Download Safe ST7 evaluation board (ST7FOPTIONS

Transcript

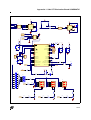

SAFE ST7 EVALUATION BOARD (ST7FOPTIONS-EVAL) USER MANUAL June 2002 DOC- ST7FOPTIONS-EVAL 1 USE IN LIFE SUPPORT DEVICES OR SYSTEMS MUST BE EXPRESSLY AUTHORIZED. STMicroelectronics PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF STMicroelectronics. As used herein: 1. Life support devices or systems are those which (a) are intended for surgical implant into the body, or (b) support or sustain life, and whose failure to perform, when properly used in accordance with instructions for use provided with the product, can be reasonably expected to result in significant injury to the user. 1 2. A critical component is any component of a life support device or system whose failure to perform can reasonably be expected to cause the failure of the life support device or system, or to affect its safety or effectiveness. ST72F26x MCU FAMILY SAFE ST7 EVALUATION BOARD USER MANUAL 1 INTRODUCTION The objective of the Safe ST7 Evaluation Board is to allow you to try out all the special features embedded in the ST72F26x MCU family. You can learn how each feature works and how to use them the best way by playing with the user controls and jumper settings. For example, you can check out what happens to your application when the voltage becomes erratic or the clock signal suddenly fails. Examples of what you can do: ■ Save application data in E2PROM when a power cut occurs and/or the main clock source fails (using the AVD and CSS options). Prove it works by resuming the application exactly where it left off after restoring the data saved by the AVD interrupt routine. ■ Drive LEDs directly (using the MCU’s high sink current I/O ports) ■ Experiment with different clock sources: external crystal or ceramic resonator, internal RC oscillator, external clock signal. The advantages of the internal RC: less cost, less components, less power consumption! ■ Check out the safe operation of the MCU in varying supply voltage conditions. You change the voltage using a trimmer. The voltage level is displayed on a 3-digit display. The LVD will automatically hold the MCU in reset state while the voltage is below the safe threshold. No need for an external reset circuit so more savings in board space and components. ■ Select different power sources, on-board 9V battery or external power supply ■ ■ Change E2PROM data or Flash program memory on-the-fly using In-Application Programming (IAP) Use Nested interrupts to let you interrupt an interrupt routine, service a higher priority interrupt and resume the one previously being serviced. This evaluation board incorporates basic input sources such as push-buttons, analog trimmer or output sources (LEDs, 7-segment displays, buzzer) and a wire-wrap area so you can easily develop your own application. The following development tools can be ordered separately: assembler, linker, C compiler, source level debugger, hardware emulator, programming boards and gang programmer. For ordering information, see our website at http://mcu.st.com or contact your local sales office. June 2002 1/28 1 Table of Contents 1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2 SAFE ST7 EVALUATION BOARD DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 2.2 BOARD FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2.3 POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2.4 OSCILLATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2.5 ICP (IN-CIRCUIT PROGRAMMING) CONNECTOR . . . . . . . . . . . . . . . . . . . . . . 7 2.6 I²C SERIAL COMMUNICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.7 SPI SERIAL COMMUNICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.8 I/O PORT FUNCTIONALITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 2.8.1 Port A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 2.8.2 Port B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 2.8.3 Port C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 2.9 JUMPER DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 2.9.1 W2 - Variable voltage enable/disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.2 W3 - Board reference voltage selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.3 TP4 and TP5 - GND and VDD pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.4 W6 - MCU power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.5 W4 and W5 - Source clock selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.6 W8 and W9 - External interrupts enable/disable . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.7 W10 - Buzzer enable/disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.8 TP1, TP2 and TP3 - Port connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.9 W15 - LEDs enable/disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.10W13 and W14 - Analog inputs enable/disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.11W12 - High Sink I/O test enable/disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.12W16, W17 and W18 - 7 seg Displays enable/disable . . . . . . . . . . . . . . . . . . . . . . . 2.9.13W1 - ICP Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.14W7 - I²C connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.9.15JP11 - SPI Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 10 10 10 10 10 11 11 11 11 11 11 11 11 11 3 SOFTWARE DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 3.1 OPTION BYTE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 3.2 MAIN MCU INITIALIZATION ROUTINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 3.3 COUNTERS AND USE OF TIMING RESOURCES . . . . . . . . . . . . . . . . . . .28 . . . 13 3.4 INTERRUPT SERVICE ROUTINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 2/28 1 Introduction 3.5 MAIN PROGRAM ROUTINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 3.6 OPERATING THE DEMOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 3.6.1 Running the LVD Demo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 3.6.1.1LVD Demo Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 3.6.2 Running the AVD Demo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 3.6.2.1AVD Demo Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 3.6.3 Running the CSS Demo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 3.6.3.1CSS Demo Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3.6.4 Running the High I/O current demo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 3.6.4.1High Sink Demo Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 3.6.5 Running the IAP demo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 3.6.5.1IAP Demo Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 3.6.6 Running the Nested & Concurrent Interrupts demo . . . . . . . . . . . . . . . . . . . . . . . . . 24 3.6.6.1Nested & Concurrent Interrupts Demo Description . . . . . . . . . . . . . . . . . . . . 25 4 APPENDIX 1: SAFE ST7 EVALUATION BOARD SCHEMATIC . . . . . . . . . . . . . . . . 26 3/28 Safe ST7 Evaluation Board DESCRIPTION 2 SAFE ST7 EVALUATION BOARD DESCRIPTION The Safe ST7 Evaluation Board is designed to support any of the SDIP32 package devices from the ST72F264 family (ST72F264, 262, 260). 2.1 OVERVIEW This board is supplied ready-to-use, to let you try out all the functions described in this manual. The board is delivered with a SDIP32 socket. You will have to build an adapter if you need evaluate the ST72F264 in other packages. Additional hardware functions can be implemented by installing components in the wire-wrap area as shown in Figure 1 below. Figure 1. Safe ST7 Evaluation Board layout Battery ICP Connector Reset Button Wire-Wrap Area MCU + Clock system PA, PB & PC Ports SPI Connector Three 7-segments LEDs I²C Connector Buzzer Voltage Trimmer Output LEDs For more details, please refer to the schematic drawing in the appendix. 4/28 1 Two Push Buttons Safe ST7 Evaluation Board DESCRIPTION The main Safe ST7 Evaluation Board components are: - Socketed ST72F264 - 16MHz crystal - Reset pushbutton - ICP connector - Socketed I²C 8K byte EEPROM (M24C08) - Socketed SPI 4K byte EEPROM (M95040) - 2 pushbuttons for external interrupts - 22 pins for expansion ports - Row of 8 LEDs for displaying binary values - Three 7-segment LEDs - High efficiency LED - Potentiometer for main voltage variation - Potentiometer for I/O current variation - 9-volt battery - Buzzer - Wire-Wrap area 2.2 BOARD FEATURES - Low voltage detector (3 levels programmable by option bytes) - Auxiliary voltage detector - Multi-Oscillator and Clock Security System - High Sink/source current - Nested/ Concurrent Interrupts - In-Application Programming - In-Circuit Programming - I²C & SPI communications interfaces - 10-bit ADC 5/28 Safe ST7 Evaluation Board DESCRIPTION 2.3 POWER SUPPLY This board is supplied with a PP3 9-volt battery demonstrating the board’s low power consumption. A complementary DC power supply input (ref. J1) is provided to supply the board by external ( 9 to 13 Volt) power. When using this power supply, take care to respect the polarities marked next to the two-pole connector. Warning: Disconnect the battery from its socket when the Safe ST7 Evaluation Board is not in use. The reference voltage on board (VDD) is selected through the W3 jumper. You can choose between two reference voltages, either a regulated 5 volts and or a voltage that varies, by moving the R5 trimmer position, from 0 to 5.6 Volts as shown in Figure 2. Figure 2. How to Change the Board Voltage Reference 5 regulated Volts selected Variable Voltage selected VDD Board VDD Board 5 regulated Volts W3 Variable Voltage 5 regulated Volts W3 Variable Voltage RV1 The 1N4004 diodes provide for polarity protection and the LD1 LED provides an indication that power is being supplied to the board. 2.4 OSCILLATION SYSTEM The board is designed to be used with an on-board 16-MHz crystal. This allows you to configure the CPU frequency up to 8 MHz. The oscillator system is designed to fit a range of application needs, and you can choose between three different sources using the W4 and W5 jumpers as shown in Figure 3. 6/28 Safe ST7 Evaluation Board DESCRIPTION Figure 3. How to Change the Oscillator Frequency Source Crystal Resonator Internal RC oscillator External Clock C4 C4 C4 W4 W4 W4 XT1 XT1 XT1 W5 W5 W5 C5 C5 C5 2.5 ICP (IN-CIRCUIT PROGRAMMING) CONNECTOR You can use In Circuit Programming (ICP) to update the entire contents of the Flash memory (including option bytes) using the ICC protocol. Figure 4 shows the connector pin assignment. If you are connecting an ST Programming Tool to Safe ST7 Evaluation Board just connect cable provided with the ST Programming Tool to the ICP connector "W2" and then power on the board. Figure 4. How to use the ICP Connector Cable to ST Programming Tool ICP Connector Pin assignment ICCDATA ICCCLK RESET VPP OSC_CLK ICP 2 1 W2 10 9 ICP 2 1 10 9 W2 7/28 Safe ST7 Evaluation Board DESCRIPTION 2.6 I²C SERIAL COMMUNICATION An external 8 Kb EEPROM memory with an I²C serial interface is connected to the I²C pins of the ST7 socket as shown in the following figure. The serial EEPROM may also be disconnected and the I²C bus used for other communications. Figure 5. How to use the I²C Connection Using the I²C BUS SCLI SDAI ST7 I²C pins SCLI SDAI I2C ST7 I²C pins I2C Using the On-board I²C EEPROM W7 M24C08 M24C08 W7 U4 U4 Install all the jumpers on the I²C connector. Remove the jumpers and use left connector side. 2.7 SPI SERIAL COMMUNICATION An external 4 Kb EEPROM memory with an SPI serial interface is connected to the SPI pins of the ST7 socket as shown in the following figure. The serial EEPROM may also be disconnected and the SPI bus used for other communications. Figure 6. How to use the SPI Connection Using the SPI Bus PB3 MOSI MISO SCK SPI ST7 I²C pins ST7 I²C pins PB3 MOSI MISO SCK M95040 U5 U5 Install all the jumpers on the SPI connector. 8/28 W 11 M95040 W 11 SPI Using the On-board SPI EEPROM Remove the jumpers and use left connector side. Safe ST7 Evaluation Board DESCRIPTION 2.8 I/O PORT FUNCTIONALITY All I/O port pins are accessible through external connectors ( TP1 for port A, TP2 for port B and TP3 for port C ). 2.8.1 Port A The PA0 and PA1 pins are connected to the ICP connector using their alternate functions, ICCCLK and ICCDATA. The PA2 and PA3 pins are used to enable the U6 and U7 7-segment LED displays (useful for multiplexing). The PA5 pin can be used to generate an external interrupt (ei0). It is connected to the ground via the SW2 push-button switch . The PA4 and PA6 pins alternate functions (SCLI and SDAI) are used for connecting an I²C communication with the external I²C EEPROM. PA7 is used to exercise the high sink I/O current capability through the High efficiency LED. Table 1. Port A Alternate Functions PA0 PA1 PA2 PA3 PA4 PA5 PA6 PA7 ICCCLK ICCDATA In Circuit Communication Clock In Circuit Communication Data SCLI RDI SDAI TDO I²C Clock SCI output I²C Data SCI input 2.8.2 Port B This port is connected simultaneously to 8 LEDs and to the three 7-segment displays. It can be used to display 8 bits of binary data. Table 2. Port B Alternate Functions PB0 PB1 PB2 PB3 PB4 PB5 PB6 PB7 ICAP1_A OCMP1_A ICAP2_A OCMP2_A MOSI MISO SCK SS Timer A Input Capture 1 Timer A Output Compare 1 Timer A Input Capture 2 Timer A Output Compare 2 SPI Master Out Slave In Data SPI Master In Slave Out Data SPI Serial Clock SPI Slave Select 2.8.3 Port C The PC0 pin can be connected to ground via the SW3 push-button in order to generate an external interrupt (ei1). 9/28 Safe ST7 Evaluation Board DESCRIPTION The PC1/OCMP1_B pin can be connected to a buzzer through the W10 jumper . The PC2 pin is used to enable the output signal to the LEDs. A high level on PC2 enables the logic states programmed by port B to be output on the 8 LEDs. The PC3 pin is used to enable the U8 7-segment LEDs display (useful for multiplexing). The PC4/AIN4 pin can be used through the W14 jumper as in analog input to measure the voltage level of R13. The PC5/AIN5 pin can be used through the W13 jumper as in analog input to measure the VREF voltage. Table 3. Port C Alternate Functions PC0 PC1 PC2 PC3 PC4 PC5 ICAP1_B / AIN0 OCMP1_B / AIN1 CLKOUT / AIN2 ICAP2_B / AIN3 OCMP2_B / AIN4 EXTCLK_A / AIN5 Timer B Input Capture 1 Timer B Output Compare 1 CPU Clock Out Timer B Input Capture 1 Timer B Output Compare 1 Timer A External Clock Analog Input 0 Analog Input 1 Analog Input 2 Analog Input 3 Analog Input 4 Analog Input 5 2.9 JUMPER DESCRIPTIONS 2.9.1 W2 - Variable voltage enable/disable This jumper allows you to disable the variable voltage and thus reduce the total power consumption of the board and extend battery life. 2.9.2 W3 - Board reference voltage selection Refer to Section 2.3 POWER SUPPLY. 2.9.3 TP4 and TP5 - GND and VDD pins These spare ground and VDD pins are for test purposes or for providing power to components in the wire-wrap area. 2.9.4 W6 - MCU power consumption This jumper is only for connecting to the MCU power supply. Its main purpose is to allow you to measure the current consumption of the µC by connecting a DC-ammeter in series. 2.9.5 W4 and W5 - Source clock selection Please refer to Section 2.4 Oscillation system. 2.9.6 W8 and W9 - External interrupts enable/disable Those two jumpers allow you to disconnect the two push-buttons SW2 and SW3 from the PA5 and PC0 pins respectively. 10/28 Safe ST7 Evaluation Board DESCRIPTION 2.9.7 W10 - Buzzer enable/disable This jumper allows you to use the buzzer by connecting it to the PC1 pin. 2.9.8 TP1, TP2 and TP3 - Port connectors These jumpers allow you to access all I/O ports. 2.9.9 W15 - LEDs enable/disable This jumper is used to connect the LEDs to ground through the resistor network. It is recommended to remove the jumper from the board if this feature is not used. 2.9.10 W13 and W14 - Analog inputs enable/disable These jumpers are for measuring the Vref analog voltage and the voltage through R13. Removing them will disable those two features (The measurement of the VDD voltage value and the measurement of the current driven through the high efficiency LED). 2.9.11 W12 - High Sink I/O test enable/disable This jumper lets you enable or disable the High efficiency LED. 2.9.12 W16, W17 and W18 - 7 seg Displays enable/disable These jumpers allow you to enable/disable the three 7-seg displays (useful for multiplexing). 2.9.13 W1 - ICP Connector Please refer to Section 2.5 ICP (In-Circuit Programming) connector. 2.9.14 W7 - I²C connector Please refer to Section 2.6 I²C serial communication. 2.9.15 JP11 - SPI Connector Please refer to Section 2.7 SPI serial communication. 11/28 SOFTWARE DESCRIPTION 3 SOFTWARE DESCRIPTION This part gives a short description of the whole program as a main routine that uses many other functions and several drivers. The configuration of the microcontroller and also the configuration of option bytes is described first, followed by an overview of the main program structure. Finally, we will provide a detailed description of how to use the board’s features. 3.1 OPTION BYTE CONFIGURATION Option bytes are only accessed using In-Circuit Programming or an ST programming tool such as an EPB. In this case, the option bytes are configured as described below. – Watchdog is configured to be enabled by software and to allow the MCU to enter Halt Mode (no reset on Halt). – The LVD threshold is fixed to the medium value. – Sector 0 size is 4 Kbytes. – No program memory protection. – Port C external interrupt mapping is configured as ei1. – The clock security system is always on. – Oscillator type is resonator oscillator. – Oscillator range is between 8 and 16 MHz. Table 4. Option byte configuration OSC OSC TYPE1 0 WDGHALT 0 TYPE0 OSC RNGE1 OSC RNGE0 OFF 0 0 0 1 1 1 WDG SW VD1 VD0 SEC1 SEC0 FMP R FMP W 1 0 1 1 1 0 0 CSS 1 12/28 PLL OSC RNGE2 EXTIT SOFTWARE DESCRIPTION 3.2 MAIN MCU INITIALIZATION ROUTINE This routine initializes the MCU as follows: – MISCR (miscellaneous register): external interrupts trigger on falling edge, no slow mode and fCPU=8 MHz. – Port A: PA7 (Driving the High efficiency LED) is an open drain output, PA6 & PA4 used by I²C as input without interrupt, PA5 (Push-button) used as floating input with interrupt, PA2 & PA3 (multiplexing 7-seg displays) as push-pull outputs. – Port B: used as push pull output to display data. – Port C: PC5 & PC4 as ADC alternate inputs, PC3 as push-pull output (multiplexing 7-seg displays), PC2 to select the LED bank (push-pull output), PC1 to drive the buzzer and PC0 as an input with interrupt (push-button). 3.3 COUNTERS AND USE OF TIMING RESOURCES – Timer A is used as a real time clock that provides a precise time base for all program routines. Timer A interrupt is enabled. – Timer B is mainly used to drive the buzzer using PWM mode without interrupts. 3.4 INTERRUPT SERVICE ROUTINES – Timer A interrupt: increment (circular buffer) several global counters used as time counters when the free running counter reaches the calculated value. – AVD interrupt: saves the current mode when the power drops and, if we are in AVD mode, the last displayed digits are saved in the external I²C EEPROM using the I²C driver. – ei1 Interrupt: this interrupt is used to wake-up the microcontroller from idle mode (HALT) and also it increments a circular variable used by the main program to enter the corresponding test. – ei0 Interrupt: this interrupt is used to test concurrent and nested interrupts. 3.5 MAIN PROGRAM ROUTINE The main program includes the initialization code and an endless loop that processes the pushbutton inputs. In fact, after initialization and enabling interrupts, the main program will continue running in an infinite loop and wait for an external interrupt to switch to one of the demo routines: (LVD, AVD/CSS, High Current I/O, IAP, Concurrent/ Nested Interrupts). By default the program is in Halt mode (to reducing power consumption). Warning: Disconnect the battery from its socket when the Safe ST7 Evaluation Board is not in use. 13/28 SOFTWARE DESCRIPTION Figure 7. Main program flowchart Begin Disable all Interrupts MCU Initialization I²C Initialization Init Timer A Safety procedure This function is used for the AVD interrupt Disable RASS Keys Enter Halt Mode Enable all interrupts : Program path/ PGM interrupt “START” message “FINISH” message LVD Demo Nested IT Demo Test “MODE” variable Concurrent IT Demo AVD Demo High Current Demo 14/28 IAP Demo SOFTWARE DESCRIPTION 3.6 OPERATING THE DEMOS The flowcharts below provide a full description of all the tests and demos that you can run. Figure 8. Operations Flowchart (1) Power-on the board / RESET HALT Mode MCU in a HALT state Push The PGM button No No Yes End Push The PGM button Display “START “ Light-on LED 0 Push The PGM button No Yes No Push The PGM button LowLoL Voltage Detector Demo f Display " LVD " Light-on LED 1 No Push the DEMO button Yes Yes Display the VDD voltage Light-on LED1 No Push The PGM button Yes No Push The PGM button AVD and CSS Demo Display "AVD CSS " Light-on LED 2 No Push the DEMO button Yes Yes Display a counter 000..999 Light-on LED2 Push The PGM button No Yes To next figure 15/28 SOFTWARE DESCRIPTION Figure 9. Operations Flowchart (2) From previous Figure High I/O Current Demo Display "HIO" Light-on LED 3 No No Push The PGM button Push the DEMO button Yes Yes Display the current inside the High Efficiency LED Light-on the high efficiency Led Light-on LED 3 No Push The PGM button Yes In-Application Programming Demo Display "IAP" Light-on LED 4 No No Push The PGM button Push the MODE Button Yes Score 0 Test XFlash memory Score 1 First Time Display "SCORE 1" Light-on LED 4 Receive & Re-program Score1 from the SPI E²PROM Display "SCORE 0" Light-on LED 4 Display "TRANSFER" Light-on LED 4 Send Score0 & Score1 Receive & Re-program to the SPI E²PROM Score0 from the SPI E²PROM Display " DONE " Light-on LED 4 Push The PGM button Yes To next Figure 16/28 No SOFTWARE DESCRIPTION Figure 10. Operations Flowchart (3) From previous Figure Concurrent Interrupts Demo Display " CONCURRENT IT " Light-on LED 5 No No Push The PGM button End of the message Light-on LED 5 Yes Yes Play music Score Light-on LED 5 Push The PGM button IT1 No Yes No Push The DEMO button End of The Score IT0 Yes Wait End of score Light-on LED 5 Display a lighting Sequence on LEDs Nested Interrupts Demo Display " NESTED IT " Light-on LED 6 Yes End of the message Light-on LED 6 No No Push The PGM button Play music Score Light-on LED 6 Push The PGM button Yes Display " FINISH " Light-on LED 7 Yes End of The Score No Push The DEMO button Yes End Display a lighting Sequence on LEDs 17/28 SOFTWARE DESCRIPTION 3.6.1 Running the LVD Demo In LVD Demo state (see Figure 11), the user can switch between the two positions of W3 as described in Section 2.3. If the power goes below the LVD level, the microcontroller enters RESET state. At power-on, the program enters LVD demo mode (because an LVD reset was detected) and displays the VDD voltage on the 7-seg display. 3.6.1.1 LVD Demo Description The program reads in a fixed 2.4V reference voltage (VREF) via the 10-bit ADC channel, does some arithmetic to convert the digital value it has read to a voltage level and finally displays the main voltage of the board (VDD) in Volts on the three 7-segment LEDs. Note: X is the converted digital value of VREF (2.4 Volts) and 3FF is the digital value of VDD, So: 3FF V DD = 2.4 × ----------X Figure 11. LVD Demo Overview ST72F264 press to reset Battery SAFE ST7 EVALUATION BOARD move the jumper to right off press until LED1 lights-on on Push to run the Demo Potentiometer LED1 The W3 jumper must be moved to the right to select the variable power supply. If the RV1 trimmer is turned completely clockwise, the board is powered by 5.6 Volts. If the trimmer is turned counter-clockwise the VDD value will decrease until we reach the LVD threshold (VIT-), at which point the microcontroller enters reset mode. 18/28 SOFTWARE DESCRIPTION In power-on, if the trimmer is turned clockwise, the device will leave reset state and we can see the VIT+ threshold on the display. Note: the VIT- reference value for a voltage drop is lower than the VIT+ reference value for power-on in order to avoid parasitic reset when the microcontroller starts running and sinks current on the supply (hysteresis). 3.6.2 Running the AVD Demo In Auxiliary Voltage Detector & Clock Security System Demo state (see Figure 12), the 7-seg display shows a counter that increments from 000 to 999. To test the AVD capability: – Disconnect the battery or decrease the VDD voltage using the power trimmer until the MCU enters RESET state. – Then, supply the board with the right voltage. – You will see that the counter does not restart at 000, but resumes counting from the last displayed value before shut-down. 3.6.2.1 AVD Demo Description For system integrity management, in addition to the LVD feature, the Safe ST7 Evaluation Board has an auxiliary voltage detector (AVD) with interrupt capability. In case of a drop in voltage, the AVD interrupt acts as an early warning, allowing software to shut down safely before the LVD resets the microcontroller. The AVD works closely with the LVD and functions only if the LVD is enabled through option byte (see “Option byte configuration” on page 12). 19/28 SOFTWARE DESCRIPTION Figure 12. AVD Demo Overview Disconnect the battery press to reset ST72F264 Battery ST72F264 press to reset Battery SAFE ST7 EVALUATION BOARD SAFE ST7 EVALUATION BOARD move the jumper to right off move the jumper to left on press until LED2 lights-on Push to run the Demo press until LED2 Push to lights-on run the Demo Potentiometer LED2 LED2 In case of power drop, and before going into reset state, the AVD interrupt will save the last displayed value in the external EEPROM (M24C08) using the I²C protocol. On power-on, the software checks if the last reset was made by the LVD, if this is the case, it downloads the previously saved value from the external EEPROM to RAM memory in order to resume counting as normal. To cause a voltage drop, we can choose between two solutions as shown in the Figure 12.The first method consists of moving the W3 jumper to the right, then decreasing the main voltage by turning the RV1 trimmer counter-clockwise. The second method consists of moving the W3 jumper to the left so that we will have a 5-Volt reference value, and then disconnecting the battery. 3.6.3 Running the CSS Demo To run this demo, we have to be in the same state as in the AVD demo see “Running the AVD Demo” on page 19. Once the main program runs at 8 MHz, Timer A is configured to manage the counting operation displayed on the three 7-segments LEDs. To test the CSS capability: – Disconnect the oscillator by removing the W4 and W5 jumpers. – You will see the frequency decreases significantly but that the counter still working. 20/28 SOFTWARE DESCRIPTION 3.6.3.1 CSS Demo Description The clock security system (CSS) embedded in the ST72F264 family of microcontrollers, protects the device against problems occurring to the main clock. To allow you to integrate security features in your application, it performs clock filter control and generates an interrupt in case of clock problems, while switching to an internal safe oscillator to allow the software to keep running at a reduced speed. The safe oscillator of the CSS block is a low frequency back-up clock source (around 3 Mhz). Figure 13. CSS Demo Overview Disconnect the two clock jumpers ST72F264 press to reset Battery SAFE ST7 EVALUATION BOARD move the jumper to left press until LED2 lights-on Push to run the Demo LED2 If the clock signal disappears, which you can provoke by disconnecting the two jumpers as shown in Figure 13, the safe oscillator delivers a low frequency clock signal (around 3MHz) for a safe oscillator period which allows the ST7 to save any critical data or perform any kind of emergency operations while the CPU is still running. The ST7 clock source switches back from the safe oscillator automatically if the original clock source recovers. You can simulate this by replacing the clock jumpers. For more details refer to Section 2.4 Oscillation system. 3.6.4 Running the High I/O current demo This demo uses the example of a high efficiency LED to provide a visible result: its relative luminosity increases linearly with the forward current, which reaches more than 50mA at only 3 Volts. The program measures the value of the current in the LED using ADC analog input channel 4 and at the same time it displays the result on three 7-segment LEDs (units in mA). 21/28 SOFTWARE DESCRIPTION To vary the forward current, we have to move the RV2 trimmer position as shown in Figure 14 You can verify the current value for yourself by connecting a serial ammeter to W12. Figure 14. High Sink I/O Demo Overview ST72F264 press to reset Battery SAFE ST7 EVALUATION BOARD move the jumper to left - + press until LED3 lights-on Push to run the Demo LED3 3.6.4.1 High Sink Demo Description This demo shows how the high sink outputs can be used and how to measure the current delivered by any of the high sink outputs on Port A. In addition to standard I/O ports which sink and sources a maximum (absolute rating) output current of 25mA, most ST7s include High sink I/Os that can sink a current (absolute rating) output of up to 50mA. This allows you to drive any type of high power device directly without needing expensive external circuitry. 3.6.5 Running the IAP demo This demo consists of re-programming XFLASH sector 1 using the In-Application Programming. To show this, it reprograms one piece of music (64 Bytes) by another one using the SPI communication protocol with the external M95040 4Kb SPI EEPROM memory. The demo software includes an IAP_driver that will be copied to the RAM area to execute the demo. It programs 16 bytes at a time. For more details about XFLASH In-Application Programming refer to the ST7 FLASH Programming Reference manual. As shown in Figure 15, you enter the IAP demo by pushing down the PGM button until LED4 lights-up and the “IAP” message appears. Then you must push the DEMO button. During this time the device will be updated and when this is finished a “DONE” message will appear. 22/28 SOFTWARE DESCRIPTION Note: If you don’t want to enter this mode, you must push the PGM button again to jump directly to the next demo. Note: This demo only runs the software that downloads the musical sequence from the external EEPROM to the XFLASH device. This music data can be output on the buzzer. In order to listen to the music and verify that the data has been changed by IAP, you have to run the nested & concurrent interrupts demos. Figure 15. IAP Demo Overview ST72F264 press to reset Battery SAFE ST7 EVALUATION BOARD keep the jumper to left press until LED4 lights-on Push to run the Demo LED4 3.6.5.1 IAP Demo Description The ST72F26x microcontroller family has a single voltage extended Flash (XFLASH) area that can be electrically erased and programmed either on a byte-by-byte basis or up to 32 bytes in parallel. In-Application Programming (IAP) allows you to update program memory contents when the device is already plugged on the application board, at minimum cost in terms of added components and board area impact. This programming mode uses an IAP driver program which has been previously programmed in sector 0. This method is fully controlled by user software. This allows it to be adapted to the user application (user-defined strategy for entering programming mode, choice of communications protocol used to fetch the data to be stored). RAM Mapping 0xA0 to 0xA1: XFLASH start address (2 bytes) 0xA2 to 0xB2: 16-byte RAM buffer. 23/28 SOFTWARE DESCRIPTION 0xB2 to 0xCE: IAP_driver storage area, (used only while the demo is running) Sector1 Mapping (Reprogrammable Area) 0xE000 to 0xE00F: 16 spare bytes for testing 0xE010 to 0xE04F: (64 bytes) Music score1 (Software reprogrammable bytes) 0xE050 to 0xE08F: (64 bytes) Music score 2 0xE090 to 0xE14F: All other constants Figure 16. IAP Demo flowchart Begin Else 0xE010..0xE04F contents Score0 (or 1) First time the chip is plugged in Test 0xE000 content Display "SCORE0" (or "SCORE1") Display "TRANSFER" Init SPI Init SPI Repeat 4 times Send Score1&2 to M95040 Receive next 16 bytes of Score1 (2) from M95040 SPI Disable Program 16 bytes of Score1 (2) to the right addresses SPI Disable Using IAP write "1" to 0xE000 Using IAP write "2" (1) to 0xE000 End 3.6.6 Running the Nested & Concurrent Interrupts demo Most ST7 microcontrollers have two different interrupt management modes. The first is called concurrent mode and does not allow an interrupt to be interrupted, unlike the nested mode where a software priority is given to each interrupt. 24/28 SOFTWARE DESCRIPTION 3.6.6.1 Nested & Concurrent Interrupts Demo Description Figure 17. Interrupts Demo Overview ST72F264 press to reset Battery press to reset ST72F264 Battery SAFE ST7 EVALUATION BOARD keep the jumper to left (2) Press to run IT0 Buzzer SAFE ST7 EVALUATION BOARD keep the jumper to left (2) Press to run IT0 (1) Press to run IT1 LED5 Concurrent Interrupt Demo Buzzer (1) Press to run IT1 LED6 Nested Interrupt Demo As shown in Figure 17 this demo is divided into two parts: The first one runs concurrent interrupts while the second uses nested interrupts. The IT0 and IT1 interrupt service routines are assigned to external interrupt vectors ei0 and ei1. You can trigger the interrupts directly by pressing the two push-buttons shown in Figure 17: IT1: outputs a piece of music (previously downloaded in the IAP demo) on the buzzer. IT0: displays a lighting sequence on LEDs. In the first demo (Concurrent Interrupts), all the interrupts have the same priority level, so the interrupt with the highest hardware priority will be serviced (in this case it is ei0). In this demo, you have to push the PGM button in order to trigger the IT1 routine, then pushing the DEMO button, IT0 won’t interrupt the IT1 routine and you have to wait for the end of music before the LEDs light up in sequence. To run the nested interrupt demo the board must be in the state shown in Figure 17, then if you push the PGM button, it will trigger the IT1 interrupt routine (music output). Before the end of the music you have to push the DEMO button in order abort the IT1 routine and service the IT0 routine. When the program returns from IT0, it resumes playing the music from the point where it was interrupted. 25/28 Appendix 1: Safe ST7 Evaluation Board SCHEMATIC 4 APPENDIX 1: SAFE ST7 EVALUATION BOARD SCHEMATIC VCC TP1 CD2 100nF PA0 PA1 PA2 PA3 PA4 PA5 PA6 PA7 R2 4.7k C2 100µF LD1 U1 L7805 D1 1 TP2 V OUT GND 3 PB0 PB1 PB2 PB3 PB4 PB5 PB6 PB7 POWER 2 1N4004 V IN D2 1N4004 1 2 R1 470 CD1 C1 J1 100nF 100µF 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 VREF TP3 BT1 PC0 PC1 PC2 PC3 PC4 PC5 Z1 2V4 W2 VCC 1 2 3 4 5 6 TP4 R4 1 2 8 1k U2A 3 1 2 W3 VCC 1 2 3 4 RV1 10k R5 4.7k Z2 5V6 26/28 VCC T1 2N2222 TS912 POWER SELECT TP5 1 2 GND Appendix 1: Safe ST7 Evaluation Board SCHEMATIC VCC VCC 8 R9 27k R10 27k VCC D 2 SPI Q 6 U4 3 W R11 PA4 PA6 1 3 100 M95040 2 4 5 E0 E1 E2 SCLK 1 2 3 CD7 100pF SDA I2C CD8 100pF WC 7 M24C08 4 4 6 W7 100 R12 7 HOLD C VCC SS 5 VSS PB6 2 4 6 8 VSS 1 3 5 7 PB5 VCC 1 W11 PB4 8 U5 PB3 ICCDATA PA1 W1 PA0 ICCCLK 2 4 6 8 10 RESET R3 10k VPP VPP 1 3 5 7 9 VCC ICP OSC1 VCC R6 4.7k 2 SW1 RESET W6 IDD U3 1 3 CD3 100nF PB7 4 PB6 5 PB5 6 PB4 7 8 W4 W5 1 2 3 9 1 2 3 XT1 4Mhz C4 22pF C5 22pF PB3 10 PB2 11 PB1 12 PB0 13 PC5 14 PC4 15 PC3 16 PC3 RESET VDD OSC1 VSS OSC2 VPP/TEST PB7/ SS ICCCLK/PA0 PB6/SCK ICCDATA/PA1 PB5/MISO PA2 PB4/MOSI PA3 NC NC NC NC PB3/OCMP2_A SCLI/PA4 PB2/ICAP2_A RDI/PA5 PB1/OCMP1_A SDAI/PA6 PB0/ICAP1_A TDO/PA7(HS) PC5/EXTCLK_A/AIN5 AIN0/ICAP1_B/PC0 PC4/OCMP2_B/AIN4 AIN1/OCMP1_B/PC1 PC3/ICAP2_B/AIN3 AIN2/MCO/PC2 CD4 32 100nF 31 30 VCC VCC VCC C3 R7 4.7k 100pF R8 4.7k VPP 29 PA0 ICCCLK 28 PA1 SW2 DEMO ICCDATA 27 PA2 SW3 PGM CD5 100nF CD6 100nF PA2 26 PA3 PA3 25 EI0 EI1 24 23 PA4 22 PA5 21 PA6 20 PA7 W8 19 PC0 18 PC1 17 PC2 W9 BZ1 W10 PC2 Buzzer ST72F264 W12 W13 VREF LD3 W14 LD4 LD6 PB3 Leds enable LD9 R14 BC547 4.7k T2 U7 7 6 4 2 1 10 9 5 PB0 PB1 PB2 PB3 PB4 PB5 PB6 PB7 U8 7 6 4 2 1 10 9 5 PB0 PB1 PB2 PB3 PB4 PB5 PB6 PB7 7 6 4 2 1 10 9 5 R16 1k PA2 W16 R15 4.7k T3 BC547 8 LD10 3 PB7 U6 PB0 PB1 PB2 PB3 PB4 PB5 PB6 PB7 1k LD8 PC2 PB6 W15 1 3 PB5 LD7 LD2 8 PB4 I/O Test RS1 2 3 4 5 6 7 8 9 LD5 PB2 3 PB1 RV2 R13 10 8 PB0 VCC R18 1k PA3 W17 R17 4.7k T4 BC547 R20 1k PC3 W18 R19 4.7k T5 BC547 27/28 Appendix 1: Safe ST7 Evaluation Board SCHEMATIC THE SOFTWARE INCLUDED IN THIS NOTE IS FOR GUIDANCE ONLY. STMICROELECTRONICS SHALL NOT BE HELD LIABLE FOR ANY DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES WITH RESPECT TO ANY CLAIMS ARISING FROM USE OF THE SOFTWARE. Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not authorized for use as critical components in life support devices or systems without the express written approval of STMicroelectronics. The ST logo is a registered trademark of STMicroelectronics ã2002 STMicroelectronics - All Rights Reserved. Purchase of I2C Components by STMicroelectronics conveys a license under the Philips I2C Patent. Rights to use these components in an I2C system is granted provided that the system conforms to the I2C Standard Specification as defined by Philips. STMicroelectronics Group of Companies Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A. http://www.st.com 28/28