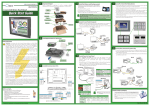

Download DP-PGMSW-M Manual - AutomationDirect

Transcript