Download Manual - Tuxedo Distributors

Transcript

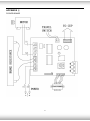

CB910 X WHEEL BALANCER USER MANUAL I CONTENT 1. REFACE-----------------------------------------------------------------------------------------------------------------------------------1 WARNING -------------------------------------------------------------------------------------------------------------------------------------1 INTRODUCTION-----------------------------------------------------------------------------------------------------------------------------1 INSTALLATION ------------------------------------------------------------------------------------------------------------------------------2 SAFETY REGULATION--------------------------------------------------------------------------------------------------------------------3 2. INSTALLATION-----------------------------------------------------------------------------------------------------------------------4 2.1HOOD INSTALLATION-----------------------------------------------------------------------------------------------------------------4 2.2MAINSHAFT INSTALLATION---------------------------------------------------------------------------------------------------------4 2.3CONFIGURATE POWER SUPPLY--------------------------------------------------------------------------------------------------4 3. TECHNICAL PERFORMANCE-----------------------------------------------------------------------------------------------5 3.1PERFORMANCE & CHARACTERISTIC------------------------------------------------------------------------------------------5 3.2MAIN TECHNICAL INDEX------------------------------------------------------------------------------------------------------------5 3.3WORKING PRINCIPLE----------------------------------------------------------------------------------------------------------------5 4. TRANPORTATION & IN-SITE INSTALLATION----------------------------------------------------------------------5 4.1TRANSPORATION---------------------------------------------------------------------------------------------------------------------5 4.2IN-SITE INSTALLATION--------------------------------------------------------------------------------------------------------------6 5. SAFETY & PREVENTION------------------------------------------------------------------------------------------------------7 6. CONSTRUCTION & OPERATION------------------------------------------------------------------------------------------8 6.1 CONFIGURATION---------------------------------------------------------------------------------------------------------------------8 6.2 DISPLAY PANEL-----------------------------------------------------------------------------------------------------------------------8 6.3 BASIC OPERATION------------------------------------------------------------------------------------------------------------------9 6.4 VALUE INPUT-------------------------------------------------------------------------------------------------------------------------10 6.5 RESIDUAL UNBALANCE VALUE DISPLAY-----------------------------------------------------------------------------------11 6.6 BALANCE MODE & ALU BALANCE MODE SELECT----------------------------------------------------------------------11 6.7 SUPPLEMENTARY EXPLAINATION-------------------------------------------------------------------------------------------12 7. PROGRAM SETUP---------------------------------------------------------------------------------------------------------------13 7.1 PROGRAM FUNCTION INTRODUCTION-----------------------------------------------------------------------------------13 7.2 ERROR--------------------------------------------------------------------------------------------------------------------------------14 II 7.3 GENERAL TROUBLESHOOTING & SOLUTION---------------------------------------------------------------------------14 7.4WHEEL BALANCER ACCESSORY---------------------------------------------------------------------------------------------15 8. MAINTENANCE-----------------------------------------------------------------------------------------------------------------16 9. DETAILED OPERATION DESCRIPTION--------------------------------------------------------------------------18 9.1 HOW TO BALANCE A WHEEL-------------------------------------------------------------------------------------------------18 9.2 PARAMETERS SETUP-----------------------------------------------------------------------------------------------------------18 9.3 CUSTOMER SELF-CALIBRATION--------------------------------------------------------------------------------------------20 9.4CUSTOMER SELF-CALIBRATION-----------------------------------------------------------------------------------------------APPENDIX 1 ----------------------------------------------------------------------------------------------------------------------------21 APPENDIX 2 -----------------------------------------------------------------------------------------------------------------------------22 III Ⅰ.PREFACE ATTENTION: Dangers or unsafe procedures that can WARNING There will be one year of warranty period on the cause minor injuries or damage to property. condition that the machine including the operation system , tools and accessories are used properly Read these instructions carefully before using the and/or without damage. During this period, the machine. Keep this manual and the illustrated materials manufacturer will repair or replace the parts returned or supplied with the equipment in a folder near the place the machine itself, sustaining the costs but not of operation so as to allow the machine operators to accepting responsibility for normal wear and tear, consult the documentation at any time. incorrect use or transportation, or failure to carry out maintenance. The manufacturer will not inform the The manual is only to be considered valid for the customer about any improvements to the products or machine serial number and model stated on the the upgrading of the production line. attached nameplate. INTRODUCTION The purpose of this manual is to provide the owner and operator of this machine with a set of safe and practical instructions for the use and maintenance of the wheel balancer. If such instructions are carefully followed, the machine The instructions and information described in this will offer you the levels of efficiency and duration. manual must always be complied with: the operator will be held responsible for any operation not specially described and authorized in this manual. The following paragraphs define the levels of danger regarding the machine. Some of the illustrations contained in this booklet have been taken from pictures of prototypes: standard production machines may differ slightly in certain respects. These instructions are for the attention of personnel with basic mechanical skills. We have therefore condensed the descriptions of each operation by DANGER: Refers to immediate danger with the risk of omitting detailed instructions regarding, for example, how to loosen or tighten the fixing devices. Do not serious injury or death. attempt to perform operations unless properly qualified or with suitable experience. If necessary, please contact an authorized Service Centre for assistance. INS WARNING: Dangers or unsafe procedures that can TALLATION cause serious injury or death. 1 SAFETY REGULATIONS Take the utmost care when unpacking, assembling, lifting and setting up the machine as indicated below. Failure to observe these instructions can damage the machine and compromise the operator's safety. Failure to comply with the instructions and danger warnings can cause serious injuries to the operator or Remove the original packing materials after positioning other persons. them as indicated on the packaging. Do not operate the machine until you have read and understood all the danger/warning notices in this manual. All regulations in force concerning safety at work must be complied with when choosing the installation The correct use of this machine requires a qualified and position. authorized operator. This operator must be able to understand the manufacturer's written instructions, be In particular, the machine must only be installed and suitably trained and be familiar with the safety operated in protected environments where there is no procedures and regulations. Operators are forbidden to risk of exposure to dripping. use the machine under the influence of alcohol or drugs IMPORTANT: for the correct and safe operation of the that could affect his/her physical and mental capacity. The following conditions are essential: - read and understand the information and instructions machine, the lighting level in the place of use should be described in this manual; - have a thorough knowledge of the features and at least 300 lux. characteristics of the machine; - keep unauthorized persons well clear of the working Environmental operating conditions must comply with area; the following requirements: - make sure that the machine has been installed in - relative humidity ranging from 30% to 80% (without compliance with all relevant standards and regulations condensation); in force; - temperatures ranging from 0°to +50°C. - make sure that all machine operators are suitably trained, that they are capable of using the machine correctly and safely and that they are adequately supervised during work; - do not touch power lines or the inside of electric The floor must be strong enough to support a load motors or any other electrical equipment before making equal to the weight of the equipment plus the maximum sure that they have been powered off; load allowed. - read this booklet carefully and learn how to use the machine correctly and safely; - always keep this user manual in a place where it can be readily consulted and do not fail to refer to it. The machine must not be operated in potentially explosive atmospheres. Do not remove or deface the DANGER, CAUTION, WARNING or INSTRUCTION decals. Replace any 2 missing or illegible decals. If any decals have become to his safety. detached or damaged, it is possible to obtain them from your nearest reseller. Warning for rotating machine part This decal, positioned next to the -Observe the unified industrial accident prevention balancing shaft, reminds the user that this regulations relating to high voltages and rotating is a rotating part and is therefore machinery whenever the machine is in use or being dangerous and should not be touched serviced. with the hands. The arrow indicates the rotation direction. - Any unauthorized changes or modifications made to the machine automatically release the manufacturer Grounding symbol: This decal, positioned from any liability in the case of damage or accidents on the rear left side of the machine, resulting from such changes or modifications . indicates where to connect the ground wire. SAFETY LABEL POSITION DIAGRAM Pay attention to keep the safety labels complete. When it is not clear of missing, you should change the new label. WEAR PROTECTIVE GLOVE You should let the operators see the safety labels clearly and understand the meaning of the label. READ OPERATION MANUAL WEAR PROTECTIVE GLASSES POWER OFF THE ELECTRICAL SOURCE OF THE MACHINE DURING MAINTANCE Meaning of the decals (including the one indicating caution) 230 V Lightning symbol This decal, positioned on the back of the machine, indicates where to insert the power supply cable and warns the user to pay attention 3 2.2 MAIN SHAFT INSTALLATION Note: The following information coming from the nameplate FIG 2 The nameplate is stuck in the center to the top on the rear of the machine. The meaning of each part is in the following: CB MAINSHAFT INSTALLATION:Before installation, use 910 B the ethyl alcohol and compressed air to clean up the With hood center hole of the shaft and connect part. Use spanner Model and screw to fix the thread shaft on the balance shaft Computerized dynamic wheel (Fig2) balancer 2.3 EQUIPPED WITH POWER SUPPLY According to the label on the connect between ower cable and body, the power cable connect socket ust be grounded with the reliable earth wire. B. CE certificate B. This mark indicates that this model of machine has got the CE certificate All the electrical devices installation must be done by C、Series No The first 3numbers is the abbreviate of the the qualified staff. Before installation, please check If model. The middle 4 is the manufacture date and the the power system is comply with the technical last 4 is company product series number. parameter marked on the nameplate of the machine. D、What on the cross line is the name and address of The wiring of the machine must have the fuse and the the company and under the cross line not includes the perfect ground protection. And install the electrical above explained but the rated electrical parameters, Leakage automatic controls switch in the power source. such as voltage、frequency、power、phase number & full And recommend the application of the stabilizer if the load current, and the weight and manufacture date of voltage of installation site is unstable. the machine. Ⅱ INSTALLATION Before installation and use of the wheel balancer, you Any electrical connect in the workshop is only done by should carefully read this installation and operation the qualified technical staffs and it should meet the manual. And keep this manual in hand for reference at enforced regulation. any time. You should be sure that all the operators have Any electrical connect must be according to the read this manual to guarantee the most perfect following: functions of the machine and meanwhile the safety. • Power on the data plate on the machine; 2.1 PROTECTIVE HOOD INSTALLATION • Voltage decrease can not exceed 4% of the rated 4 . voltage on the data plate when full load (10% when -rim width 1.5~20″ start) -net weight 140 kg -Operators must: -max wheel diameter 44inch • Install the plug; -working environment:temperature 0℃-50℃,RH: • install 30ma circuit breaker; 30% —80% (no condense); • install power cable fuse; • provide with effective workshop electrical connect to 3.3 WORK PRINCIPLE ground; The micro CPU will provide the normal information if it - prevent the authorized operation and pull out the plug checks each unit in the normal situation. And the to prolong the working life when not use the machine. operators can execute the balance operation. When - if the machine directly connected to the power source balancing, MCPU can control the rotation of the through the power board not the plug, we should use balancer tester main shaft through the drive interface. the qualified staffs to operate. The unbalance signal sensed by balance sensor is sent to the micro-processor port through A/D converter. CPU will integrated analyze the unbalance signal and angle signal to calculate the unbalance value and display the Perfect ground is necessary for the correct operation. value through the LED unit. We can realize the Do not connect the machine with air pipe, water pipe, man-machine talk through keyboard and LED. telephone line and the other unsuitable objects. BALANCE SENSOR A/D CONVERTER L E D DISPLAY ANGLE SPEED SENSOR TIRE Ⅲ .CB910 WHEEL BALANCER MCPU ANGLE SPEED TEST CONTROL INTERFACE KEY INPUT UNIT MAINSHAFT ROTATION DRIVE INTERFACE TECHNICAL CHARACTERISTIC BALANCE SENSOR MAINSHAFT 3.1CHARACTERSIC: -adopts quality computer with the feature of high MAINSHAFT DRIVE intelligence and high stable -mechanical main shaft adopts high precision bearing POWER UNIT Fig 3 driven, wear-resistant, low noise -press stop key to realize the emergency stop -full automatic dynamic/static balance check FIG 3 CB920 WHEEL BALANCER WORK PRINCIPLE -balance 3 ALU rim and 1 motorcycle tire -self-calibration and full automatic trouble diagnosis Ⅳ. TRANSPORTATION & 3.2MAIN TECHNICAL SPECIFICATION INSTALLATION -rated voltage 220V/110V(selectable)50/60HZ -power 250W 4.1 TRANSPORTATION -speed 7S(if the weight of the wheel is about 20Kg) -Place, carry and store the machine according to the -accuracy ±1g indication of the label on the package carton. -noise ≤69dB - -rim diameter 10″~24″ temperature-10℃-+60℃ -maximum wheel weight 65kg -When transport and use the machine, do not pull the 5 Store environment: RH20%-95% rotation shaft, or it will cause the permanent damage. And the installation site as shown in Fig5. Fig 4 Fig5 4.1.2 Remove the upper cover of the package carton and check and confirm the wheel balancer, spare parts and documents you purchased according to the packing list. If you have any question, please contact with the dealer. Package materials such as plastic, PBV, nail, screw, timber and carton must be placed into a scrap bin to treat according to the local regulation. Do not lift the machine at any other position. 4.1.1After being sure that the package of your machine is perfect, you can carry the wheel balancer to the 4.2 INSTALLATION installation site.(Fig4). The choice of the installation Remove the connect bolt. And carry down the wheel should comply with the following requirements. The balancer to place it on the flat and solid floor. We ambient temperature is 0℃-50℃ and the RH ≤85%. should store it indoor to avoid it from being exposed to 6 the sunlight for long time and the moisture. exclusively to measure the extent and position of car wheel unbalances, within the limits specified in the technical data section. Furthermore, models equipped Ⅴ.SAFETY AND PREVENTION with motors must be provided with a suitable guard. 5.1.1 Before operation, please confirm that you have read the entire warning label and the instruction manual. Any use other than Not according with the safety instruction can cause the those described in this manual is to be considered injuries to the operators & bystanders. improper and unreasonable. 5.1.2 Keep your hands and the other parts of your body from the location with the potential danger. Before starting the machine, you must check it there existing Do not start the the damaged part. If any break or damage, the machine machine without the wheel locking equipment. will not be used. 5.1.3In emergency situation, if the tire not fixed, you should press ―STOP‖ to stop the rotation of the wheels. Protective Adopts high strength protective cover to prevent the tire hood plays the role of prevention and safety. from flying in any direction and can only fall on the ground to protect the safety of the operators. 5.1.4 Before balancing, operators should check all the Do not clean or tires and wheels to find the possible faults. Do not wash the wheels mounted on the machine with balance the tires and wheels with fault. compressed air or jets of water. 5.1.5 Do not exceed the load capability of the wheel Get to know your balancer and do not attempt to balance the wheel machine. The best way to prevent accidents and obtain top performance bigger than the designed dimension. from the machine is to ensure that all operators know how the machine works. 5.1.6 Wear suitable clothing such as suitable safety suit such as glove, glasses and working suit. Not wear necktie, long hair, loose clothing. The operators should Learn the function stand beside the machine when operation the machine. and location of all the controls. Keep from the unauthorized personnel. 5.1.7 Before balancing, you must confirm the Carefully check that installation of the wheel suitable. Before rotation, be all controls on the machine are working properly. sure the nut turn 4turns around the thread shaft and firmly locked on the main shaft. GENERAL CONDITIONS OF USE The machine must be installed properly, operated correctly and serviced regularly in order to prevent accidents and injuries. The wheel balancers described in this manual must be used 7 6.CB920 CONFIGURATION & 6.2 CB920 OPERATION DISPLAY OPERATION 6.1 CONFIGURATION 7 6 5 1. In the state of parameter input, it is the distance from wheel to balancer input key .You can change the Br set 10 value of the window by press the up/down key. 11 2. Br value input key You can change the Br set value of the window by press the up/down key. 9 8 4 3. In the state of parameter input, it is the diameter of 12 the rim input key. You can change the D set value of the window by press the up/down key. 2 3 1 4. High accuracy balance press key When the display 1. power &plug 2. return spring 3. hinging handle 4. travel switch 5. scale 6. control panel 7. display panel 8. weight tray 9. protective hood 11. body is ―00‖,press this key. The display will display residual unbalance less than 5g. 10. balance shaft body Unbalance value conversion key 12. power source switch 8 Static Balance Mode Key: It is static mode Static Mode light when the lamp light Motorcycle Mode light Motorcycle balance mode key ALU1 Mode light ALU1 aluminum alloy balance alloy mode key ALU2 Mode light ALU2 aluminum alloy balance alloy mode ALU3 Mode light key 6.3 BASIC OPERATION ALU3 aluminum alloy balance alloy mode 6.3.1 Switch on the main switch on the left side of the key machine,the display will display ―CB-953‖ and then ―0‖、 ―0‖(it will display ―0.00‖, ―0.00‖ in ounce state) 6.3.2 MOUNT WHEEL Emergency press key Preparation before test:Check and clean the dust and mud and if there are foreign bodies, such as metal and stone, clipped on the surface of the tire. And also check Start key the air pressure of the tire is according with the pecified value. Check if there are deformation on the rim positioning surface and installation hole. Check if there are any foreign bodies in the tire. Take off the original weight. The installation methods of the wheel : Positive Inner unbalance value and parameter of the tire display positioning, negative positioning & flange disk when handling the middle and big sizes of tires. You can select the methods according to the different conditions. 6.3.2.1 SMALL CAR WHEEL POSITIVE POSITION Outer unbalance value and parameter value of the tire Positive positioning is the normal method. It is featured display with simple and quick operation. It is mainly suitable to the common steel rim and aluminum alloy rim with small deformation. Unbalance point positioning lamp 9 NOTE: The choice on the cone should be adapted to the rim center hole and pay attention to its direction. Or it will cause the inaccurate measurement. 6.4 INPUT VALUE Main shaft wheel(direction of the rim installation surface is inside) cone quick nut 6.3.2.2 When the deformation of the outside of the wheel, adopt this method to positioning to grantee the accurate positioning of the steel rim inner hole and main shaft. It is suitable to the steel rim, especially the thick ALU 6.4.1 Input DIS(Distance) Pull the scale to the inner position to add the weight to input the and press the key DISvalue into the display. At this moment, the display will display ―DIS‖:―XXX‖,And the default system is mm. Main shaft wheel tower spring bowl suitable cone 6.4.2 Input Br (RIM Breadth) Value Use the Br measurement caliper to measure the Br of quick nut 6.3.2.3 FLANGE DISK POSITIONING(OPTIONAL) the rim, press the key to input the Suitable to the big tire assemble Br value into the display. At this moment, the display will display ―Br‖:―XXX‖. 6.4.3 Input the DiA(Diameter)Tire Diameter Value After confirming the rim diameter, press the to input the rim diameter into key the display. At this moment, the display will display ―D‖: ―XXX‖. 6.4.4 UNIT CONVERSION: Main shaft wheel ①The unit conversion of the Br of the rim from flange disk(fixed on the main shaft) cone inch to mm: quick nut 10 Normally, the display of Br should be in inch. When you 6.4.8 Add the corresponding weight at the unbalance need the unit of the display to be mm, you can use the point and start test again until the balance of the tire. key to realize the unit conversion from inch to mm. ②The unit conversion of the DIA of the rim from inch to mm: 1. When start the machine, use hand to pull the wheel Normally, the display of D should be in inch. When you to help it start rotation, especially to the relative bigger need the unit of the display to be mm, you can use the tire, to prolong the working life of the motor. key to realize the unit conversion from inch to mm. 2. Check if there are any mistakes on the dimension. After unit conversion, the unit of the display values of Check if the balance methods meet the configuration of rim Br and D are , but when you switch off and then the rim and select the balancer most easily on the wheel balancer, the unit will be still inch. to balance. ③The unit conversion from gram to ounce: 3. Check if the quick lock nut tight or not. Normally, the unit of the unbalance value is gram (g). If you want to make the ounce(Oz) to be the unit, you can 4. When the balance ends, remove the tire. Pay execute the g/Oz conversion. The unit of the displayed attention to handle it with gentle and avoid knocking the unbalance value is gram(g). The way to main shaft. realize the unit conversion from gram to ounce is to press 5. When clipping the weight. Use the hammer to clip the weight on the rim without too much force. Do not 6.4.5 When press the start key ,the wheel balancer knock the main shaft hardly to avoid damaging the starts to run. A few seconds later, the sensor. The position to add the Weight should be free machine automatically stops. The machine can also from the grease and should be dry. start by lowering down the protective hood which can be set by the program. 6.5 RESIDUAL UNBALANCE VALUE DISPLAY 6.4.6 DISPLAY UNBALANCE VALUE the weight you use is less than 5 g, the wheel balancer When the spin ends, the display will display the inner will not display the value and only displays the state of The minimum value of the standard weight is 5g so if ―00‖. When you need to display the residual unbalance and outer value, you should press unbalance value of and the display will the rim. Use your hand to pull the wheel. When all the immediately display the inside or outside unbalance positioning lamps light inside and outside light, the value of less than 5g. The maximum residual weight adding position will be indicated. unbalance value is 4 g. 6.4.7Rotate the wheel, when the left side positioning 6.6 BALANCE MODE SELECT lamp all light, at this moment, the highest Select the balance mode according to the weight position is adding position and the balance mode. Press the the inner unbalance position and when the right side corresponding key to select the balance mode. When positioning lamp all light, at this moment, the you switch on the machine the machine will automatic highest position is the outer unbalance position. enter into the dynamic balance mode and no need to 11 select. 3 1 Dynamic—clip the weight on both side of rim(dynamic balance test once start Di1=Di+ ) ” 1 /4” /2” /2” Di2= from 0 point to the 1 1 / Static—use this mode when there can not add weight 4” on both sides Outer of the flange disk - ” “ D1=D-1” Mot—optional for balancing ” the motorcycle D2=D-2 ” When balance the motorcycle, you need the special motorcycle adaptor accessory and with the assistance of the extension scale to measure Di, Br and Di. Input the measure value into the Di, Br and Di display window. The input method is similar to the parameter input of ALU3-clip the weight inside and the the car. position to add weight outside is same to ALU2. 1 2 /2” ALU1-to balance the light aluminum ALU3 alloy rim. Adopt clip the weight on the Di1=Di shoulders of the rim Di2= from 0 1 1 /4” point to the 3 ALU1 1 /2” /4” Outer of the 3 /4” ” flange disk- ” Di1=Di+ D1=D ” D2=D-2 ” Di2=Di+Br- ” D1=D-1” D2=D-1” 6.7 SUPPLEMENTARY EXPLAINATION: Once switching on, you will see standard dynamic balance mode setup by the computer. When selecting ALU mode and the configuration of the aluminum alloy rim is similar to the above standard ALU1\ALU2\ALU3, ALU2-for ALU rim, hidden weight you can get relative accurate balance effect. If the inside section of the tire similar to the one given be the program, you need do some adjustment on the position and weight of the weight. General speaking, 1~2 times ALU2 of adjustment can reach relative satisfactory balance 12 effect. the tire and clip a weight of 100g at the 12clock position when all the unbalance position indication lamps light. And then start the machine again to realize the self 7 PROGRAM SETUP calibration. 7.1 PROGRAM FUNCTION INTRODUCTION The shortcut to enter Press program key to enter the program setup menu. the self-calibration is to press and hold on -p- (protective hood set-up): Press key again for 5seconds and you can enter into CAL-CAL. Keep in mind that the position to add the weight of 100g must to confirm the entrance. Select to set be in the 12clock position or you will cause the up the ON& OFF of the protective hood control function. inaccuracy of the balance. key to confirm to return to the above level. Press The above operation step vector diagram is as follows: SP(protective hood control function set-up) P: Select the key of and you can enter and press to enter. The setup is same to theabove. APP(unbalance unit setup) can setup to 1Grand 5Gr。 BIP (beeper setup) can set the on/off of the beeper. After confirming all the function setup, of you can press UP ENT Press to store. to enter the special function setup. IN TES (sensor test) can test the photocell and stat/dynamic piezoelectric sensor. Select next menu :Press and then press of to enter into CAL –CAL,this function is used when long time no use of the machine or the Self-calibration setup: Press and Press lost of the accuracy. to enter the program again to confirm and the display will display ADD -0. Press the start key to start the test. After running, the display will display ADD -100. Rotate 13 7.2 ERROR INDICATION DISPLAY CAUSE SOLUTION ERR OPN protective cover not lower down Lower down the protective cover ERR SP rotation speed not enough Check the motor and belt. ERR OFF stop the error Press the start key or raise up the protective cover. ERR FAC factory set-up fault Correct factory set-up ERR USR customer set-up fault Customer set-up If the problems still can not be solved, please contact with the professional persons .When changing the computer board, phase sensor or pressure sensor, you should factory-calibration &self-calibrate again. 7.3GENERAL TROUBLESHOOTING & SOLUTION: Description Cause Solution Start the machine but 1. .Check the circuit of 220V is normal or not. 1. not display. 2. power board fault 3. The cable between the power board and computer power source. loose 4. computer board fault Display is normal but 1. contact switch not good the start button and 2. machine breakdown 2. Changer the power board 3. Check the plug cable 4. Change the computer board 1. Open the housing of the machine and plug in and tight the contact switch input push button not plug. working. Display is normal but Check and connect the external 2. Start the machine again 1. not braking after start. The cable between the power board and computer 1. Plug in and tight the cable between loose the computer board and power 2. power board fault board. 3. computer board fault 2. Change the power board 3. Change the computer board Balance is not 1. sensor lead connect or contact no good 1.Connect again accurate & difficult 2. memory value lost 2. Correct the memory value according to reach “00” Each spin, the to the manual. 1. There are foreign body on the rim or the assemble 1. Change the wheel surface in the rim center deformation 2. Oven, recalibrate the sensor. 2. sensor damp or quick nut not tightly clamped 3. Fix the anchor bolt. 3. The external power voltage or the air pressure not There are foreign bodies on the wheel or the 1. Change the wheel unbalance of the wheel value too big. 2. Check the sensor and wiring. 3. Check power source and change of the value will not exceed 5g. enough. The flange dick not locked. Each spin, the 1. range of the change of value will be 2. sensor damage 20-90g. 3. external power source voltage too low Balance is not 1. Sensor damp or damage accurate & difficult 2. Program chore assemble stabilizer. 1. Calibrate again,oven and then self-calibration or change. to reach “00” 2. 14 Self-calibration again When second 1. Wheel internal hole irregular 1. Change the wheel mount & demount, 2. Flange disk assemble not properly 2. Check the assemble surface and the error will exceed try again. 10g. 7.4 Standard Accessory Thread Cone Shaft 100g weight Br Caliper Quick Nut Hood Hammer Spring Bowl Bowl Protect Optional Accessory Big Cone Flange Disk Weight Attach Tape Caliper STANDARD ACCESSORY LIST Pliers-----------------------------------------------------------------------------------------------------------1 piece Br Caliper-----------------------------------------------------------------------------------------------------1 piece Cone-----------------------------------------------------------------------------------------------------------1 set Quick Nut-----------------------------------------------------------------------------------------------------1 piece Thread Shaft-------------------------------------------------------------------------------------------------1 piece M10X160 Screw--------------------------------------------------------------------------------------------1 piece Standard Weight--------------------------------------------------------------------------------------------1 piece Bowl------------------------------------------------------------------------------------------------------------1 piece Bowl Protect-------------------------------------------------------------------------------------------------1 piece Spring---------------------------------------------------------------------------------------------------------1 piece 15 periodically lubricated by the operators. If the machine is used very frequently, more than 8. MAINTENANCE 2hours per day, we should annually check the bearing. And we will check once a year if the machine is used less than 2hours a day. When WARNING test, do not open up the bearing so you need The manufacturer will not bear any responsibility in insert a screwdriver to test the noise. Due to the the event of claims resulting from the use of function of the bearing is to clamp and support non-original spare parts or accessories. and not suitable to change or remove the grease. In addition, the speed of it is not too fast compared to the machine so no need to change WARNING the grease. If you note the run of the bearing Unplug the machine from the socket and make abnormal or there is noise, change the bearing. If sure that all moving parts have been locked the customer confirms the bearing is not changed, before you only need change the grease. Disassemble performing any adjustment or maintenance the bearing and open up the sealing ring and fill operation. the XHP103 grease. These operation should be guided by the profession personnel and calibrate the machine after changing the grease. If the WARNING change of the grease not correctly, it will Do not remove or modify any part of the machine influence the accuracy of the machine. On this (except for service interventions). condition, you need to reinstall the sealing ring and assemble the machine and adjust again. Technical safety card for using grease in the CAUTION wheel balancer Keep the work area clean. Mobilgrease XHP Never use compressed air and/or jets of water to NLGI degree remove dirt or residues from the machine. Take Type of thickener all possible measures to prevent dust from Colour, appearance building up or rising during cleaning operations. Penetration on the processed item 25°, ASTM D 217, Keep the wheel balancer shaft, the securing ring mm/10 nut, the centering cones and flange clean. These Dropping point, °C, ASTM D 2265 components can be cleaned using a brush Viscosity oil base, ASTM D 445, cSt @ 40°C previously dripped in environmentally friendly Change of penetration consistency, ASMT D 1831 solvents. Handle cones and flanges carefully so (established upon the rolling of the greases), mm/10 as to avoid accidental dropping and subsequent 4 spheres test, impression diam., ASTM D 2266, mm damage that would affect centering accuracy. 4 spheres test, welding load, ASTM D 2509, kg After use, store cones and flanges in a place Test Timken OK load, ASTM D 2509, lb where they are suitably protected from dust and Stability of oxidisation bomb method, ASTM D 942, dirt. If necessary, use ethyl alcohol to clean the pressure display panel. Perform the calibration procedure drop at 100 hours, kPa at least once every six months. Corrosion prevention, ASTM D 1743 Emcor rust, IP 220, wash away with acid water LUBRICATION Rust protection, IP 220-mod, wash away with The only rotating parts of the wheel balancer are distilled water the motor and balance shaft. These parts must be 16 Corrosion on copper, ASTM D 4048 When purchasing 1Athis product, your distributor will Resistance to water spray, ASTM D 4049, % spray also inform you 15 of the possibility to return another Wash away with water, ASMT D 1264, loss (weight%),end-of-life @ 79°C piece5 of equipment free of charge as long as it is of equivalent type and had the same SCRAPPING functions as the purchased product. If the machine is to be scrapped, separate all electrical, electronic, plastic and ferrous Any disposal of the product performed in a components and dispose of them separately, as different way from that described above will be provided for by local regulations in force. liable to the penalties provided for by the national regulations in force in the country where the ENVIRONMENT INFORMATION product is disposed of. If the machines have the crossed-out bin symbol Further measures for environmental protection on their data plate are recommended: recycling of the internal and , the following disposal external packaging of the product and proper procedure must be applied to. disposal of used batteries (only if contained in the This product may contain substances that can be product). hazardous to the environment and to human health if it is not disposed of properly. Your help is crucial to reduce the amount of natural resources used for manufacturing Electrical and electronic equipment must never electrical and electronic equipment, minimize the be disposed of in the usual municipal waste but use of landfills for product disposal and improve must be separately collected for their proper the treatment. hazardous substances from being released in the quality of life, preventing potentially environment. The crossed-out bin symbol , placed on the product and on this page, reminds the user that FIREFIGHTING MEANS TO BE USED the product must be disposed of properly at the Consult the following table to choose the most end of its life. suitable fire extinguisher. Dry materials Thus, the hazardous consequences non-specific treatments of the that Water YES substances Foam YES contained in these products, or improper use of Powder YES* parts of them, may have on the environment or on CO2 YES* human health are prevented. Furthermore, this YES* Use only if more appropriate extinguishers helps to recover, recycle and reuse many of the are not at hand or when the fire is small. materials contained in these products. Flammable liquids Water NO Electrical and electronic manufacturers and Foam YES distributors set up proper collection and treatment Powder YES systems for these products for this purpose. CO2 YES Electrical equipment Contact your local distributor to obtain information Water on the collection procedures at the end of the life NO Foam NO of your product. Powder YES 17 CO2 YES value with the unit of mm, you can press Warning torealize the conversion between the units. This table contains general instructions to be used as guidelines for users. All the applications 3.3 Check the Dia value, which means the of each type of extinguisher must be obtained diameter of the rim, marked on the tire. from the relevant manufacturer. to adjust the displayed Press in the right side display window until the displayed IX. DETAILED MACHINE value to be the rim diameter value. You can also OPERATION: use 9.1 How to balance a tire? to mm. 1. Switch on the power source 4、Lower down the protective cover(you can also 2. Select the cone according to the tire. Assemble press the start key). After the machine start, the tire on the main shaft of the wheel balancer rotate and test, it will automatic stops. In the left and firmly lock it. /right window ,the corresponding values will be 3. Input the tire parameter. displayed. Rotate the tire, when all the position to realize the conversion of the Br unit indication lamps light. Pls add the weight corresponding to the value displayed in the window in the 12clock position inside/outside. Once again, start the machine to test. The window will display thye unbalance value. The balance process will be completed until reaching the balance range you requied. 9.2 MACHINE PARAMETER SETUP 3.1 Pull out the scale of the balancer to measure the Dis value which means the distance from the P insider of the tire to the body. According to measured reading, the unit of which is cm, press to adjust the value to make the value displayed in the right side window to be the Press program key measured value. set-up menu. But the unit of this displayed to enter the program value is mm. eg You should input 55mm if the measured value is 5.5cm. P ON 3.2 Use the width measurement scale to measure the distance.Press Br value means the rim SP to input the Br value which is the implied value with the unit of inch. If you want to convert this value into the 1.1 -p- (protective cover set) press 18 to confirm enter and select UP/DOWN key to setup the on and off of the protective cover . Press to confirm. 1.2 -SP-(protective press cover function BIP ON BIP OF F EN T set) , the display will be sown as the picture on the left. SP UP o n SP 1.4 BIP (beeper setup) press Di and you can setup on/off of the beeper. Press the Di to enter o into the next level n Press to confirm the entrance Selectkey to BIP ON BIP OF F UP EN T setup the on and off of the protective cover control function . Press the key to confirm. AP P 1.3 PP(minimum unbalance value setup) Press Di, you can enter to setup the unit of 1Gr and 5Gr. All adopts diagraph not arrow. ―UP‖— ―Ent‖ press key to enter the special functiosetup. There are 2 optional selection ―IN‖– AP P 1 AP P 5 Press ―TES‖ and ―CAL‖ –―CAL‖ IN TE S CAL CAL to confirm the entrance and adjust the selection of the corresponding unit Select by press the Di、Di and press to confirm. 19 will display repetition to enter. In the state of I and press N‖—―TES‖, press Press to enter into the test to confirm. You can also enter into this state by press and hold on for 5seconds after input the parameter of the tire. state. POS XX In the state of POS, rotate the tire X clockwise. The ADD 0 value in the right window will increase. If counterclockwise, it will decrease. Press XX In the state of STA, press piezoelectric X sensor and the display will be ―ADD‖-―O‖ STA ADD 100 vertical to the main shaft. And the value in the right window will change. This means the installation of the sensor is correct. to rotate tire/rim. Press DYN XX X add 10o In the state of DYN, press piezoelectric sensor parallel to the main shaft. And the value in the The window will display―ADD‖-―100‖and then use right window will change. This means the your hand to rotate the tire until all the right lamp installation of the sensor is correct. on the display light up. At this moment, you can attach weight of 100g at 12clock position outside. 9.3 Customer self-calibration You must attach the weight at this position or the calculation angle is not accuracy to influence the measurement accuracy. Start up the machine CAL CAL once again and press to rotate the machine. In the state of IN TES, press sav you can enter into CAL –CAL which means the state of customer self-calibration state. This da t function should be applied when long time no use of the machine or the machine has lost the After the customer calibration, the display will be accuracy. ―‖-―DAT‖. Press to enter the program and once again. At this moment, self-calibration completes. 20 the customer APPENDIX Ⅰ POWER BOARD 21 APPENDIX Ⅱ CIRCUIT DIAGRAM 22 APPENDIX HOOD INSTALLATION SCREW M10X30 WASHER10 SPRING WASHER10 SPRING SCREW M10X20 23