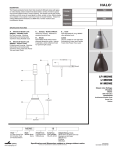

Download LFI-3751 Product Data Sheet

Transcript