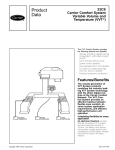

Download Carrier 50HEQ003-006 Unit installation

Transcript