Download STM8L1526-EVAL evaluation board

Transcript

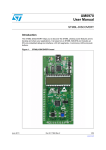

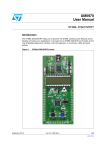

UM0684 User manual STM8L1526-EVAL evaluation board Introduction The STM8L1526-EVAL evaluation board is a complete demonstration and development platform for STMicroelectronic's STM8 core-based STM8L152C6 microcontroller which supports I2C, SPI, USART, 12-bit ADC, 12-bit DAC, LCD driver, 2 KB internal SRAM, 32 KB EEPROM and SWIM debugging. The full range of hardware features on the board helps you evaluate all peripherals (motor control, USART, audio DAC, LCD, IR LED, IrDA, SPI Flash, MicroSD Card, temperature sensor and EEPROM… etc.) and develop your own applications. Extension headers facilitate easy connection of a daughterboard or wrapping board for specific applications. An ST-LINK is integrated on the board as the embedded in-circuit debugger and programmer for the STM8 MCU. Figure 1. September 2009 STM8L1526-EVAL evaluation board Doc ID 15437 Rev 1 1/46 www.st.com Contents STM8L1526-EVAL Contents 1 2 3 2/46 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 Demonstration software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.3 Order code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Hardware layout and configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2.1 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.2 Clock source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 2.3 Reset source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 2.4 LCD glass module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 2.5 Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 2.6 EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 2.7 RS-232 and IrDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 2.8 Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 2.9 MicroSD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 2.10 Analog input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 2.11 Serial Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 2.12 Temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 2.13 Development and debug support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 2.14 Display and input devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 2.15 IDD measurement and comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 2.16 Comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 2.17 IR LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3.1 RS-232 connector CN1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3.2 Power connector CN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3.3 TFT LCD connector CN3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3.4 Daughterboard extension connector CN4 and CN10 . . . . . . . . . . . . . . . . 22 3.5 LCD glass connector CN5 and CN6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 3.6 Motor control connector CN7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Doc ID 15437 Rev 1 STM8L1526-EVAL 4 Contents 3.7 STice connector CN8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 3.8 ST-LINK programming connector CN9 . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 3.9 USB type B connector CN11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 3.10 SWIM connector CN12 and CN16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 3.11 Audio jack CN13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 3.12 MicroSD connector CN14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 3.13 BNC connector CN15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Appendix A STM8L1526-EVAL I/O assignment . . . . . . . . . . . . . . . . . . . . . . . . . . 43 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 Doc ID 15437 Rev 1 3/46 Features STM8L1526-EVAL 1 Features 1.1 Hardware 1.2 ● Three 5 V power supply options: power jack, ST-LINK USB connector or daughterboard ● Audio speaker and microphone connected to the DAC and ADC of the STM8L152C6 ● 1 GByte SPI interface MicroSD Card ● 128 Mbit SPI serial Flash ● I2C compatible serial interface 64 KBit EEPROM and SMBusTemperature sensor ● RS-232 communication ● IrDA transceiver ● Inductor motor control connector ● SWIM debug support, ST-LINK embedded ● 122x32 dot matrix LCD connected to the SPI interface of the STM8L152C6 ● Joystick with 4-direction control and selector ● Reset and User button ● 4 color LEDs and one bicolor LED ● MCU consumption measurement circuit ● LCD glass 28 x 4 segments (7 digits alpha numeric) connected to the LCD driver inside the STM8L152C6 ● Extension connector for daughterboard or wrapping board ● MCU voltage choice 3.3 V or adjustable from 1.65 V to 3.6 V ● STice connector footprint ● Board RoHS compliant (lead free) Demonstration software Demonstration software is preloaded in the board’s Flash memory for easy demonstration of device peripherals in stand-alone mode. For more information and to download the latest version available, please refer to STM8L1526-EVAL demonstration firmware available on web: www.st.com/mcu. 1.3 Order code To order the STM8L152C6 evaluation board, use the order code STM8L1526-EVAL. 4/46 Doc ID 15437 Rev 1 STM8L1526-EVAL Hardware layout and configuration The STM8L1526-EVAL evaluation board is designed around the STM8L1526C6T6 (48-pin LQFP package). The hardware block diagram Figure 2 illustrates the connection between the STM8L152C6 and the peripherals (LCD glass, dot matrix LCD, serial Flash, EEPROM, temperature sensor, USART, IrDA, audio, MicroSD Card, Motor control and embedded STLINK). Figure 3 and Figure 4 help you locate these features on the actual evaluation board. Figure 2. Hardware block diagram MicroSD card SPI Dot Matrix LCD Voltage translator Serial Flash RS232 transceiver USART LCD driver 2 Hardware layout and configuration USART DB9 connector IrDA transceiver LCD Glass module Joystick GPIO MC control connector LEDs STM8L1526 STM8L1526C6T6 ADC Potentiometer Micro-Phone Amplifier GPIO User Key ADC BNC connector DAC 1.65V to 3.6V adjustable regulator Audio DAC 3.3V regulator EEPROM MCU consumption measurement I2C Temperature Sensor SWIM Embedded ST-LINK USB TypeB connector Doc ID 15437 Rev 1 Extension connector for GPIOs 5/46 Hardware layout and configuration Figure 3. STM8L1526-EVAL STM8L1526-EVAL layout CN4, CN10 Extension header CN7 Motor control U16 STM8L1526 CN8 STice connector LD6 IR LED LCD glass module U2 IrDA CN15 BNC connector CN1 USART CN11 ST-LINK USB connector CN12 & CN13 SWIM connector U7 Dot matrix LCD CN14 MicroSD Card CN2 Power Jack CN13 Audio Jack RV1 VDD_Adjustment RV2 Potentiometer 6/46 B1 reset key U17 joystick Doc ID 15437 Rev 1 B2 user key STM8L1526-EVAL Figure 4. Hardware layout and configuration STM8L1526-EVAL jumpers and solder bridges Doc ID 15437 Rev 1 7/46 Hardware layout and configuration 2.1 STM8L1526-EVAL Power supply The STM8L1526-EVAL is designed to be powered by a 5 V DC power supply and to be protected by PolyZen from a wrong power plug-in event. It is possible to configure the evaluation board to use any of following three power supply sources. 1. 5 V DC power adapter connected to CN2, the power jack on the board (power supply unit (PSU) on silk screen). ● 5 V DC power with 500 mA limitation from CN11, the USB type B connector for STLINK (ST-link on silkscreen (STL)). ● 5 V DC power from CN10, the extension connector for daughterboard (daughterboard power source (DTB) on silkscreen). The power supply is configured by setting the related jumpers JP1, JP2 and JP11 as described in Table 1. Table 1. Jumper Power related jumpers: JP1, JP2, JP11 Description STLink DTB PSU JP2 selects one of the three possible power supply resources. For power supply jack(CN2) to the STM8L1526-EVAL only, JP2 is set as shown to the right. Setting For power supply from the daughterboard connectors(CN10) to STM8L1526EVAL only, JP2 is set as shown to the right. STLink DTB PSU For power supply from ST-LINK connector (CN11) to STM8L1526-EVAL only, JP2 is set as shown to the right (default setting). STLink DTB PSU JP2 STLink DTB PSU For power supply from power supply jack (CN2) to both STM8L1526-EVAL and daughterboard connected on CN4 and CN10, JP2 is set as shown to the right (daughterboard must not have its own power supply connected). VDD is connected to fixed +3.3 V DC power when JP1 is set as shown to the right (default setting). 1 2 3 VDD is connected to adjustable DC power from 1.65 V to 3.6 V when JP1 is set as shown to the right. 1 2 3 VDD power is directly connected to MCU VDD when JP11 is set as shown to the right. Note: For manual IDD measurement the jumper on JP11 must be removed and replaced by an ammeter connected between JP11 pin 2 and pin 3. 1 2 3 Connect VDD power to MCU with current-sampling resistor, 2 ohm or 2 Kohm, in-series for IDD current measurement when JP11 is set as shown to the right (default setting). 1 2 3 JP1 JP11 8/46 Doc ID 15437 Rev 1 STM8L1526-EVAL Hardware layout and configuration To enable MCU power consumption measurement, JP11, JP3 and LCD glass module should be re-configured as described in Table 1 and Table 2. Table 2. MCU power consumption measurement related jumpers Jumper Description The microphone output is connected to ADC of the STM8L152C6 when JP3 is closed. Default setting: Fitted For MCU power consumption measurement, JP3 must be kept open to avoid current injection. For motor control application, JP3 must be kept open to avoid conflict between the speaker and motor control connector, CN7. JP3 LCD glass The LCD glass module must be mounted on the "IO" position for MCU power module consumption measurement. Refer to Section 2.4: LCD glass module for details. The LED LD8 is lit when the STM8L1526-EVAL evaluation board is powered by the 5 V correctly, the LED LD9 is lit if the MCU is powered by a low voltage (VDD < 1.8 V). Note: The AC220V to DC5V power adapter PSU-5V2A (recommended, can be ordered from ST, it is not provided with board by default) or equivalent (polarity compatible with CN2) can be used to power the STM8L1525-EVAL board via the power jack CN2 on the board. To order the recommended power supply, use the order code PSU-5V2A. 2.2 Clock source Two clock sources are available on the STM8L1526-EVAL for the STM8L152C6 and embedded RTC. ● X2, 32 kHz crystal for embedded RTC ● X1, 16 MHz crystal with socket for the STM8L152C6 microcontroller, it can be removed from the socket when the internal RC clock is used. Table 3. 32 kHz crystal X2 related solder bridges Solder bridge Description PC5 is connected to 32 kHz crystal when SB3 is set as pad1 connected to pad2 (default setting). SB3 PC5 is connected to STice connector CN8 and extension connector CN4 when SB3 is set as pad2 connected to pad3. PC6 is connected to 32 kHz crystal when SB4 is set as pad2 connected to pad3 (default setting). SB4 PC6 is connected to STice connector CN8 and extension connector CN4 when SB4 is set as pad1 connected to pad2. Note: I/O ports PA2 and PA3 can be used as GPIO on extension connector by closing solder bridges SB1 and SB2 when crystal X1 is removed from it's socket. Doc ID 15437 Rev 1 9/46 Hardware layout and configuration 2.3 STM8L1526-EVAL Reset source The reset signal of the STM8L1526-EVAL is low active and the reset sources include: ● Reset button B1 ● Debugging tools from SWIM connector CN12 and CN16 ● Daughterboard from CN10 ● Embedded ST-LINK ● RS-232 connector CN1 for ISP Table 4. Reset related jumpers Jumper 2.4 Description Setting JP15 The board Reset is managed by pin 1 of connector CN1 (RS-232 DCD signal) when JP15 is closed. This configuration is used for boot loader application only. Default Setting: Not fitted JP13 PA1 is connected to the Reset source listed above when JP13 is set as shown to the right: (Default setting). 1 2 3 PA1 is connected to ground when JP13 is set as shown to the right. So, the MCU is kept on Reset when you connect STice to CN8 for debugging. 1 2 3 LCD glass module An LCD glass module (MB821) with 8-digit liquid crystal display is mounted on the STM8L1526-EVAL evaluation board. It can be connected to the LCD driver of the STM8L152C6 MCU or can work as a set of jumpers by mounting it in two possible positions, position IO or position LCD. ● Position IO. All peripherals (USART, IrDA, MicroSD Card, dot matrix LCD, serial Flash, LEDs, joystick, bicolor LED, potentiometer, MCU consumption measurement, motor control and microphone) shared with LCD glass are connected to the STM8L152C6 and the LCD glass is disconnected when LCD glass module is mounted on position IO as shown below (default setting). See Figure 5. ● Position LCD. LCD glass is connected to the LCD driver of the STM8L152C6 and all peripherals shared with the LCD glass are disconnected when the LCD glass module is mounted on position LCD as shown below. In this position, as well as the LCD, there are other resources available on the board: – I2C EEPROM or Key button depending on JP7 jumper position – Audio speaker amplifier or BNC depending on JP10 jumper position. – IR LED depending on JP6 jumper position. See Figure 6. 10/46 Doc ID 15437 Rev 1 STM8L1526-EVAL 2.5 Hardware layout and configuration Figure 5. LCD glass module in position I/O Figure 6. LCD glass module in position LCD Audio The STM8L1526-EVAL supports: ● a speaker connected to the DAC output of the STM8L152C6 through an audio amplifier which can be enabled or disabled by setting JP9. The choice between BNC or DAC output on PF0 is done by JP10, refer to Table 5 for details. ● a microphone connected to the ADC input of the STM8L152C6 through a microphone amplifier. The microphone output can be connected or disconnected to the STM8L152C6 by setting JP3 to closed or open, refer to Table 2 for details. Table 5. Jumper JP9 Audio related jumpers Description Setting The speaker amplifier is enabled when JP9 is closed. Default setting: Fitted PF0 is connected to BNC connector CN15 when JP10 is set as shown to the right. 1 2 3 PF0 is connected to speaker when JP10 is set as show to the right (default setting). 1 2 3 JP10 The LCD glass module must be mounted on "IO" position for Microphone. Refer to Section 2.4: LCD glass module for details. Doc ID 15437 Rev 1 11/46 Hardware layout and configuration 2.6 STM8L1526-EVAL EEPROM A 64 KBit EEPROM is connected to the I2C bus of the STM8L152C6. Table 6. EEPROM related jumpers Jumper JP14 Description Setting The I2C EEPROM U29 is in write protection mode when JP14 is not fitted. Default setting: Fitted PC1 is connected to the User button when JP7 is set as shown to the right . 1 2 3 PC1 is connected to I2C_SCL when JP7 is set as shown to the right (default setting). 1 2 3 JP7 Note: The E2PROM used on the board (ref M24C64-DFW5TP) is limited in VDD range from 1.7 to 5.5 V by specification therefore its behavior is not guaranteed for VDD from 1.65 to 1.7 V. 2.7 RS-232 and IrDA Both RS-232 and IrDA communication is supported by D-type 9-pin RS-232 connectors CN1 and IrDA transceiver U2 which connect to the USART of the STM8L152C6 on the STM8L1526-EVAL evaluation board. The signal Bootloader_RESET is added on the RS-232 connector for ISP support. RS-232 or IrDA can be selected by setting JP5. Table 7. Jumper RS-232 and IrDA related jumper Description Setting USART_RX is connected to the RS-232 transceiver and RS-232 communication is enabled when JP5 is set as shown to the right (default setting). 1 2 3 USART_RX is connected to the IrDA transceiver and IrDA communication is enabled when JP5 is set as shown to the right. 1 2 3 JP5 The LCD glass module must be mounted in the IO position for RS-232 and IrDA. Refer to Chapter 2.4: LCD glass module for details. Note: 12/46 Hardware flow control is not supported by the RS-232 interface (CTS and RTS not managed by MCU). Doc ID 15437 Rev 1 STM8L1526-EVAL 2.8 Hardware layout and configuration Motor control The STM8L1526-EVAL supports three-phase brushless motor control via a 34-pin connector, CN7, which provides all required control and feedback signals to and from motor power-driving board. Available signals on this connector include emergency stop, motor speed, 3 phase motor current, bus voltage, heat sink temperature coming from the motor driving board and 6 channels of PWM control signal going to the motor driving circuit. The I/O pins used on the motor control connector, CN7, are multiplexed with some peripherals on the board. The motor control application can be enabled by setting jumpers JP3, JP4 and JP8. Table 8. Jumper Motor control related jumpers Description JP4 JP4 redirects the PFC synchronization signal to the timer 3 input capture 2 pin, additionally to the timer3 external trigger input. Default setting: Not Fitted. JP8 JP8 should be kept open when the encoder signal is input from pin31 of CN7. JP8 should be kept closed when analog signal is from pin31 of CN7 for special motor. Default setting: Not Fitted. JP3 For motor control application, JP3 must be kept open to avoid conflict between speaker and motor control connector, CN7. Some rework that is required to be done to the board is listed below: ● Remove 0 ohm resistors, R69, R75,R80,R58,R35,R42,R31,R34,R62,R39,R55 and R48 (all resistors are marked in red in Figure 7) to release I/Os used by motor control and shared with another peripherals. ● Remove MicroSD Card from SD Card socket CN14 (SD Card socket is marked in red in Figure 7). ● Solder resistor R82 (0 ohm), R59 (0 ohm) and R29 (0 ohm), all components to be soldered are marked in green in Figure 7. The LCD glass module has to be mounted in the IO position for motor control. Refer to Section 2.4: LCD glass module for details. Doc ID 15437 Rev 1 13/46 Hardware layout and configuration Figure 7. 14/46 STM8L1526-EVAL STM8L1526-EVAL motor control re-configuration of board Doc ID 15437 Rev 1 STM8L1526-EVAL 2.9 Hardware layout and configuration MicroSD Card The 1 GByte MicroSD Card connected to the SPI port of the STM8L152C6 is available on the board. MicroSD Card detection is managed by standard I/O port, PD6. The LCD glass module must be mounted in the IO position for MicroSD Card. Refer to Chapter 2.4: LCD glass module for details. 2.10 Analog input The BNC connector, CN15, is connected to PF0 of the STM8L152C6 as an external analog input or DAC output. The 50 ohm terminal resistor can be enabled by closing solder bridge SB6. A low-pass filter can be implemented for the BNC connector by replacing R126 and C86 for ADC input or replacing R127 and C86 for DAC output (with suitable resistor and capacitor as requested by end user's application). There are also 3 analog signals available on the board. 1. 10 Kohm potentiometer RV2 connected to PC7. 2. IDD measurement output signal connected to PD3 for MCU power consumption test. 3. External ADC input which can be connected to TP8 (AIN+) and TP5 (AIN-). Solder bridge SB5 should be kept on open for this analog input. The LCD glass module has to be mounted in the IO position for IDD measurement and potentiometer RV2. Refer to Section 2.4: LCD glass module for details. 2.11 Serial Flash The M25P128 serial Flash is connected to the SPI bus of the STM8L152C6. The chip select is managed by standard I/O port, PE4. The LCD glass module has to be mounted in the IO position for serial Flash. Refer to Section 2.4: LCD glass module for details. 2.12 Temperature sensor A temperature sensor STLM75M2E is connected to the I2C bus of the STM8L152C6 through two transistors to support a wide voltage range from 1.8 V to 3.3 V on the I2C bus. A voltage lower than 1.8 V is not supported due to the VGS threshold of transistor TR1 and TR2. The LCD glass module has to be mounted in the IO position for the I2C_SMB signal. Refer to Section 2.4: LCD glass module for details. Doc ID 15437 Rev 1 15/46 Hardware layout and configuration 2.13 STM8L1526-EVAL Development and debug support An embedded ST-LINK, STM8 debugger developed by STMicroelectronics, is available on the STM8L1526-EVAL as the default debugger. Third-party debuggers are also supported by the SWIM connector, CN12, or low-cost SWIM connector, CN16. The SWIM connector or embedded ST-LINK can be enabled by setting jumper JP6. Table 9. SWIM debugging related jumper Jumper Description Setting PA0 is connected to SWIM connector CN12, CN16 and embedded ST-LINK when JP6 is set as shown to the right (default setting). 1 2 3 PA0 is connected to IR LED, LD6 when JP6 is set as show to the right. 1 2 3 JP6 A 60-pin connector CN8 is available also for STice user, it can be used even with MCU silicon mounted on the board by setting jumper JP13. (The STice connector is available only on the MB818 with an MCU socket). Table 10. Jumper JP13 16/46 STice related jumper Description Setting PA1 is connected to Reset sources when JP13 is set as shown to the right, the board is working on standalone mode without STice connected (default setting). 1 2 3 PA1 is connected to GND when JP13 is set as show to the right. All I/Os of STM8L152C6 silicon on the board is kept on "floating input" which allows debugging based on STice connected to CN8. 1 2 3 Doc ID 15437 Rev 1 STM8L1526-EVAL 2.14 Hardware layout and configuration Display and input devices The 122x32 dot-matrix LCD connected to the SPI port of the STM8L152C6, 4 general purpose color LED's (LD 1,2,3,4), and one bicolor LED LD5 are available as display devices. The 4-direction joystick (U17) with selection key and general purpose button (B2) are available as input devices. The STM8L1526-EVAL evaluation board also supports a second optional 2.4" TFT LCD that can be mounted on the CN3 connector. The 2.4" TFT LCD is not populated by default. MB542 is the reference of the 2.4" TFT LCD to be connected on CN3. ) Table 11. LCD modules 122x32 dot-matrix LCD U7 (default) Pin on U7 Description Pin connection 2.4" TFT LCD CN3 (optional) Pin on CN3 Description Pin connection 1 Vss GND 1 CS PB4 2 Vcc +3.3V 2 SCL PB5 3 VO - 3 SDI PB6 4 CLK PB5 4 RS - 5 SID PB6 5 WR - 6 CS PB4 6 RD - 7 A +5V 7 SDO PB7 8 K GND 8 RESET RESET# 9 VDD 3.3V 10 VCI 3.3V 11 GND GND 12 GND GND 13 BL_VDD 3.3V 14 BL_Control 3.3V 15 BL_GND GND 16 BL_GND GND The LCD glass module must be mounted on the "IO" position for LCD, LED's and joystick. Refer to Section 2.4: LCD glass module for details. Doc ID 15437 Rev 1 17/46 Hardware layout and configuration 2.15 STM8L1526-EVAL IDD measurement and comparator For IDD measurement the circuit shown in Figure 9 is implemented on the STM8L1526EVAL. Figure 8. STM8L1526-EVAL IDD measurement circuit In Run mode, IDD current is measured using MAX9938FEUK+ (U20) connected to the 2ohm shunt resistor. In this case IDD_CNT_EN remains at a high level during measurement and the jumper must be connected between pin 1 and pin 2 of JP11. In Halt mode, the operational amplifier MAX9938FEUK+ (U20) is connected on the 2 Kohm shunt resistor. To measure a current corresponding to the Halt mode the procedure is: 1. Configure ADC to measure voltage on IDD_measurement pin. 2. Configure PE6 as interrupt input on falling edge. 3. Enter in Halt or active Halt mode with IDD_CNT_EN low. 4. LP_WAKEUP falling edge wakeup the MCU after 150 ms. 5. Start ADC conversion as soon as possible after wakeup in order to measure the voltage corresponding to low power mode on 1 uF capacitor. 6. Reset the counter by programming IDD_CNT_EN high to avoid 2 Kohm to be connected later on VDD_MCU. In Halt mode, the 2 K resistor is connected when T3 goes off after entering Halt mode. Q12 output of the counter allows connection of the 2 K when the current IDD becomes very low. The measurement timing is given in Figure 9. 18/46 Doc ID 15437 Rev 1 STM8L1526-EVAL Figure 9. Hardware layout and configuration STM8L1526-EVAL IDD Halt mode measurement timing diagram Halt mode IDD measurement timing Ru n Wake-up H alt ID D Measure C lear C N T MC U mode 0 150mS 300mS 450mS ID D_C NT_EN (PE7) Q12= L OW _POW ER _EN (T3 pin 3) Q13 = LP_WAK EU P (PE6) Q13n = U21 p in 4 The Halt mode measurement procedure can be used in Halt mode and slow or fast active Halt modes if the IDD current does not exceed 12 uA else the Run measurement procedure should be used up to 12 mA. Comparator Three I/Os are used to implement a comparator feature to be used as low precision ADC in Figure 10. ● Comparator noninverting input PD1 connected to the reference capacitor (Cref). ● One I/O PE0 used as output, connected to the reference resistor (Rref) used to charge Cref. ● Comparator inverting input used as ADC input PC7 to be connected to the potentiometer. 1 2 COMP2 CMP_Rref PE0 PE5 Rref COMP2A PD0 4 2 Figure 10. STM8L1526-EVAL low precision ADC based on comparator 1 CMP_Cref PD1 12 GND 11 Cref PC3 + 5 TIM2/3 6 2.16 PC4 PC7 P1 VDD_ADJ 1 2 10K VREFINT 1.2V GND Doc ID 15437 Rev 1 19/46 Hardware layout and configuration STM8L1526-EVAL The measurement is performed in three steps: 2.17 1. Internal reference voltage VREFINT is connected to the comparator inverting input and Cref to noninverting input to measure the time required to charge the capacitor to internal reference voltage VREFINT by PE0 used as output through Rref. 2. The potentiometer is connected to inverting input to measure the time required to charge Cref to the voltage on potentiometer. 3. The potentiometer voltage is calculated by software interpolation or using a conversion table. IR LED One IR LED, LD6, is driven by either PA0 through two transistors T1 and T8, or PA0 directly; depending on the setting of the solder bridge SB7. Table 12. IR LED related solder bridges Solder bridge SB7 Description LD6 is driven by PA0 through two transistors, T1 and T8, when SB7 is set as pad1 connected to pad2 (default setting). LD6 is driven by PA0 directly when SB7 is set as pad2 connected to pad3. Note: 20/46 JP6 needs to be set correspondingly for IR LED, please refer to Table 9 for details. Doc ID 15437 Rev 1 STM8L1526-EVAL Connectors 3 Connectors 3.1 RS-232 connector CN1 Figure 11. RS-232 connector CN1 with ISP support Table 13. RS-232 connector CN1 with ISP support Pin number 3.2 Description Pin number Description 1 Bootloader_RESET 6 NC 2 RS232_RX (PC2) 7 NC 3 RS232_TX (PC3) 8 NC 4 NC 9 NC 5 GND Power connector CN2 The STM8L1526-EVAL evaluation board can be powered from a DC 5 V power supply via the external power supply jack (CN2) shown in Figure 12. The central pin of CN2 must be positive. Figure 12. Power supply connector CN2 viewed from front DC+5V GND 3.3 TFT LCD connector CN3 CN3 is used to support TFT color LCD board (MB542), it is not populated by default. Doc ID 15437 Rev 1 21/46 Connectors 3.4 STM8L1526-EVAL Daughterboard extension connector CN4 and CN10 Two 26-pin male headers CN4 and CN10 can be used to connect the daughterboard or standard wrapping board to the STM8L1526-EVAL evaluation board. All GPI/Os are available on it. The space between these two connectors and position of power, GND and RESET pin are defined as a standard which allows to develop common daughterboards for several evaluation boards. The standard width between CN4 pin1 and CN10 pin1 is 2700 mils (68.58mm). The standard was implemented on the majority of evaluation boards. Each pin on CN4 and CN10 can be used by a daughterboard after disconnecting it from the corresponding function block on the STM8L1526-EVAL evaluation board. Please refer to Table 14 and Table 15 for details. Table 14. Daughterboard extension connector CN4 Pin Description 22/46 Alternative function How to disconnect with function block on STM8L1526-EVAL board 1 GND - 3 PC5 32 kHz crystal Set SB3 to 2<->3 5 PC7 Potentiometer Remove R28 7 PD1 CMP_Cref / Motor control connector (PFC sync) Remove R35 9 PD3 IDD_Measurement Remove R50 11 PA0 SWIM / IR_LED Set JP6 to open 13 PA1 RESET button Set JP13 to open 15 PA4 Remove R69 LED1 / Motor control connector (Current Disconnect power driver board from A) Motor control connector 17 PA6 Remove R80 LED3 / Motor control connector (Current Disconnect power driver board from C) Motor control connector 19 GND - 21 PD5 Joystick_right / Motor control connector (MC_WH) Remove R34 Disconnect power driver board from Motor control connector 23 PD7 Joystick_up / Motor control connector (MC_UL) Remove R31 Disconnect power driver board from Motor control connector 25 PC1 I²C SDA Set JP7 to open 2 PC4 I²C_SMB Remove R27 4 PC6 32 kHz crystal Set SB4 to 1<->2 6 PD0 Motor control connector (PFC sync) Disconnect power driver board from Motor control connector 8 PD2 Bicolor_LED / Motor control connector (MC_UH) Remove R48 Disconnect power driver board from Motor control connector Doc ID 15437 Rev 1 STM8L1526-EVAL Table 14. Connectors Daughterboard extension connector CN4 (continued) Pin Description How to disconnect with function block on STM8L1526-EVAL board Alternative function 10 GND - 12 PA2 16MHZ crystal Set SB2 to close Remove X1 and C30 14 PA3 16MHZ crystal Set SB1 to close Remove X1 and C38 16 PA5 LED2 / Motor control connector (Bus voltage) Remove R75 18 PA7 LED4 / Motor control connector (Encoder index) Remove R58 Disconnect power driver board from Motor control connector 20 PD4 Remove R39 Joystick_down / Motor control connector Disconnect power driver board from (MC_VH) Motor control connector 22 PD6 Motor control connector (EmergencySTOP) / SDcard_detect Remove SD Card from card socket 24 PC0 I²C SDA Remove R115 26 PC2 UART_IrDA_RX Set JP5 to open Table 15. Daughterboard extension connector CN10 Pin Description Alternative function How to disconnect with component on STM8L1526-EVAL board 1 GND - - 3 PB1 Motor control connector (Dissipative brake & PFC PWM) Disconnect power driver board from Motor control connector 5 PB3 Audio_ADC_IN Set JP3 to open 7 PB5 LCD_SDcard_Flash_SCK - 9 PB7 LCD_SDcard_Flash_MISO Remove R73 and SD Card from card socket 11 RESET# 13 PE1 Joystick_Left / Motor control connector (MC_VL) Remove R62 Disconnect power driver board from Motor control connector 15 PE3 Micro SD card_CS Remove SD Card from card socket 17 PE5 Motor control connector (MC_CurrentB) Disconnect power driver board from Motor control connector 19 D5V - - 21 NC - - 23 NC - - - Doc ID 15437 Rev 1 23/46 Connectors STM8L1526-EVAL Table 15. Daughterboard extension connector CN10 (continued) Pin Description Alternative function How to disconnect with component on STM8L1526-EVAL board 25 PF0 Motor control connector (Current B) / BNC / Audio_DAC_out Set JP10 to open 2 PB0 Motor control connector (Encoder A) Disconnect power driver board from Motor control connector 4 PB2 Motor control connector (Encoder B) Disconnect power driver board from Motor control connector 6 PB4 Dot-matrix LCD_CS Remove Dot-Matrix LCD module 8 PB6 LCD_SDcard_Flash_MOSI - 10 GND - - 12 PE0 CMP_Rref / Motor control connector (NTC_bypass) Remove R42 Disconnect power driver board from Motor control connector 14 PE2 Joystick_sel / Motor control connector (MC_WL) Remove R55 Disconnect power driver board from Motor control connector 16 PE4 Serial Flash_CS Remove R73 18 PE6 IDD_Measurement_Wakeup Remove LCD glass module (MB821) 0ohm resistor to be added? 20 PE7 IDD_Measurement_CNT_EN - 22 PC3 UART_IrDA_TX - 24 MCU_VDD - 26 NC - Note: All I/O's marked in grey can be disconnected with function block on the STM8L1526-EVAL board by removing LCD glass module (MB821) board. 3.5 LCD glass connector CN5 and CN6 Two 36-pin male headers, CN5 and CN6, can be used to mount the LCD glass module (MB821) on it. Two possible mount positions may be selected by the user for either an LCD glass demonstration or other peripherals on STM8L1526-EVAL board. 24/46 Doc ID 15437 Rev 1 STM8L1526-EVAL 3.6 Connectors Motor control connector CN7 Figure 13. Motor control connector CN7 viewed from above 33 31 29 27 25 23 21 19 17 15 13 11 9 7 34 32 30 28 26 24 22 20 18 16 14 12 10 8 Viewed from above Table 16. Motor control connector CN7 Description 3.7 Pin of Pin of CN17 pin CN17 pin STM8L152C6 STM8L152C6 Description EMERGENCY STOP PD6 1 2 GND PWM-UH PD2 3 4 GND PWM-UL PD7 5 6 GND PWM-VH PD4 7 8 GND PWM-VL PE1 9 10 GND PWM-WH PD5 11 12 GND PWM-WL PE2 13 14 PHASE A CURRENT PA4 15 16 GND PHASE B CURRENT PE5 17 18 GND PHASE C CURRENT PA6 19 20 GND NTC BYPASS RELAY PE0 21 22 GND DISSIPATIVE BRAKE PWM PB1 23 24 GND +5V power +5V 25 26 PFC SYNC PD0 and PD1 27 28 VDD_Micro PFC PWM PB1 29 30 GND Encoder A PB0 31 32 GND Encoder B PB2 33 34 PA5 PB3 PA7 BUS VOLTAGE Heatsink temperature Encoder Index STice connector CN8 The STice can be connected to emulate the STM8L1526-EVAL board. Jumper JP13 must be set to connect pin 2 and 3 when the STice is connected on CN8. It is used to keep the STM8L152C6 MCU on reset as explained in Section 2.3: Reset source. Doc ID 15437 Rev 1 25/46 Connectors STM8L1526-EVAL Figure 14. STice debugging connector CN8 viewed from above Table 17. 1 59 2 60 STice debugging connector CN8 Pin number 26/46 Description Pin number Description 1 PA0 2 RESET# 3 PA2 4 PA3 5 PA4 6 PA5 7 PA6 8 PA7 9 GND 10 VDD_MCU 11 VDDA 12 VDDA 13 VLCD 14 PE0 15 PE1 16 PE2 17 PE3 18 PE4 19 PE5 20 PD0 21 PD1 22 PD2 23 PD3 24 PB0 25 PB1 26 PB2 27 PB3 28 PB4 29 PB5 30 PB6 31 PB7 32 PF0 33 PD4 34 PD5 35 PD6 36 PD7 37 PC0 38 PC1 39 VDD_MCU 40 GND 41 PC2 42 PC3 43 PC4 44 PC5 45 PC6 46 PC7 47 PE6 48 PE7 49-60 NC Doc ID 15437 Rev 1 STM8L1526-EVAL 3.8 Connectors ST-LINK programming connector CN9 The connector CN9 is used only for embedded ST-LINK programming during board manufacture. It is not populated by default and is not intended for the end user. 3.9 USB type B connector CN11 The USB connector CN11 is used to connect embedded ST-LINK to PC for debugging of board. Figure 15. USB type B connector CN11 viewed from the front Table 18. USB type B connector CN11 Pin number 3.10 Description 1 VBUS(power) 2 DM 3 DP Pin number Description 4 GND 5,6 Shield SWIM connector CN12 and CN16 Figure 16. SWIM debugging connector CN16 viewed from the above 1 Table 19. 3 4 SWIM debugging connector CN12 and CN16 Pin number 3.11 2 Description Pin number Description 1 VDD 2 SWIM line (PA0) 3 GND 4 RESET# Audio jack CN13 A 3.5mm stereo audio jack CN13 connected to audio DAC is available. Doc ID 15437 Rev 1 27/46 Connectors 3.12 STM8L1526-EVAL MicroSD connector CN14 Figure 17. MicroSD connector CN14 viewed from the front Table 20. MicroSD connector CN14 Pin number Description Pin number 1 5 MicroSDcard_CLK (PB5) 2 MicroSDcard_CS (PE3) 6 Vss/GND 3 MicroSDcard_DIN(PB6 ) 7 MicroSDcard_DOUT(P B7) 4 +3V3 8 9 3.13 Description MicroSDcard_detect (PD6) BNC connector CN15 Figure 18. Analog input connector CN15 viewed from bottom 1 2 5 4 Table 21. Analog input connector CN15 Pin number 28/46 3 Description Pin number Description 1 GND 4 GND 2 GND 5 Analog input PF0 3 GND Doc ID 15437 Rev 1 STM8L1526-EVAL 4 Schematics Schematics The schematics are shown on the following pages: ● Table 19: STM8L1526-EVAL on page 30 ● Table 20: MCU on page 31 ● Table 21: LCD glass connector on page 32 ● Table 22: Audio on page 33 ● Table 23: Peripherals on page 34 ● Table 24: Power on page 35 ● Table 25: Extension and STice on page 36 ● Table 26: LCD and SD Card on page 37 ● Table 27: RS-232 and IrDA on page 38 ● Table 28: Motor control on page 39 ● Table 29: EEPROM and temperature sensor on page 40 ● Table 30: ST_LINK (SWIM only) on page 41. ● Table 31: MB821 on page 42 Doc ID 15437 Rev 1 29/46 U_MCU MCU.SchDoc ST_LINK_SWIM RESET# I2C_SMB U_LCD_Glass LCD_Glass.SCHDOC Doc ID 15437 Rev 1 PA4_LCDCOM0 PA5_LCDCOM1 PA6_LCDCOM2 PD1_LCDCOM3 PA7_LCDSEG0 PE0_LCDSEG1 PE1_LCDSEG2 PE2_LCDSEG3 PE3_LCDSEG4 PE4_LCDSEG5 PE5_LCDSEG6 PD0_LCDSEG7 PD2_LCDSEG8 PD3_LCDSEG9 PB0_LCDSEG10 PB1_LCDSEG11 PB2_LCDSEG12 PA4_LCDCOM0 PA5_LCDCOM1 PA6_LCDCOM2 PD1_LCDCOM3 PA7_LCDSEG0 PE0_LCDSEG1 PE1_LCDSEG2 PE2_LCDSEG3 PE3_LCDSEG4 PE4_LCDSEG5 PE5_LCDSEG6 PD0_LCDSEG7 PD2_LCDSEG8 PD3_LCDSEG9 PB0_LCDSEG10 PB1_LCDSEG11 PB2_LCDSEG12 PB4_LCDSEG14 PB5_LCDSEG15 PB6_LCDSEG16 PB7_LCDSEG17 PD4_LCDSEG18 PD5_LCDSEG19 PD6_LCDSEG20 PD7_LCDSEG21 PC2_LCDSEG22 PC3_LCDSEG23 PC4_LCDSEG24 PC7_LCDSEG25 PE6_LCDSEG26 PE7_LCDSEG27 PB4_LCDSEG14 PB5_LCDSEG15 PB6_LCDSEG16 PB7_LCDSEG17 PD4_LCDSEG18 PD5_LCDSEG19 PD6_LCDSEG20 PD7_LCDSEG21 PC2_LCDSEG22 PC3_LCDSEG23 PC4_LCDSEG24 PC7_LCDSEG25 PE6_LCDSEG26 PE7_LCDSEG27 C40 VDD U11 1 100nF VCCA VCCB R32 0 2 A1 B1 R37 0 3 A2 B2 4 GND DIR VDD Audio_IN R124 10K Audio_IN I2C_SMB RS232/IrDA_RX SPI_MISO SDcard_detect RS232/IrDA_TX MicroSD_CS SPI_SCK SPI_MOSI LCD_CS Flash_CS +3V3 8 7 6 5 C34 100nF U_RS232_IrDA RS232_IrDA.SCHDOC Bootloader_RESET RS232/IrDA_RX RS232/IrDA_TX U_LCD_MicroSD_Flash LCD_MicroSD_Flash.SchDoc SN74LVC2T45DCUT C33 VDD U10 100nF 1 VCCA VCCB 2 A1 B1 3 A2 B2 4 GND DIR C24 100nF SN74LVC2T45DCUT VDD +3V3 U26 8 VCCA VCCB 7 A1 B1 6 A2 B2 5 GND DIR C65 100nF SN74LVC2T45DCUT VDD C69 VDD U22 +3V3 100nF 1 8 VCCA VCCB 2 7 A1 B1 3 6 A2 B2 4 5 GND DIR C74 100nF C76 VDD 100nF 1 2 3 4 U_Peripherals Peripherals.SchDoc LED4 LED3 LED1 LED2 BiD_LED CMP_Rref CMP_Cref JOY_UP JOY_RIGHT JOY_LEFT JOY_DOWN JOY_SEL Potentiometer +3V3 8 7 6 5 LED4 LED3 LED1 LED2 BiD_LED CMP_Rref CMP_Cref JOY_UP JOY_RIGHT JOY_LEFT JOY_DOWN JOY_SEL Potentiometer SPI_MISO SDcard_detect MicroSD_CS SPI_SCK SPI_MOSI LCD_CS Flash_CS RESET# SN74LVC2T45DCUT VDD User_Button BNC IR_LED U_Power Power.SchDoc IDD_Measurement LP_WAKEUP IDD_CNT_EN IDD_Measurement LP_WAKEUP IDD_CNT_EN U_MotorControl MotorControl.SCHDOC R52 0 R40 [N/A] MC_HeatsinkTemperature MC_DissipativeBrake MC_PFCpwm MC_PFCsync1 MC_EnA MC_EnB MC_CurrentB MC_EnIndex MC_CurrentC MC_CurrentA MC_BusVoltage MC_UH MC_NTC MC_PFCsync 2 MC_UL MC_WH MC_VL MC_VH MC_WL MC_EmergencySTOP ST_LINK_SWIM RESET# Audio_OUT PB3_LCDSEG13 U_ST_LINK ST_LINK.SCHDOC I2C_SLK I2C_SDA U_Audio Audio.SchDoc MC_CurrentB MC_EnB MC_EnA MC_PFCsync 1 MC_PFCpwm EX_PC5 EX_PC6 Audio_OUT User_Botton IR_LED BNC PC[0..7] PF0 PB[0..7] PD[0..7] PE[0..7] PA[0..7] I2C_SLK I2C_SDA PB3_LCDSEG13 PC[0..7] PF0 PB[0..7] PD[0..7] PE[0..7] PA[0..7] RESET# EX_PC5 EX_PC6 U_EEPROM_TemSensor EEPROM_TemSensor. SCHDOC Bootloader_RESET U_Extension_STice connector Extension_STice connector. SCHDOC Schematics 30/46 Figure 19. STM8L1526-EVAL STMicroelectronics Title: STM8L1526-EVAL Number: MB818 Rev: C.1(PCB.SCH) Date: 7/31/2009 Sheet 1 of STM8L1526-EVAL Note: All text in the each sheet is in Italic format to be different with Net label. 2 3 1 2 3 4 20pF PA4_LCDCOM0 PA5_LCDCOM1 PA6_LCDCOM2 PA7_LCDSEG0 X1 16MHz (with socket) C38 R26 60 VDD_MCU VDDA 20pF VLCD C60 1uF PE0 PE1 PE2 PE3 PE4 PE5 PD0 PD1 PD2 PD3 PB0 PE0_LCDSEG1 PE1_LCDSEG2 PE2_LCDSEG3 PE3_LCDSEG4 PE4_LCDSEG5 PE5_LCDSEG6 PD0_LCDSEG7 PD1_LCDCOM3 PD2_LCDSEG8 PD3_LCDSEG9 PB0_LCDSEG10 TP9 PA0 PA1 PA2 PA3 PA4 PA5 PA6 PA7 AVSS VDD VDDA VREF+ VLCD PE0 PE1 PE2 PE3 PE4 PE5 PD0 PD1 PD2 PD3 PB0 PE7 PE6 PC7 PC6 PC5 PC4 PC3 PC2 VSSIO VDDIO PC1 PC0 PD7 PD6 PD5 PD4 PF0 PB7 PB6 PB5 PB4 PB3 PB2 PB1 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25 PE7 PE6 PC7 PC6 PC5 PC4 PC3 PC2 PC1 PC0 PD7 PD6 PD5 PD4 PF0 PB7 PB6 PB5 PB4 PB3 PB2 PB1 PE7_LCDSEG27 PE6_LCDSEG26 PC7_LCDSEG25 User_Botton I2C_SLK PC4_LCDSEG24 PC3_LCDSEG23 PC2_LCDSEG22 1 Doc ID 15437 Rev 1 C30 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 SB3 solder bridge CCO U16 PA0 PA1 PA2 PA3 PA4 PA5 PA6 PA7 1 SB4 solder bridge 609-1306-ND(2.54mm) SWIM connector 4 1 B1 RESET (Black) ST_LINK_SWIM 2 C82 100nF 3 3 JP6 JP15 Bootloader_RESET IR_LED 2 3 3 3 D1 BAT60 2 2 3 C25 6.8pF 4 MC306-G-06Q-32.768 (manufacturer JFVNY) 1 RESET# 1 1 2 214017 SWIM connector CN12 JP13 1 C32 6.8pF 2 R111 0 R117 10K X2 1 2 3 4 0 VDD RESET# EX_PC5 EX_PC6 CN16 3 VDD 4 2 1 STM8L1526-EVAL Figure 20. MCU VDD_MCU JP7 I2C_SDA PD7_LCDSEG21 PD6_LCDSEG20 PD5_LCDSEG19 PD4_LCDSEG18 3 Audio_OUT 2 1 PB7_LCDSEG17 PB6_LCDSEG16 PB5_LCDSEG15 PB4_LCDSEG14 PB3_LCDSEG13 PB2_LCDSEG12 PB1_LCDSEG11 JP10 TP8 AIN+ R127 0 R126 SB5 0 BNC STM8L152C6T6 C86 [N/A] VDD_MCU C53 1uF C61 100nF C48 1uF close to PF0 of MCU C51 100nF PA[0..7] PB[0..7] PC[0..7] PD[0..7] PE[0..7] PF0 STMicroelectronics Title: 31/46 STM8L1526-EVAL MCU Number:MB818 1 2 3 Rev: C.1(PCB.SCH) Date: 7/31/2009 4 Sheet 2 of Schematics PA[0..7] PB[0..7] PC[0..7] PD[0..7] PE[0..7] PF0 C31 100nF VDDA L1 BEAD TP5 AIN- Schematics 32/46 Figure 21. LCD glass connector CN5 Doc ID 15437 Rev 1 PC4_LCDSEG24 PC7_LCDSEG25 PD6_LCDSEG20 PD7_LCDSEG21 PB6_LCDSEG16 PB7_LCDSEG17 PB2_LCDSEG12 PB3_LCDSEG13 PD2_LCDSEG8 PD3_LCDSEG9 PE3_LCDSEG4 PE4_LCDSEG5 PA7_LCDSEG0 PE0_LCDSEG1 PD1_LCDCOM3 PA6_LCDCOM2 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 S28 2 S29 4 S24 6 S25 8 S20 10 S21 12 S16 14 S17 16 S12 18 S13 20 S8 22 S9 24 S4 26 S5 28 S0 30 S1 32 COM4 34 COM3 36 I2C_SMB Potentiometer SDcard_detect JOY_UP SPI_MOSI SPI_MISO MC_EnB Audio_IN BiD_LED IDD_Measurement MicroSD_CS Flash_CS LED4 CMP_Rref CMP_Cref LED3 Header 18X2 CN6 PE7_LCDSEG27 PE6_LCDSEG26 PC3_LCDSEG23 PC2_LCDSEG22 PD5_LCDSEG19 PD4_LCDSEG18 PB5_LCDSEG15 PB4_LCDSEG14 PB1_LCDSEG11 PB0_LCDSEG10 PD0_LCDSEG7 PE5_LCDSEG6 PE2_LCDSEG3 PE1_LCDSEG2 PA4_LCDCOM0 PA5_LCDCOM1 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 S31 2 S30 4 S27 6 S26 8 S23 10 S22 12 S19 14 S18 16 S15 18 S14 20 S11 22 S10 24 S7 26 S6 28 S3 30 S2 32 COM1 34 COM2 36 IDD_CNT_EN LP_WAKEUP RS232/IrDA_TX RS232/IrDA_RX JOY_RIGHT JOY_DOWN SPI_SCK LCD_CS MC_PFCpwm MC_EnA MC_PFCsync1 MC_CurrentB JOY_SEL JOY_LEFT LED1 LED2 Header Title: STM8L1526-EVAL LCD Glass connector Number:MB818 Rev: C.1(PCB.SCH) Date: 7/31/2009 Sheet 3 of STM8L1526-EVAL STMicroelectronics STM8L1526-EVAL Figure 22. Audio C45 Speaker+3V3 JP9 Audio_OUT PF0 R38 R30 10K R33 22K 470nF C47 [N/A] 1 10 2 22K U15 1 4 3 2 C43 0 2 1 CN13 330pF R36 C37 1uF Standby VINVIN+ Bypass VOUT1 VOUT2 VCC GND 5 8 6 7 TS4990IST U24 KDMG15008-03 ST-613 Speaker+ +3V3 C28 1uF C12 R15 1K U4 KECG2740TBL 2 1 10uF R12 100 R11 2.2K C16 5 +3V3 TP7 MIC+ 3 100nF C11 47pF U9 TS461CLT 1 TP6 MIC_OUT R16 1 VDD JP3 R13 0 4 PB3 500 2 Doc ID 15437 Rev 1 VDD Audio_IN C17 [N/A] RV3 [N/A] C29 C27 4.7uF 15K R18 100K R25 18K R22 680 2 3 R21 100K R20 C26 2.2uF 180pF R24 82K C13 4.7uF Title: 33/46 STM8L1526-EVAL Audio Number:MB818 Rev: C.1(PCB.SCH) Date: 7/27/2009 Sheet 4 of Schematics STMicroelectronics 1 2 3 4 CN15 BNC C4 +5V C3 100nF VDD U1 1 8 VCCA VCCB 2 7 A1 B1 100nF 3 6 A2 B2 4 5 GND DIR R10 SN74LVC2T45DCUT VDD 10K 1 2 3 4 5 PF0 VB334 50 +3V3 2 PC1 R66 0 B2 USER (Blue) CMP_Cref PE0 R35 0 R42 R41 100nF 680 0 VDD LD4 Blue 1 R104 100 R43 R69 0 PA4 330 R47 R48 R75 0 PA5 680 2 R49 R54 0 LED2 PD2 BiD_LED R80 0 PA6 680 2 VDD LED1 R58 0 PA7 680 LED3 LD5 L-317EGW-SS LED4 B 2 2 RV2 10K 1 0 Potentiometer User Button LEDs +3V3 T1 9013 2 100nF 100nF 100nF C50 C58 C62 3 1 4 6 100nF R2 680 0 0 0 0 0 DWON LEFT RIGHT UP MT008-A 1 2 R8 1.2K T8 9013 2 Joystick D STMicroelectronics Title: STM8L1526-EVAL Peripherals IR_LED Low Voltage LED Number:MB818 1 2 3 Rev: C.1(PCB.SCH) Date: 7/28/2009 4 Sheet 5 of 12 STM8L1526-EVAL R9 1K R1 22 3 R89 10K C 4 10K R55 R39 R62 R34 R31 100nF 2 U6 LM393PT 3 PE2 PD4 PE1 PD5 PD7 C57 R6 1K VDD JOY_SEL JOY_DOWN JOY_LEFT JOY_RIGHT JOY_UP C55 1 1<->2 close by default 8 solder bridge VDD R17 +3V3 LD9 Red 1 PA0 +3V3 1 3 IR_LED Selection R46 10K R57 10K R45 10K R61 10K R65 10K 1 2 2 +5V +3V3 3 SB7 100 300 COMMON 2 R122 R4 300 U17 5 100 VDD LD6 SFH409-2 R5 Bi-color LED R72 1 Doc ID 15437 Rev 1 R28 PC7 Potentiometer LD3 Red 1 C79 100nF 3 CMP_Rref PD1 1 C49 LD1 Green 1 2 LD2 Orange 1 2 3 User_Button BNC connector R79 4K7 4 R110 A 1 VDD SB6 Schematics 34/46 Figure 23. Peripherals 1 2 3 STM8L1526-EVAL Figure 24. Power 4 U20 MAX9938FEUK+ 2 R50 10K 5 C67 1uF VDD R91 2K[1%] 5 1 2 6 2[1%] S 5 VDD 3 U25 SN74LVC1G04DCKT VDD D Doc ID 15437 Rev 1 Q11 VCC Q12 Q9 Q13 Q7 Q5 Q8 Q4 MR Q6 RS Q3 Rtc GND Ctc 16 15 14 13 12 11 10 9 Vin C19 10uF VDD +3V3 C22 10uF PE6 LP_WAKEUP TP2 VDD_ADJ VDD U12 LD1086D2M +5V PE7 3 IDD_CNT_EN Vin C66 1nF R90 15K R84 30K Vout R23 2 124[1%] 3 Oscillator frequency 30KHz RV1 3386P-201H[5%] 1 1 SV 2 Z1 SMAJ5.0A-TR 2 DC-10B U5V D5V JP2 E5V 1 3 5 Header 3X2 TP4 5V +5V R19 C20 10uF C85 1uF R125 2K2[1%] CV SG CG1 CG2 CG3 3 4 5 6 C8 220uF BNX002-01 LD8 red 1 TP1 Ground STMicroelectronics 2 1K Title: STM8L1526-EVAL Power 35/46 Number:MB818 1 2 3 Rev: C.1(PCB.SCH) Date: 7/27/2009 4 Sheet 6 of 12 Schematics 2 4 6 C1 100nF C21 100nF E5V U3 3 VDD_ADJ 2 U5 ZEN056V130A24LS 1 1 JP1 R14 40.2[1%] 1 2 3 VDD 2 C23 100nF 10K R78 10K 74LV4060PW CN2 3 2 Vout ADJ 1 2 3 4 5 6 7 8 3 G 3 IDD_Measurement R123 5 1 2 6 STT5PF20V C59 100nF U23 2 T3 STT5PF20V 4 SN74LVC1G66DCKT 4 R92 PD3 0 T2 3 4 VDD R70 2 I/O O/I C GND VCC GND 1 4 3 1 3 4 TP3 +3V3 U13 LD1086D2M33 +5V 1 U21 S 5 G JP11 D 1 1 3 2 VDD_MCU Schematics 36/46 Figure 25. Extension and STice CN8 QTH-030-01-L-D-A Doc ID 15437 Rev 1 VDD_MCU PE1 PE3 PE5 PD1 PD3 PB1 PB3 PB5 PB7 PD4 PD6 PC0 PC2 PC4 EXT_PC6 PE6 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48 50 52 54 56 58 60 GND GND GND GND VDDA VLCD 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49 51 53 55 57 59 61 62 63 64 PA0 EXT_PA2 PA4 PA6 RESET# EXT_PA3 PA5 PA7 PE0 PE2 PE4 PD0 PD2 PB0 PB2 PB4 PB6 PF0 PD5 PD7 PC1 RESET# CN4 EXT_PC5 PC7 PD1 PD3 PA0 PA1 PA4 PA6 EX_PC5 VDD_MCU VDDA PD5 PD7 PC1 1 3 5 7 9 11 13 15 17 19 21 23 25 2 4 6 8 10 12 14 16 18 20 22 24 26 PC4 EXT_PC6 PD0 PD2 EX_PC6 SB2 SB1 EXT_PA2 EXT_PA3 PA5 PA7 PD4 PD6 PC0 PC2 PA2 PA3 Header 13X2 on the left CN10 PC3 EXT_PC5 PC7 PE7 RESET# R93 680 PB1 PB3 PB5 PB7 PE1 PE3 PE5 D5V VLCD PF0 1 3 5 7 9 11 13 15 17 19 21 23 25 2 4 6 8 10 12 14 16 18 20 22 24 26 PB0 PB2 PB4 PB6 PE0 PE2 PE4 PE6 PE7 PC3 VDD Header 13X2 on the right PA[0..7] PB[0..7] PC[0..7] PD[0..7] PE[0..7] PF0 STice connector Exension connector STMicroelectronics Title: STM8L1526-EVAL Extension&STice Number:MB818 Rev: C.1(PCB.SCH) Date: 7/27/2009 Sheet 7 of STM8L1526-EVAL PA[0..7] PB[0..7] PC[0..7] PD[0..7] PE[0..7] PF0 STM8L1526-EVAL Figure 26. LCD and SD Card CN14 SPI_MISO SPI_SCK SPI_MOSI MicroSD_CS 8 7 6 5 4 3 2 1 PB7 PB5 +3V3 PB6 PE3 RVS DO Vss SCLK Vdd DI CS RVS SW1 SW2 10 9 G1 G2 G3 G4 PD6 SDcard_detect PJS008-2000 (SMS064FF or SMS128FF) MicroSD card +3V3 R74 [N/A] LCD_CS R68 [N/A] C71 +3V3 100nF U7 1 2 3 4 5 6 7 8 PB4 Doc ID 15437 Rev 1 R85 0 Vss Vcc VO CLK SID CS A K ZYMG12232B-GB1 Dot Matrix LCD +5V +3V3 C56 Flash_CS R67 10K PE4 R73 0 100nF U18 7 HOLD C 8 VCC D 1 S VSS 2 Q W M25P128-VME6G 6 5 4 3 +3V3 CN3 2.4" LCD connector (MB542 with AM240320L8TNQW-00H) 1 2 3 4 5 6 7 8 +3V3 T5 [N/A] 2 [N/A] T6 [N/A] 2 +3V3 +3V3 9 10 11 12 13 14 15 16 VDD VCI GND GND BL_VDD BL_Control BL_GND BL_GND STMicroelectronics Title: 37/46 STM8L1526-EVAL LCD&SDcard TFT LCD Do not fit 1 2 Number:MB818 3 Rev: C.1(PCB.SCH) Date: 7/27/2009 4 Schematics 1 R96 1 RESET# 3 R98 [N/A] 3 R99 [N/A] CS SCL SDI RS WR RD SDO RESET Schematics 38/46 Figure 27. RS-232 and IrDA +3V3 100nF C15 C9 100nF RS232/IrDA_TX 1 21 20 19 18 17 16 15 JP5 23 3 PC2 28 24 1 2 C1+ C1C2+ C2- 14 13 12 PC3 Bootloader_RESET RS232/IrDA_RX U8 2 T1IN T2IN T3IN 21 20 R1OUT R2OUT R3OUT R4OUT R5OUT nEN VCC GND V+ VT1OUT T2OUT T3OUT R1IN R2IN R3IN R4IN R5IN nSHDN C14 100nF 26 25 27 3 CN1 DB9-male UART2 C18 100nF C10 100nF 9 10 11 DCD RXD TXD 1 6 2 7 3 8 4 9 5 4 5 6 7 8 +3V3 22 Doc ID 15437 Rev 1 ST3241EBPR U2 5 3 4 +3V3 R3 5 R7 47 C5 100nF C7 4.7uF TxD RxD Anode (VCC2) Cathode VCC1 Vlogic GND TFDU4300 IrDA C6 100nF STMicroelectronics Title: STM8L1526-EVAL RS232&IrDA Number:MB818 Rev: C.1(PCB.SCH) Date: 7/28/2009 Sheet 9 of STM8L1526-EVAL C2 4.7uF 1 2 6 7 8 SD 1 2 3 STM8L1526-EVAL Figure 28. Motor control 4 VDD MC_EmergencySTOP Motor control connector CN7 R95 3.3K R29 [N/A] PD6 Doc ID 15437 Rev 1 PA4 R77 0 MC_CurrentA PE5 R71 0 MC_CurrentB R94 0 C72 [N/A] R83 MC_NTC MC_DissipativeBrake PE0 PB1 +5V 0 MC_PFCpwm MC_EnA MC_EnB C64 [N/A] PB1 PB0 PB2 EMERGENCY STOP MC-UH MC_UL MC_VH MC_VL MC_WH MC_WL CURRENT A CURRENT B CURRENT C NTC BYPASS RELAY DISSIPATIVE BRAKE +5V POWER PFC SYNC PFC PWM Encoder A Encoder B GND GND GND GND GND GND BUS VOLTAGE GND GND GND GND GND Heatsink Temperature Vdd_Micro GND GND Encoder Index 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 R60 R64 100K R44 VDD 0 C52 100nF R82 PA5 [N/A] R59 PB3 [N/A] R63 Default setting: Open R53 0 C54 [N/A] C63 100nF 0 MC_connector PA6 R51 0 MC_CurrentC PD2 PD7 PD4 PE1 PD5 PE2 MC_UH MC_UL MC_VH MC_VL MC_WH MC_WL C73 1nF 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 PA7 0 C41 [N/A] MC_BusVoltage MC_HeatsinkTemperature MC_EnIndex JP8 MC_PFCsync2 MC_PFCsync1 PD1 R76 0 PD0 R56 0 C42 [N/A] JP4 C39 [N/A] Default setting: Open C46 [N/A] C44 [N/A] C36 10nF C35 [N/A] Title: STM8L1526-EVAL Motor Control 39/46 Number:MB818 1 2 3 Rev: C.1(PCB.SCH) Date: 7/31/2009 4 Sheet 10 of 12 Schematics STMicroelectronics Schematics 40/46 Figure 29. EEPROM and temperature sensor U29 I2C_SDA I2C_SLK PC0 PC1 R115 R116 0 0 5 6 7 8 JP14 R119 10K SDA SCL WC VCC VSS E2 E1 E0 4 3 2 1 C84 M24C64-FDW5TP EEPROM VDD 100nF Doc ID 15437 Rev 1 VDD TR2 BSN20 2 R112 R113 R114 4K7 4K7 4K7 +3V3 R120 R118 4K7 4K7 G U28 1 3 I2C_SMB PC4 R27 0 2 S G 1 3 S D 1 2 3 4 SDA VDD SCL A0 OS/INT A1 GND A2 8 7 6 5 C83 100nF STLM75M2E D TR1 BSN20 Temperature sensor Title: STM8L1526-EVAL EEPROM&TemperatureSensor Number:MB818 Rev: C.1(PCB.SCH) Date: 7/27/2009 STM8L1526-EVAL STMicroelectronics 1 2 3 4 VDD R88 C75 20pF 2 +3V3 8MHz +3V3 1 2 3 SWIM_PULLUP_CTL 4 5 OSC_IN OSC_OUT 6 STM_RST 7 8 C80 9 100nF+3V3 AIN_1 10 M25_CS 11 U2_TX 12 R105 1 3 1K +3V3 VDD_2 VSS_2 JTMS PA12 PA11 PA10 PA9 PA8 S2_MOSI S2_MISO S2_CK PB12 CN9 8 6 4 2 STM_JRST STM_JTDI STM_JTCK SWIM_IN SWIM U2_RX U2_CK T_JTCK T_JTDO T_JTDI T_NRST T_JRST Doc ID 15437 Rev 1 VBAT PC13 PC14 PC15 OSC_IN OSC_OUT /RST VSSA VDDA PA0 PA1 U2_TX R81 36 35 34 33 32 31 30 29 28 27 26 25 T4 9013 2 R87 1K STM_JTMS USB_DP USB_DM U1_RX U1_TX ST_LINK_LED +3V3 U19 1 VccA VccB 2 SWIM_IN A1 B1 3 SWIM_RST_IN A2 B2 4 GND DIR T_JTMS T_JTCK VDD 8 7 SWIM 6 SWIM_RST 5 R101 680 R121 R100 47 47 ST_LINK_SWIM RESET# SN74LVC2T45DCUT 13 14 15 16 17 18 19 20 21 22 23 24 100K SWIM_PULLUP_CTL 1 48 47 46 45 44 43 42 41 40 39 38 37 X3 U27 STM32F103C8T6 VDD_3 VSS_3 PB9 PB8 BOOT0 PB7 PB6 PB5 JNRST JTDO JTDI JTCK 1 T7 9012 2 R86 1K U2_RX U2_CK S1_CK S1_MISO S1_MOSI PB0 PB1 PB2/BOOT1 PB10 PB11 VSS_1 VDD_1 C77 20pF R97 1K SWIM_IN SWIM_RST SWIM_RST_IN STM_JRST STM_JTDO STM_JTDI STM_JTCK SWIM_IN SWIM 100K +3V3 STM8L1526-EVAL Figure 30. ST_LINK (SWIM only) 7 GND 5 STM_JTMS 3 STM_JTDO 1 SWIM +3V3 +3V3 JTAG MCU R103 ST_LINK_LED +3V3 510 R109 1K5 VDD +3V3 CN11 RED R102 R106 4K7 4K7 U5V 1 2 3 4 0 0 AIN_1 R107 R108 22 USB_DM 22 USB_DP LED C68 100nF C78 100nF C81 100nF C70 100nF STMicroelectronics Title: USB-typeB connector STM8L1526-EVAL ST_LINK (SWIM only) USB 41/46 Number:MB818 1 2 3 Rev: C.1(PCB.SCH) Date: 7/28/2009 4 Sheet 12 of 12 Schematics VCC DD+ GND SHELL SHELL LD7 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 CN4 Header 18 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 S28 S29 S24 S25 S20 S21 S16 S17 S12 S13 S8 S9 S4 S5 S0 S1 COM4 COM3 S31 S30 S27 S26 S23 S22 S19 S18 S15 S14 S11 S10 S7 S6 S3 S2 COM1 COM2 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 CN3 Header 18 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 CN1 Header 18X2 CN2 Header 18X2 Schematics Doc ID 15437 Rev 1 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 42/46 Figure 31. MB821 U1 PD878-DP-FH-W-LV-6-RH Title: Number:MB821 STM8L2xx EVAL LCD board Rev: A.1(PCB.SCH) Date: 9/10/2009 Sheet 1 of 1 STM8L1526-EVAL STMicroelectronics STM8L1526-EVAL Appendix A Table 22. Pin No. STM8L1526-EVAL I/O assignment STM8L1526-EVAL I/O assignment STM8L1526-EVAL I/O assignment Pin name STM8L1526-EVAL I/O assignment 1 PA0 SWIM / IR_LED 2 PA1 RESET button 3 PA2 16MHZ crystal 4 PA3 16MHZ crystal 5 PA4 LED1 / Motor control connector (Current A) 6 PA5 LED2 / Motor control connector (Bus voltage) 7 PA6 LED3 / Motor control connector (Current C) 8 PA7 LED4 / Motor control connector (Encoder index) 9 VSS GND 10 VDD VDD_MCU 11 VDDA VDDA 12 VREF+ VDDA 13 VLCD - 14 PE0 CMP_Rref / Motor control connector (NTC_bypass) 15 PE1 Joystick_Left / Motor control connector (MC_VL) 16 PE2 Joystick_sel / Motor control connector (MC_WL) 17 PE3 Micro SD card_CS 18 PE4 Serial Flash_CS 19 PE5 Motor control connector (Current B) 20 PD0 Motor control connector (PFC sync) 21 PD1 CMP_Cref / Motor control connector (PFC sync) 22 PD2 Bi-color_LED / Motor control connector (MC_UH) 23 PD3 IDD_Measurement 24 PB0 Motor control connector (Encoder A) 25 PB1 Motor control connector (Dissipative brake & PFC PWM) 26 PB2 Motor control connector (Encoder B) 27 PB3 Audio_ADC_IN / Motor control connector (Heatsink_temperature) 28 PB4 Dot-matrix LCD_CS 29 PB5 LCD_SDcard_Flash_SCK 30 PB6 LCD_SDcard_Flash_MOSI 31 PB7 LCD_SDcard_Flash_MISO 32 PF0 BNC / Audio_DAC_out Doc ID 15437 Rev 1 43/46 STM8L1526-EVAL I/O assignment Table 22. Pin No. Note: 44/46 STM8L1526-EVAL STM8L1526-EVAL I/O assignment (continued) Pin name STM8L1526-EVAL I/O assignment 33 PD4 Joystick_down / Motor control connector (MC_VH) 34 PD5 Joystick_right / Motor control connector (MC_WH) 35 PD6 Motor control connector (EmergencySTOP) / SDcard_detect 36 PD7 Joystick_up / Motor control connector (MC_UL) 37 PC0 I²C SDA 38 PC1 Key Button / I²C SCL 39 VDDIO VDD_MCU 40 VSSIO GND 41 PC2 UART_IrDA_RX 42 PC3 UART_IrDA_TX 43 PC4 I²C_SMB 44 PC5 32 kHz crystal 45 PC6 32 kHz crystal 46 PC7 Potentiometer 47 PE6 IDD_Measurement_Wakeup 48 PE7 IDD_Measurement_CNT_EN All I/O's marked in grey are shared with LCD glass module. Doc ID 15437 Rev 1 STM8L1526-EVAL Revision history Revision history Table 23. Document revision history Date Revision 10-Sep-2009 1 Changes Initial release. Doc ID 15437 Rev 1 45/46 STM8L1526-EVAL Please Read Carefully: Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any time, without notice. All ST products are sold pursuant to ST’s terms and conditions of sale. Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no liability whatsoever relating to the choice, selection or use of the ST products and services described herein. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such third party products or services or any intellectual property contained therein. UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK. Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any liability of ST. ST and the ST logo are trademarks or registered trademarks of ST in various countries. Information in this document supersedes and replaces all information previously supplied. The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners. © 2009 STMicroelectronics - All rights reserved STMicroelectronics group of companies Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America www.st.com 46/46 Doc ID 15437 Rev 1