Download AWOS Installation Checkout Manual

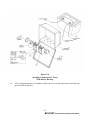

Transcript