation immediately. Do not operate the machine until repairs have been completed. Maintenance and repairs must be done by authorized personnel only. Never manually depress the electrical switch on the left lift arm when the hopper is raised. To Maintain The Stability Of This Sweeper In Normal Operation, The Counterweights, Overhead Guard, Rear Bumper Guard, Or Any Similar Equipment Installed By The Manufacturer As Original Equipment, Should Never Be Removed. If It Becomes Necessary To Remove Such Equipment For Repair Or Maintenance, It Must Be Reinstalled Before The Sweeper Is Placed Back In Operation. Wheel Assembly May Explode Causing Serious Personal Injury Or Death. Wheel Assembly Must Be Serviced By Properly Trained And Qualified Personnel In Accordance With Federal Osha Standard 29 Cfr Part 1910.177.<D> Do Not Add Air To Tire And Rim Assemblies That Have Been Operated In A Serious Underinflated Or Flat Condition. The Tire And Rim Components Can Explode Causing Serious Or Fatal Injuries. CAUTION! This machine is not approved for use on public paths or roads. This machine is not suitable for picking up hazardous dust. When operating this machine, ensure that third parties, particularly children, are not endangered. Before performing any service function, carefully read all instructions pertaining to that function. Do not leave the machine unattended without first turning the key switch off (O), removing the key and applying the parking brake. Turn the key switch off (O) before changing the brushes, and before opening any access panels. Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts. SAVE THESE INSTRUCTIONS 4 - FORM NO. 56041668 American-Lincoln Technology 3366XP / 4366XP CONSIGNES DE PRUDENCE ET DE SÉCURITE SYMBOLES Les symboles reproduits ci-dessous sont utilisés pour attirer l’attention de l’opérateur sur des situations dangereuses. Il est donc conseillé de lire attentivement ces indications et de prendre les mesures adéquates en vue de protéger le personnel et le matériel. DANGER ! Ce symbole est utilisé pour mettre l’opérateur en garde contre les risques immédiats pouvant provoquer des dommages corporels graves, voire entraîner la mort. ATTENTION ! Ce symbole est utilisé pour attirer l’attention sur une situation susceptible d’entraîner des dommages corporels graves. PRUDENCE ! Ce symbole est utilisé pour attirer l’attention de l’opérateur sur une situation qui pourrait entraîner des dommages corporels minimes, ou des dommages à la machine ou à d’autres équipements. Veuillez lire toutes les instructions avant d’utiliser l’appareil. CONSIGNES GENERALES DE SECURITE Les consignes spécifiques de prudence et de sécurité mentionnées ici ont pour but de vous informer de la survenance de tout risque de dommages matériels ou corporels. • • • • • • • • • • • • • • • • • • • • • • • • • • ATTENTION ! Cette machine ne pourra être utilisée que par du personnel parfaitement entraîné et dûment autorisé. Evitez les arrêts subits lorsque la machine est chargée et se trouve sur des rampes ou des plans inclinés. Evitez les virages serrés. Adoptez une vitesse réduite lorsque la machine est en descente. Ne nettoyez que lorsque la machine monte la pente. Lorsque vous utilisez le système hydraulique ou travaillez à proximité de celui-ci, veillez à porter une tenue appropriée et des lunettes de protection afin d’éviter tout risque de blessures ou toute projection d’huile. Positionnez la clé de contact sur off (O) et déconnectez les batteries avant de procéder à l’entretien des composants électriques. Ne travaillez jamais sous une machine sans y avoir placé, au préalable, des blocs de sécurité ou des étais destinés à soutenir la machine Ne déversez pas d’agents nettoyants inflammables, ne faites pas fonctionner la machine à proximité de ces agents ou d’autres liquides inflammables. Ne nettoyez pas cette machine avec un nettoyeur à pression. Les gaz d'échappement (monoxyde de carbone) évacués par la machine peuvent entraîner de graves dommages corporels, voire la mort. Veillez donc toujours à bénéficier d’une ventilation suffisante lorsque vous utilisez la machine. Ne pas décharger la trémie sur une carrière à ciel ouvert ni sur un quai. Ne pas décharger la trémie quand elle est positionnée sur une pente. La machine doit être à l’horizontale. A ne faire fonctionner que lorsque les couvercles, portes et panneaux d’accès sont fermés de façon sûre. Ne jamais se déplacer avec la trémie en position relevée. Observer s’il y a des obstructions, particulièrement au-dessus de la tête. Ne pas transporter des passagers sur la machine. Signaler immédiatement les dommages ou un fonctionnement défectueux. Ne pas faire fonctionner la machine tant que les réparations n’ont pas été achevées. L’entretien et les réparations ne doivent être effectuées que par du personnel autorisé. Ne jamais appuyer sur l’interrupteur électrique se trouvant sur le bras de levage de gauche quand la trémie est relevée. Pour Maintenir La Stabilite De Cette Balayeuse En Fonctionnement Normal, Les Contrepoids, Le Protege-Conducteur, Le Protecteur De PareChocs Arriere Ou Tout Equipement Semblable, Installe Par Le Fabricant Comme Equipement D’origine, Ne Doivent Jamais Etre Enleves. S’il Devient Necessaire D’enlever Un Tel Equipement Pour Reparation Ou Entretien. Il Faut Remonter Cet Equipement Avant De Remettre La Balayeuse En Service. L’ensemble De Roues Peut Exploser En Causant Des Blessures Serieuses Ou La Mort. L’ensemble De Roues Doit Recevoir Du Service D’un Personnel Correctement Entraine Et Qualifie Conformement A La Norme Federale Osha 29 Cfr Section 1910.177. Ne Pas Ajouter De L’air Aux Ensembles De Pneu Et Jante Qui Ont Ete Utilises Dans Une Condition Serieuse De Sous-Gonflage Ou De Pneu A Plat. Les Composants Du Pneu Et De La Jante Peuvent Exploser En Causant Des Blessures Serieuses Ou Mortelles. PRUDENCE ! Cette machine n'est pas conçue pour une utilisation sur les chemins ou voies publics. Cette machine n'est pas conçue pour le ramassage des poussières dangereuses. Lors de l'utilisation de cette machine, assurez-vous que des tiers, et notamment des enfants, ne courent pas le moindre risque. Avant de procéder à toute opération d’entretien, veuillez lire attentivement toutes les instructions qui s’y rapportent. Ne laissez pas la machine sans surveillance sans avoir, au préalable, coupé le contact, enlevé la clé de contact (O) et tiré le frein à main. Positionnez la clé de contact sur off (O) avant de remplacer les brosses ou d’ouvrir tout panneau d’accès. Prenez toutes les mesures nécessaires pour éviter que les cheveux, les bijoux ou les vêtements amples ne soient entraînés dans les parties mobiles de la machine. CONSERVEZ SOIGNEUSEMENT CES INSTRUCTIONS American-Lincoln Technology 3366XP / 4366XP FORM NO. 56041668 - 5 OPERATION OF CONTROLS AND GAUGES GLOW PLUG (DIESEL) HORN LIGHT SWITCH (OPTION) WORK LIGHT SWITCH (OPTION) MAIN BROOM LIFT WATER TEMPERATURE GAUGE HOUR METER FUEL GAUGE OIL GAUGE VOLT METER BROOM & FAN SWITCH SHAKER MOTOR SWITCH RIGHT SIDE BROOM LIFT WET SWEEP BYPASS (OPTION) LEFT SIDE BROOM LIFT (OPTION) CHECK ENGINE LIGHT (GAS/LP) GAS/LP DIESEL THROTTLE CONTROL IGNITION SWITCH TURN SIGNAL (OPTION) FOOT BRAKE HOPPER ROTATE & DUMP HOPPER LIFT ACCELERATOR & DIRECTIONAL CONTROL PEDAL CIRCUIT BREAKERS BACKUP ALARM SWITCH (OPTION) PARKING BRAKE SEAT ADJUSTMENT P4586ecp FIGURE 2 WATER TEMPERATURE GAUGE (See Figure 2) The water temperature gauge is located on the instrument panel to the left of the fuel gauge. The gauge is activated by a sender in the engine. It displays the engine water temperature in °F. HOUR METER (See Figure 2) This meter is located to the left of the oil pressure gauge on the instrument console. This meter is activated when the engine begins running. The meter indicates actual “run” time of the machine. The meter can be used to indicate when maintenance should be done to the machine. FUEL GAUGE (See Figure 2) The fuel gauge is located between the water temperature gauge and the volt meter on the instrument panel, and indicates the level of fuel contained in the fuel tank. OIL PRESSURE GAUGE (See Figure 2) The oil pressure gauge is located on the instrument panel to the right of the hour meter. The gauge is mechanical and activated by a sender in the engine. It displays the engine oil pressure in PSI. VOLT METER (See Figure 2) The volt meter is located on the control panel to the left of the fuel gauge. The meter indicates the charging or discharging of the battery. When the key is in the accessory position the gauge will register approx. 12 volts. The meter will indicate approximately 13 to 14.5 volts when the engine is running. This indicates that the alternator is working correctly. 6 - FORM NO. 56041668 American-Lincoln Technology 3366XP / 4366XP OPERATION OF CONTROLS AND GAUGES BROOM & FAN SWITCH (See Figure 2) The broom and fan switch is located to the left of the right side broom lever. This switch “powers” the brooms and the vacuum fan system. It has on-off positioning. SHAKER MOTOR SWITCH (See Figure 2) The shaker motor switch is located below the broom and fan switch. This is a momentary switch that will activate the filter shaker motors. Hold the switch for 20 to 30 seconds to activate the shaker motors. When the shaker motors have been activated, the brooms and impeller fan will stop. The shaker motors will only operate with the hopper in the “SWEEP” position. The switch is not on the control panel if the machine is equipped with the CDC Dust Control Filter Option. TIMED SHAKER MOTOR SWITCH (OPTION) (See Figure 2) The shaker motor switch is located below the broom and fan switch. This is a momentary switch that will activate the filter shaker motors for 20 to 30 seconds after it has been pushed. When the shaker motors have been activated, the brooms and impeller fan will stop. The shaker motors will only operate with the hopper in the “SWEEP” position. HYDRAULIC FLUID SIGHT GLASS (See Figure 3) The sight glass is located on the side of the hydraulic oil reservoir. The sight glass indicates the level of the hydraulic oil in the reservoir. Fluid level must be visible in the sight glass when the hopper is in the down position. If the sight glass is completely full, then there is too much fluid in the reservoir. P4696a American-Lincoln Technology 3366XP / 4366XP HYDRAULIC SIGHT GLASS FIGURE 3 FORM NO. 56041668 - 7 OPERATION OF CONTROLS AND GAUGES RIGHT SIDE BROOM LIFT UP DOWN P4687 FIGURE 4 P4385-1 FIGURE 5 RIGHT SIDE BROOM LIFT AND POWER CONTROL (See Figure 4) The right side broom lift and power control is located on the right side of the instrument panel. To raise and stop the side broom, grasp the lever and push the lever to the locking notch, marked “UP”. To lower the side broom, grasp the lever, push it up and to the left, away from the locking notch. Let the lever lower -until it rests by the “DOWN” mark. The broom will automatically begin rotating as it is lowered. To turn “ON” the side brooms, move the Hopper Lift/Side Broom Lever forward to the “ON” position (See Figure 9). IGNITION SWITCH (See Figure 5) The keyed ignition switch is located to the right of the steering column on the front face of the instrument console. It has four positions. 1. The key turned to the center “OFF” position will shut off the engine. The following items can be activated in the “OFF” position. (A.) Horn (B.) Light Options 2. The key turned to the right “IGN/ON” position will allow all the following items to be activated (but will NOT start the engine): (A) Horn (B) Light Options (C) Turn Signals (D) Instrument Panel Gauges 3. The key turned to the far right “START” position will start the engine. This position is a momentary position. The key will revert to the “IGN/ON” position when it is released. WET-SWEEP BYPASS SWITCH (OPTION) (See Figure 2) The wet-sweep bypass switch is located to the right of the steering wheel under the shaker motor switch. The switch activated will shut off the vacuum motor. This will keep the dust filters from being ruined by the water pickup from sweeping water. 8 - FORM NO. 56041668 American-Lincoln Technology 3366XP / 4366XP OPERATION OF CONTROLS AND GAUGES NEUTRAL NEUTRAL FORWARD REVERSE FOOT BRAKE P4689 FIGURE 6 P4066 FIGURE 7 4-WAY TURN SIGNALS (OPTION) (See Figure 2) The turn signal option is located on the steering column and works as automotive turn signals work, forward on the lever for right and back on the lever for left. The 4 way flasher will activate when the turn signal lever is pulled out. FOOT BRAKE (See Figure 6) The foot brake pedal is located to the right of the steering column on the floor of the driver compartment. The foot brake on front wheels is a mechanical system actuated by the brake pedal. ACCELERATOR & DIRECTIONAL CONTROL PEDAL (See Figure 7) The accelerator and directional control pedal is located on the floor of the operator’s area, to the right of the brake pedal. The accelerator and directional control pedal controls the machine direction and travel speed. 1. 2. 3. 4. 5. Put foot pressure on the upper portion of the pedal. The machine will move forward. Increase the foot pressure on the upper portion of the pedal to increase the forward speed. Put foot pressure on the lower portion of the pedal. The machine will move in reverse. Increase the foot pressure on the lower portion of the pedal to increase the reverse speed. To stop the machine, put light foot pressure on the opposite end of the accelerator and directional control pedal. If the machine is moving forward, put light foot pressure on the lower portion of the pedal. If the machine is moving in reverse, put light foot pressure on the upper portion of the pedal. BACK UP ALARM (OPTION) (See Figure 2) The back up alarm is operated by a switch that is located under the lower section of the Accelerator and directional control pedal. The alarm makes a loud audible noise when the machine is being driven in reverse. SEAT ADJUSTMENT (See Figure 2) This lever is located on the right of the seat. This lever allows the seat to be adjusted forward or back when the lever is moved. American-Lincoln Technology 3366XP / 4366XP FORM NO. 56041668 - 9 OPERATION OF CONTROLS AND GAUGES LOCKED POSITION PARKING BRAKE (See Figure 8) The parking brake lever is located in the left side of the driver compartment floor. This lever when raised to the upright position will “lock” the foot brake pedal in the down position. PARKING BRAKE P4691 FIGURE 8 CIRCUIT BREAKERS (See Figures 2 & 8a) The circuit breakers are located to the left of the steering wheel. When a circuit breaker “pops” out, this is an indication of an electrical problem that must be corrected before the breaker can be reset. There can be up to seven circuit breakers in the row. They control the following circuits, beginning with number 1 on the left: CB-1 = Filter shaker motors CB-2 = Horn CB-3 = Starter relay CB-4 = Ignition CB-5 = Accessory CB-6 = Options CB-7 = Cab Options GLOW PLUG - DIESEL (See Figure 8a) 1 2 3 P4393 4 5 6 7 FIGURE 8a WARNING! It is advised that in no circumstances should either or any other unauthorized starting aids be used at the same time as the Glow Plugs. To operate the glow plugs, the following procedure should be adopted. 1. Before operating he starter motor, press the “GLOW PLUG” button for approximately 20 to 30 seconds. 2. With the “GLOW PLUG” button still depressed, engage the starter motor until the engine starts. 3. Continue to press the “GLOW PLUG” button for a few seconds after the engine has started until even running has been obtained. 4. If the engine does not start, disengage the starter motor but keep the “GLOW PLUG” button depressed for a further 10 to 15 seconds. When a further attempt is made to start the engine, keep the glow plugs energized while starting and for a few seconds after the engine has fired until it is running smoothly. 10 - FORM NO. 56041668 American-Lincoln Technology 3366XP / 4366XP OPERATION OF CONTROLS AND GAUGES HOPPER LIFT / SIDE BROOM LEVER (See Figure 9) HOPPER ROTATE & DUMP HOPPER LIFT LOWER RAISE HOPPER The Hopper Lift/Side Broom lever is located to the left side of the drive compartment. The lever is a three position control that operates the hopper lift, side broom and optional left side broom. DUMP NOTE The hopper lift lever will not function until the hopper has been rotated to clear the body of the sweeper. RETURN The lever is spring centered from the rear position. The center position turns OFF the side broom (or brooms) and is the HOLD position when dumping the hopper. The lever is detonated in the forward position. Move the lever forward to turn ON the side broom when sweeping or to LOWER the hopper when dumping the hopper. Move the lever back to RAISE the hopper when dumping. Release the lever when the hopper has reached the desired height. The lever will return to the center HOLD position. CONTROLS HOPPER DUMP/RETURN CONTROL LEVER (See Figure 9) The Hopper Dump/Return lever is located to the left of the drive compartment. The lever is a two position control that operates the hopper dump system. The lever is spring loaded to the center position which “STOPS” rotation of the hopper. To rotate the hopper, move the lever forward to the dump position and hold. Release the lever when the hopper reaches the desired position. The return the hopper after dumping, move the lever back to the RETURN position. The hopper will rotate back and the hopper will lower to the seated position. Release the lever once the hopper has been seated in the body of the sweeper. P4686 FIGURE 9 WARNING! Never turn off the engine with the hopper in the lifted position. THROTTLE CONTROL (See Figures 10 & 10a) The throttle control is located on the left side console. Gas and LP equipment have a throttle switch. Diesel versions have a lever. Both have 3 throttle speed positions - IDLE, 1, and 2. To operate the diesel, grasp the lever and push up and right to desired locking notch. To reduce to idle, grasp the lever and push up and to the left (away from both locking notches). Let the lever lower until it rests at the bottom of the slot. For the Gas/LP switch, the bottom position is idle, the top position is top RPMs (2450 “no load”), and the middle is lower speed (2050 “no load” RPMs). “Load” (brooms and/or brushes and/or dust control operating) and “No Load” (brooms, brushes & dust control off) RPMs are the same for gas and LP equipment; there will be a slight drop between “Load” and “No Load” RPMs with diesels. Always return the throttle lever to the idle position before turning off the key to stop the engine. LEFT SIDE BROOM LIFT (OPTION) MAIN BROOM LIFT LEFT SIDE BROOM LIFT (OPTION) MAIN BROOM LIFT UP UP UP UP SWEEP SWEEP DOWN DOWN FLOAT FLOAT MACHINE CHECK ENGINE LIGHT ! THROTTLE SWITCH CHECK ENGINE LIGHT SYMBOL THROTTLE SYMBOL THROTTLE LEVER THROTTLE SYMBOL SWEEPER/ SCRUBBER FIGURE 10 SWEEPER American-Lincoln Technology 3366XP / 4366XP FIGURE 10a Gas/LP 1st 2nd Diesel 1st 2nd 950 950 950 950 (1 speed level) (2 speed levels) P4688ecp Gas/LP Diesel RPMs IDLE “NO LOAD” 950 2050 950 2150 2050 2450 2150 2550 FORM NO. 56041668 - 11 OPERATION OF CONTROLS AND GAUGES CHECK ENGINE LIGHT (Gas, LP Only) (See Figure 10a) The check engine light (MIL) is located on the left side console. If the light comes on, it indicates a problem with the engine. Go to the GM Engine Service Manual, Section 7, for directions on how to diagnose the problem. LEFT SIDE BROOM LIFT AND POWER CONTROL (OPTION) (See Figure 10) The left side broom lift control is located on the left side of the instrument panel. To raise and stop the side broom, grasp the lever and push the lever to the locking notch marked “UP”. To lower the side broom, grasp the lever and push it up to the right away from the locking notch. Let the lever lower until it rests by the “DOWN” mark. To turn “ON” the side brooms, move the Hopper Lift/Side Broom Lever forward to the “ON” position. MAIN BROOM LIFT (See Figure 10) The main broom lift control is located to the left of the driver’s seat. To lower the main broom, grasp the lever and push up and to the left to clear the locking notch. Move the lever down to the first or second notch in the elongated slot. The first notch, “SWEEP”, is for normal sweeper (2 to 3 in. or 5 to 8 cm. broom pattern). The second notch, “FLOAT”, is for heavy sweeping (4 to 5 in. or 10 to 13 cm. broom pattern), To raise the main broom, push the lever up and slide into the locking notch in the “UP” position. You may operate the main broom in either the “SWEEP” or “FLOAT” position. However, the “SWEEP” position should be used for normal sweeping and will result in increased broom life. The “FLOAT” position should be used only when sweeping in extremely uneven areas. WORK LIGHT SWITCH (OPTION) The work light switch is located under the light switch to the left side of the steering wheel. It allows the operator to work the rear work light option when the headlights are on. LIGHT SWITCH (OPTION) The light switch is located under the horn to the left side of the steering wheel. It will work various light options that are available for this machine, such as: - Head Lights Tail Lights Side Broom Lights Instrument Lights All gauges with the exception of the hour meter can have an option internal instrument light. HORN BUTTON The horn button is located to the left of the steering column. The horn button is always active. Push the horn button to sound the horn. CAB (OPTION) The all-weather cab is available for this machine along with several “cab only” options: - Windshield Wipers Defroster Fan Interior Light Pressurizer These options have their controls located on the cab. LOW OIL SHUTDOWN This engine is equipped with a low oil pressure shutdown. If the engine oil pressure drops too low, the engine will shut down. Add engine oil until the oil is brought up to the correct level. 12 - FORM NO. 56041668 American-Lincoln Technology 3366XP / 4366XP OPERATING INSTRUCTIONS NOTE Before starting the engine, perform these pre-start checks. PRE-START CHECKLIST 1. Clean engine air filter element if needed 2. Check engine oil level 3. Check radiator coolant level 4. Check hydraulic fluid level 5. Check fuel level 6. Check all systems for leaks 7. Check brakes and controls for proper operation BEFORE STARTING ENGINE 1. Set Parking Brake. 2. Make sure all controls are in the “Off” position. TO START ENGINE 1. Be sure accelerator and directional control pedal is in neutral. 2. Turn key to “On” position & release. 3. If engine fails to start after following the above procedures, refer to Engine Manual. NOTE When machine has been stored in below-freezing temperatures, run engine at not over 1/2 throttle with machine standing still for 5 to 10 minutes to warm engine and hydraulic oil. POST-START CHECKLIST (Engine Running) 1. Check main and side brooms to make sure they are free of debris which will inhibit rotation & pick-up. NOTE: Always wear hand protection when cleaning debris from brooms and/or brushes. 2. Check squeegees to make sure there is no damage and they meet the floor. TO OPERATE SWEEPER 1. Make sure parking brake is released. 2. Lower the side and main broom to the floor. (The main broom control may be placed in either the “FLOAT” or “SWEEP” position.) 3. Turn Broom Fan Switch on. 4. Pull engine throttle to “UP” position. (Engine must always be operated at full governed speed while sweeping to obtain recommended brush speed and dust control). 5. Push forward on directional control pedal to place machine in motion. 6. Vary your foot pressure on the directional control pedal to obtain desired travel speed. TO STOP SWEEPER 1. Allow directional control pedal to return to neutral (centered) position. (Pedal will automatically return to neutral when foot pressure is released.) FOR NORMAL OPERATION, DEPRESS DIRECTIONAL CONTROL PEDAL WITH HEEL INTO NEUTRAL. 2. Depress the foot brake. 3. Turn Broom Fan Switch off. 4. Put the broom controls (Side and Main) in the “UP” position. 5. Push engine throttle down. Turn key to “OFF.” 6. Set parking brake. American-Lincoln Technology 3366XP / 4366XP FORM NO. 56041668 - 13 OPERATING INSTRUCTIONS SIDE AISLES MAIN AISLE SIDE AISLES P4134/0001 P-4134 FIGURE 11 WARNING! Do not turn the steering wheel sharply when the machine is in motion. The sweeper is very responsive to movement of the steering wheel. Do not make sudden turns. Sweep in straight paths. Do not bump posts. Do not scrape the sides of the machine. When the machine is in motion, do not push the directional/speed control pedal all the way forward. This is the same as starting in “High” and will put a strain on the motor and drive system. 1. 2. 3. 4. 5. 6. 7. Plan your sweeping in advance. Try to arrange long runs with minimum stopping and starting. Sweep debris from narrow aisles out into main aisle ahead of time. Do an entire floor, or section at one time. Pick up oversize debris before sweeping. Don’t turn steering wheel too sharply when machine is in motion. The machine is very responsive to movement of the steering wheel - so avoid sudden turns. Try to follow as straight a path as possible. Avoid bumping into posts or scraping the sides of the machine. When placing the machine in motion, avoid slamming the directional control pedal all the way forward quickly. This is equivalent to starting out in “HIGH” and puts needless strain on the engine and drive system. Always allow the machine to warm up before operating in cold temperatures. Periodically turn sweeping (main) broom end for end to prevent the bristles from “setting” in one direction. NOTE Replace sweeping broom when bristles are worn to 3-inch (8-cm.) length. 14 - FORM NO. 56041668 American-Lincoln Technology 3366XP / 4366XP OPERATING INSTRUCTIONS NOTE After stopping the engine, perform these post operation checks. POST-OPERATION CHECK LIST 1. Clean debris hopper. 2. Check brooms for wear or damage. 3. Check all flaps for wear, damage and adjustment. 4. Fill the fuel tank. WARNING! The gasoline tank access is located behind the driver’s seat. DO NOT mistake the hydraulic reservoir for the fuel tank. 5. Check all systems for leaks. LIFT LEVER DUMP LEVER FIGURE 11a TO EMPTY DEBRIS HOPPER 1. Set engine throttle to full throttle position. 2. Push the hopper rotate and dump lever to the “DUMP” position. The hopper will begin to rotate. 3. Once the hopper rotation speed doubles, the hopper lift lever will work. Raise the hopper to the desired level (MINIMUM OF 8” or 20 cm OF LIFT REQUIRED) by pulling back the hopper lift lever to the “RAISE” position. 4. Drive forward 12 to 18 inches slowly with the hopper up before completing the dump cycle. 5. Push the hopper rotation and dump lever to the “DUMP” position to complete dump cycle. 6. Drive in reverse 12 to 18 inches or 30 to 46 cm. slowly with the hopper up to clear the dumpster before lowering the hopper. 7. Pull the hopper rotation and dump lever to the “RETURN” position and the hopper will automatically rotate and lower to its proper position. WARNING! Never turn off the engine with the hopper in the lifted position. American-Lincoln Technology 3366XP / 4366XP FORM NO. 56041668 - 15 OPERATING INSTRUCTIONS TOWING INSTRUCTIONS 1. Locate tow control shaft extension as shown in Figure 12. The tow control shaft is located underneath the pump. 2. To open hydraulic circuit to wheel drive motor turn shaft 90°. 3. After towing, turn shaft 90° to its original position. DRIVE PUMP TOW VALVE SHAFT VIEW OF DRIVE PUMP FROM FRONT OF MACHINE C0192 FIGURE 12 DUST FILTERS The Filter Panel can be periodically removed from the hopper and blown off with compressed air (not to exceed 100 P.S.I.) or cleaned with soap and water. (Do not attempt to use Filter Panels that have not dried completely.) THE DUST CONTROL SYSTEM The baffle system that is built into the debris hopper is designed minimize dust in the air while the machine is sweeping. The debris from sweeping is thrown into the hopper. The impeller vacuum fan pulls the lighter dust up and through a baffle system. The Pre-Clean Flap separates the heavier dust particles to an area below the filter. The lighter dust particles are captured by the dust filter. This allows the dust filter to remain cleaner and need less shaking to remove dust. When the dust filter becomes clogged the filter shaker switch should be pushed to start the dust shaker cycle. This will extend the life of the filter. NOTE The main broom and impellor fan will shut off automatically when the shaker motor is cycling. P4695 16 - FORM NO. 56041668 FIGURE 13 American-Lincoln Technology 3366XP / 4366XP GENERAL MACHINE MAINTENANCE MAIN BROOM RETAINING BOLT DRIVE HUB LEFT BROOM CHAMBER DOOR IDLER ARM FIGURE 14 HOW TO REPLACE THE MAIN BROOM Replace the main broom when the bristles are worn to 2 inches in length. 1. Open the left broom chamber door. 2. Put the main broom control in the “SWEEP” position. 3. Remove the retaining bolt. (See Figure 14) 4. Remove the idler arm assembly. 5. Remove the main broom and discard. 6. Put a new main broom in the broom chamber. 7. Rotate the new broom to the right on the drive hub until it engages the drive hub broom tabs. 8. Put the idler arm assembly in place. 9. Put the retaining bolt in place and tighten. 10. Close the broom chamber door. 11. Start the engine. 12. Put the broom lever in the “SWEEP” position. 13. Let the broom sweep in place for 30 seconds. 14. Put the broom lever in the “UP” position. 15. Back the machine off the test spot. 16. Inspect the polished area where the broom swept, for broom bristle contact with the floor. The area of broom bristle contact with the floor should be 2 to 3 inches or 5 to 8 cm. wide. MAIN BROOM LEVEL ADJUSTMENT The main broom level is factory set and should not need adjustment, if the level gets out of adjustment and the broom bristle contact pattern is not an even 2” to 3” wide, the broom arm lift frame will have to be adjusted. The frame is supported by two flange bearings. These bearings are located inside the broom doors. The carriage bolts on the two end flanges will have to be loosened. The frame can then be leveled and the bolts tightened. American-Lincoln Technology 3366XP / 4366XP FORM NO. 56041668 - 17 GENERAL MACHINE MAINTENANCE 1/16" SET DOOR FLAP EVEN WITH FLOOR HOW TO ADJUST MAIN BROOM WEAR PATTERN When the bristles of the broom begin to wear out the following adjustments may be made to keep a 2 inch (5 cm) broom pattern. 1. Loosen the wing nut located in the engine compartment. 2. Set the broom lever to the “Sweep” position and adjust the torque knob to obtain a 2 inch (5 cm) broom pattern. The torque knob will move the linkage rod that adjusts the sweeping pattern of the broom for wear. 3. Tighten the wing nut against the torque knob. SIDE BROOM LEVEL ADJUSTMENT As the side broom wears, simply loosen the two wear adjusting bolts and slide the broom-motor assembly into a position so that the broom contacts the floor at a 3 degree angle when lowered. SIDE BROOM REPLACEMENT Put the side broom lift control in the “UP” position. Remove the retaining screw in the bottom middle of the side broom. Remove the side broom. Transfer the side broom flange, spacer, screws, washers, and nuts to the replacement side broom. Put the replacement side broom on the shaft. Put the retaining screw and washer in position and tighten. BROOM FLAPS The Urethane Flaps are susceptible to damage and should be inspected regularly and maintained in good condition. The side and hopper flaps are adjustable and should be maintained even with the floor. The rear flap must be maintained 1/16” (16 cm.) above the floor. All flaps should be replaced when worn or damaged to such an extent that they cannot perform their normal function. 18 - FORM NO. 56041668 American-Lincoln Technology 3366XP / 4366XP GENERAL MACHINE MAINTENANCE THROTTLE CABLE GOVERNOR & CHOKE LINKAGE #10 OIL #10 OIL DUMP SYSTEM PIVOT POINTS #10 OIL FRONT WHEEL BEARINGS DRIVE WHEEL SWIVEL BEARINGS #10 OIL Perform the following lubrication procedures after every 50 hours of machine use: 1. Lubricate dump system pivot points, with a good grade multipurpose grease. Do the following lubrication procedures after every 100 hours of machine use. 2. Lubricate drive wheel swivel bearing, and the front wheel bearings with a good multi-purpose grease. 3. The steering gear assembly has a grease fitting, located on the front section of the steering gear housing. Use E.P. Lithium grease to lubricate the steering gear through the grease fitting. 4. Lubricate all other moving joints of the machine with #10 oil. 5. Lubricate the clamp ends of the throttle cable with NAPA #765-1363 or equivalent anti-seize lubricant. American-Lincoln Technology 3366XP / 4366XP FORM NO. 56041668 - 19 GENERAL MACHINE MAINTENANCE 20, 30, 2, 21 31 30 33 10 11, 28 27 1,7,19 12, 34 14 4,13,29 31 25 3,36,37,38 9 15 8 25 25 24 16,35 25 16,35 25 C0260 20 - FORM NO. 56041668 22 5 6, 18 25 23, 26 6 American-Lincoln Technology 3366XP / 4366XP GENERAL MACHINE MAINTENANCE MAINTENANCE SCHEDULE EVERY 8 HOURS or DAILY operation check and clean/adjust if necessary: 1. Inspect panel filter for damage and clean. 2. Check engine oil level 3. Check hydraulic fluid level 4. Check radiator core for blockage 5. Check all flaps for wear or damage 6. Check brooms for wear or damage, adjust as required 7. Check panel filter (clean side) for leakage 8. Check brake pedal and parking brake 9. Check for LP/Diesel odor at connections 10. Check water separator (Diesel) 11. Clean engine air filter dust cap and check filter 12. Check hydraulic return filter 13. Check coolant level EVERY 50 HOURS 14. Check tension on all belts 15. Check battery electrolyte level (If battery is not maintenance free) 16. Lubricate dump system 17. Check all hydraulic hoses for wear or cuts 18. Rotate main brush (end-to-end) 19. Clean or replace panel filter Perform recommended engine maintenance (See engine manual) EVERY 100 HOURS 20. Change crankcase oil 21. Change engine oil filter 22. Lubricate drive wheel swivel bearing 23. Lubricate front wheel bearings 24. Lubricate steering gear box 25. Lubricate all moving joints 26. Check brake pads for wear and adjust accordingly 27. Lubricate clamp ends of the throttle cable with NAPA #765-1363 or equivalent anti-seize lubricant. Perform recommended engine maintenance (See engine manual) EVERY 250 HOURS 29. Flush radiator coolant system 30. Remove spark plugs - clean or replace (Gas, LP) 31. Check distributor - service or replace (Gas, LP) 32. Clean and lubricate governor linkage (Diesel) 33. Replace fuel filter 34. Replace hydraulic return filter element 35. Check brass bushings & pins on hopper & lift arms Perform recommended engine maintenance (See engine manual) EVERY 500 HOURS 36. Clean hydraulic reservoir 37. Clean hydraulic intake strainer 38. Change hydraulic fluid Perform recommended engine maintenance (See engine manual) American-Lincoln Technology 3366XP / 4366XP FORM NO. 56041668 - 21 TECHNICAL SPECIFICATIONS (as installed and tested on the unit ) Model Model No. Sound Pressure Level (ISO 11201) Sound Power Level (ISO 3744) Total Weight Vibrations at the Hand Controls (ISO 5349-1) Vibrations at the Seat (EN 1032) Gradeability dB (A) dB (A) lbs/kg m/s2 m/s2 Model Model No. Sound Pressure Level (ISO 11201) Sound Power Level (ISO 3744) Total Weight Vibrations at the Hand Controls (ISO 5349-1) Vibrations at the Seat (EN 1032) Gradeability 22 - FORM NO. 56041668 dB (A) dB (A) lbs/kg m/s2 m/s2 revised 1/07 4366XP LD LPG 4366XP LD Petrol 4366XP LD Diesel 579-549 579-548 579-551 92.3 Lwa 112.1 3580 / 1624 0.93 m/s2 0.54 m/s2 21% (11.8°) 4366XP VD LPG 4366XP VD Petrol 4366XP VD Diesel 579-547 579-546 579-550 92.3 Lwa 112.1 3800 / 1724 0.93 m/s2 0.54 m/s2 21% (11.8°) 3366XP LD Petrol 3366XP LD Diesel 579-548CE 579-551CE 92.3 Lwa 112.1 3580 / 1624 0.93 m/s2 0.54 m/s2 21% (11.8°) 3366XP VD Petrol 3366XP VD Diesel 579-546CE 579-550CE 92.3 Lwa 112.1 3800 / 1724 0.93 m/s2 0.54 m/s2 21% (11.8°) American-Lincoln Technology 3366XP / 4366XP Overenstemmelseserklaering Declaration of conformity Konformitätserklärung Declaración de conformidad Atbilstības deklarācija Megfelelősségi nyilatkozat Certifikat o ustreznosti Declaration de conformité Verklaring van overeenstemming Dichiarazione di conformità Vastavussertifikaat Deklaracja zgodności Försäkran om överensstämmelse Modell/ Modèle/ Model/ Malli/ Modelo/ Μοντέλο/ Modelo/ Modelis/Модель: Samsvarserklaering Vaatimustenmukaisuusvakuutus Atitikties deklaracija Osvědčení o shodě Certifikát súladu Floor Treatment Machines Type/ Tyyppi/ Tipo/ Τύπος/ Tüüp/ Tipas/ Tips/ Typ/ Típus/ Тип/ Tip: 6150, MVP60, 3366XP, 5730B, 7730B, 7750, 7760. D Der Unterzeichner bestätigt hiermit dass die oben erwähnten Modelle gemäß den folgenden Richtlinien und Normen hergestellt wurden. GB The undersigned certify that the above mentioned model is produced in accordance with the following directives and standards. DK Undertegnede attesterer herved, at ovennævnte model er produceret i overensstemmelse med følgende direktiver og standarder. N Undertegnede attesterer att ovennevnte modell är produsert I overensstemmelse med fölgende direktiv og standarder. E El abajo firmante certifica que los modelos arriba mencionados han sido producidos de acuerdo con las siguientes directivas y estandares. I Il sottoscritto dichiara che i modelli sopra menzionati sono prodotti in accordo con le seguenti direttive e standard. EST Allakirjutanu kinnitab, et ülalnimetatud mudel on valmistatud kooskõlas järgmiste direktiivide ja normidega. LV Ar šo tiek apliecināts, ka augstākminētais modelis ir izgatavots atbilstoši šādām direktīvām un standartiem. CZ Níže podepsaný stvrzuje, že výše uvedený model byl vyroben v souladu s následujícími směrnicemi a normami. SLO Spodaj podpisani potrjujem, da je zgoraj omenjeni model izdelan v skladu z naslednjimi smernicami in standardi. F Je soussigné certifie que les modèles ci-dessus sont fabriqués conformément aux directives et normes suivantes. NL Ondergetekende verzekert dat de bovengenoemde modellen geproduceerd zijn in overeenstemming met de volgende richtlijnen en standaards. FIN Allekirjoittaia vakuuttaa että yllämainittu malli on tuotettu seuraavien direktiivien ja standardien mukaan. S Undertecknad intygar att ovannämnda modell är producerad i överensstämmelse med följande direktiv och standarder. GR Ο κάτωθι υπογεγραμμένος πιστοποιεί ότι η παραγωγή του προαναφερθέντος μοντέλου γίνεται σύμφωνα με τις ακόλουθες οδηγίες και πρότυπα. P A presente assinatura serve para declarar que os modelos supramencionados são produtos em conformidade com as seguintes directivas e normas. LT Toliau pateiktu dokumentu patvirtinama, kad minėtas modelis yra pagamintas laikantis nurodytų direktyvų bei standartų. PL Niżej podpisany zaświadcza, że wymieniony powyżej model produkowany jest zgodnie z następującymi dyrektywami I normami. H Alulírottak igazoljuk, hogy a fent említett modellt a következő irányelvek és szabványok alapján hoztuk létre. SK Dolu podpísaný osvedčuje, že hore uvedený model sa vyrába v súlade s nasledujúcimi smernicami a normami. EC Machinery Directive 98/37/EC EC Low Voltage Directive 73/23/EEC EC EMC Directive 89/336/EEC EC Outdoor Noise Directive 2000/14/EC EC Particulate Emissions EN 12100-1, EN 12100-2, EN 294, EN 349 EN 60335-1, EN 60335-2-72 EN 61000, EN 50366 1.5.2007 Randy Rollins, Vice President Operations American-Lincoln 14600 21st Avenue North Plymouth, MN 55447 USA Nilfisk-Alto Industrivej 1 9560 Hadsund, Denmark ©Nilfisk-Advance Incorporated, 2007 .pas 14600 21st Avenue North Plymouth, MN 55447-3408 www.americanlincoln.com Phone: 800-331-7692 Fax: 877-877-2586 ©2007 American-Lincoln