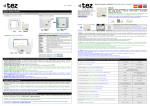

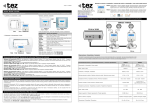

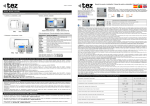

Download IVC Series Small PLC Programming Manual

Transcript